This car came in with a Check Engine light on and no other apparent symptoms according to the driver. When the car’s owner was asked how long the Check Engine light has been on, the customer stated “a few weeks†(translation “a few months or as long as I can remember, in customer speakâ€).

When the technician took the car out for an initial test drive, before checking out the car, the technician noticed that the car’s brake assist performance was less than it should be, causing the driver to have to apply more pressure than normal on the brake pedal to get the car to stop.

Most technicians would automatically assume that this Volvo had a leaking brake booster, which in some rare cases could cause an intake air leak code to be generated in the ECU. In the case of this Volvo, it was not so cut and dry.

If you have been working on Volvos for a while, you would know that most 1999-2015 Volvos that have a leak in the brake booster diaphragm will make an audible “hiss†noise from under the dash on the driver’s side when the brakes are applied at idle.

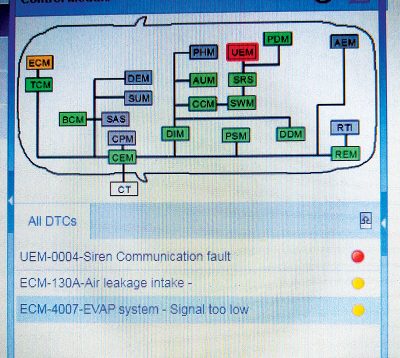

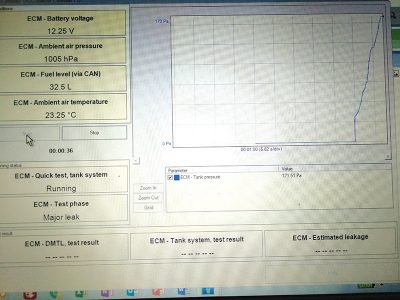

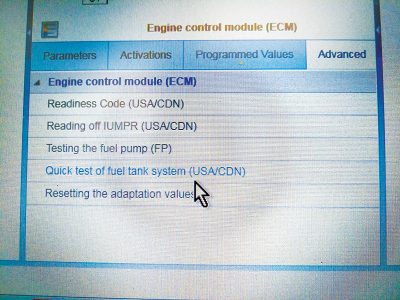

Now this is one of the many areas where using Volvo’s VIDA system is far superior to using a generic scan tool for diagnosing this type of problem. When you use VIDA, you can click on the codes and go right to Diagnostic Procedure, Possible Causes, and DTC Setting Conditions. And with VIDA, you can click on the Vehicle Communication tab, click on the ECU and, under the Advanced tab, you can run a quick test of the fuel tank system.

Try that with a generic scan tool.

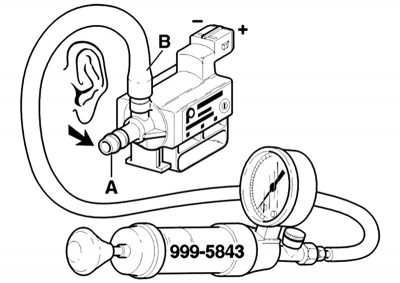

The quick test is not always that quick. It depends on a lot of factors. Of course it’s a lot quicker than trying to get the car to run the tank system monitor by itself. The fuel tank system quick test runs a complete test of the car’s EVAP system and can detect most leaks, blockages and component malfunctions.

And on 1999-2005 Volvos, the first part of the fuel tank quick test is to check and see if the car’s ECU has the latest version of the ECU software loaded. In some cases the ECU can generate fault codes like ECM – 130A falsely if the software has not been updated; this can only be checked with VIDA.

On this Volvo, the code ECM – 130A could be caused by any unmetered air leak in the engine’s intake system, a defective air mass sensor (not likely), or a blocked PCV system, which is very common and should be checked on every Volvo you service. A clogged PCV system can cause a lot of problems, but for it to set a code is rare.

Do not replace the air mass sensor just because you have this code; this is a rookie mistake that is made all too often.

The code ECM – 4007 (Evap System Signal Low) could be caused by a blocked hose between the EVAP canister and the EVAP canister purge valve, a blocked hose between the EVAP canister purge valve and the intake manifold or, more commonly, a faulty EVAP canister purge valve.

The EVAP canister purge solenoid valves on these cars may fail after they have been in service for a lot of miles. As they age, the plunger starts to stick and can become misaligned. There is actually a Volvo service bulletin about these valves, TJ 28228.

On the 2002 V70 in this case study, the two codes ECM – 130A and ECM – 4007 were not caused by the usual suspects like leaking vacuum hoses or even a weak canister purge solenoid.

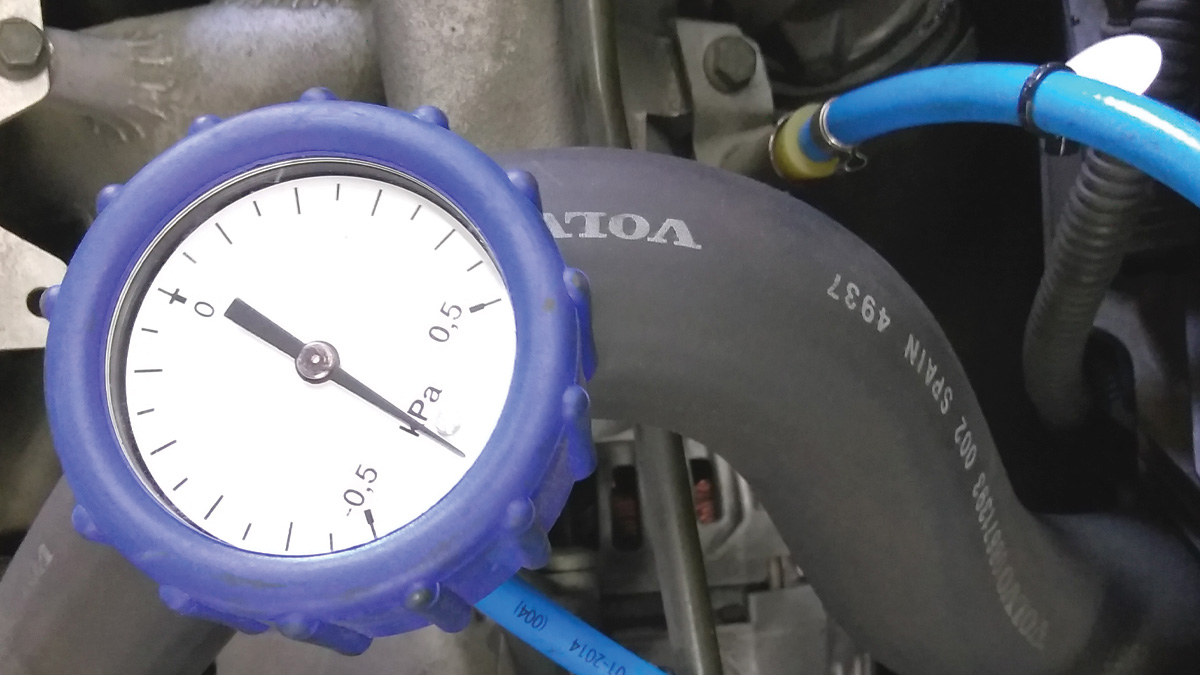

The technician noticed that when the car had the key on and the engine off (KOEO), the brake vacuum pump would cycle on and off constantly. This is usually caused by a leak in the vacuum pump check valve or hoses.

During the visual inspection under the hood, the technician also noticed that a lot of the hoses for the EVAP purge valve, and the brake vacuum pump check valve had recently been replaced.

The hose that was used was aftermarket bulk fuel hose and was not designed to be used for this application. This kind of hose was designed to carry liquid under low to medium pressure; it was not made to stand up to engine vacuum, and is prone to get soft and kink in high heat conditions.

Remember, when replacing hoses always replace them with the same type of hose that came on the car from the factory. Using just any hose could become a safety problem for your customers.

The cause of the vacuum pump cycling on and off turned out to be a cracked and leaking brake vacuum pump check valve.

The causes that led the ECM to log the codes ECM 130 – A and ECM – 4007 turned out to be hidden in plain sight.

The first sign of trouble was at the hose that connects to the intake manifold. Since the hose was replaced with the wrong type of hose, it would soften and collapse as the engine warmed up, causing the flow to the EVAP and Brake Vacuum Assist to be cut off.

The collapsed hose and leaking check valve could have been the cause for all the codes and symptoms. But wait! There’s more! Â

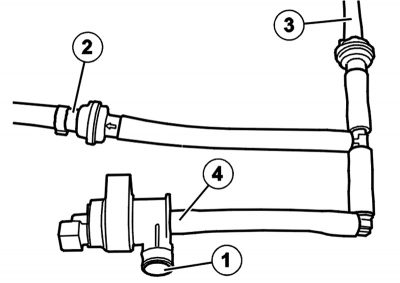

When the technician was replacing the hoses and brake vacuum check valve on this car with new Volvo factory parts, he noticed that the anti-backfire valve in the hose that goes to the turbo inlet had been installed backwards. Yes folks, those little arrows mean something.

These anti-backfire valves are like air diodes; the vacuum only flows one way, which means that, with the valve installed backwards at position 3 in the diagram, fuel vapors from the canister would be bled off away from the intake manifold and into the turbo.

When the service advisor called the customer to sell the hoses and check valve, they asked the customer if they knew anything about the “new†hoses that had been installed in the EVAP system. After some coaxing, the customer stated that his brother, who “used to work on cars,†had “fixed†some leaking hoses for him. When the customer was asked if the Check Engine light came on soon after his brother had “fixed†the car, the customer stated, “Come to think about it, yes it did.†Well, hopefully his brother did not “fix†anything else on this Volvo.

After the technician repaired all the damage caused by the brother of the customer, the rest of the EVAP system was checked. Then, the technician ran the fuel system quick test with Volvo’s VIDA tool and test drove the car to see if the monitors would run.

The moral of this story is to keep your eyes open, and remember that attention to detail is one of the modern technician’s greatest tools.

Download PDF

0 Comments