There are plenty of “first gen†S/V40s out there that have piled on the miles. Here are the most common aging issues they’re apt to develop, and how to fix them.

Technicians who’ve worked on Volvos over the last couple of decades have seen huge changes from a growing assortment of engines and transmissions to the adoption of CAN and fiber optics. Volvo continues to advance automotive technology at a rapid pace, so it is a challenge for technicians in the trenches to keep up with these vehicles. The following discussion of vehicle aging issues experienced in a typical shop should help you meet that challenge.

We’ll limit our attention to the first-generation (1999 through 2004) S40 sedan and V40 wagon, popular models that have probably been finding their way into your shop for years. Assembled in the Netherlands, they can be powered by a small turbocharged four, and early versions were engineered with a mix of old-school 12V electrical systems and a partial CAN.

Fuel pressure leak-down

One issue seen on this series is a failing fuel pressure regulator. Your customer will complain of hard starting when the car is cold, or after it sits for a while.

You can confirm that the symptoms are indeed caused by this issue by removing the cover over the throttle body and looking at the fuel pressure regulator. It’s best to leave the car sit overnight so you can examine it cold, or at least give it a few hours to cool down. Pull the regulator’s vacuum hose. If you find evidence of fuel, replace the regulator — don’t forget to relieve the residual fuel pressure before removing the screws.

You can also test the regulator by attaching a pressure gauge to the fitting at the end of the fuel rail. Start the engine, allow it to warm up, then shut it off and let it sit for at least 20 minutes. A good regulator should be able to maintain 29 psi (200 kPa) for at least 20 minutes after the ignition switch is turned off. Although that’s the factory recommended test, we have had mixed results — we’ve found that it won’t always identify a failing regulator.

By the way, a bad fuel pressure regulator usually won’t set a DTC (Diagnostic Trouble Code) because the excess fuel that enters the engine is usually burned off before closed loop is achieved.

False air

A lack of fuel control, hard starting, and DTCs, usually PO171, may be caused by a leaky AAC (Assisted Air Control) valve hose. Cracking hoses are normal signs of aging and we suggest that you check this hose on every ’99 through ’04 S/V40 that comes in. If you look closely at the bottom of this hose on the intake manifold side, you will likely see cracks, which could eventually lead to causing an unmetered air leak. Even a small crack admits “false†air and can set codes, so the rule of thumb is, if it’s brittle, replace it. Use a Volvo OE hose and new clamps if you want the repair to last as long as the first one did.

About to burst

Checking brake hose condition should be a regular part of your safety inspection on all vehicles, not just Volvos. We have seen many high-mileage Volvos with cracks in these hoses, and also with bubbles or bulges in the outer skin, which is due to ruptures in the inner hose. Needless to say, whether the hose is cracked or bubbled it should be replaced as this is a dangerous condition.

You may see this more often in older models, particularly with the front hoses. You may have seen several of these cars come in on a tow truck with a seeping front hose and a panicked customer. Luckily, Volvo has built-in backup systems so if a brake hose fails you won’t lose all ability to stop, but the driver will still be alarmed by the low pedal. The only service problem here is that these issues are hard to spot on an S/V40 unless you know where and how to look for them.

To properly inspect these hoses, remove the wheels and pull back the spring that shields the top part of the hose. Look carefully at the hose right above the strut bracket and there’s a good chance you’ll see cracks and/or bulges. You should recommend that all four hoses be replaced, and doing a full brake system fluid flush and refill with an approved DOT 4 fluid makes sense. Use only the high-quality Volvo OE replacement parts here because your customers’ safety is in your hands.

Dead temp sensor, no code

An out-of-range or totally failed CTS (Coolant Temperature Sensor, also known as the ECT for Engine Coolant Temperature sensor) can be an issue on S/V40s, and it doesn’t always set a code. When the sensor acts up, it can cause poor running, hard starting, and poor fuel economy. The best way to check for this is to watch the live data and make sure the temperature numbers make sense. With the engine cold, plug in your scan tool, turn the ignition switch to position “2,†and see if you read something near the ambient temperature. Check other available temperature sensor readings, such as that from the IAT (Intake Air Temperature) sensor, while you’re at it. If the IAT number suggests that you’re in the Temperate Zone, yet the CTS/ECT matches a temperature you might encounter in Antarctica, you can bet that the latter has failed. Now, start the engine and watch the data from the CTS/ECT, which has two PIDs, one for the PCM/ECU, and one for the dash gauge. If these readings start going in different directions, the sensor is bad.

Unfortunately, a code is not set in many cases. The sensor glitch may be intermittent, and only go out of whack for a few seconds at a time. Regardless, you will have recognized the problem with the above procedure. You should replace the thermostat along with the sensor because it has to be removed anyway, and it amounts to extra insurance that the thermostat is not contributing to the problem. Make sure you use a Volvo OE replacement as we have seen too many aftermarket sensors fail prematurely.

Lack of low beams

On the ’99 through ’04 S/V40 series, Volvo used the CEM (Central Electronic Module) to power the low-beam headlights. The headlight relays are built into the module, and over time the circuit board tends to overheat and compromise the soldered connections (also, the relays themselves tend to get weak and fail — sometimes you can give the CEM a tap and it will bring the low beams back on line). Technicians have been known to open up the CEM and poke around with a soldering gun, and try to replace the relays. Some are successful, but most of the time the problem comes back in a few months. So if you find a CEM that has worn out, make sure you replace it with a new one from Volvo, but make sure you check the basics first. Some technicians prefer to diagnose electrical problems “backwards,†from the load to the main power and grounds, which is often faster. Start with the low-beam bulb — is the bulb itself good? If the answer is yes, move on to the connector for power and ground. If you have ground and no power, the problem is most likely the CEM, but make sure you check the fuses and the inputs and outputs at the module’s connector before replacing it. The good news is that unlike all other Volvos that use a CEM, this one does not require a software download. The bad news is you have to tell the customer it’s going to cost over $600 to fix what they thought was just a burned-out bulb.

Escaping exhaust

Did you ever notice when you start one of the 40-series cars that it sounds louder, then gets quieter as it warms up? On the early S/V40s with the B4204T 1.8L turbo engine, the exhaust manifold nuts on the head studs start to loosen up over time with the result that the gaskets fall apart. As the manifold gets hot, it expands and seals up the exhaust leak, so if the car comes in with a hot engine you may not even hear it. Sometimes you’ll get a fuel trim code PO171 (too lean). Whenever you see this code, make sure to check the exhaust manifold gaskets as a part of your testing. A smoke machine can help here.

If these gaskets are not replaced and are allowed to leak for a long time, the exhaust manifold may permanently warp and there might even be valve damage. Also, the fuel control system’s continuous compensation can cause catalyst failure. When performing this repair, you should check the manifold with a straight edge and recommend replacement if it’s out of tolerance. Replace all the manifold studs and nuts with new ones — you don’t want a brittle stud breaking off in the head while you’re putting it back together. Also, replace the turbo oil return line seal and gasket.

Heavy vibration

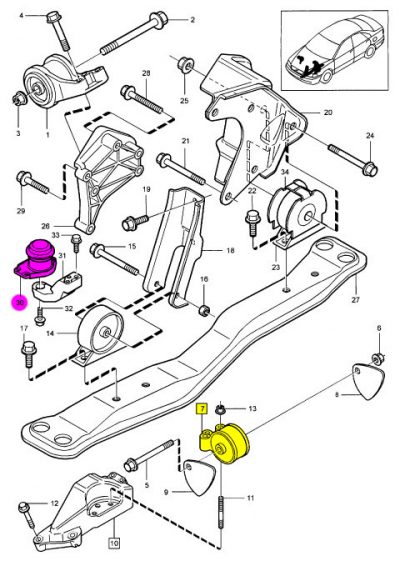

If a customer complains of heavy vibration when the car is in gear at a stop, the cause may be a collapsed motor mount. Volvo used hydraulic liquid-filled motor mounts on the right and left sides (#30 and #7 in the diagram below) on the early 40-series cars, and over time they may develop small cracks that allow the fluid to seep out. The hydraulic mounts are the main culprits in the vibration the driver feels, but if they have failed you should inspect the other mounts also.

The passenger’s side hydraulic mount is relatively easy to change. Start by supporting the engine with either the Volvo tool #999 506, or by carefully using a block of wood and a floor jack under the oil pan. You will need to raise the engine only a few millimeters. Remove the bracket for the power steering hose, the three bolts that attach the mount to the right inner fender, and the three bolts that attach the mount assembly to the engine block bracket. Volvo has an updated mount for this position, so be sure to use an OE Volvo mount. Some aftermarket motor mounts are solid rubber, which defeats the whole purpose of hydraulic motor mounts.

Before installing the new mount, check the threads in the block mounting holes. These can become stripped if a previous tech was careless when he changed the motor mount or timing belt. If they are stripped, replace the engine block bracket along with its three bolts. If everything looks good, carefully start the three bolts that hold the mount assembly to the block and also start the three bolts that hold the assembly to the body. Tighten the block bolts to 49 ft. lbs. (67 Nm) and the body bolts to 37 ft. lbs. (50 Nm), and reattach the power steering hose bracket.

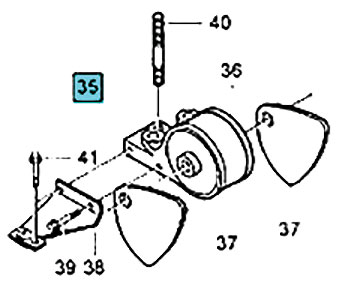

For the driver’s side mount, start by removing the battery and air filter box. Support the transmission by using a floor jack and a block of wood, then remove the bolts and nuts (diagram box 35).

Replace the mount with the Volvo updated Part #30620778. Tighten the bracket nuts to 33 ft. lbs. (45 Nm) and main bolt and nut to 72 ft. lbs. (98 Nm). Make sure you test drive the car before and after the repair to confirm the fix.

Loud noise underfoot!

Many instances of broken sway bar brackets have occurred over the years. You will hear and feel a large clacking noise under your feet going over bumps on your test drive. This job is not for the faint-hearted — it can take the whole 3.3 hours that it bills if you’re not lucky. The aluminum brackets with built-in bushings come in two-piece kits with new bolts (Part #30620989).

After this repair, the car should get a four-wheel alignment. Volvo says that if you mark the location of the front axle cross member, you don’t have to do an alignment, but that’s in a perfect world. If your customer has managed to break a sway bar bracket, the car is probably out of alignment anyway.

After your initial test drive to confirm the noise, put the car on the rack and raise it to eye level. Remove the front tires and grab the sway bar at the part closest to the body. If the bracket is broken, the bar will move freely and hit the body. Usually only one side is broken, but you should replace them both, and it’s also a good time for new sway bar links.

Start the job by removing the splash guards under the engine, and the lateral strut bar between the control arms. Remove all the bolts from the front and rear motor mount brackets and the bolts for the rear member. Now, lower the rear member, remove the header pipe from the catalytic converter, and support the exhaust. Be careful not to put a strain on the oxygen sensor wires.

Next, remove the rear engine mounting from the transmission and push the engine forward so you can take the heat shield off the steering rack. Remove the bracket that holds the power steering pipes and let it hang. Take out the four bolts that hold the steering rack to the sub-frame and support the rack.

Mark the position of the sub-frame with a crayon or permanent marker to keep it as close to alignment specs as possible. Now support the sub-frame with a transmission jack and remove the six bolts. Lower the sub-frame to gain access to the sway bar brackets, remove the nuts at both sway bar link ends, and the bolts on the sway bar brackets. Now the fun part: Remove the sway bar from the car and mark the position of the bushings. Using a pair of Channellock® pliers, pull the aluminum brackets apart (a pry bar can be used if you prefer).

Guess what — you’re now halfway there! Assemble the sway bar brackets and bushings (do not use any grease or oil on these bushings as it will damage the rubber). Using your Channellock® pliers again, snap the upper and lower parts of the bracket assembly together on the sway bar — make sure they’re facing the right way. After you have both sides assembled, you’re home-free. Just put everything back together in the reverse order.

Download PDF

0 Comments