In the independent Volvo repair world, a lot of shops are starting to see more older Volvos coming in with complaints of misfire and poor running. The independents see more of these cases than dealer techs who mainly work with the newer Volvos and cars still under the factory warranty.

Most technicians will agree that overall, Volvos tend to be more reliable than other makes when it comes to breakdowns. Most Volvos will still limp into the shop, except in the case of major problems such as a broken timing belt.

Diagnosing Volvo misfires is not much different from the way you diagnose other cars, you just have to know what to look for. The most important thing you need when diagnosing a Volvo or any other car is the right information. When the customer brings his Volvo into your shop, the person checking them in needs to be able to ask the right questions about the symptoms, to give the technician a place to start the diagnosis.

Customers are not technicians, so you have to guide them to provide full information. If it’s practical in your shop, the tech that will be working on the car should interview the customer about their symptoms. This can save a lot of time and confusion.

When starting any diagnostics, begin with the basics! Volvo has been using OBD II on all its models since 1995 and, as early as 1989 240 models, had the ability to store some malfunction data in the ECM.

So after getting as much information as possible from the customer about the symptoms and a test-drive, check to see if there are any stored codes. If the car has stored a code or codes, check to see if there is any freeze data to go with it. Freeze frame data is a gift; in a lot of cases the answer to the problem is right there.

Now if you happen to have codes, ask yourself, do these codes have anything to do with the symptom or problem? In many cases, especially on 1999 and newer Volvos, there may be a lot of stored codes in multiple models that have nothing to do with the customer’s current problem.

A common mistake made on late model Volvos is replacement of perfectly good air mass sensors, based only on the fact that the ECM has stored a code for one. This is one of those codes that can be generated for many reasons. You need to check the live data if the air mass sensor numbers look out of range. There are a few basic checks you should do before recommending replacement.

Number one, check for air leaks. If the car has a post air mass sensor air leak, the ECM will try to compensate for it and the data numbers for the AMM, O2 sensors, MAP and Throttle unit will be all over the place. On 1999 and newer Volvos it’s always important to know if the crankcase ventilation system is functioning correctly and is not plugged. If the PCV system is blocked in these late model Volvos it can cause all kinds of problems. The excess crankcase pressure can actually reduce engine vacuum, causing the ECM to think the air mass sensor is out of range.

Checking the PVC system pressure should be part of your everyday inspection program; this system was covered extensively in the first issue of Volvo TechTips. It cannot be overstressed how important a functioning PCV system is to late model Volvos. If left unchecked, the unvented pressure can cause the engine to consume engine oil at a rapid rate, and can cause engine seals like the crank and cam seals to pop out, causing massive oil leaks. Checking for PCV pressure is easy; just run the engine until it reaches normal operating temperature. While the car is at idle remove the dipstick and insert a combination vacuum/pressure gauge like Volvo special tool number 999-7226.

You should see negative vacuum, not positive pressure. The most common Volvo misfire problem related to a plugged PCV system occurs when engine oil is forced out through the oil filler cap seal. This oil accumulates under the spark plug cover and begins to seep into the spark plug wells. As the plug wells fill with oil, the ignition coils start to short to ground and misfire. This is also common in 850 series cars that use standard ignition wires.

If the misfire symptom is intermittent and there are no codes stored that are related to the problem, start by checking the live data numbers for irregularities. If the symptom only happens when the car is cold, you should keep the car overnight to try to replicate the symptoms.

When performing diagnostics on 1999 and newer Volvos, the best tool for the job is a laptop with Volvo’s VIDA and DICE Tool installed. VIDA can monitor and record 10 Data PIDs at once, even in a graphing format. This is great when you’re looking for that needle in the haystack. Volvos can have a lot of codes and data that a generic scan tool may not even detect and, if they do, it’s usually a generic P code. VIDA can tell you if the fault is intermittent or permanent and if the sensor signals were high, low or missing. The difference is very important in figuring out the car’s problem and verifying the fix.

For example, suppose a 2002 Volvo XC70 stores a fault code for #5 injector. Most generic scan tools would read P0223 Injector #5 signal fault. If you use VIDA to scan this Volvo you will get ECM 2350 followed by signal missing, high, low, intermittent or permanent. The testing for each one of these conditions can be very different.

When performing your initial check out on the Volvo in question, part of checking the basics is battery voltage and condition; a weak battery can wreak havoc on Volvos with CAN networks. A good rule of thumb is, if the customer’s battery is older than five years it may be time to replace it.

Most people who buy Volvos buy them for one main reason and it’s not the fact that they have the most comfortable seats in the industry; it’s safety. If your customer’s Volvo is randomly misfiring or stalling, it’s not safe to drive. The modern day auto tech has to think like a detective and use the clues and information available to find out “who done it†or, more accurately, what caused it. Of course, instead of DNA and fingerprints we have DTCs and live data.

If you work on a lot of Volvos, you know that the majority of misfire complaints can be traced to ignition coils that have lived past their useful life span. But of course when Volvo coils fail they almost always store a code in the ECM. The majority of high mileage coil failures that are being seen in the aftermarket are in Volvo models starting in 1998 with the S/V70 series cars. Volvo did use coil over plug systems as early as 1991 in the 900 series cars, but for some reason the early coils don’t fail as much as the ones on later models. Verifying that a coil has failed is relatively easy. The preferred method is to mark each coil with the corresponding cylinder number and then switch the coil in question with a known good coil.

After that, all you have to do is start the car and watch the live misfire data and see if the bad coil has moved cylinders. If your scan tool does not monitor misfire data you can just clear codes, drive the car and see if you get a new code for the cylinder with the questionable coil.

That being said if you have to replace the coils you should recommend that all of then be replaced at once, unless you like the customer having to come back every few months with another failed coil. Use only high quality replacement coils for the same reasons. OE Volvo coils have a 2-year unlimited mile warranty. Volvo misfires can be caused by multiple things and, yes, most of the time it’s the coils and plugs.

But this article is also going to help you with the not so everyday misfire causes.

Here is a case study of a Volvo that should have been easy to figure out but was not. A new customer brought in a 2005 Volvo S60 with a 2.4L non-turbo engine. The car was well maintained and only had 68K miles on the odometer. The customer stated that the car would intermittently shake and run rough at idle. Sometimes it would happen once a day and sometimes it would only happen once every two weeks.

The customer stated that the car had been to two other shops that could not fix the problem. The first shop replaced the coils and spark plugs with OE Volvo parts. The shop that replaced the coils and plugs was a Volvo specialist with a good reputation, so we had no cause to question their work.

After interviewing the customer and examining the repair orders from the other shops we noticed that all of the shops that worked on this problem had checked the car for stored codes and had come up with none.

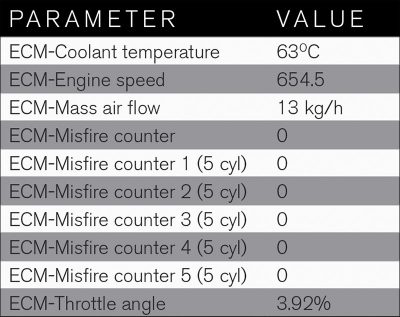

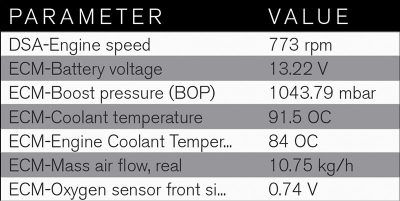

When we plugged the car into our VIDA we got the same result — no stored codes in the ECM or any modules that could cause similar symptoms. We went to vehicle communication and checked the live data.

The car was at operating temp and all the data was normal. We watched the misfire counters and nothing happened. We decided to have a technician drive it home for a few days with the VIDA laptop until the symptom happened. The first day nothing happened. The next day when the car was cold, the symptom occurred for about 10 seconds! It was definitely a misfire on more than one cylinder, and it happened so fast no codes were stored.

When he got to the shop we were lucky enough to see it happen again with the VIDA misfire counters monitoring data on all five cylinders. At idle 2 and 5 were missing just for a second — not enough for this Volvo to store codes but there it was. We decided it may be a mechanical problem like a broken valve spring, so we decided to do a compression check.

The technician removed the brand new coils and then removed the first spark plug. This is when we saw the first problem; the plugs were brand new, high quality OE Volvo spark plugs, but they were not for this engine. These plugs were designed for the R version of the S60, the S60R and the V70R. The main difference is the length of the threaded portion of the plug. As you can see in the picture, the spark plug for the R version of this Volvo is 5mm longer than the correct plug for this engine. The longer plugs did not come in contact with the tops of the pistons and the gaps were normal.

Upon closer inspection of the plugs we found the problem. The plugs that were installed on cylinders 2 and 5 had broken electrodes that would move up and down when cold. So on the intake stroke the electrode would slide down, shorting the plug. Then on the compression stroke the pressure would push the electrode back into place so it would fire somewhat normally. As the plug got hot it would expand, fixing the electrode in the correct position. This S60 would never display its symptom for long enough to set a misfire code.

This example shows why it’s important not to assume anything and why you should always start with the basics. It’s good practice to read the data on all the cars you diagnose before and after the repairs, not only to confirm the fix but to get used to what the normal data numbers look like. The more experience you have reading scan tool data, the better you will become at recognizing when the data numbers are out of normal range.

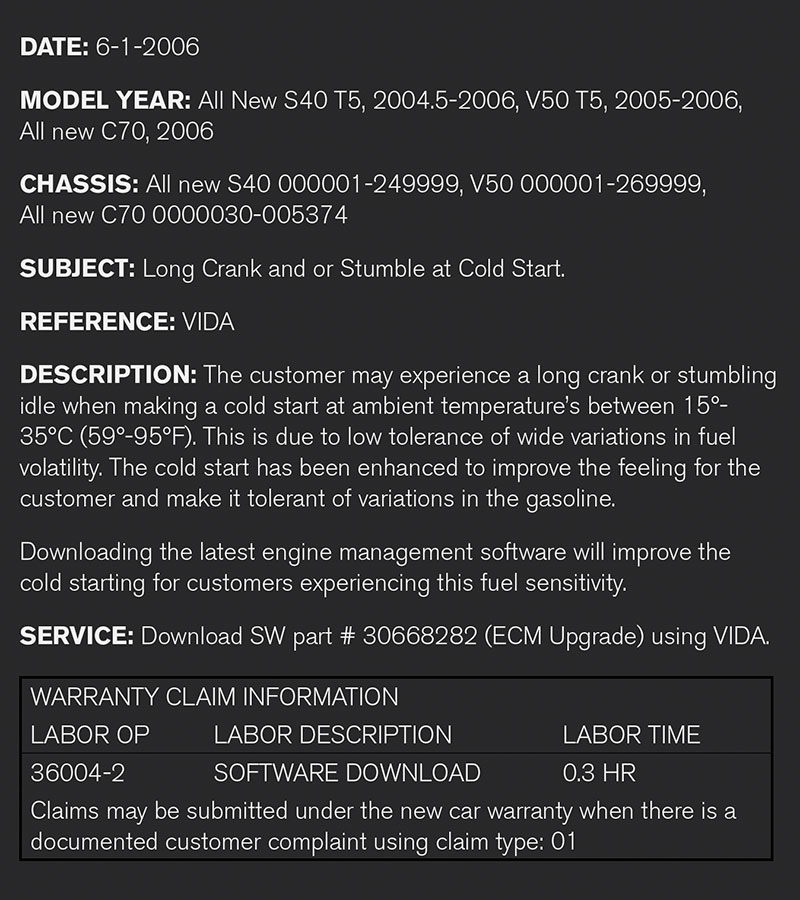

If you have a hard time remembering scan tool data numbers, a good tip is to use your phone to take screen shots of the data before and after repairs or make a journal. It’s also a good idea to check for TSB and recall information on the car you’re working on. This simple step can save you a lot of time and money. Volvo engineers will often develop software or service procedures to fix common problems or improve the performance and reliability of their cars. Here is just one example: TSB-No: 28-71.

When checking a Volvo with a no-code misfire, start by checking the live data. Is the temperature correct for the ECT? Volvo temp senders can fail at higher mileage and don’t always set a code. It’s always best to check ECT readings from a cold start all the way to normal operating temperature. On the live data you will see two ECT readings — one for the gauge and one for the ECM even though the signals come out of the same sensor.

Watch to see if the temperatures deviate from each other. This is a sure sign of a worn ECT sensor. A malfunctioning ECT sensor can cause a misfire after a cold or hot start, usually by telling the car’s ECM that the coolant temp is full cold (-32°C). This can cause the injectors to flood the engine and foul the spark plugs.

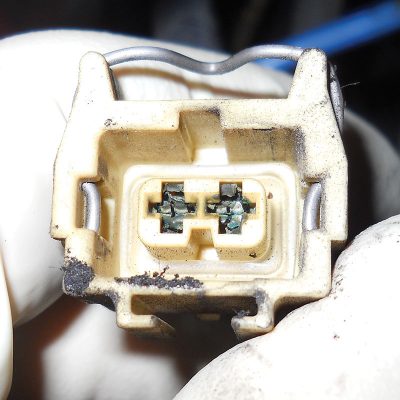

As Volvos age, the vacuum hoses on the engine can start to deteriorate and develop cracks. Usually an unmetered air leak won’t be bad enough to cause a misfire, but it will affect a lot of sensor data as the car’s ECM tries to compensate for the air leak. These readings can often store a code in the ECM. It’s common that functioning parts like air mass sensors are replaced just because of a stored code and the car’s real problem is not addressed. To avoid this kind of thing make sure you always check the data. Check electrical connectors and grounds. Resistance caused by corrosion can affect the sensor readings a great deal.

When performing any engine performance diagnostics on a Volvo, it’s always a good idea to make checking for post air mass sensor air leaks part of checking the basics. The best tool for this is a smoke machine. This tool will pay for itself over and over again.

Make sure your smoke machine is for emissions testing so you can regulate the pressure. Most techs only use their smoke machine to find intake and emission system leaks.

One of the cool things you can do with it is to check for leaking valves. Just put the cylinder you want to check in the top dead center position and blow smoke through the hose for your compression gauge. If you see smoke coming out of the exhaust, you probably have a burnt exhaust valve and if smoke is coming out of the intake, you may have a worn intake valve. Sometimes you can also see a leaking head gasket by removing the coolant reservoir cap while blowing smoke into each cylinder and watching for smoke and bubbles coming up in the coolant.

Most Volvo misfires can be traced to ignition or fuel problems, but if all those systems check out OK, it may be time to check for a mechanical problem in the engine. Although rare in Volvos, engine problems like leaking head gaskets, burnt valves or seats and broken valve springs are possible.

Volvo fuel injector failures are very rare but can happen. Faulty Volvo injectors will almost always store a code, except in the case of clogged or leaking injectors. However Volvo injectors are very tough, even at high mileage, so you won’t see many that need replacement.

When diagnosing a Volvo or any other modern car, your best tools are information and data. Volvo tends to use similar data PIDs on most of their systems, so the more you read live data, the better you will be at spotting the numbers that are out of range.

Download PDF

0 Comments