Learn how collision impact to the wheel speed sensor, the tone ring, or the wiring that transmits rotational speed data from the wheel to the ABS control module can “confuse†the computer, and what collision repair technicians should do about it.

After post-collision checks confirm that there are no leaking brake lines, you may be tempted to attribute any ongoing anti-lock brake system (ABS) performance problems to computer or other underhood components. Before you recommend swapping out the control module, brake fluid pump, or master cylinder, remember that key inputs to the ABS decision process originate at the wheels. The entire ABS operation is vulnerable to impact damage to the wheel speed sensor, tone ring, wiring, and brake lines, all of which are located on or near the wheels.

Erratic signals to the ABS control module, problems that do not set a code, or worse, brake pulsations that occur even though there has been no emergency braking situation or driver input all can result from failure to properly check and repair ABS wheel speed sensor issues after a collision.

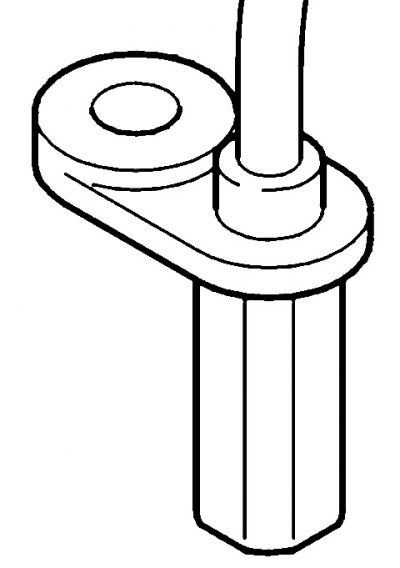

Accurate real-time information about the rotational speed of each wheel is critical to the operation of anti-lock brake, traction control, stability control, and some suspension and steering systems. The ABS control module receives wheel speed information from a combination of a stationary speed sensor and a toothed wheel (reluctor/tone ring) that rotates with the axle at each wheel. As the tone ring rotates, it generates a magnetic field that is strongest near a tooth, and weakest in the gap between teeth.

The wheel speed sensor (WSS) converts the magnetic field into a voltage signal that appears on your scan tool or scope as either an alternating current sine wave, or a Hall Effect style digital square wave pattern, depending on the sensor technology on the vehicle. The frequency of the voltage signal varies with the speed of the wheel. The voltage data goes to the ABS control module, which uses it to actuate solenoids that increase, maintain, or decrease brake fluid pressure to each individual wheel. If the anti-lock brake system is performing erratically or not at all, one of the most likely causes is a control module that no longer sees a voltage signal for a given wheel, or sees a signal that is out of range.

The control module sets a fault code, and the ABS light comes on. Volvo diagnostic information suggests three possible causes to investigate first when you see a wheel speed sensor trouble code: a loose wheel speed sensor, damaged toothed wheel, or damaged cables.

Into the Gap

A major cause of ABS failure is a gap between the wheel speed sensor and the tone ring that has changed from the Volvo factory specification. When that happens, the voltage signal going to the ABS control module changes in frequency, or may cease being transmitted.

Collision impact can alter the gap in a variety of ways. Look for cracks in the tone ring, in the wheel speed sensor housing, or in the mounting that holds the WSS in position. Collision debris or rust lodged between the sensor and tone ring also can throw the gap out of spec. Missing or chipped teeth on the tone ring will alter the voltage signal.

Surf the wave (forms)

If you find no problems in a visual inspection, there may still be damage that is too small to easily see, or is hidden behind nearby components. Use your scan tool to check for fault codes. Each wheel speed sensor-related DTC you find will point to the individual wheel where a sensor is receiving or transmitting out-of-spec or no voltage data.

Some damage may create an intermittent glitch that causes ABS activation at inappropriate times, but does not set a fault code. You may need a scan tool with a high sampling rate in order to see the glitch.

Using a digital scope, connect its leads at the Brake Control Module (BCM) and watch for distorted waveform patterns as you rotate the wheel. A cracked toothed wheel/tone ring will appear as a much narrower riser than normal square wave blocks. If a gap in the toothed wheel has been filled in with rust or debris (from a collision impact or from magnetized metallic brake dust), the waveform may appear as if two or more riser blocks have merged into one very wide block. If a tooth has been chipped, damaged, or just shrunken from normal wear, the waveform will show a much narrower riser block when that worn tooth passes the wheel speed sensor.

A weak sensor signal may not show up on a test of a sensor that has been disconnected. Back-probing at the Brake Control Module (BCM) allows you to test the circuit with the sensor connected, making it easier to catch a weak signal that does not show up on a disconnected sensor test.

The tone wheel is mounted on the end of the axle, and spins with axle rotation. If wheel bearings are damaged, worn, or loose, the tone wheel will wobble as the axle rotates. The wheel speed sensor is mounted on a stationary bracket, so a wobbling tone wheel changes the gap with the speed sensor. Even if the sensor and tone ring are in good condition, voltage signals from that wheel will be off due to the bearing damage and resultant wobble. Similarly, bent wheels or mismatched tire sizes may alter the air gap at a given axle.

Replace a damaged tone ring, WSS, or its housing or mounting bracket. If there are no fault codes set, wipe the wheel speed sensor off with a soft bristle brush, and reinstall.

Wheel speed sensors are delicate devices. It doesn’t take a big hit to cause a break in the wire windings inside the sensor. A road test may help identify internal damage to a wheel speed sensor or its feed wire. If the ABS light comes on when the vehicle is driven over bumps, there may be a problem with internal sensor wiring.

Visual inspection of ABS sensor wiring before and after a road test may reveal a changed wire position. Even a small amount of vibration can cause a wire to shift position enough to alter the voltage signal.

The Brake Control Module Doesn’t Like Different

Assuming the vehicle is driving straight on a level road, the computer ideally wants all four wheels turning at the same rate. Differences between wheel speed sensor readings on the left and right sides of a given axle are usually more important than the absolute value of the voltage measurement. Regardless of what tool or measurement method you use, if the wheel speed value for any one wheel is significantly different from the others, focus your diagnostic efforts on that wheel.

Look for a loose wheel sensor, too little or too large a gap between the wheel speed sensor and the toothed wheel/tone ring, wheel bearing play or axle vibrations, dirt between the sensor and toothed wheel, or a damaged toothed wheel or speed sensor. Also make sure that tire sizes and diameters match, as well as inflation pressures.

Volvo diagnostic trouble codes (DTCs) will point you to the likely problem wheel. It should be noted, however, that too low a voltage signal on one wheel may indicate a problem with the opposite wheel on that axle. For example, if you see the voltages as a percentage of each side of the axle, but the low side speed sensor and toothed wheel appear to be in good shape, check the high side. The opposite side may be generating a very high voltage signal due to a fault such as a crack in the toothed wheel on that side.

Download PDF

0 Comments