Subtle differences mark improvements over the years

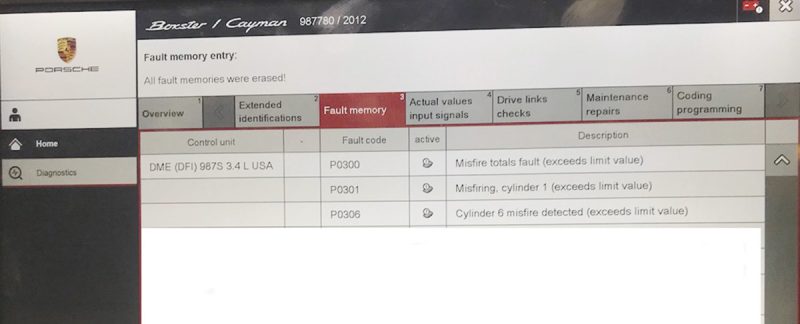

Many in the general driving public seem to regard problem diagnostics as just a matter of a free or inexpensive code reader sourced at any auto parts store. The repair shop or technician is sometimes questioned when quoting a price for diagnosis of a Check Engine light. At times it is understandable why customers feel that way but, in reality, old fashioned investigative work with the correct tools and equipment can dig deep and correctly identify the culprit or culprits far more quickly and accurately than guesswork.

For example, Porsche has updated the part numbers for ignition coils several times for both early and late model coil over plug applications. It may seem logical to sell a set of updated, new and improved coils to solve misfire codes and, while the coils are removed and for just a few bucks more, put a set of spark plugs in. How refreshing — an old fashioned “tune-up.†While this approach may solve the misfire issue and send a customer on his or her way, it all too often is not a solution, at least not a permanent one.

Oil fouled spark plugs are a first tip-off. Excessive carbon buildup on intake valves and ports are also proof of oil burning as well as obvious tailpipe odor and blue smoke. Oil vapors are introduced into the intake air system to purge the crankcase of unburned blow-by gases. However if the quantity of oil being burned is excessive it can quickly foul those new plugs. The result may not be just a misfire warning, but now possible catalytic converter efficiency codes and maybe lean mixture codes. Visible smoke may also accompany the complaint or condition, giving the tech a suspicion that the engine is worn and needs overhaul. And, that may be true, but, if a complete diagnosis is not done, a less expensive alternative may be lost.

What, you say, does this have to do with oil scavenge pumps and crankcase ventilation? Well, plenty. Porsche uses air-oil separators on their water-cooled engines from 1997 on up.

Porsche also utilizes auxiliary pumps to evacuate oil and air from the crankcase, thus reducing the total emissions output from the engine. Previous articles on Porsche oil pumps provide insight to pressure supply or related problems and fixes, yet the “scavenged oil†generally gets ignored.

Because the Porsche engines use the lubricating oil for hydraulic control, the oil passes through screens and orifices that exacerbate the oil being diluted with air. The spray from rotating cams, chains and various cam elements produces what can be referred to best as a chocolate milkshake. Air must be separated from the oil because aerated oil doesn’t do as good a job as clean, air-less oil.

Every oil manufacturer blends additives into their motor oil. Some of these additives help reduce bubbles and foaming in the oil. These dispersion additives break surface tension to achieve this goal. Racing or high RPM application lubricants contain a higher concentration of these additives. Extended oil change intervals combined with high oil operating temperatures negatively affect the concentration of the anti-foam additives. The longer the oil is in service and the hotter the oil temperature, the more the oil is susceptible to bubbles and foaming.

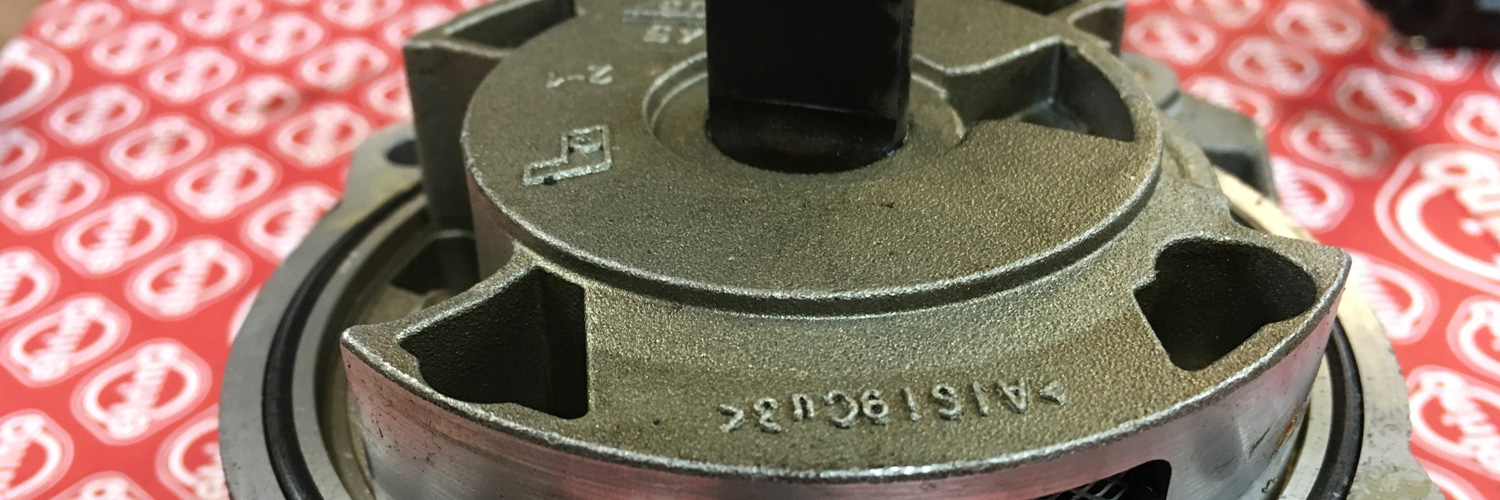

Scavenge pumps as shown in photos are powered by the camshafts. They are very efficient as they pump equal parts air and oil and evacuate the oil from the camshaft area back to the sump. Single stage pumps send air diluted oil back to the sump . The need for increased vacuum inside the crankcase (less air equals less aerated oil) exceeded the idling engine’s ability to build high vacuum levels. Various methods of vacuum amplification and vacuum storage tanks were just not enough.

Enter the dual stage or tandem pumps. These pumps are “piggy-backed†with the gear pumps and have large air/vacuum pumps on them.

A view of the inside pump vanes shows the relatively simple design to evacuate air and oil from the engine and cylinder heads.

This ensures that intake manifold vacuum variation due to variable cam timing does not interfere with vacuum required for power brake boosters and adequate crankcase evacuation. Once the scavenged but still aerated oil is sent back to the oil storage area it has one more process to pass through to further remove air trapped within the liquid oil.

Putting any liquid into a spinning container will separate the liquid from the solid and the gas from the liquid. Medical diagnostics use a centrifuge for this job. The same principle is applied to sending the oil back to the collection area by swirling the oil just before it re-joins the reservoir.

Various “swirl pots†have been used over time. These return tubes create a centrifuge motion within them, which further assists in separating air from oil. The oil may end up back to the sump but what about the air now released? It is still mixed with oil in a mist.

Porsche streamlined the scavenged oil return tube in 2005. This simple return swirl pot actually works quite well and returns oil to the top of the sump oil level.

Air cooled Porsche engines of the past employed true dry sump oil systems as discussed in previous articles. The use of a separate oil storage tank separated the engine oil supply from the engine’s violent internal atmosphere. This helped to de-aerate the oil.

Up until recent production models of GT3/GT2 and Turbo applications, Porsche still used the separate oil tank. The latest models, however, have switched to the 9A2 architecture and now share similar characteristics with the 9A1 direct fuel injected engines. All of these engines use cylinder head scavenge pumps to evacuate the cylinder heads, and four stage scavenge pumps inside the sump.

Porsche requires a fairly high vacuum in the crankcases. GT3s and GT4s spin much higher RPMs and therefore create more windage and thus more need for scavenge and air/oil control. Crankcase vacuum is higher in these applications – so much so in the GT3 that the crankshaft seals have been made in reverse. The lip faces out on these engines as the greater vacuum can actually pull the seal lip off the rotating crank.

Here is another example of high crankcase vacuum. If, during an oil service, the technician overfills the sump, what next? Attempting to drain off the excess through the drain plug often results in a very messy situation. Removing the excess through the oil filter can be just as messy and more time consuming.

Try this. Next time you change the oil in a Porsche with direct fuel injection 2010 and newer, have a technician sit in the car, then raise the car on your lift. Have your technician start the engine. While the engine is running, remove the drain plug, and not a drop of oil will come out until he shuts off the engine. At this point, once excess oil is drained, have the driver re-start the engine, re-install the drain plug and re-check the oil level. As mentioned previously, the vacuum is so high that it holds the oil in the engine even with the drain plug removed.

Take note of the photo showing a typical scavenge pump located on each on cylinder banks one and two on the Porsche 996 GT3 street and Cup racing applications.

This simple gear oil pump is driven by the exhaust camshafts. Scavenged oil is removed directly from each cylinder head and returned to the separately mounted oil tank. When the 997 GT3 engine was introduced a change was made to the bank one oil scavenge pump.

The same basic pump mounted to the bank one side of the engine provides not only the scavenge section, but also piggybacks the vacuum pump.

This tandem pump provides for adequate crankcase vacuum and insures proper vacuum for the brake booster and other vacuum engine controls. As PDK transmissions become more popular, the need for vacuum increases because the closed thermostat cooling systems use vacuum solenoids and actuators to regulate the cooling systems.

Normal crankcase vacuum is measured in inches of water, from -4.0 to -6.0. This vacuum is slightly higher in the high revving engines. The air is drawn from the crankcase through an air/oil separator. When these devices fail it can lead to vacuum values off the chart, so much so that it is difficult or impossible to remove the oil filler cap with the engine running. Visible smoke can also be a sign of a ruptured AOS diaphragm. A technician may also discover unexplained lean run codes due to the controlled vacuum leak into the crankcase.

Many designs complete a full circle, that is to say many engineering exercises end up back where they started. After all, when things work well why change them? The swirl pots in the latest 9A1 and 9A2 engines went back to the large swirl pot design. Porsche now uses twin swirl pots.

The used or “spent†oil goes back into the oil pan or reservoir or tank, or wherever it is stored. The oil quantity requires monitoring for proper oil level. A few cars and trucks still utilize the now obsolete dipstick. The dipstick unfortunately is becoming a rare feature.

A word of caution here. Porsche oil levels have been a mystery to consumers since the 911 was introduced in 1964. The results of low oil level are obvious and most times painful to the customer’s pocket. But too high an oil level can be as disastrous to the late model water-cooled engine as it was back in the air-cooled days. Ingestion of oil from the sump into the intake manifold has many effects, all of them bad.

As the engine operating temperature rises during normal operation, the oil level can increase dramatically. The over-filled oil will enter the intake manifold, the oil dilutes the fuel charge therefore effectively lowering the octane rating. This can and will cause loss of power, increased emissions and poor fuel economy.

The oil is now in the intake stream. Regardless whether the engine is direct fuel injected or port injected, the oil comes in contact with the hot valves, guides and ports and begins the dreaded carbon buildup. We have all seen this buildup and its effects on emissions, power output, and cold starts just to mention a few.

Oil type, brand and rating are all considerations. Vehicle manufacturers make recommendations, just as they do for oil change intervals, but we all know there are many different ways drivers use their cars, so how can one oil do it for everyone? It can’t. Maybe a high mileage highly advertised big name oil can give 15,000 miles, but don’t think the additive package in those oils will handle the rigors of high RPMs. The additive package doesn’t contain the higher levels of anti-foaming agents. It has more additives for, say, moisture and long periods of sedentary garage queen service.

Use quality oil, a performance brand is a must if track driven, fully warm up the oil before checking the dipstick or electronic sensor, leave ½ quart low and advise customer the reason. Recommend annual or, better yet, semi-annual oil service. Have the oil analyzed every service and keep tabs on the progression of aluminum, lead, and silicone materials in the oil. A rising level of aluminum, silicone iron, or lead over time can help predict what needs attention inside the engine.

Download PDF

0 Comments