Heating and cooling functions depend on proper operation of the HVAC system

When the temperature begins to rise during warmer months, every shop expects more customers to start coming in with HVAC system problems. These can range from insufficient cooling, fogging issues, and blend door problems, to poor blower motor performance. It is critical to keep the HVAC system working properly in today’s Volkswagens, not only for comfort, but for safety reasons as well. As always, check erWin® for repair information on all Volkswagen vehicle repair.

The real workhorse of any automotive climate control system is the blower motor. This single motor must pull air from the exterior of the vehicle into the HVAC casing, past the A/C evaporator, and into the cabin. Depending on the driver’s choice, the blower motor may continually be in use while driving. It has a difficult job and, if not functioning properly, may provide little interior cabin airflow.

Volkswagen’s Climatronic™ control system can automatically adjust blower settings as well as air distribution flap controls. This helps to ensure comfort through most conditions with minimal input needed by the driver. Extreme ambient temperatures can cause issues that impede safe driving if the HVAC system is not in proper working order. If it is very hot outside, all the windows might fog over. In extreme cold, ice can form on interior windows as well as fogging. These are safety concerns and should be taken seriously, as they can limit visibility.

The blower motor must have a clear, unobstructed intake duct from which to pull in fresh air. If the intake for the blower becomes damaged or blocked, performance can be negatively affected. Most commonly, a very dirty cabin filter or organic plant matter are to blame for intake blockage. This blockage can vary greatly depending on where the vehicle is parked and the time of year.

An issue often neglected by vehicle owners is cleaning out the cowl area of their vehicle. Many motorists are not aware that pollen, dirt, and plant matter may accumulate under the hood. This can eventually lead to a buildup of material that impedes fresh air blower performance. In extreme cases, organic matter can clog the cowl drain, causing rain water to overflow into the fresh air intake. This can damage the blower motor and associated components, necessitating replacement.

In certain new model VWs, issues have arisen with water/snow ingress into the blower motor, causing failures. The models affected are the 2011-15 Jetta and Sportwagon, 2012-15 Passat, 2010-14 Golf, 09-15 Tiguan, and 2009-15 CC. On all models affected, updated water deflectors must be installed. Installing these can minimze water and snow ingress into the blower casing. Details can be found in TSB 87 15 15.

On Passat model years 2012-15 the blower casing may take on water/ice through the cowl drain located in the passenger side of the fender liner area. In this case, a modified fender liner as well as an updated water deflector can help to limit water and snow intrusion. Always check for service bulletins when beginning diagnosis of any issue, as they may cover issues you may not be unaware of.

When diagnosing a complaint of poor HVAC system performance, always start with a scan of the vehicle’s systems after connecting an auxiliary power supply. Often, faults are stored in the climate control unit, leading to a quicker diagnosis of issues. If the blower motor is suspected of being faulty, the vehicle will store DTCs, such as 1273-fresh air blower, mechanical fault, static/sporadic. DTC B10BE07-fresh air blower front-mechanical fault, may also be stored in the climate control unit.

During blower motor diagnosis, it is important to physically inspect the motor itself for damage. Volkswagen has taken great care to protect the blower motor, however damage can still occur. If the motor is difficult to spin, is noisy, or is hitting the support cage surrounding the motor, it should be replaced. If the car has ingested water through the fresh air intake, the blower motor takes the brunt of the damage.

Water can quickly damage the electrical components as well as the bearing surface on which the motor rides, which can render the motor inoperable or increase noise from the blower motor. This water damage can appear as a green corrosion buildup on connectors and the motor windings. If you must replace the blower motor due to water ingress, it is wise to replace the blower resistor at the same time, as both reside in the same area and may have been damaged/corroded as well.

Key components in the HVAC system include fuses, resistors, the compressor, the Climatronic control, and the heater core.

Fuses: Always check your fuses when diagnosing an inoperable blower motor in case they may have popped. This can be from a momentary blockage and may not require motor replacement. The fuse position varies from model to model but is most commonly located in either the driver side A pillar fuse block or in the underhood fuse block.

Resistors: The blower motor in Volkswagens requires a resistor to properly modulate speed and air output. If the blower only operates at the high speed setting, it is likely that the resistor has failed, requiring replacement. When the resistor has failed, the blower motor receives full 12v power. This is generally the high speed setting on the control head. This allows limited blower function, aiding in safety for the driver. This feature is a carefully-designed Volkswagen safety feature.

The blower motor resistor rarely fails but, when it does, the symptoms are very apparent. In vehicles with manual or automatic fan settings, one or more of the fan speeds may be inoperable. In certain cases, the blower may not operate at any speed at all. This is when a power probe may come in handy. It is possible to bypass the resistor and test the blower motor directly for operation.

Replacing the resistor is normally a straightforward operation. After removal of the passenger side lower cover, the blower motor and resistor pack are visible and accessible for testing and replacement. Thanks to the work of VW design engineers, few tools and little time are needed to get to this piece of the HVAC system.

Compressor: The A/C compressor also plays a critical role in the climate control system. Its job is to pump the refrigerant at high pressure through the A/C system. Volkswagen strives to increase efficiency and comfort by using variable orifice compressors in their vehicles. This design replaces the old-school compressor clutch that only offered an on/off design. The variable orifice compressor offers many advantages such as cooler temperatures, reduced compressor load on the engine, and improved fuel economy.

Instead of using a clutched pulley, VW compressors have a standard pulley with a built-in breakaway design. This is used to keep the compressor from completely locking up if becomes too hard to turn. Often, a low or empty refrigerant level can cause this. The refrigerant and oil normally act as lubricants, keeping the inside of the compressor spinning smoothly. Without them, overheating of the internals may occur, causing extreme drag.

If the compressor exhibits strange noises or if customers complain of drive belt noise, it is wise to inspect the compressor pulley. Using a stethoscope is a good way to localize strange noises from accessories. Visual inspection is also possible but may be difficult without removing the dust cap on the front of the compressor. Often, when the pulley has separated, bits of material may remain on the bearing surface, creating loud noise as it spins.

The Volkswagen N280 compressor regulator valve controls the internal pressure of the A/C compressor by regulating an orifice internally and controlling flow. It is activated by the Climatronic control unit to meet cooling needs. The regulator valve is a key component of the compressor, acting similarly to the clutch in an old style A/C system by varying the flow of refrigerant into the system. It is constantly energized and gets lots of use. When failures happen at the compressor, they can usually be traced back to the regulator valve.

When testing the compressor regulator valve, keep in mind that it receives a pwm (pulse width modulated) signal. It operates on a lower voltage (0–5 volts) than battery voltage. Do not test by power probing these units. Damage most likely will occur.

You can back probe the connector at the compressor and check for proper incoming signal voltage. Again, the most common failure point on these units is the valve itself in the compressor. The control valve is not serviceable and, if it is faulty, a new compressor assembly must be fitted.

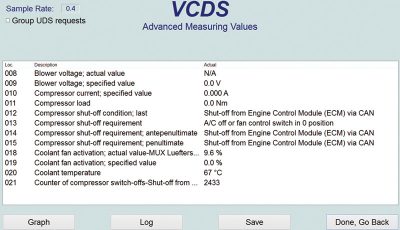

Climatronic control: The Climatronic control unit is the brain that controls the HVAC system for the car. It sends and receives all inputs. When scanning the vehicle, this control unit houses all of the faults, measuring blocks, and activations needed for diagnosis. Interrogating this unit should be your first step in any climate control diagnosis. When performing a full scan of the vehicle, assure that it is properly connected to a stabilized auxiliary power supply.

Here are common fault codes you may find stored in the control unit.

- 62E, p1582 – Coolant temperature signal

- 4F9, p1273 – Fresh air blower fault

- 1BD, p445 – Loss of refrigerant pressure

- 318, p792 – A/C pressure switch

- 4F7,p1271 – Airflow flap positioning motor

- 332, p818 – Evaporator temperature sensor

- 538, p1336 – CAN-Bus fault

The electric cooling fan is a necessary component of the climate control system. When the refrigerant is forced through the condenser at the front of the vehicle, the vapor is condensed into a liquid. This thermal reaction creates a lot of heat. When the vehicle is moving, air is naturally forced through the condenser where it is cooled. In stop and go traffic the electric fan is especially needed to pull air across the condenser. The electric fan helps dissipate the heat, which can otherwise increase engine coolant temperatures to unsafe levels if left unchecked.

As part of programming, if failure of the electric cooling fan or fan control module occurs or if refrigerant pressure is too high, the A/C system will disables to ensures that the engine coolant level does not reach unsafe levels. This usually triggers a fault code to store in the Climatronic control unit, aiding diagnosis. However the fans report to the engine control unit, not the climate control unit, so electric cooling fan fault codes will be stored there. It is also possible to run activations on the electric fan to test for proper function. If the fan is bad, this will limit the A/C system operation. The Climatronic control unit will store shutoff condition information that can directly identify faulty components.

Heater Core: When driving in cooler ambient temperatures, it becomes necessary to heat the cabin air to more comfortable levels. This is done by using a heater core. The heater core transfers heat from engine coolant to the cabin of the vehicle. The climate control system utilizes the heater core to direct air across the core, warming it for the cabin.

Heater core problems are rare but do occur from time to time. The primary cause of clogged heater cores is lack of coolant changes. Always use only Volkswagen approved coolant with a 50/50 mix with distilled water. This will ensure proper pH level and protection. The distilled water is also necessary to eliminate any minerals or sediment which may be present in tap water. If neglected or topped up due to leaks, the coolant may begin to accumulate a sandy sludgy texture in the cooling system if not changed frequently enough.

If the core becomes internally clogged with material or sediment, it cannot efficiently transfer heat to the outside of the core. This results in poor heat output, particularly at idle speeds when coolant flow is at its lowest. With poor heat output, particularly in colder climates, this can become a safety issue, creating ice buildup on windows and a cold driver! In dual zone climate systems, a clogged heater core can sometimes only affect one side of the vehicle. This is due to the position and airflow across the core itself.

Using an infrared thermometer, it is possible to determine if the heater core is properly transferring heat. The inlet side should be approximately 20 degrees F warmer than the outlet. If both sides are the same temperature, the core is definitely clogged.

If a clogged heater core is suspected, it may be possible to back flush it to increase flow through the core, bringing back sufficient heater performance. This can increase coolant flow enough to increase heater output and allow for more thorough diagnosis of the HVAC system.

A heater core back flush is relatively straightforward operation needing just basic tools. Heater cores have one inlet and one outlet for the coolant to flow through. The first step is to remove both hoses going to the core and re-attach two short sections of rubber hose or old coolant hose. This is used to feed and drain the core as it is flushed. The primary tool for the flush is a standard blow gun with a pressure regulator inline. The regulator is necessary to lower air pressure to safe levels. If too much pressure is used, damage to the heater core can occur. Safe pressure is between 15–20 psi, no higher. Using a mild detergent may help break up deposits in the heater core, but be careful not to use anything too strong. Standard dish detergent works fine.

After soaking the core for 15 minutes, use the blow gun on the outlet side of the heater core. Rapid short bursts of air will force the remaining liquid through the core and out via the inlet of the core. The bursts of air pressure help break up deposits and increase flow. Do not use full shop air pressure, which can cause damage. Repeat these steps if a lot of debris is seen exiting the core. Flow will be increased through the heater core after this procedure. This is not a sure fix and is usually only used to confirm a suspected clogged core, which must then be replaced.

Volkswagen has made it much easier to replace a heater core. 2012-present Passat models, as well as 2011-current Jettas share the same replacement method.

Access to the heater core is from the driver side inner tunnel. After minimal trim removal, the core is readily accessible. This is a far cry from previous generations which required entire dash pad removal. Check erWin® for all Volkswagen vehicle repair.

Vehicle climate control systems are always changing to increase efficiency and comfort. This is why its important to stay up to date. These systems may seem quite complicated, but still rely on basic principles. With a good general understanding of these systems, and proper use of OEM repair procedures, most issues that arise can be quickly diagnosed and repaired.

Download PDF

0 Comments