Take the Nissan LEAF® Technologies & Repair Considerations class from I-CAR to learn about sectioning structural components, working with ultra high strength steel, repairing Advanced Driver Assistance Systems, and more.

The 2018 LEAF features a variety of different steel types including Ultra High Strength Steel (UHSS) for collision energy management and ultimate occupant protection. The Nissan LEAF Technologies & Repair Considerations class (course #NI007E01) from I-CAR goes beyond part sectioning and replacement considerations. It covers safety precautions when working around the LEAF’s high-voltage batteries, wiring, and power management systems, and the disconnect steps you’ll use to protect yourself and sensitive electronics.

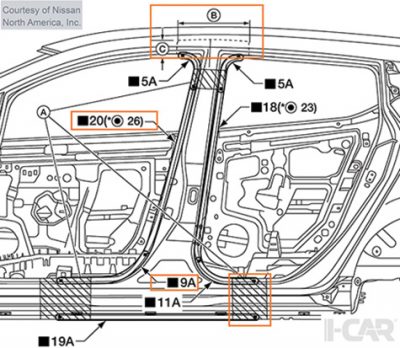

The course explains how to read Nissan repair diagrams to learn what you can or cannot section, how to sequence welding steps for assemblies

with multiple components, and whether a plug weld or spot weld is appropriate. The class also explains camera aiming, sensor calibration, and other post-repair procedures that are required to reset the LEAF’s many Advanced Driver Assist System (ADAS) technologies.

The class lists which components cannot be heated, straightened, or repaired. You’ll learn the symbols that indicate which parts to section as well as where to cut.

You’ll learn Nissan codes that differentiate between a spot weld and plug weld; how to tell the number of layers or plates in a joint; how many welds to make for a given component or assembly; and symbols for other collision repair procedures or parts.

If you remove a camera or any related part, including windshield glass, front grille, door mirror, mounting brackets, or other hardware, you must perform a calibration, also called a camera-aiming adjustment. If you replace the camera itself, conduct a read and write configuration to ensure that it can accept instructions from, and send data to, the control module. You’ll need Nissan’s CONSULT III Plus to perform any calibration or read and write configuration.

The I-CAR LEAF class helps repair professionals understand and interpret the service manual, such as by providing video instruction on performing a post-repair calibration of the Distance Sensor for Intelligent Cruise Control® (ICC). The video shows detailed steps for positioning and setup of the front and rear targets, mounting and aligning the laser measuring assembly, and confirming that measured values are within specified ranges.

If the ICC calibration fails, a Nissan Service Manual troubleshooting chart offers assistance. By showing possible causes from that ICC calibration failure chart, and what service procedures resolve each different problem, the I-CAR class helps teach you to diagnose common problems. This class demonstrates Nissan’s commitment to providing training on the latest vehicles and their technologies to ensure safe and proper repairs back to manufacturer specifications.

0 Comments