A review of how it works, maintenance, and now there’s an extended warranty.

If you work on Mercedes-Benz vehicles then most likely you have encountered the Sensotronic Brake Control (SBC) system in the course of your work. Beginning in 2003 with the W211 E-Class models through the 2011 SL models the Sensotronic system was in production. Mercedes-Benz and Bosch teamed up on this groundbreaking development project which entered into series production at the Stuttgart automobile plant under the name Sensotronic Brake Control.

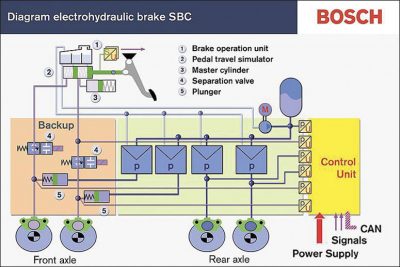

As a brake-by-wire system, it turns the conventional hydraulic brake system into an even more powerful electro-hydraulic system. Its microcomputer is integrated into the car’s data network and processes information from various electronic control units. In this way, electric impulses and sensor signals can be instantly converted into braking commands, providing a significant safety and comfort gain for drivers.

Theory and Operation

We all understand that in a conventional braking system, the driver’s foot pressing against the brake pedal generates pressure in the brake master cylinder, which then acts upon the brake calipers, pressing the brake pads against the brake disks, causing friction that slows the vehicle.

Engineers sought to shorten the time involved in this mechanical hydraulic braking application. With Sensotronic Brake Control, the driver’s foot pressing against the brake pedal is sensed by a pedal travel sensor. This signal, along with various other signals such as wheel speed, is processed by an electronic control unit that calculates the optimum brake pressure for each wheel. Electrohydraulic valves allow pressure from a high-pressure pump and pressure accumulator to act upon the brake calipers, again pressing the brake pads against the brake disks, causing friction that slows the vehicle. Because of the electronics involved, SBC can offer even greater active safety than conventional brake systems, particularly when braking in a corner, on a slippery surface, or in a panic stop.

The most important performance characteristics of Sensotronic Brake Control include the extremely fast build-up of brake pressure and precise monitoring of driver and vehicle behavior by means of sensors. Brake force control plays a very important role in the overall safety of the vehicle. Keeping this in mind, Mercedes-Benz has programmed the system in such a way that when slowing down from a high speed, the larger part of the brake force continues to act on the front axle which prevents hazardous over-braking of the rear axle. At low speeds or during partial braking the system automatically increases the brake force share at the rear axle to improve brake system response.

During research in Daimler’s Berlin driving simulator it had been discovered that almost two-thirds of all drivers are startled when ABS pulsation sets in, or drivers do not apply enough brake force for the situation, lengthening the stopping distance of their vehicle. Sensotronic Brake Control helps eliminate these problems and, as a result, this innovative system offers significant benefits in terms of handling safety.

One example includes emergency braking: SBC recognizes the driver’s sudden switch from the accelerator to the brake as an indication of an emergency situation, and is able to react automatically. In this case the system increases the pressure in the brake lines and positions the brake pads against the brake discs so that they can grip with full force the moment the driver actually steps on the brake.

In the case of slippery or wet conditions, through brief regular application of the brakes, SBC ensures that the film of water on the brake discs is stripped away so that the brakes can always operate to full effect. This automatic drying function is activated whenever the windshield wipers have been operating for a certain length of time. The finely-metered brake impulses are not noticeable to the driver.

An additional support system in some models further ensures greater safety and improved comfort: the Start-Off Assist system, also known as SBC Hold. This feature applies the brakes to hold the vehicle still until disengaged by the driver, relieving driver fatigue from having to press the brake pedal continuously, and is particularly useful when stopping on hills and steep gradients. Once the vehicle has been braked to a stop, a little extra pressure on the brake pedal is enough to activate this function. The vehicle is then held firm by the SBC Hold function, allowing the driver to take their foot from the brake pedal. The letters “SBC H†will light up in the instrument cluster. Pressing either the brake or accelerator pedal releases SBC Hold.

Summary of Advantages of SBC

- Improved metering of required brake pressure – each wheel can be precisely controlled independently.

- Improved BAS (Brake Assist System) function – monitors the release of the accelerator pedal and application of the brake. The maximum brake pressure is available immediately. Pre-filling of the system (overcoming play) removes any physical play to ensure fastest brake application by applying a slight pressure to the system when the BAS function is anticipated.

- Electronic Brake Proportioning (EBP) – allows brake proportioning front to back and side to side.

- No pedal vibration during ABS operation – eliminates startling and distraction of the driver during critical moments.Â

- Improved driving dynamics: ABS, ASR, and ESP – faster response to brake request inputs.

- Pressure reduction at standstill – system pressure is reduced to a level sufficient to hold the vehicle steady, reducing stress on system components.

- Dry braking function – lightly actuates brake pads to keep the brake disks dry. If windshield wipers are in use, as signaled via CAN Bus, brakes are activated approximately every 7 to 14 minutes.Â

Components

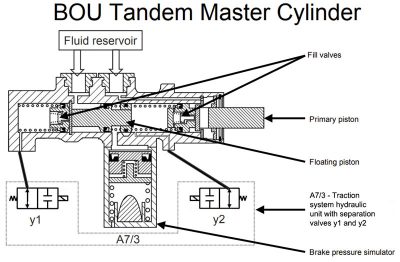

In addition to the components found in a conventional braking system, Sensotronic adds a Brake Operating Unit (BOU), and uses the existing wheel speed sensors and a modified traction system hydraulic unit known as the SBC control module (A7/3).

The BOU, located where a conventional master cylinder with vacuum booster might be found, consists of the brake fluid reservoir, an SBC pedal value sensor (B37/1), a tandem master cylinder, and a brake pressure simulator to provide force feedback via the brake pedal to the driver. There is no vacuum booster in an SBC system. WIS document GF42.46-P-4210SL has a good explanation of the system’s function and operation, and is a worthwhile read.Â

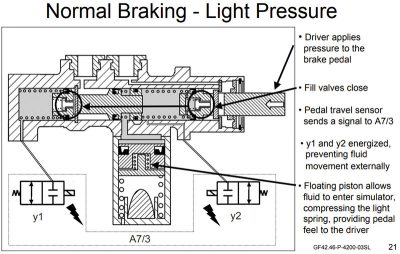

The pedal value sensor, physically connected to the brake pedal, has two Hall-effect sensors which convert pedal travel to an electrical signal, providing input to the SBC control module A7/3. Take a look at the nearby image labeled ‘normal braking’ to see how the driver’s braking effort and the BOU interact. Note that the valves leading to the brake hydraulic system, y1 and y2, are closed during normal operation: Brake pressure is delivered and controlled by the SBC control module, based on the brake pedal travel.

In case of system failure, the valves y1 and y2 remain open, allowing the driver’s brake pedal force to deliver pressure to the brake system as with conventional brakes. However, braking performance is diminished since there is no power assist, and of course a warning is displayed in the instrument cluster.

The SBC traction system hydraulic unit consists of:

- SBC control module (A7/3n1) – This is the brains of the operation and is responsible for the calculations and interpretations of the various input signals. This also operates the ESP and related traction control systems.

- High pressure charge pump (A7/3m1) – Pressurizes the brake fluid to supply the system.

- Pressure reservoir – A pressure accumulator to provide a ready

source of instant pressure and dampen pressure fluctuations.

There are 3 pressures stages used for the brake system calipers, similar to those known from the standard ABS function, but these can be applied as needed to any or all wheels. They are:

- Pressure increase

- Pressure hold

- Pressure release

Operation

SBC has a wake-up and a pre-check diagnostic function. The wake-up feature happens when opening a door, operating the central locking system, depressing the brake pedal, turning the key to position 1, or operating the parking brake. The wake up signal comes from the left front SAM. This ensures the pressure reservoir is sufficiently charged.

The Pre-Drive Check (PDC) may be performed after wake-up. Here, pressure is applied to the brake calipers, to check the reservoir pressure, pressure sensors, control valves, sense any leaks, and overall operational checks.

WARNING: Pressure applied to the brake calipers during the PDC will apply the brakes, which can injure or crush body parts, or eject the caliper pistons from the cylinders if the brake pads are removed. Do not perform work on the brake system unless the PDC has been disabled, as explained below.

The PDC self-tests are also conducted regularly during operation, about once every 16 brake applications.

Service and Repair

WARNING: YOU CAN BE HURT! When servicing brake pads or rotors, or with most repairs on the brake system, the system must first be deactivated to prevent the Pre-Drive Check (PDC) from being performed and possibly causing injury or vehicle damage. Deactivating the system will discharge the pressure reservoir and prevent the charge pump from operating.

To deactivate the system, either use XENTRY Diagnostics, or follow the procedure explained in a Video released by Daimler, which is only viewable by Authorized Mercedes-Benz Dealers. You should check with your dealer to see if they have any advice on using this procedure. We repeat those instructions here:

To deactivate the SCB Pre-Drive Check (PDC), start with all wheels completely off the ground, switch off all electrical consumers and open the driver’s window. Switch the ignition off and remove the key. Close all doors, centrally lock the vehicle, and wait at least 30 seconds for the system to power down. Once time has passed, unlock the vehicle with the remote key and wait at least 15 seconds. Lock the vehicle again, and the PDC is deactivated. Keep the keys well away from the vehicle, since operation of the key could re-activate the SBC system and cause a safety hazard.

After repair work on the brake system, the SBC system MUST be re-activated BEFORE the engine is started! Failure to activate will prevent proper operation and generate fault codes.

To activate the system, either use XENTRY Diagnostics, or use the procedure from the video we mentioned above.

After performing the necessary work, reactivate SBC: Unlock the vehicle with the remote key. Reaching through the open window, switch the ignition on using the key to Position 2, switch the ignition off for 5 seconds, then switch the ignition on again. On the driver’s side, turn the rear wheel forwards at a rate of 1 to 2 revolutions per second for at least 3 seconds. Bring the wheel to a stop, then within 60 seconds, turn the driver’s front wheel at a rate of 1 to 2 revolutions per seconds until the wheel stops by itself (the SBC applies the brakes). The tail lights will flash three times to confirm the activation. The brakes will be applied several times at each wheel.

Lower the vehicle and switch the ignition off. Start the engine, pump the brake pedal slowly about 10 times: If no faults are indicated, the activation was successful. If any faults appear, repeat the activation routine. If necessary, check for diagnostic trouble codes using XENTRY Diagnostics. Remember, check the tail lamps for those three flashes.

Activating SBC will re-charge the pressure accumulator, preform a PDC, move the pads towards the rotors and erase the fault memory. Be sure to top up the brake fluid reservoir level.

Keeping the fluid right

WARNING:

Failure to follow the procedure described precisely can expose you to risk of serious personal injury or vehicle damage. If unsure, use XENTRY. |

In the course of servicing an SBC system you may find yourself having to bleed the system either to remove air or when flushing during routine maintenance. Vehicles with this system will have the same brake fluid change intervals as other conventional mechanical/hydraulic vehicles. Most Mercedes-Benz maintenance schedules call for a fluid change every 20k miles or 2 years, whichever comes first.

Moisture and dirt are the two major offenders when it comes to tripping up a Sensotronic system. A lack of cleanliness when filling or topping a system is one reason brake fluid may appear dirty or contaminated. The more common reason is moisture in the system: Brake fluid is hygroscopic, meaning it absorbs water from the atmosphere. This means that the brake fluid’s water content will gradually increase over time, which is why it is absolutely critical to always use only brake fluid from newly-opened containers. Mercedes-Benz generally recommends only DOT 4 brake fluid – avoid using anything else. Of course, check the owners manual to verify the correct brake fluid required.

Moisture in the brake fluid lowers the fluid’s boiling point, which is undesirable. As the brakes get hot during use, some of the heat is transferred into the brake caliper and thus into the hydraulic fluid. During strenuous braking, temperatures can become so high that the brake fluid boils, introducing bubbles of gas into the hydraulics. This is bad news since the bubbles of gas increases the overall compressibility of the brake fluid leading to a spongy pedal and, in extreme cases, can lead to significantly reduced brake system effectiveness.

A diagnosis scan tool, such as XENTRY Diagnostics, with a bleeding system menu is needed for this operation. You also need a power brake bleeder and a battery maintainer to ensure battery voltage remains stable. Here is the procedure from the workshop manual:

- Connect the battery maintainer.

- Deactivate SBC brake system using XENTRY.

- Connect the brake fluid changing equipment (power bleeder).

- Raise vehicle with lift and remove wheels.

- Carry out bleeding operation using the XENTRY menu.

- Check brake fluid level in reservoir and correct if necessary.

Trying to service the later model Mercedes-Benz vehicles without the proper equipment and repair information will be futile and will result in many lost hours of work. That 2-year service interval is important. We’ve seen neglected SBC systems that needed costly repairs because the fluid hadn’t been changed often enough. Informing your customers of this need will greatly improve their chances of having no problems in the system down the road.

Extended Warranty

As an independent service workshop, you need to be aware that Mercedes-Benz USA in 2018 extended the Limited Warranty for the SBC control module (including the hydraulic unit) to 25 years with unlimited mileage. Before making repairs, check with your local dealer to see if the warranty applies.

Also be aware that Mercedes-Benz USA has issued in 2005 two Safety Recall campaigns (RC2005110001 and RC2005070007) to address certain system issues in the SBC system. In summary, the Recall campaigns state that a ground wire may become loose, disabling the system and potentially increasing stopping distance.

This means that, first, you should make it a habit to check for open Recall campaigns at NHTSA.gov; if any campaigns are open have your customer visit the Mercedes-Benz dealer to have the campaign fulfilled. Second, if the SBC control unit appears to have a fault, check with your local Mercedes-Benz dealer about possible warranty coverage.

The Future is Here

Mercedes-Benz, based on customer feedback, decided to discontinue its SBC system following a number of problems which has led to vehicle recalls. By 2005 over 2 million vehicles worldwide were recalled.

Like most innovative technology, there are “growing pains.†For example, several years ago “drive by wire†was just an engineering vision. Through much testing and refinement the system became the norm, and now almost all production vehicles use some form of electronic throttle control. So it will be with “brake by wireâ€: As technology advances and more safety measures are incorporated, SBC or a future form of it will indeed be the norm in production automobiles.

Mechatronics – a new term gaining popularity within the automotive industry is rapidly developing into a buzz word in a quiet technological revolution. Mechatronics brings together two disciplines which in many cases were thought to be irreconcilable, namely mechanics and electronics.

One such system, Active Body Control, takes the previously unobtainable ideal of being able to vary spring rates and suspension reaction at each individual wheel, during all types of driving and road conditions, and makes it a reality.

In this way, purely mechanical automobile functions will, in the future, likely be controlled by high-performance microcomputers and electronically controllable actuators. These could either replace the conventional mechanical components completely, or enhance their function. The mechatronic interplay therefore opens up what were previously speculative ideas to possibilities which further raise the safety and comfort levels of modern passenger cars.

Download PDF

0 Comments