Volkswagen’s quest for the perfect transmission brings us the versatile, reliable and, yes, different, DSG six-speed box

Ever since the first automobile was built, automakers have been looking for the ideal transmission that would transmit power seamlessly from one gear to the next, provide enough ratios so that there’s always one perfectly suited to any driving condition, and that will operate at optimal efficiency. A plus would be a transmission that would operate as an automatic, but also make available manual shifting for those who like to drive with élan.

The problem is, for the last hundred-plus years that cars have been taking people from where they are to where they need to be, all the rules have continued to change. Today’s sophisticated electronically-controlled engines bear little resemblance to their forebears, we’ve gone from rear wheel drive to front wheel drive to all wheel drive, we now have emissions and fuel economy standards with which to comply, and we have motorists who today have extraordinary expectations for driveability and reliability.

So the design of today’s transmissions, like those of other automotive parts and systems, are challenged by moving targets that will likely never stop to take a rest while technology catches up.

In the early 2000s, Volkswagen engineers produced a unique 6-speed transmission that could be driven in automatic or semi-automatic mode. What distinguished this transmission from other designs was that it was actually two manual transmissions operating in concert, without the need for a manually-operated clutch, making it a Direct Shift Gearbox (DSG). It was quite an ingenious design, and offered a number of features not found in other transmissions:

- With six speeds, there would always be a gear ratio available for nearly every possible driving condition and availability of engine torque and speed.

- It could be shifted manually without the need for a driver-operated clutch.

- Being based on two complementary manual transmissions, it had fewer and stronger components, and fewer and simpler control systems.

- It was still electronically controlled, for precision and interface with other vehicle dynamics and the demands of various driving conditions.

- The strength and durability of helically-cut drive gears help make for smooth, quiet operation even under heavy torque demands.

How do three plus three equal six?

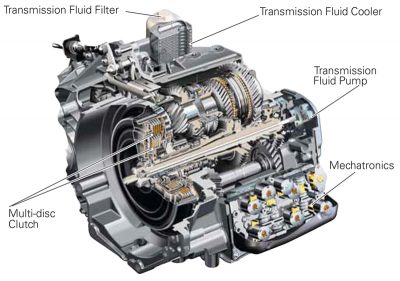

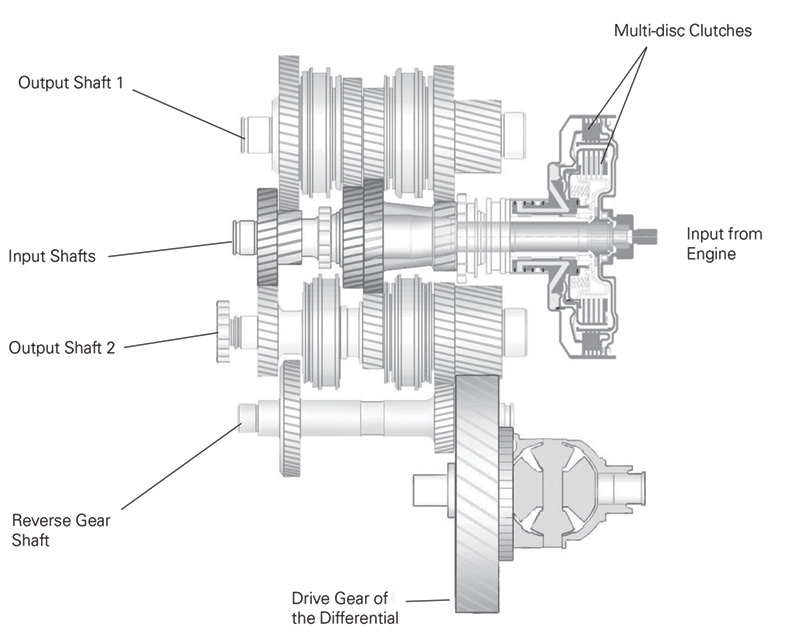

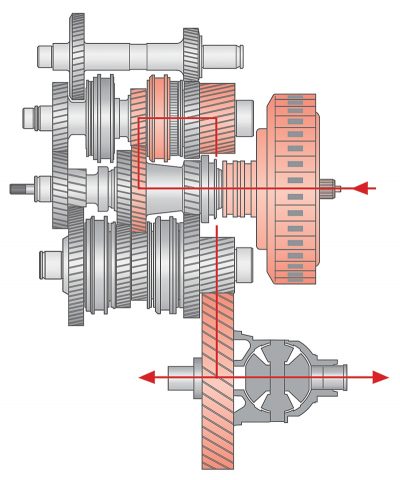

Actually, three plus four equals seven, if you count reverse. The essence of the DSG transmission is two manual transmissions — one for first, third, fifth, and reverse, and the other for second, fourth, and sixth gear. Each of the two transmissions has its own wet clutch assembly, and all transmission functions are controlled by a Mechatronics electronic control unit, which, interestingly, is internal to the transmission and is constantly immersed in transmission fluid.

Being based on two manual transmission units, the driven gears are always meshed with the equivalent of a “cluster†gear, so they’re always waiting for synchronizer action to mechanically connect them to their respective “mainshaft,†and ready for the clutch on that mainshaft to engage and transmit power on to the drive wheels.

The ingenuity of the DSG is that each of the two transmissions is always engaged in one of its gears, as determined by the Mechatronics unit. So if power is transmitted through first gear in one gearbox, the other gearbox already has second gear engaged. So all that’s needed is instructions from the Mechatronics unit to disengage the clutch at the first transmission while it smoothly engages the clutch of the second transmission.. And, just like that, the car has shifted from first into second gear.

Now, as you would expect, once the vehicle is being propelled in second gear, the Mechatronics unit directs the first transmission to disengage first gear, which is no longer needed, and engage third gear so it is ready for the Mechatronics unit to pass the torch on up to third gear. And so the process continues up through all six forward speeds. The two clutches are mounted concentrically on a mainshaft to further promote smooth upshifts and downshifts.

In the meantime, the Mechatronics unit constantly monitors driving conditions, so that the transmission not currently engaged shifts either up or down depending on anticipated power needs and driving conditions.

With engine speed necessarily dropping when upshifting, throttle modulation is not needed, especially since the dual-clutch setup can change gears very quickly and smoothly. However, when the transmission is downshifting, the ECU is smart enough to know to “blip†the throttle to match revs to the new, lower gear. It’s all quite clever.

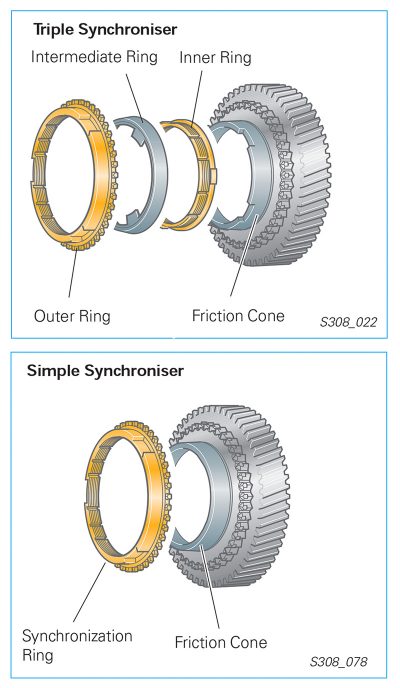

A particularly interesting feature of the DSG transmission is the synchronization of the various gears. First, second, and third gears are actually equipped with what Volkswagen refers to as triple synchronization. We’re all familiar with how a synchro ring works in a conventional manual transmission. A soft, tapered conical ring is moved into mesh with a mating ring and, as the tapers join up, the speed of the two devices match speeds, providing the synchronization needed to avoid clashing of gears. This triple synchronization provides much larger heat transfer surfaces, necessary because the rotational speed differences are higher in these lower gears. Fourth, fifth, and sixth gears all use the more conventional single synchronizer.

With VW triple synchronization, there are three, not just one, synchro rings, so that the first matches speed with the second one, the second matches speed with the third, and the third matches with the tapered cone on the gear itself.

This DSG design also includes two other driver-friendly provisions — a “hill holder†function that holds the stopped vehicle on an uphill road even if brake pedal pressure is relaxed, and also a â€creep†function that allows the car to ease forward on level ground if the brake pedal is not depressed.

How smart is the brain?

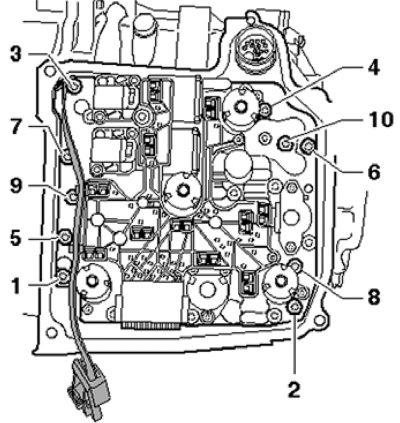

The Mechatronics unit is quite sophisticated, incorporating no fewer than twelve separate sensors, input from which the ECU uses to operat eight hydraulic gear actuators, six pressure modulation valves, five control valves, and the pressures and cooling of the two wet clutch assemblies. It is also a “smart†module, with the capability of learning the positions of the clutches and of the actuators for each gear, and the main transmission fluid pressure. It is also adaptive and can “learn†operators’ driving habits and adjust shift characteristics accordingly.

Furthermore, VW engineers did a surprisingly thorough job of anticipating possible component and system failure, and, as a result, integrated a host of fail-safe modes and actions into the Mechatronics unit. What this means is that drivers, and sometimes even technicians, may not be aware of a malfunction within the DSG transmission, since the Mechatronics unit may already be compensating for a sensor or other component that’s not doing its job.

The technician’s job is made even easier by the fact that most of the controlling functions of this transmission are found within the Mechatronics unit, which is largely self-diagnosing. Other malfunctions also tend to be intuitive in their diagnosis. Mostly, to the benefit of both the motorist and the technician, these transmissions tend to have few failures.

Zero in on the problem

Because most of the sensors, solenoids, control valves, and actuators are integrated into the Mechatronics unit, a Check Engine light with an accompanying OBD II fault code will alert the driver and technician to the specific problem area. More serious conditions may be brought to the driver’s attention by a repeated flashing of the PRNDS indicators. Other indications of a problem with this transmission can include an anomaly found during a test drive, observing that the transmission goes into limp-in mode, shuddering when accelerating from a stop, or banging when the transmission shifts into first gear.

An astute driver may also notice the failure of the transmission to shift up or down into the next numerical gear, or possibly operate only in a fail-safe mode of, perhaps, just second or third gear (out of the six he or she is accustomed to…). Similarly, slippage during shifting would alert an observant driver to a clutch problem, and would likely be accompanied by a Check Engine light and appropriate fault code.

If the Check Engine light illuminates, follow the appropriate diagnostic tree. Most of the time you’ll find that the Mechatronics unit is the source of trouble, since it performs such a vast and diverse array of functions. The units are not serviceable, and must be replaced if faulty. Note that these units are vehicle-specific, so if you determine that you have to replace a faulty one, you’ll need to provide the VIN to the parts department of your local VW dealership and they will need to order a new unit specific to that vehicle.

Less common are clutch failures, which require removal of the transmission from the vehicle and a host of special tools and procedures. Any other failure calls for replacement of the entire transmission.

But if it is the Mechatronics unit…

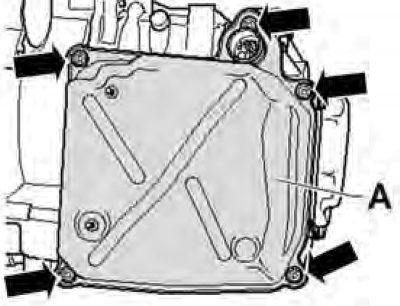

The Mechatronics unit is located with the valve body within the transmission housing, and is accessible after removal of the side cover; there is no conventional sump on the bottom to remove. Replacement of the Mechatronics unit is not a simple procedure, and Volkswagen has produced a detailed video and instructional program covering the proper tools and procedures needed for this job, and the company considers it essential that technicians study both the video and the training material before undertaking this repair.

While most of the electro-hydraulic actuators, solenoids, and valves are integral with the Mechatronics and are, therefore, non-serviceable, there are a few sensors and other separate components that are located remotely and can be serviced separately. Your diagnostic software program should identify their role and location, and you can also find support by asking the folks at your local Volkswagen parts department, who will be familiar with the system you’re working on.

Download PDF

0 Comments