Function issues testing and repairs: 2013-2014

The Volvo XC90 is more popular than it’s ever been, not just with longtime Volvo fans, but with the rest of the world too. This is because the XC90 series, even from the beginning in 2003, was one of the best SUVs on the road. These SUVs can handle almost any on- or off-road conditions your customers can put them through.

Even the earliest XC90s came with one of the most comprehensive traction control systems on the road, and with every year since their inception, the systems have gotten better.

Of course, the newest generations of the XC90 (2016 on) are light years ahead of the early versions, but they have a lot in common with earlier models as well. And there are still a lot of the early XC90s on the road; you probably see a fair number of them come through your shop on any given week. They are getting older, and with age and mileage, you will start to see problems you have not seen before.

Customers love these cars, and most XC90 owners want to keep them going as long as possible. It’s our job to make sure that these Volvos are as safe to drive as the day they rolled off the assembly line in Sweden.

How can we do that?

Well, one way is to help your customers by performing detailed routine inspections when they bring the cars in for regular service.

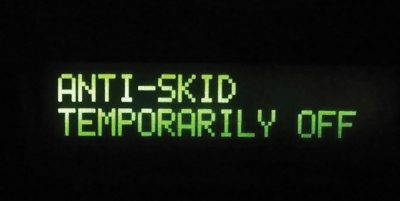

And when your customer reports a warning light or message in the information window, you need to take it seriously.

These warning lights and messages don’t just pop on and off for no reason.

If your customer gets a message that says something like “ANTI-SKID TEMPORARILY OFF†or “DTSC SPIN CONTROL OFF†it means just that — while that message is on, one of the major safety systems on that Volvo is not working.

It’s important to educate your customer about the warning indicators and what they mean. You don’t need to scare them, but they should know that continuing to drive the car in this condition can be risky in some road conditions, like wet weather and snow driving.

How it Works: Roll Stability Control (RSC)

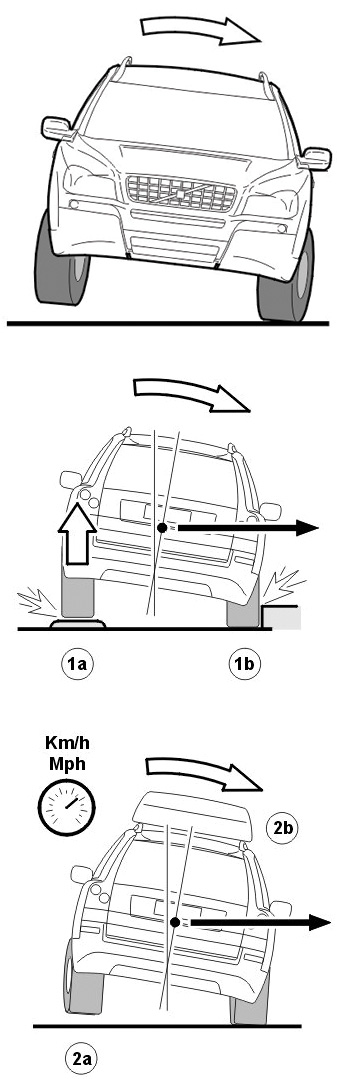

The Volvo XC90 has an active system which counteracts any tendency to roll over and gives the vehicle added stability during abrupt avoidance maneuvers.

If there is a risk of the car turning over, RSC is activated. This function is integrated in the Dynamic Stability and Traction Control (DSTC) system. It lowers the engine torque and stabilizes the vehicle by braking at one or more wheels.

Active YAW Control

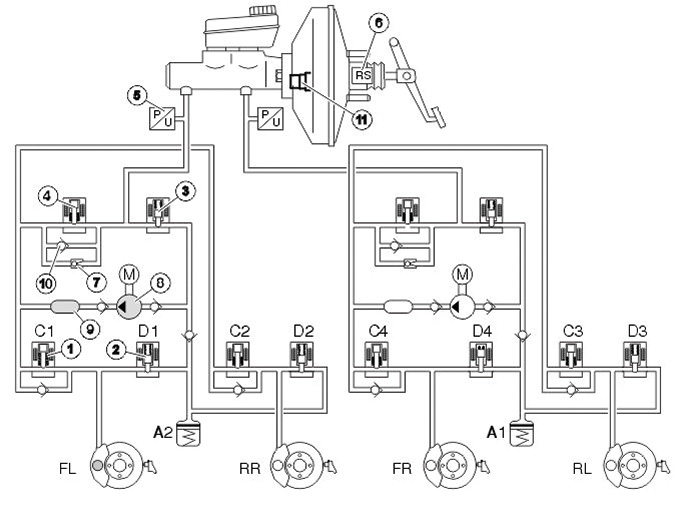

The Brake Control Module (BCM) with DSTC uses continuous information from the different sensors in the system to calculate the positions of the steering wheel and car. The BCM calculates the driving manner of the driver by measuring the steering wheel angle, the engine torque, the speed of the car and brake pressure. The BCM also calculates the behavior of the car by monitoring the steering wheel angle, steering wheel angle speed, yaw rate speed and lateral acceleration.

When the differences between the movements of the driver and the behavior of the car exceed a certain point, Active Yaw Control limits the engine torque to maintain lateral stability in all driving conditions. Active Yaw Control also activates the power brake booster and the individual brake control. This controls the hydraulic modulator separation valves and electronic shuttle valves, and the inlet and outlet valves, which correct the car in the event of a skid.

During Active Yaw Control, when the car skids, a vacuum valve opens on the power brake booster. The power brake booster then quickly builds up pressure without the driver activating the brake pedal. At the same time the hydraulic pump (8) starts and builds up brake pressure.

The hydraulic pump takes over braking after the initial phase. The BCM then activates the valves in the hydraulic modulator and checks the individual wheel brake forces by raising, maintaining, or lowering the pressure individually to stabilize the car. The brake pedal moves up and down during activation.

If the driver presses the brake pedal during stability control operation, the control module, through the pedal pressure sensor (6) in the power brake booster, will take account of the pressure exerted by the driver in the stability control.

Some of the more common traction control problems in the early XC90s are:

- Worn or broken wheel sensors

- Rusted or damaged teeth on the ABS sensor pulse wheels

- Resistance caused by corrosion in the traction control system wire connectors

- Worn or damaged steering wheel spiral cable

- In some cases, software updates not performed

- Calibration issues

- Malfunctioning CAN network module

- Short or open in CAN network wiring

- Worn or malfunctioning sensor

- And much more.

Volvo has issued multiple TSBs, or as Volvo calls them, Technical Journals (TJs), that have to do with traction control systems on the XC90.

| Code | Description |

| DY | Warning lights and chimes/Anti-spin/Anti-skid (DSA, Tracs, STC, DSTC) indication/no indication |

| YP | Anti-lock brake system (ABS)/Does not work or engages unexpectedly |

| PA | Anti-spin function/Does not work |

| PJ | Stability function/Does not work |

| Control Module | Code | Fault Type |

| BCM | C006364 | Intermittent |

| BCM | 0121 | Intermittent |

One example is TJ 28031.

DSTC = Dynamic Stability and Traction Control

BCM = Brake Control Module

DESCRIPTION: Anti-skid warning lamp with DSTC warning message may be set after a few minutes of driving after system start-up, with DTC BCM-C006364 or BCM-0121.

The symptoms indicate that there could be a plausibility problem with the alignment of the Steering Angle Sensor (SAS) or a faulty wheel alignment. However, the DTC could present if both SAS alignment and wheel alignment are within specifications due to algorithm specifications in BCM software.

PRODUCT MODIFICATION: New BCM software was released in 2013 week 22 in production and is also available to upgrade existing vehicles from model year 2006.

SERVICE: Order and download BCM Upgrade software, PN 30677015.

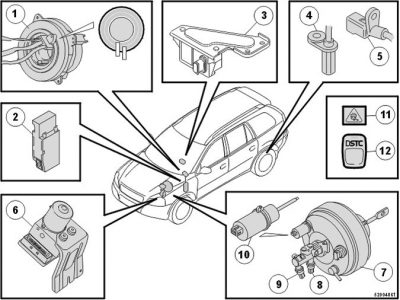

XC90 Traction Control Components and Testing

- Steering wheel angle sensor (spiral cable assembly)

- Steering wheel Angle Sensor (SAS)

- YAW rate sensor (AYC)

- Wheel sensor, front

- Wheel sensor, rear

- Brake control module

- Power brake booster

- Brake fluid pressure sensor front

- Brake fluid pressure sensor rear

- Brake pedal position sensor

- Traction control warning light

- Dynamic Stability and Traction (DSTC) switch

Steering Angle Sensor (SAS)

The steering angle sensor, or contact reel, has multiple functions. Not only is it a sensor that tells the BCM and CEM what angle the wheel is turned, it’s also the only connection for all the electronics mounted in the steering wheel, including the driver’s air bag.

The SAS is a module in the Control Area Network (CAN), so when it’s replaced you will need to use VIDA to download new software so the car will recognize it.

In some cases, problems with the SAS module can be fixed with a software update. Here are a couple of things to check before replacing the steering angle sensor.

Is the car out of alignment?

If the car pulls to one side and the suspension checks out OK, start with a four wheel alignment. Most modern alignment machines have the capability to calibrate the steering angle sensor as part of the alignment.

Check the network with VIDA to see if the latest version of the SAS software is installed.

YAW Rate Sensor or Active YAW Control Sensor (AYC)

The active yaw rate sensor is one of the most important parts of the XC90’s outstanding traction control system. This fairly delicate and complex sensor measures the vehicle’s yaw, or angle of attack, in any driving condition.

The yaw sensor tells the traction control system the degree and direction of vehicle lean. The sensor also uses inputs from the wheel speed and steering angle sensors to calculate whether corrective action is needed to stabilize the vehicle.

The XC90’s yaw sensor is one of the main reasons that it is very difficult for a driver to roll one of these cars.

The main reason these sensors fail is because of a build-up of corrosion in the connectors.

If you have to replace the yaw sensor, make sure to use a new Volvo Genuine Part, and be careful handling the part. If you drop it on a concrete floor, you may damage it enough to ruin it.

On the XC90, the yaw sensor is located under the right front seat under the amplifier module.

When you remove the amplifier module, take care to not damage the wire connectors. It is common for someone to not plug the connector with two orange fiber optic cables all the way into the amplifier, causing intermittent problems with the MOST network and infotainment system.

ABS Sensors

Volvo ABS sensors are pretty rugged and don’t usually fail even after many years of service. The problems with the sensors are more commonly due to rust or damage to the ABS sensor pulse wheels.

Broken, worn, or missing teeth are more common in areas that experience snowfall in the winter, especially if salt is used on the roads. Of course, you will come across the occasional ABS sensor failure due to damage to the cable from running over something.

It’s also common to have ABS sensor codes stored for front wheel sensors due to missing, loose, or broken axle bolts on the end of the outer CV shafts.

Brake Control Module (BCM)

It is extremely rare to have a late-style BCM malfunction. BCMs on post-1999 Volvos are rarely replaced, and the ones that are were probably due to a misdiagnosis.

Before you replace a BCM, check out Volvo’s technical journal TJ -12913.

In most cases, BCM codes are caused by other parts of the traction control system malfunctioning. Most actual BCM issues can be fixed with the latest BCM software update.

Vacuum Brake Booster

You will see the occasional brake booster failure in higher mileage Volvos. They usually won’t store trouble codes, except in rare cases you may get an ECM code P0171 for an unmetered intake air leak.

When vacuum brake boosters fail, you will usually hear a hissing sound from under the dash when the brake pedal is depressed.

Brake Fluid Pressure Sensors

Here is another Volvo part that is very reliable and that rarely is replaced.

The one problem you may see on older sensors is that fluid can work its way into the sensor and start to leak out into the connector. You may get a code stored in the BCM for a short to ground in the pressure sensor circuit. This can be especially true in brake fluid systems where the customer has failed to regularly flush and fill the brake fluid.

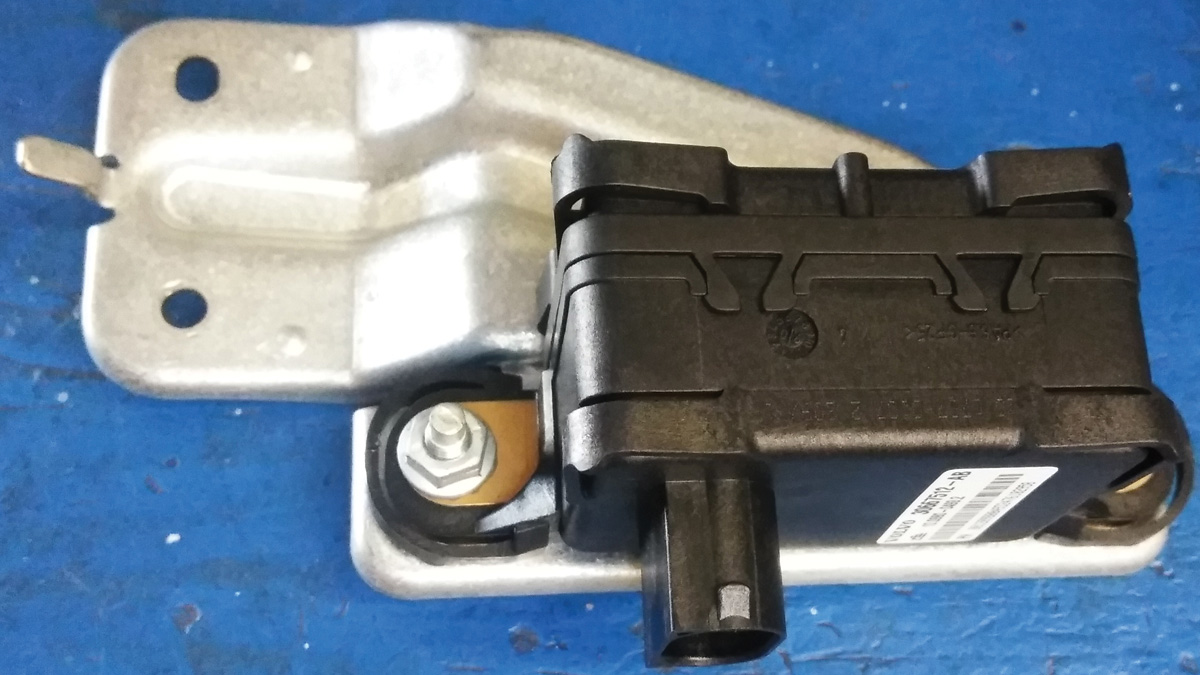

Brake Pedal Position Sensor

This sensor is mounted on the body of the vacuum brake pressure booster. It uses a piston to measure the position of the brake booster’s bellows, telling the BCM the relative position of the brake pedal. These sensors are fairly easy to replace, and they do go bad from time to time.

When you get the new sensor from Volvo, it will come with a new clip and sealing o-ring, so do not reuse the old o-ring. All you need is a pocket screwdriver or pick to compress the clip that holds it into the booster.

If you want to check out the brake pedal position sensor circuit, try the following.

Check the cables between:

- Pedal position sensor terminal #1 and brake control module terminal #7 (#A7)

- Pedal position sensor terminal #2 and brake control module terminal #5 (#A5)

- Pedal position sensor terminal #3 and brake control module terminal #3 (#A3)

Check for open circuit, short circuit to ground, and short circuit to voltage.

Hint: Connect an ohmmeter between terminals 2 and 3 on the pedal position sensor’s connector. The resistance should be approximately 0.5 K ohms with the brake pedal inactivated and approximately 2.5-3 K ohms with depressed brake pedal.

Connect the ohmmeter between #1 and #3 on the pedal position sensor’s connector. The resistance should be approximately 2.5-3 K ohms with the brake pedal inactivated and approximately 0.5 K ohms with depressed brake pedal. If resistance is incorrect, replace the pedal position sensor.

DSTC Switch

Volvo gives the customer an option to turn their traction control on and off. There it is, right below the climate control, right next to the side view mirror folding switch (if so equipped).

These switches are rarely replaced (maybe because they’re rarely used); that’s probably why some later Volvos deleted this switch.

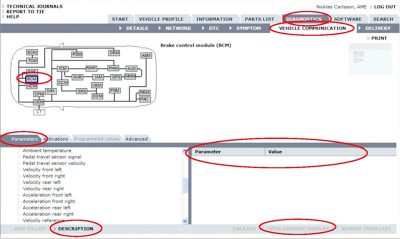

When testing the traction control system on a Volvo, the best tool is still Volvo’s VIDA software program. You can hook up your VIDA-equipped laptop, go to the Vehicle Communication tab and click on BCM and select up to ten parameters to monitor. You can have someone drive the car while you watch the numbers for any glitches, or you can you can use your DICE tool and your VIDA to record the parameters during a test drive and replay later to spot any problems.

appreciated article, organized and informative

my wifes xc90 had problems due to a bad pump. easily fixed.