Supplemental Restraint Systems (SRS) – the air bags, seat belts, associated sensors, controllers, and instrument panel indicator lamps – include multiple layers of monitoring to help provide a 100% readiness status. Read on to familiarize yourself with some things that could light the SRS warning lamp on the instrument panel.

Just as sound systems have evolved from single channel mono devices to the multichannel surround sound of today, the air bags, seat belt pre-tensioners, sensors, controllers and other Supplemental Restraint System (SRS) components on Nissan vehicles have advanced to provide occupant protection during a collision. Nissan SRS is engineered to be robust and self-monitoring.

Notes for Technicians

Diagnostic information in this article applies only to the Nissan year and models mentioned. Consult the service manual for the Nissan vehicle on which you are working prior to doing any repairs.

Before servicing the SRS, turn the ignition switch off and disconnect both battery cables. For approximately three minutes after the cables are removed, it is still possible for the air bag and seat belt pre-tensioner to deploy. Do not work on any SRS connectors or wires until at least three minutes have passed.

When working near the air bag Diagnosis Sensor Unit or the air bag system sensors with the ignition on or engine running, do not use air or electric power tools or strike near the SRS components with a hammer. The vibration could activate a sensor and deploy an air bag. Also, do not use electrical test equipment to check SRS circuits unless instructed to do so in the Nissan service manual.

SRS Damage Analysis

The electronics used in Nissan SRS self-monitoring functions are so sophisticated that almost any failure in a restraint systems component will set a diagnostic trouble code (DTC) and light the SRS warning lamp on the instrument panel. Pulling DTCs at the estimating stage helps identify fault codes relating to the various air bags, seat belt pre-tensioners, crash zone sensors, control modules, and other SRS components, even in cases where there is no instrument panel warning light illuminated. Some codes point to a malfunction, some identify if various air bags, seat belt pre-tensioners, and other SRS components have been deployed and must be replaced, and some indicate a need for component calibration or initialization.

This information helps you get a preliminary feel for how extensively the restraint system has been damaged. It provides an efficient head start on development of a repair plan that results in complete and safe vehicle restoration. A complete damage analysis also helps make your estimate more thorough and accurate.

DTCs can indicate the need for further investigation of components or circuits that you may otherwise have missed. They can help prevent supplements for work that may have been better scheduled at an earlier point in the repair sequence, and avoid unanticipated late-stage sublets that delay job completion and increase the number of car rental days.

Warning Light Does Not Tell the Whole Story

The SRS warning light system may not provide a complete listing of system faults. Some faults may set a DTC, but not trigger a instrument panel light. A lit warning lamp does not always mean that a deployment has occurred, as some SRS malfunctions could occur without a collision. An unlit warning lamp could be hiding previously stored intermittent faults that do not set a current code. And sometimes the absence of a warning light could indicate a dead bulb or other lamp problem, rather than an absence of DTCs.

Plug In – for a More Complete Picture

When you key-on the ignition, whether the air bag light comes on or not, plug your CONSULT III scan tool into the OBD II connector to get a list of all SRS fault codes. Codes that point to a specific source of the fault are relatively easy. For example, on the 2012 Altima, the codes B1033 and B1034 refer to crash zone sensor malfunctions. Diagnosis involves a visual check of the wiring harness connections, and if that is not the problem, replacement of the crash zone sensor.

A broad-based code may point to an entire circuit for you to investigate in order to pinpoint the exact fault. An example on the 2012 Altima is the code B1054, which refers to an open in the driver’s air bag stage 2 circuit. That circuit includes the air bag, the Diagnosis Sensor Unit (DSU), the Spiral Cable (aka clock spring), related wiring harnesses and wires, and of course, power and ground. After replacing any faulty part, you’ll calibrate or initialize the replacement component if required, then repeat the scan. If the code does not reappear, your repair is successful.

SRS Self-Diagnosis

Detailed SRS self-diagnosis results can be read using a CONSULT III plus. The warning lamp default in key-on, engine-off (KOEO) operation is User mode, which provides general problem alerts that may not tell the whole story. If there are no malfunctions, the light will come on for 7 seconds, then go off. If the light stays on, an air bag or seat belt pre-tensioner has been deployed, or there is a malfunction in the ACU, the air bag power supply circuit, or the warning lamp circuit. If the light does not come on at all, either the SRS controller – an Airbag Control Unit (ACU) in Nissan parlance — or the warning lamp itself is malfunctioning.

The Nissan SRS can provide more detailed diagnostic information for technicians, but you must first switch from User to Diagnostic mode (see sidebar: How to Change Self-Diagnosis Modes, p31). For a proper diagnosis, use the CONSULT III plus scan tool, as Nissan cannot verify the accuracy of other tools.

Scan, Inspect, Repair, Re-scan

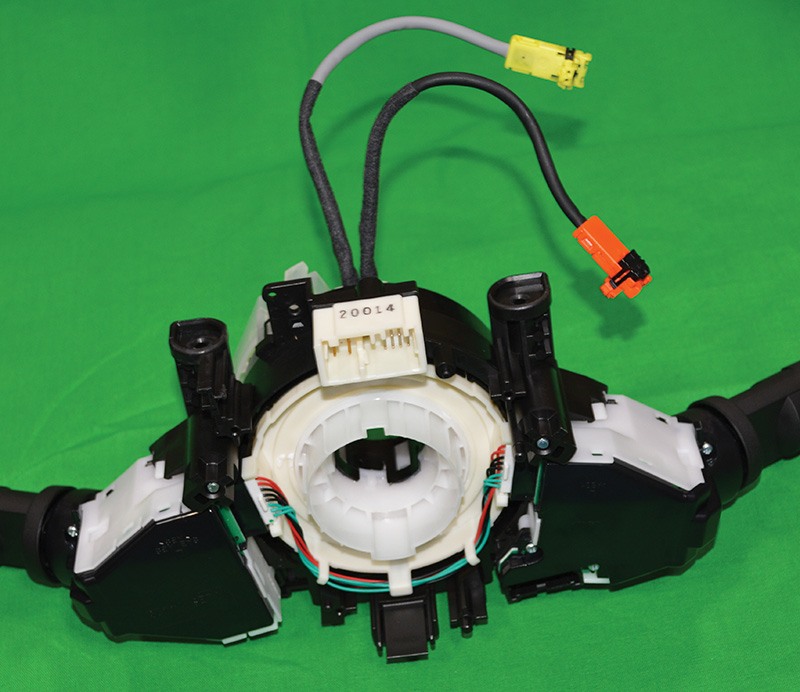

The electrical connections between the air bag and the diagnosis sensor unit pass through the spiral cable. The white nib at the top of the spiral cable assembly on this 2012 Versa must be centered while the wheels are pointed straight ahead, and the steering wheel held in place until installation is complete.

A scan allows you to read and clear trouble codes, collect sensor and control module data, perform input and output tests, program, code, calibrate, or initialize replacement components, and conduct many other diagnostic functions. Generic scan tools may be simple code readers with only basic data collection capabilities. The CONSULT III plus is the only scan tool that enables you to perform every factory scan function needed for diagnosis and repair verification on Nissan SRS components. Additionally, it offers bi-directional communication capabilities so you can not only read, but also activate and test various modules and system components, and allows you to code, re-flash or upgrade modules.

The steering angle sensor mounts in the bottom of the spiral cable for this 2012 Versa. If the original SAS is undamaged, it can be transferred from the old spiral cable and dropped into place in the new one.

Once you have pulled all SRS-related DTCs, use CONSULT III plus to look up the explanation of each code. CONSULT III plus will present a logical repair order sequence to follow for each different code, based on Nissan service manual information. (Be sure to review this information carefully.) After each step in the sequence, re-scan to confirm that the DTC is no longer present. At the first step in which your re-scan did not show the same fault code popping up again, your repair of that malfunction has succeeded, and you can clear its code from memory. If the DTC is still showing, you have further diagnostic work to do.

For example, the code “B1051†for the 2012 Altima points to a possible short to ground in stage 1 of the dual-stage driver air bag module. CONSULT III plus will tell you first to visually check the stage 1 wiring harness connection, and replace the harness if it has visible damage, a poor connection, or is loose.

The pre-tensioner for the 2014 Sentra, like an air bag, ignites a gas charge that then forces a gear or ratchet to move in a direction that tightens the belt. The pre-tensioner is deployed simultaneously with the driver’s and front passenger’s air bags, and must be replaced after a front collision in which the air bags and pre-tensioner are deployed.

If that does not clear the code, inspect the spiral cable circuit for damaged wiring or harness connections. Also inspect for continuity from the driver air bag module terminal 1 on connector M82, to terminal 29 on the spiral cable connector M29, and from the driver air bag module terminal 2 on connector M82 to terminal 30 on spiral cable connector M29. Check to confirm that there is no continuity to ground from terminal 1 or terminal 2 on the air bag module connector M82. Repair as needed and re-scan using CONSULT III plus.

If the same DTC reappears, replace the air bag diagnosis sensor unit, and re-check the system. If the code is still present, replace the driver air bag module, and re-scan. If the code appears again, replace the related wiring harness.

Scan once again. If you made it this far into the repair order sequence, you will have inspected and replaced everything in the driver’s air bag stage 1 circuit, and the fault will have been eliminated. Clear the DTC, and move on to the next fault code, if any.

Spiral Cable, AKA: Clock Spring

The steering wheel mounted driver’s air bag requires electrical connections to be maintained while the wheel is being turned. Nissan’s spiral cable connects both the power and ground sides of the driver air bag circuit. It winds and unwinds as the driver turns the steering wheel, all while maintaining hardwired electrical connections.

All driver air bag DTCs; B1049 – B1052 and B1054 – B1057, require inspection of the spiral cable circuit if the prior diagnostic step revealed no damage to the driver air bag wiring harnesses.

Inspect the spiral cable for any sign of damage to its wiring, connectors, or housing. Look for burns or melted connectors to the driver air bag. The ignition of gas when the air bag deploys generates enough heat to melt the plastic connectors to the spiral cable. If there is no visible damage to the harnesses, check for continuity on both the power and ground sides of the circuit. If there is continuity on the power side, but not on the ground side, the spiral cable can be re-used.

Check the Nissan service manual for the exact points that must align with each other on the spiral cable and the steering wheel. The spiral cable has, in most cases, enough extra length to rotate approximately 2.5 turns in either direction. With the front wheels pointed straight ahead, the spiral cable must be installed in the neutral position of approximately 2.5 turns of the cable from either end position back to the center. If it is not centered properly during installation, it could break as the steering wheel is rotated during driving.

Complex System, Simple Repair

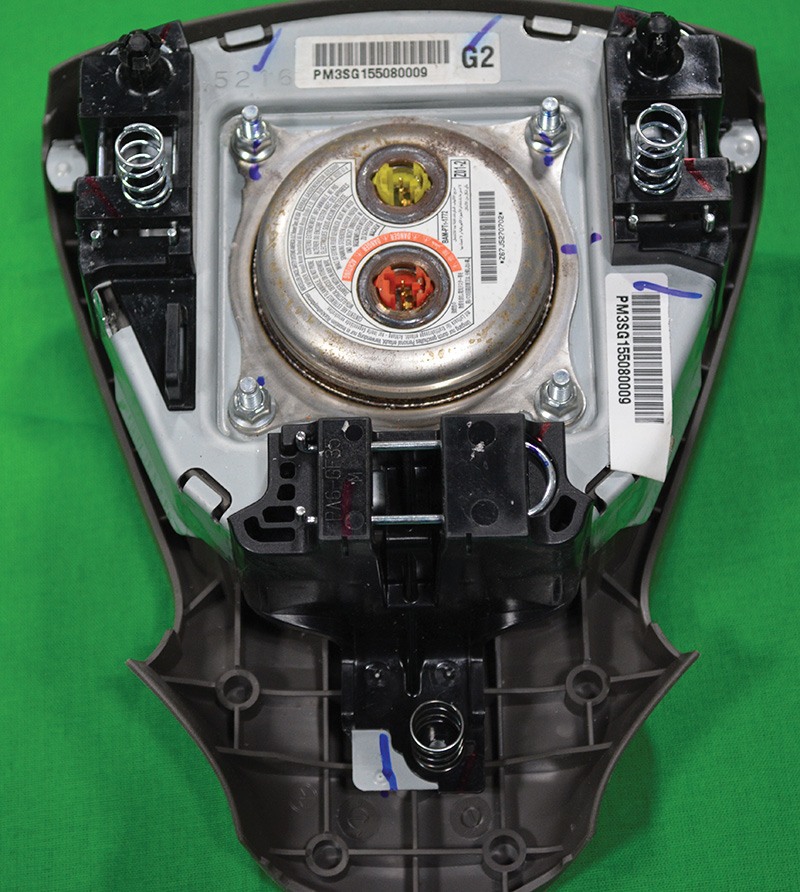

The driver’s and front passenger’s air bags for most 2007 and newer Nissans are a dual-stage design that includes connections for two separate inflator circuits, one for partial inflation in a minor collision, and a second for maximum inflation in the event of a higher impact. Shown is the driver’s air bag for a 2014 Sentra.

Nissan’s Occupant Classification System (OCS) uses input from technology in the front passenger seat to determine if there is an occupant, and whether their weight is in the range of a young child or an adult. The information is fed to the ACU. If the front passenger is a child, the ACU may not deploy the air bag. Depending upon the crash severity and the age and model of the Nissan vehicle, if the right front seat occupant is an adult, the ACU may activate the passenger air bag in two separate stages timed a few milliseconds apart, to stagger the impact of the air bag’s explosive force against the seat occupant.

The OCS in the 2012 Altima includes a sensor mat and a control module. Trouble codes B1017, B1020 and B1021 all point to a fault in the 2012 Altima’s OCS control module. Code B1018 suggests that the sensor mat is malfunctioning. Code B1019 covers any other possible causes of OCS failure. The sensor mat and control module are both built into the front passenger seat cushion, and form a single assembly. Do not attempt to disassemble the right front seat cushion assembly. The repair for any of these five different DTCs is replacement of the entire front passenger seat cushion assembly.

The only circumstance in which there are OCS repair options on the 2012 Altima is if your scan reveals DTC B1022, which points to a communication failure between the OCS control module and the air bag diagnosis sensor unit (DSU). Even then, the repair order sequence is brief.

- Visually check the wiring harness connection

- Replace the harness if it has visible damage

- If the DTC is still current, replace the RH front seat cushion assembly (do not disassemble)

- If the DTC is still current, replace the air bag diagnosis sensor unit (DSU)

Seat Belt Pre-tensioner Diagnosis? Use Only CONSULT.

Beginning with the 1999 Maxima, Nissan included seat belt pre-tensioners in the SRS, and expanded that to other models in subsequent years (check your Nissan service manual for details on which SRS components are on the vehicle in your bay). On the 2012 Altima, DTCs B1209 (front collision detection) and B1210 (side collision detection) require you to replace all seat belts, including pre-tensioners, after a collision in which pre-tensioners were deployed.

It may not be easy to tell simply by visual inspection whether or not a seat belt pre-tensioner has been activated. If a pre-tensioner was deployed, but has not been replaced, the ACU will not clear the fault code. Instrument panel warning lights can’t tell you the deployment status of a given pre-tensioner. You’ll need to use CONSULT to determine which pre-tensioners have been activated.

The Airbag Control Unit is Boss

The air bag diagnostic sensor unit monitors operating status of all SRS components, sets trouble codes, and activates air bags and seat belt pre-tensioners in a collision or rollover event.

The ACU continuously monitors the operating status of all SRS sensors, air bag assemblies, seat belt pre-tensioners and buckle switches, the OCS, and the restraint systems warning lamp portion of the combination meter, on vehicles equipped with these components. It maintains a real-time record of the status of all SRS components. It turns on the instrument panel warning lamp, and records trouble codes (DTCs) for diagnostic use by technicians armed with the Nissan CONSULT III plus scan tool.

In a collision event, it sends the signal to the squib to ignite the appropriate air bag(s) and seat belt pre-tensioner(s).

Replace All Deployed SRS Components

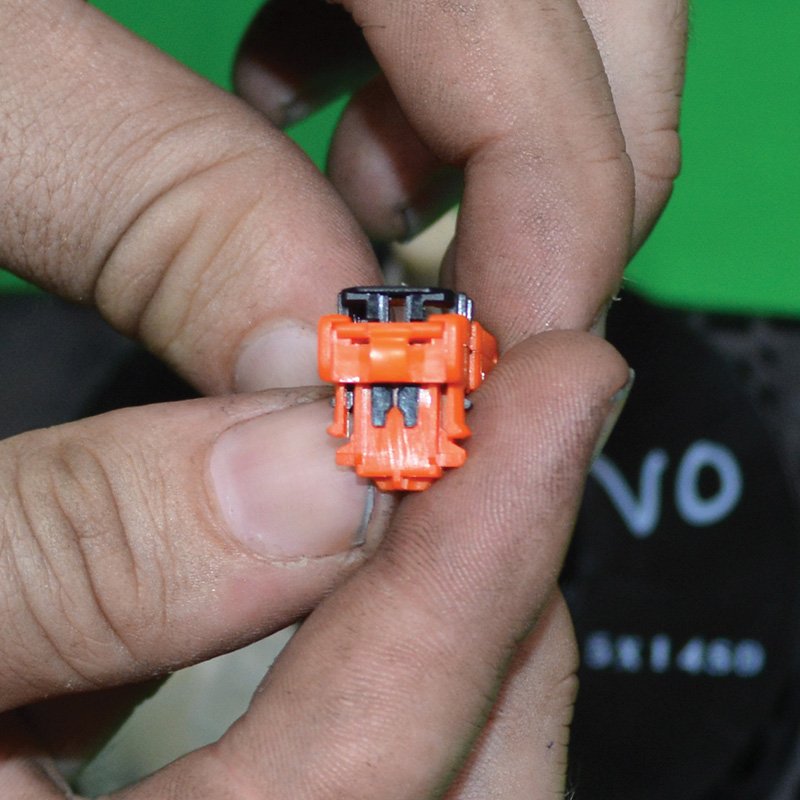

Nissan air bag connectors feature two types of lock, to provide reliable electrical continuity. Orange squeeze tabs on the side lock horizontally, and a black clip on the top snaps into place to lock the connector vertically.

If any SRS components have been deployed, you must replace the deployed components and also replace the ACU. If you see the B1209 or B1210 codes while working on a 2012 Altima or Maxima, don’t stop at just replacing the air bags and belt pre-tensioners. The DTCs disappear only after you also replace the ACU.

Do not install the new ACU before replacing all other SRS components. One common error is to replace the deployed air bags, but not notice that the seat belt pre-tensioners also need replacing. If you install a new ACU, but have not yet replaced the seat belt pre-tensioner, the replacement ACU will see it and set a fault code. You will have to replace the pre-tensioner, but because the only way the DTC can be erased is to replace the ACU, you must then also install another new control module.

Is Everyone Ready?

All SRS components must continuously update the controller of their operating status. Once all malfunctioning or damaged components are replaced, you must calibrate, initialize, or program the replacement ACU to ensure that it can communicate with each new component. Use CONSULT III plus to see the part number of the original ACU before disassembling the vehicle. You’ll need the part number and code or I.D. for its software programming, to ensure ordering the correct replacement. Check the service manual for procedures to initialize or program the ACU before removing the original unit.

How to Change Self-Diagnosis Modes

NOTE: In User mode, if the air bag warning light has come on for 7 seconds and then is not blinking, there is no malfunction, and the system will not switch to Diagnosis mode. In Diagnosis mode, if no malfunction is detected, you can switch back to User mode by turning the ignition from OFF to ON. Once in Diagnosis mode, the air bag warning lamp will flash on and off in a different sequence for each SRS component or system where it sees a malfunction. After the initial 7 seconds on, the lamp will begin a flash pattern that is associated with the malfunctioning component. Refer to your Nissan service manual for descriptions of all flash patterns used in the SRS warning lamp system. The warning lamp system covers additional SRS component faults. It uses flash patterns that are unique to each type of malfunction. The flash pattern will repeat until you make the indicated repair, after which you can clear the code. CONSULT III plus is the Nissan factory diagnostic tool for the SRS. It records and displays the same information as the warning lamp system, plus additional data that further narrows the diagnostic search. CONSULT III plus displays DTCs for individual SRS components, identifies whether the fault is likely on the power or ground side of the circuit, and points out if two circuits may be shorted together. CONSULT III plus is very useful for finding intermittent faults. An intermittent incident that occurred in the past but is not being detected currently can be reviewed by going to the SELF DIAG (PAST) option in CONSULT III plus. You can then replace the malfunctioning component and clear the code. If the incident was previously repaired but not cleared from memory, erasing it is easy using CONSULT III plus. If the warning lamp lights up, but you can find no DTC using CONSULT III plus, one likely cause is that the fault was repaired, but the trouble code was not cleared in the ACU. Clear the DTC by turning the ignition switch OFF for at least 1 second, then back ON. The Nissan Supplemental Restraint System is a multi-channel structure featuring multiple layers of protection for vehicle occupants, continuous self-monitoring, and reporting for driver notification and technician diagnostic assistance. Failure of any one SRS component will keep that vehicle in your bay, but the Nissan SRS does an excellent job of pointing you to the malfunctioning part(s). |

All photos Courtesy of Nissan of Union City, GA

0 Comments