In this month’s article, Transmission Diagnosis and Valve Body Replacement Part Two, we continue the discussion of transmission diagnostics and replacement from Part One, with a focus on the relearning functions and steps required to successfully complete a transmission repair or replacement on Nissan vehicles.

If a transaxle or sub-assembly of the Nissan transaxle is replaced and is not relearned properly, the vehicle may experience no-go driveability, shifting problems, harsh engagements, slippage, MIL lights, DTCs or, worse, failure of the new component or transmission installed.

After the mechanical repairs are done on the transmission, there are several controls and functions that need to work together in perfect harmony in order to properly operate the electronically controlled transmission.

As mentioned in the last article, the after repair service procedures described and outlined here in Part Two are meant to familiarize the technician with transmission relearn functions common to multiple Nissan models and years, but are generic for the purposes of this article.

Always consult the Nissan service information provided for the specific year, make, and model you are servicing.

Let’s start with three very important distinctions in terminology when working with Nissan vehicles, before we dive into the transmission fun.

- Programming and Reprogramming: When Nissan refers to the word “Programming or Reprogramming†in their service information, this refers ONLY to the base software files “flash-programmed†into an ECM or TCM module to make it function.

- Data Write: In Nissan “parlance,†Data Write is the part of the procedure where we write data FROM a new/used component TO the ECM/TCM to establish the solenoid’s electrical operating characteristics. This is often a point of confusion when working on Nissan transmission repairs or replacements.

- Erase Data or Relearn Function: This language would be directing us to reset a memory, such as the CVT Fluid Degradation Monitor, or similar function. This is done with a scanner in most cases.

When servicing Nissan transmissions, you will be directed by service information to perform ONE or ALL of the above functions, and it is important to know the differences in terminology here.

NOTE: One more important caution before we get started. It is imperative, for proper transmission longevity and function, that both the ECM and TCM have the most current, up to date software. Always check for TSBs pertaining to reprogramming for your specific model and model year before you work on, or release, the vehicle after repairs.

Communication With Other Network Modules

The first thing in play here enables the ability of the ECM and other network modules to communicate with and report input/output data to the TCM. So part of any relearn procedure first deals with establishing proper communication between required modules. Each of the three Nissan CVT variations lists “Additional Service When Replacing Transaxle†procedures, and each of the three procedures includes establishing and authenticating the communication between modules.

Erase Previously Learned Values

All electronic transmissions today in one way or another “learn the driver†as they drive along and continuously store data as the vehicle is operated. In Step-Shift transmissions, this may be a “Clutch Variance Index,†where clutch wear is monitored by the TCM. This allows the computer to adjust fluid pressures to the clutches, sheaves, or friction packs via PWM duty cycle control (theory and operation were discussed in Part One of this article).

In a Nissan CVT transmission, the TCM also monitors CVT fluid degradation. These values must be reset during repair or replacement of the transmission or service of the fluid if directed to do so.

Learning Solenoid’s Inherent Electrical Characteristics

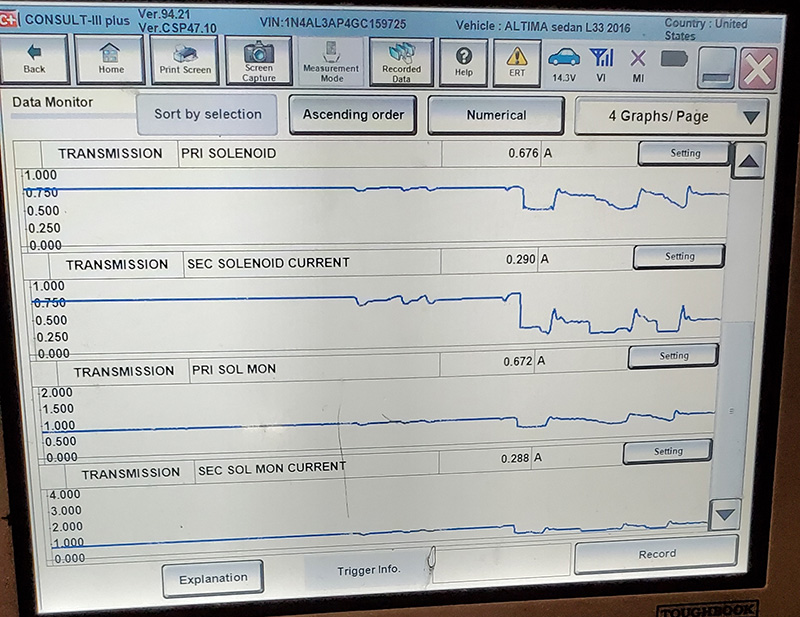

Another critical learned value to ensure proper transmission control in CVT applications is to establish a baseline for control of the electrical solenoids, which direct oil pressure to the CVT primary and secondary pulley sheaves.

The way the TCM is designed to do this, is to know (learn) what the electrical characteristics of that solenoid are, in order to tailor the PWM duty command to precisely control the

sheave pressures.

This is accomplished by engineering the TCM’s circuitry and software to look at (retrieve) feedback from the solenoid’s control circuit (the TCM monitors current driving the solenoid) to establish the electrical characteristics of the individual solenoid itself.

This must be done when replacing or relearning the transmission, the TCM, or both components together, as the previous transmission/TCM will still have the previous sub-unit’s operating characteristics stored.

Failure to perform these functions properly when required may result in slippage, premature belt wear or failure, premature solenoid failure, or internal transmission damage, as well as possible DTCs related to pressure implausibility and other faults. Thus this is a very important step to complete when servicing Nissan (or any) transmissions.

The TCM or ECM will monitor the current and voltage through the solenoids when under load, and with this data the system can mathematically calculate exactly how much current is required to move the solenoid to the desired setting for precise control of the sheave pressures. Once these values are stored in the memory, this becomes the baseline for the PWM duty cycle adjustments made during operation of the vehicle. This MUST be done properly, according to the steps laid out in the service information.

OK, so we’ve talked about why we are required to relearn modules during transmission repair and replace operations, and what the various relearn procedures seek to accomplish. But what tools can we utilize to complete these functions in an independent repair shop?

1. Programming Using Nissan CONSULT III Plus OEM Software

Shops can source and purchase the Nissan CONSULT III Plus Full-Version (dealer-level) software. When using the Consult, service information instructions and pathing follow the Nissan Consult software platform exactly. Consult III Plus software and

hardware requirements are available on the nissan-techinfo.com website.

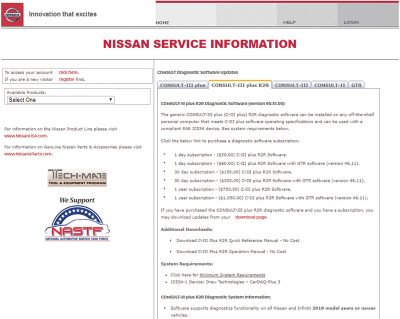

2. Programming using J-2534 Pass-Thru and CONSULT III Plus R2R

Most independent shops are familiar with the J-2534 pass-through protocol and use it for programming multiple models. For the independent aftermarket, the correct new interface to use with J-2534 for Nissan vehicles is the CONSULT III Plus R2R software.

CONSULT III Plus R2R software is Nissan’s protocol interface for J-2534. The CONSULT III Plus R2R software is required for the programming of any Nissan or Infiniti module via the generic J-2534 device. Do not attempt to program a Nissan module without first installing this software.

How to find it: From the nissan-techinfo.com home page, click on U.S. (or, your home country), then click on the Diagnostic Software button.

Once you are on the CONSULT Diagnostic Software Updates page, on the right hand side of the page, select CONSULT III Plus R2R tab, and simply select the software subscription option you desire. Be sure to read the system hardware requirements so you can safely run the software.

NOTE! The Nissan CONSULT III Plus R2R software supports diagnostics functionality and VIN writing on all Nissan 2018 model years or newer vehicles. This software will also program and reprogram Nissan ECMs and TCMs on older models, from 1999 up to 2018 vehicles.

It’s good to spend some time clicking through and looking at the information provided on the nissan-techinfo.com website. Better to familiarize yourself now rather than five minutes before you want to program a vehicle.

Getting Hands On: Relearning the Transaxle, TCM, or Sub-assemblies

Now, let’s look at the “Additional Service When Replacing Transaxle†procedures you will be directed to perform VIA SERVICE INSTRUCTIONS when we finish repairs and need to initialize a Nissan transmission, TCM, or control valve, depending on year/era.

NOTE! All service procedures summarized here for Nissan CVT transmissions, control valves, and TCM module replacement depend on model, year, and transaxle application. Always refer to Nissan service information for the specific model you are servicing.

After replacing the transaxle, TCM, or control valve on 2007-2012 Altima models for example:

The 2007-2012 Altima transmission relearns involve using a chart to select one of three service patterns to run after the repair, either Service Pattern “A,†Pattern “B,“ or Pattern “C.“

These transaxles contain a ROM inside the unit which the TCM accesses while operating; there is no direct “flash-programming†that is performed on these models.

Rather, on ROM equipped vehicles, when selecting Service Pattern “A,“ “B,“ or “C“ from the chart, we are simply running an automated test verifying that the TCM and the ROM are able to perform; the initialization process for these transaxles and components occurs automatically, for our purposes.

Service Pattern “A†is chosen if only the TCM is being replaced. Pattern “A“verifies that the TCM can communicate with the ROM in the transaxle. If communication is OK, the TCM automatically reads data from transaxle ROM and this is all that is needed to initialize the transaxle to the TCM.

If Service Pattern “A“ won’t run, meaning if the transaxle range indicator “P†does not light up on the panel, then we are directed to (1) Check the harness between the TCM and the ROM assembly in the transaxle for opens or shorts, or (2) the terminals are disconnected, loose, or bent from the connector housing.

If the transmission is being replaced with a new or used unit, or if the TCM is being replaced with a new or used transaxle, then Service Pattern “B†is chosen.

Service Pattern “B†indicates several steps, too many (18 steps) to list in detail here. Essentially, Service Pattern “B†has us warming the vehicle to greater than 68 degrees F and then applying a number of sequenced manual steps using the brake, accelerator pedals, and the scanner to erase and rewrite data to the TCM. After these steps are complete, the procedure finally has us checking to confirm that data in the CALIB DATA values matches the data table provided in the service procedure.

If Pattern “B†won’t run, we are directed to three possible fixes: (1) Check the harness between the TCM and the ROM assembly in the transaxle for opens or shorts, (2) the terminals are disconnected, loose, or bent from the connector housing, or (3) correct power supply or ground of the TCM to solve the issue.

Service Pattern “C†is called for if both Pattern “A†and “B†are needed, as in the case of a transaxle and TCM replacement at the same time.

Remember that on 2007-2012 models, when replacing any transaxle, TCM, or valve body with used parts, you must perform the above relearning functions as per instructions.

If you look carefully, the relearn procedure and step requirements are different based on whether or not we are repairing the vehicle with new or used parts; therefore particular attention to these instructions should be followed to ensure a successful repair.

After replacing the transaxle, TCM, or control valve on 2013 Altima models for example:

From the service information “Additional Service When Replacing Transaxle†section, steps provided for the 2013 Altima CVT/TCM replacement:

Check The Serial Number (Part 1)

Write down the serial number of the new transaxle assembly.

When the transmission, sub assembly, and/or TCM has been replaced, you may be directed to record the serial number of the transmission. This serial number is stamped into, or on a plate, on a boss on the case near where the bell housing bolts to the engine on the 2013 CVT.

It is recommended that the technician records the serial number before the transmission is installed, as this number will be needed to initialize and verify the unit, and it may be difficult to verify or read once the unit is installed in the vehicle.

Some models have a QR code as well; on the 2013 Altima it is located at the shift shaft/selector switch cover. The QR code also contains the serial number and calibration information.

On 2013 vehicles, pay particular attention to instructions; steps vary depending on whether the transaxle, TCM, or both are being replaced.

Check The Serial Number (Part 2)

You may be instructed next to: (1) Turn the ignition switch ON, (2) Insert/load the CD supplied with the transaxle into the tool,

(3) Select Work Support in Transmission, (4) Select Write IP CHARA – Replacement AT/CVT. NOTE: RECORD THIS DATA DURING THIS STEP ONLY! DO NOT WRITE DATA! (5) Check to be sure that the serial number displayed on the screen and those recorded from transaxle agree. (6) Go back to MENU of Work Support.

Initialize TCM

You will then be instructed to: (1) Set parking brake, (2) Select Erase Memory Data, (3) Touch “Start†according to the instructions on the screen. Is step completed? YES, go to step (4), if NO, turn ignition off, wait ten seconds and repeat section (3). Initialize TCM steps again, until completed.

Write the Data

Example: Write the data of the new solenoid in TCM according to the following instructions:

- Shift the selector lever to the P position.

- Turn ignition switch off and wait ten seconds.

- Turn ignition switch ON.

- Select Work Support in “TRANSMISSION.â€

- Select Write IP CHARA – REPLACEMENT AT/CVT.

- Write data according to the instructions on the screen. (Note: When writing is complete, the shift position indicator of the combination meter displays “P.â€)

Now that we’ve provided an overview look at 2007–2012 relearn Service Pattern “B†and “C†procedures and the 2013 procedures, we need to cover one more thing, the CD supplied with new transmissions or sub-assemblies.

Nissan now (thankfully) promotes diagnosis and replacement of “sub-assemblies,†meaning that the control valve (valve body) can now be replaced and coded separately. Therefore it needs a TCM data-write procedure for the replacement of the valve body if replaced separately from the entire transmission.

If the transaxle or control valve sub-assembly (valve body) is replaced, you will need to record the serial number (calibration number) of the control valve before installing it.

A new CVT transaxle or control valve sub-assembly will come from Nissan with a CD containing the solenoid characteristics for the new control valve unit.

Once repairs are complete, carefully follow the published “Additional Service When Replacing Transaxle†procedures. You will be prompted through clearing and writing the new data from the control valve to the TCM, in similar fashion to writing data from the new transaxle to TCM in the description above.

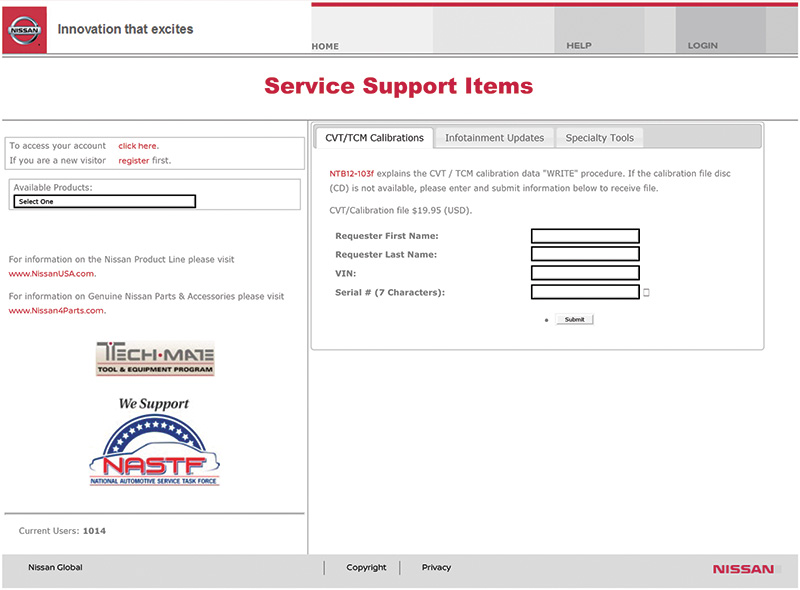

NOTE: In the event you do not have a CD, (installing a used part, for example) you may enter the serial number or QR code on the nissan-techinfo.com website, where you can purchase and download the correct file for $19.95. From the U.S. homepage, click on Service Support Items on the right of your screen, and enter the serial number in the CVT/TCM Calibrations option.

In all cases, no matter what year or model you are servicing, it is important to get the transmission initialization procedures done properly, to ensure the longevity of your repair.

Download PDF

0 Comments