Over a decade in, what you now need to know for tire work.

Wise men tell us that if we want to know where we’re going we need to look at where we’ve been. Tire pressure monitoring (TPMS) is a relatively new technology to the automotive industry. It’s really a harmonious fusion between the automotive industry and the tire industry. Tire technology has made many advancements from radial tires to run flats. But there is one item that always needs attention: inflation pressure.

Why do tires lose air?

Even a perfectly good-looking tire with no obvious defects or visible punctures will lose air over time. This is due to osmosis. Osmosis or permeation is the ability of air to pass through the structure of the tire rubber. It exits the tire sometimes at the rate of 1-3 psi per month. The exact air loss is usually determined by the model and make of the tire. Different rubber blends provide different rates of permeation.

Nitrogen has been a buzz word in tire inflation as well. The racing industry figured out pretty quickly that tires filled with nitrogen rather than air also exhibit less pressure change with temperature swings. That means more consistent inflation pressures during a race as the tires heat up. The molecules of nitrogen are bigger, so they penetrate the rubber at a slower rate. However, there are pros and cons to using nitrogen.

A change in thinking

In the fall of 2000, following several fatal accidents involving underinflated tire failure and vehicle rollover, Congress signed into law the Transportation Recall, Enhancement, Accountability and Documentation Act (TREAD). Many lawsuits initiated this action. Arguments on both sides pointed to issues from improper posted inflation pressures to faulty vehicle design. CBS news reported NHTSA links to 148 deaths and more than 525 injuries in the United States due to separations, blowouts, and other tread problems in a certain manufacturer’s tires, many made at one particular plant, 6.5 million of which were recalled during the summer. One factor caused by low air pressure is an increase in the running temperature of the tires, which contributes to decreased belt adhesion.

This law mandates the use of a suitable TPMS technology to alert drivers to a severe under-inflation condition of their tires. The law requires that all new vehicles produced for the U.S. market after September 2007 have TPMS. This action not only provides a safety factor, but also peace of mind. Generally, drivers are not aware that they have a low tire until it’s too late, at which point the tire usually cannot be saved and further risk to life and limb due to possible blowouts ensues.

There are basically two types of monitoring systems that have been developed to keep an eye on tire pressures, and Mercedes-Benz has used both technologies. Most of the vehicles you service will have one or the other of these systems, either indirect or direct.

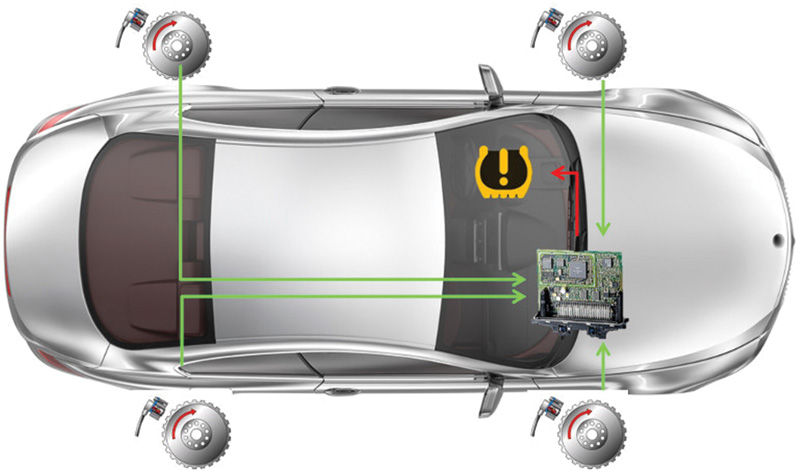

In indirect systems, the pressure is monitored using the wheel speed sensors . The ABS control unit detects the pressure loss of a tire by means of the different rolling circumference. A tire with a low air pressure effectively has a smaller diameter, so has to make more revolutions than one with the correct air pressure. However, this system is not as precise as the direct measurement type, and requires a pressure loss of approximately 30% before a warning message is displayed. The advantage is the relatively low price as numerous vehicle components already in place can be used. The only things required are adapted ABS software and an additional display in the instrument panel.

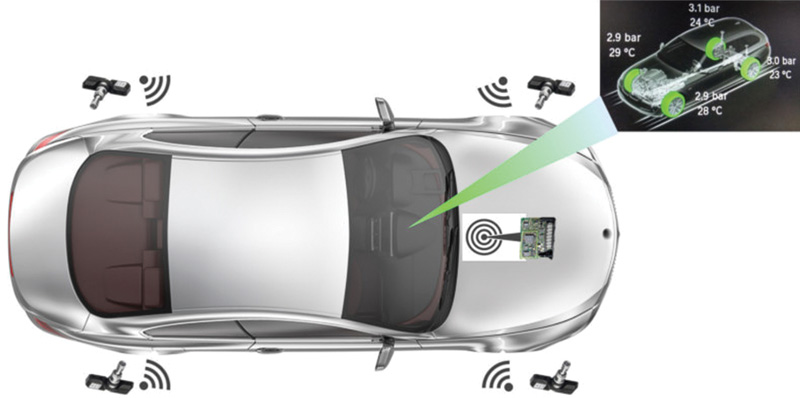

Direct measurement systems are considerably more precise, but involve additional components (and service complications), and are therefore more expensive. In this system, a battery-powered sensor is located in each wheel. These measure the temperature and the pressure of the tire, and transfer the measured values wirelessly to the TPMS control unit and/or display unit. Tire stem antennas transmit the radio signal.

Direct systems compare the tire pressure with a reference value stored in the tire pressure monitoring system control unit. This has the advantage that pressure losses of several tires can be detected at the same time. One disadvantage of the direct measuring systems is that the batteries will fail after approximately five to 10 years. Whenever you determine through diagnosis that there are one or more weak batteries in a vehicle, you should replace the sensor(s).

Changing out the sensors requires removal of the tire from the rim. Mercedes-Benz recommends that you follow the tire machine manufacturer’s instructions regarding dismounting and mounting the tire, paying particular attention to the area where the valve stem is mounted. Be sure to check the sensor for damage or improper torque. Should you change the sensor each time you replace a tire? Most of the time you will want to if the sensor is over five years old. This will save your customer time in the long run.

What your customers need to know

There are a few factors that could cause the tire pressure warning to illuminate, one of which is a leaking tire. As mentioned previously, it’s normal for even a good, undamaged tire to lose air pressure over time. A tire can typically lose 1-2 psi of pressure for every 10-degree F. drop in ambient temperature. When the tires are warm, whether from driving or being in the sun, their pressure will be significantly higher than after the vehicle has been parked outside on a cold winter day. This change alone could trigger the TPMS warning lamp.

The recommended inflation pressure listed in the Operator’s Manual or on the label inside the fuel door is a “cold†pressure, meaning the car has been parked outside in ambient temperature conditions for at least an hour. Mercedes-Benz recommends that you check tire pressures with a high-quality gauge (accurate to one psi) at least once per month and not to wait for the TPMS indicator to illuminate. Advise your customers to refer to the Operator’s Manual for information about resetting the vehicle’s TPMS after correcting pressures, rotating, or replacing the tires.

We’ve found many times that our customers are misinformed about what the TPMS system is designed to do, so you as a technician and your service advisors will be ahead of the game if you take the time to explain the subject to them. A typical conversation with a customer often starts out like this: “My tire pressure warning light is on. I know something’s wrong with the system because I looked at my tires and they look fine.†Nine times out of 10 we will first check the tire pressures with an accurate gauge and find that they are out of spec. Mercedes-Benz has produced a short video to help your customers understand the system better. Give them this link and have them watch it to help them become better informed: https://bit.ly/2tmae2M.

Let’s take a look at one of the more common vehicles you may service

C-Class vehicles can be equipped with either of the two types of tire pressure monitors depending on the model year. Later models all use the direct type with tire pressure sensors mounted in all four the wheels.

Then there’s the TPMS control unit. The tire pressure sensors measures the pressure and temperature and send this data to the control unit every 60 seconds. Information on tire pressures can be seen in the multifunction display. After a few minutes of driving, the current pressure is shown in the service menu of the multifunction display. The TPMS will be restarted when you have adjusted the inflation pressure to a new level, perhaps for different load or driving conditions. The TPMS is then recalibrated to the current tire inflation pressures.

If the tire pressure monitor detects a significant pressure loss in one or more tires, a warning message is sent to the multifunction display. A warning tone also sounds and the tire pressure warning lamp lights up in the instrument cluster. If the pressure of at least one tire is continuously below the warning threshold for 12 minutes during a trip, a warning signal is set and stored in the memory of the control unit and displayed in the instrument cluster at the end of the trip. If the customer complains of this message in the display, your first course of action should always be to do a thorough tire inspection, set the tires to the recommended inflation, and drive the vehicle for 10 minutes to ensure the problem has been corrected. If the warning message still appears or comes back, then there is a malfunction in the TPM system. Further diagnosis with your XENTRY or compatible scan tool is in order.

Wheel mounted sensors

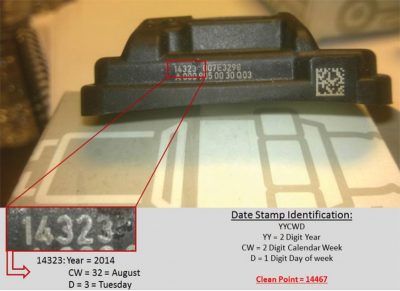

Most direct TPMS sensors use ultra-high frequency (UHF) radio in one of the “unlicensed†ISM bands (industrial, scientific, and medical) for transmitting the data, usually around 434 MHz in Europe and 315 MHz in much of the rest of the world. Currently, there are more than 150 SKUs of tire sensors fitted to North American vehicles. Mercedes-Benz uses several different makes of sensors, such as the common one made by Schrader.

Early sensors were found to have been replaced without need due to the wrong tire valve caps. A TSB shows a detailed analysis of the valves and states that corrosion was causing an issue due to different metallic materials in their makeup. In order to avoid corrosion, only plastic valve caps should be used on vehicles with tire pressure monitoring systems.

Every TPMS sensor must be “relearned†to the vehicle following the prescribed OE relearn procedure after replacement, regardless of whether it is genuine OE or aftermarket. The relearn procedure is mandatory to ensure that not only the replacement sensor works properly, but also that the vehicle’s complete TPMS functions properly as well.

Some aftermarket sensors require special programming to meet the vehicle’s application specifications prior to installation and relearn. These may include “programmable,†“universal,†or “cloneable†sensors. In addition to this extra step, technicians may need to invest in specialized tools, training, and software to complete the process. Even if a shop has the specialized programming tool, it may need to be updated to provide the latest application or software changes in order to meet the specifications of a particular vehicle. We highly recommend that you stick with genuine Mercedes-Benz-supplied sensors to avoid the issues sometimes associated with aftermarket products.

Other components

The following are other components and systems that are involved in the direct-type TPMS in a model 204 with a code 470 system. Other models will be similar, but be sure to consult WIS or XENTRY for the layout of the model you’re working on:

- The instrument cluster, which displays the warning and pressure readings

- The outside temperature sensor

- Front SAM control unit

- The tire pressure monitor control unit

- The steering column tube module control unit

The Brains of the Outfit

Beyond the pressure sensor in each wheel, the most important component listed above is the Tire Pressure Monitor Control Unit, which is located in the left trunk area. It’s responsible for the following tasks:

- Reading sensor signals

- Evaluation of input factors

- Actuation of components

Reading the input factors involves both one-way radio (the radio frequency signals mentioned previously), and interior CAN B.

The signals from all the tire pressure sensors are read via the two-way radio signal. The CAN bus reads the following signals: vehicle speed, outside temperature, and the odometer. The input factors that have been read in are evaluated by the integrated microprocessor and the relevant components are then actuated via the CAN B as well as the instrument cluster display for warnings, tire pressure readings, and messages.

Indirect systems

In older indirect monitor systems, the rolling circumference changes based on air pressure, and the existing wheel speed sensors send info on individual wheel rpm to the control unit. This data is evaluated by means of a comparison of the rpm in the ESP and BAS control unit. The ESP and BAS control unit compares the FL and RR wheel rpm, and the FR and RL wheel rpm. Also incorporated into the equation are the:

- Lateral acceleration

- Yaw rate

- Wheel torque

The vehicle needs to be driven at a speed of at least 12mph for a few minutes to read properly. This type of system will set a warning without stating a position and will be inactive when braking.

Resets

Resetting or performing the relearn procedure after a wheel change can be done using the controls on the steering wheel:

- Adjust tire inflation on cold tires to the recommended pressures listed on the gas filler flap.

- With the ignition switch “on,†use the left/right arrow buttons on the steering wheel to select “Serviceâ€.

- Press the up/down arrow buttons to select “Tire Pressure,†and press “OK.†“Tire Pressure Monitor Active†is now displayed.

- Press the down arrow button and “Use Current Pressures as New Reference Values Press ‘OK’ to Confirm†will be displayed.

- Press the “OK†button to Confirm. After driving a few miles, the set pressure values will be stored as the base setting.

- If the TPMS light comes back on, or the instrument cluster states “TPMS Malfunction,†diagnose for faults in the Tire Pressure Control Module.

There may be times when you need to connect the scan tool to relearn the system or to diagnose the faults if you cannot get it to relearn.

Check the Bulletins!

It should be noted that there are several TSBs concerning certain TPMS faults. TSB – LI40.15-P-046651 in particular is one where if you receive customer reports in the above model vehicles of the instrument cluster displaying “Tire Pressure Monitor Inoperative,†and there is a corresponding stored fault code of 5581 (front or rear sensor localization failed), this is because the difference in the signal strength between the front and rear axle may not be enough for the wheel assignments to be accurately made. The bulletin will go on to explain that the remedy involves a hardware modification as well as some software updates or resets when the repairs are completed.

The latest

The batteries in TPMS sensors naturally wear down eventually, and replacement costs money and labor. Now there are prototypes in the works of “battery-less†sensors. Also in coming technology, the Companion App, developed by Mercedes-Benz Research and Development, provides vehicle information and door-to-door navigation instructions using the customer’s Apple iPhone or Android device. Depending upon the model, you may be able to check your tire pressures with your smart phone!

Download PDF 〉

0 Comments