Corrosion is a major cause of poor performance of electrical circuits. Here are a few proven measures for limiting post-repair corrosion potential.

Corrosion is the enemy of performance of almost every system in today’s vehicles. Corroded electrical connections and wiring reduce the ability to send power to actuate devices. It also scrambles digital data and prevents clear, timely communication with the software that adjusts vehicle response to driving load and road conditions. As an interrupter of the delivery of power and data, corrosion reduces the safety, handling, comfort, fuel economy, and other metrics that are key to vehicle operation.

Automotive engineers now design many connectors with watertight or moisture-resistant housing construction. If you find a sealed connector, you can bet that it is going into a water-challenged location on the vehicle, defined by Mercedes-Benz as anywhere that isn’t in the vehicle interior or trunk. Use whatever connector the parts catalog specifies. It may list a part number without explicitly stating that the part is waterproof and seals the connection when properly installed. Failing to use a non-waterproof connector where one is called for only creates an opportunity for moisture to cause corrosion or otherwise weaken performance of your repair, and we all know customers hate comebacks more than you do.

Corrosion on an electrical contact or connection point is one cause of resistance buildup in that circuit. When your checks show excessive resistance compared to the OEM specification for a given circuit you should, in addition to looking for loose connections or frayed wiring, keep an eye out for evidence of corrosion. If you find corrosion in any connector or wire, you’ll need to eliminate the corrosion and protect that contact point from future moisture ingress.

Corrosion on wires – that blue stuff so often seen in flood cars – is fatal for the harness. It cannot be repaired, the correction will only get worse, so replace the affected harness.

They’re everywhere!

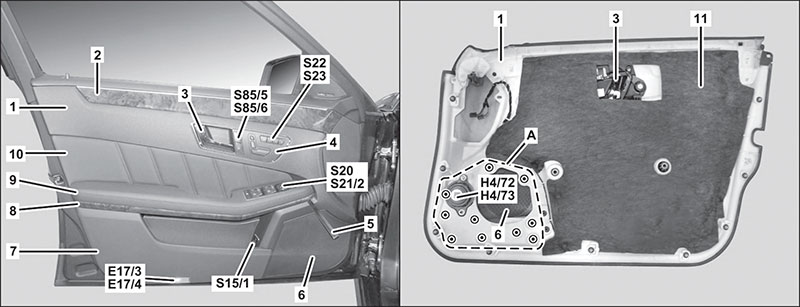

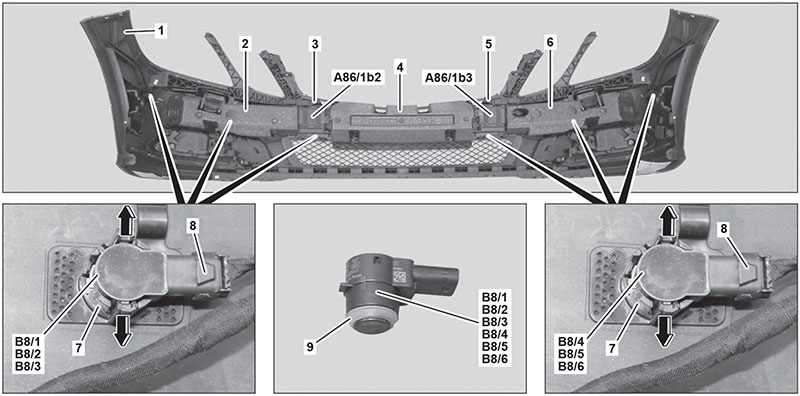

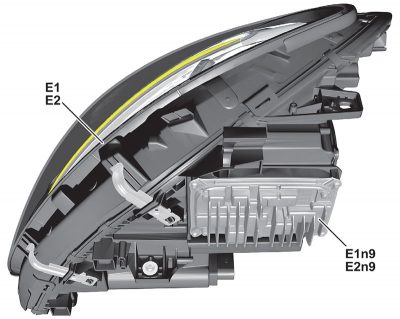

Examples of applications for which waterproof connector housings are used include virtually all engine sensors and connections, steering sensors and contacts, headlight connectors, exterior mirror harnesses, windshield wipers, and other components that are either safety-critical or exposed to the elements.

Examples of applications that are protected by the placement of a gasket or seal between the connector and potential moisture sources include door electronics, engine control units, electronic water pumps, tail lamps, and cameras and radar sensors mounted in bumpers, grilles, and deck lids.

Wiring harness repair versus replacement

Wiring harnesses are repaired as an alternative when replacement cost is high. When repaired using procedures and materials specified in the Mercedes-Benz Workshop Information System (WIS), the repaired wiring harness function is equal to that of a new part. Note that a badly-damaged or safety-related harness should be replaced and not repaired.

Insulation faults

When the tubing or insulation protecting the wire strands is damaged, any moisture present can cause corrosion. Repair damaged cable tubing, then rewind the exposed area using PVC tape, except orange high-voltage wiring which always must be replaced for safety. If the wire insulation is damaged but no wire strands are severed, it may also be repaired with PVC tape. If the insulation is damaged and any wire strands are severed, cut the wire and re-join it using a Raychem connector.

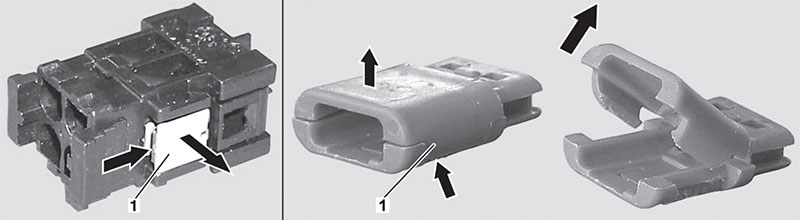

Connector housing faults

Faults in the connector housing increase the risk of moisture contamination affecting the wiring. These include a housing that is cracked, loose, deformed or not able to close completely. Most connector housings are available as spare parts, and they are not expensive. Most have a part number on them if you look closely. Always replace a cracked or damaged housing, as well as any missing, damaged, or incorrectly mounted seals or grommets.

Contacts and housings

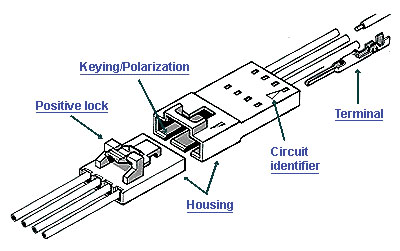

Electrical contacts used by Mercedes-Benz come in a variety of types. Some components have wires soldered to them, ending in a connector. The type of locking or coupling mechanism, the size, shape, material and current rating of the contacts, and whether the housing is watertight or not are just a few of the things that differentiate one connector type from another. Some of the more common contact types have names like MQS, SLK2.8 and JPT. In Group 00.19 of the Workshop Information System, there are hundreds of pages of resources to help you identify and repair these contacts correctly.

Mercedes-Benz connector housings generally use “keysâ€, which are teeth, lugs or other special protrusions into the housings to make them unique. Only housings with the correct keying pattern are able to mate with each other, to help prevent incorrect connections. Some are also color-coded to aid in the identification of correct pairings.

Coating types

Electrical contacts feature a tin, silver or gold coating. The coating is not only important for contact reliability but for corrosion-resistance. Tin is used in dry environments, while silver and gold are used where moisture can be a concern, and for safety-related systems such as airbags or traction control systems. Gold offers the highest resistance to harmful corrosion, followed closely by silver.

Male and female contact must each have the same type of coating as the other in order to establish the best connection. When replacing contacts, always use parts that feature the same coating type on the contacts as the original part.

Single-wire seals for watertight connections and gold or silver contact coatings for corrosion resistance may not be offered by knockoff brand wiring and connectors. To ensure that your repair gets the performance capabilities required, use only Mercedes-Benz original replacement parts.

And don’t assume that because an electrical connector housing looks familiar that it contains the same type of internal contacts as one you’ve seen before. Mercedes-Benz often uses connector housings that have a similar appearance but use a different contact type inside. Always refer to the parts catalog for the exact part numbers when replacing electrical connectors.

Do not repair list

Some lines and connectors must be replaced if damaged. The ‘do not repair’ list includes safety-related or sensitive items such all connectors for the Supplemental Restraint System (SRS) and Electronic Stability Program (ESP) system, any high-voltage wiring (including power inverters for the MAGIC-SKY roof, 110 VAC supplies and Hybrid or Electric Vehicle components) and all network (CAN, FlexRay) cables. Coaxial cables used for antennas and high-speed video data cannot be repaired successfully and must also be replaced. The optical fibers used in D2B and MOST networks are not wires at all, but optical fibers, and cannot be repaired. Any aluminum wiring as well as all wires 6 mm2 or larger in cross-section are also unrepairable. Look for the complete list in WIS document AH00.19-1000-08A.

A notable exception to this list is the SRS squib (ignitor) connectors for certain airbag, pyrofuse squib and seat-belt tensioner connections: Special pigtail wiring harnesses are available which can be spliced into the existing harness (between 100 and 1000 mm from the connector) using Raychem connectors. Look in the parts catalog or ask your dealer: These repair harnesses, where available, are clearly marked on the same picture as the component it connects to.

While new contacts may be crimped to wire ends in quantity, you must take extra care when processing more than a small few to ensure the contacts are re-pinned into the correct housing cavities. Large connectors, with more than a few dozen contacts, require even more diligent care, to prevent malfunctions or worse.

When repairing damage by splicing wires, if more than 10 conductors in a bundle are affected, the harness must be replaced instead. When using Raychem splices, stagger their location so they don’t create an overly large ‘lump’ in the harness. Twist-on Raychem connectors are used to join more than two wires, or wires of different cross-sections, while in-line Raychem connectors are used to join two wires of the same size.

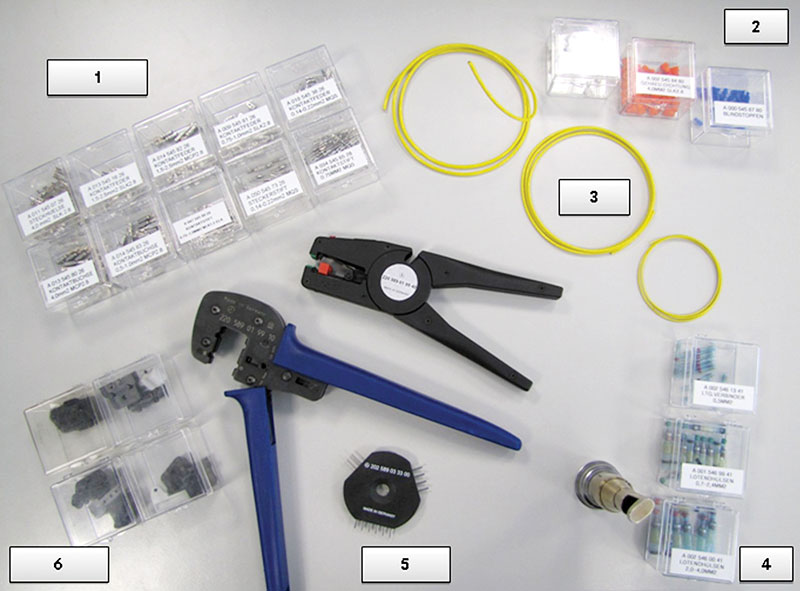

Mercedes-Benz offers several wiring harness repair kits for various repairs. Although these require a considerable investment, any other methods or tools could compromise the performance, longevity or safety of the vehicle. The most common kits are the basic kit (W000 589 13 99 00) and the passenger supplement kit (W220 589 04 99 00), which covers almost everything you might encounter. The kits include contact removal, wire preparation, crimping, and sealing tools and materials. WIS has all the detailed procedures on using this equipment properly. A flat-wire repair kit (W211 589 01 99 00) is also offered. Ask your local Mercedes-Benz dealer if they might loan you their tool set to perform a proper repair.

If just a few contacts need to be replaced, most contact types are sold as ‘cable tail’ sets. These contacts are pre-crimped onto a specified wire size. It is a worthwhile idea to keep a couple of each contact type of these in stock, since all that’s needed is a Raychem connector, hot air blower and a stripping tool.

Note: Be careful when pulling or pushing wiring to rule out a short circuit or loose contact: Pulling too hard can cause damage to the contact or seal.

Approved wiring harness repair methods

There are seven different harness repair methods approved by Mercedes-Benz. Some include special parts to make the job easier and more effective. See WIS document AH00.19-1000-04A to learn which repair options and replacement parts offer the best solution to your problem. WIS document AR00.19-P-1000-05A will guide you through a damage assessment.

- Crimping, using the correct crimping tools

- Radial solder connection (Raychem)

- Axial solder connection (Raychem)

- Combination of Raychem and Cable Tail

- Conventional soldering for solder-type contacts

- Rapid connection technology

- Flat conductor repair

Each repair type is covered in detail in WIS. The index for wiring repairs is WIS document AR00.19-P-0100A. Here is a summary:

Repair methods

A crimping handle with various crimping dies, each for a specific type of contact, are found in the Mercedes-Benz wiring repair kit. Follow the instructions for the manual crimper carefully. It is important to select the correct crimping die set, and to use it properly. A correctly-crimped contact has better electrical properties than a soldered contact. Resist the urge to fold over the contact’s wings with pliers and solder the wire in place: This significantly reduces a contact’s reliability and performance. After crimping, tug the wire to verify a good crimp: You want it to fail now, not later.

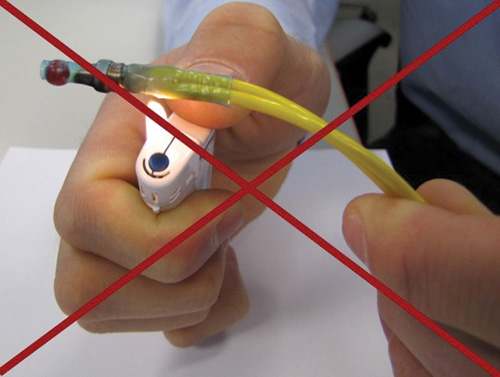

Raychem connectors have a little dab of solder and flux, surrounded by a heat-shrink casing filled with hot-melt glue. Twist the wires together and heat the Raychem connector with a temperature-controlled hot air blower (and not a cigarette lighter!) to ensure a permanent, watertight connection. Cable tails are attached the same way, to replace a contact instead of simply joining a wire.

Older models use solder-type contacts, often round 2.5 mm and 4 mm is diameter. In classic models these are used almost everywhere. Heat the contact and wire, then apply solder to the wire and contact – don’t apply solder to the soldering iron, as the contact and wire may not be hot enough to ensure a correct contact.

Rapid Connection Technology (RCT) is an insulation-displacement system, used to connect smaller single wires together. You simply lay the wires into the slots and squeeze the connector body closed to make the splice. These can only be used in dry locations, and must be wrapped in felt tape to prevent rattling.

Flat wire repairs are tricky, but with the flat-wire repair kit you can crimp new contacts onto the end of the flat wiring used in roof and some door harnesses. We recommend you speak to your dealer about this, as the harnesses are ore likely better to be replaced.

Ignore any of these steps and you could end up with a variety of problems. Too short a section of stripped wire or an improperly mounted crimp contact may result in either the single-strand insulation or the connector seal being pinched. This could allow any moisture in the area to penetrate the connection and cause contact corrosion. If the stripped section of strands is too long it may position the single strand insulation outside of the crimping arms, resulting in insulation that is not crimped at all.

After repairs, use fabric tape to protect a wiring repair against chafing and to create a neat appearance. In the engine compartment and other high load areas, heat shrink tubing or corrugated hose combined with insulation tape are preferred for their better moisture resistance.

Uncoupling a connector

Each connector type has its own method and tool for unpinning. All of the needed unpinning tools are included in the wiring repair kit, and specific and detailed instructions are found in WIS. Resist the urge to use a pick, paper clip or other tool to unpin a contact, as you are very likely to not only damage the contact but the connector housing as well. Some contact housings have secondary locks that must be released before you unpin them.

Seals and gaskets

As mentioned, connectors subject to moisture are generally sealed. Larger connectors, where the number of wires makes individual wire seals prohibitive, have sealed backs and edges. Smaller connectors generally use single-wire seals. Be sure to identify what kind of seals are in use, and inspect them carefully before allowing them to remain in the vehicle – especially if you think they’re leaking. Single-wire seals are crimped onto the wire ends just like non-sealed contacts, but using different crimp dies and special contacts of course. The seals are readily available. The different colors are only to help in identifying what you have in your hand, because they are too small to have part numbers on them.

Look for sealed connectors and contacts in the doors, behind the bumpers at PARKTRONIC sensors and lighting units large and small. Engine parts, wheel sensors, fuel system components and cameras also all use seals. Nicks and scratches allow moisture to migrate through capillary action to where it can cause performance-robbing corrosion, so not only inspect them carefully, but handle them carefully too. Don’t forget the possibility of water entry through failed gaskets, for example at the tail lamps.

Downhill flow

A connector that is positioned below a potential water source that develops a leak is vulnerable to corrosion. When an electrical circuit begins acting fishy, a quick visual inspection may save you a lot of diagnostic time. If you find corrosion on or in any of the connectors on that circuit, suspect condensation from an air conditioning unit, a plugged drain from the evaporator, a deteriorating radiator or water pump hose, or any other upstream moisture source as potential culprits. Once you locate and eliminate the moisture source, you can replace or repair the electrical connector and consider rerouting the cable away from potential future leaks.

Winning

With attention to these sometimes odd sources of moisture, you can beat wiring repair corrosion.

0 Comments