The turbocharger boost pressure in Volvos is controlled by the Boost Pressure Control (BPC) valve whose pressure regulator is affected by the pressure from the turbocharger.

The Engine Control Module (ECM) determines current throttle angle and boost pressure to achieve the calculated engine torque output.

The Engine Control Module (ECM) affects the controlling pressure using the turbocharger control valve.

When the pressure increases, the Boost Pressure Control (BPC) valve pressure regulator is affected. When boost pressure has increased to the maximum permissible value, the boost pressure control valve opens and part of the exhaust gases bypass the turbocharger’s turbine which limits the boost pressure. Turbocharger control takes place constantly by measuring the current boost pressure and comparing it to the requested boost pressure.

Controlling turbocharger boost pressure

When the engine control module determines that a higher boost pressure is permissible, the turbocharger control valve opens further and a proportion of the pressure acting on the boost pressure control valve pressure servo is allowed through to the turbocharger inlet.

In this way the control pressure is reduced, the boost pressure control valve opens later, and turbocharger pressure can increase. The engine control module affects the turbocharger control valve by grounding one of the terminals with a fixed frequency, where the signal’s duty cycle determines how much the valve should open and therefore how much the boost pressure can increase.

Boost pressure reduction

The charge pressure is reduced when driving in first gear and reverse with engine speed rpm below 3,000 rpm to reduce the risk of wheel spin. If the engine has an automatic transmission, the transmission receives information from the TCM about when reduced charge pressure is required, for example, when shifting.

If the car has a manual transmission, the ECM determines which gear is selected based on the transmission and final drive gear ratios, engine speed (rpm), and vehicle speed.

On cars with automatic transmission there is also boost pressure reduction in the winter mode.

Boost pressure can also be reduced to protect the engine from damage. If the knock sensors detect that the engine is knocking above a given threshold value, and if ignition has been retarded and the air/fuel ratio has been enriched, the ECM will reduce the boost pressure until knock ceases.

A reduction in boost pressure also takes place if there is a risk of the engine overheating. If the Engine Coolant Temp (ECT) sensor indicates that the temperature has exceeded 118 degrees C (244 degrees F), the ECM lowers the boost pressure to reduce heat generation.

Automatic high altitude compensation

Because the ECM determines boost pressure using the signal from the intake air pressure sensor, there is automatic boost pressure control compensation when driving at altitude and in different temperatures. The engine power is not, therefore, noticeably affected by air density or temperature.

When altitude exceeds around 6,000 feet above sea level, the ECM cannot compensate boost pressure any further because the air is too thin.

Boost pressure monitoring

The ECM constantly monitors boost pressure using the Mass Air Flow (MAF) sensor and the intake air pressure sensor.

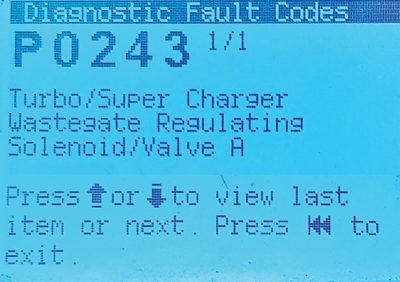

If boost pressure exceeds permitted levels, the ECM closes the turbocharger control valve so that the engine torque can only be controlled through limiting the throttle opening. A Diagnostic Trouble Code (DTC) is stored at the same time.

If the calculations display too low boost pressure, a diagnostic trouble code is stored.

If a fault occurs in a component that affects boost pressure calculation, the ECM will always limit throttle opening.

If there is a fault in any of the sensors, the boost pressure control goes over in an open loop. This means that it is controlled by fixed duty cycle which is a direct function of accelerator pedal position sensor and engine speed (rpm).

Case Study: 2000 VOLVO C70 2.4 L Turbo With Low Turbo Boost Complaint

This car is an early model turbo system, but most of the Volvo turbo control systems have remained similar up until the last few years.

The customer that brought this car in said that the car had been losing power when the car was accelerating onto the freeway, and the Check Engine light had just come on in the last week.

The customer stated that the car seemed to perform normally on city streets.

The technician took the car on a test drive to confirm the customer’s complaint.

As the technician was accelerating on city streets, the car seemed to perform normally, but once the technician was able to go onto the freeway and accelerate past 30 mph, the power problem became clear.

The car felt like it was falling on its face. The tech experienced a loss of power around 2,500-3,000 rpm, and he had to hold the pedal down to get up to freeway speeds.

It almost felt like a transmission slipping symptom.

The tech drove the car back to the shop to start the diagnosis.

He started with a visual inspection of the engine compartment to check for any obvious issues like loose or broken hoses or wiring; on first look there were no smoking guns.

The technician hooked up a laptop that had Volvo’s VIDA software program and read the stored data and trouble codes.

The ECM had stored the codes ECM 6806 and ECM 6800.

The setting criteria for ECM 6806 is as follows:

Condition

If engine speed (rpm) is above 3,500 rpm and the engine is operating at a high load, the control signal to the turbocharger control valve is at maximum and the boost pressure (from the boost pressure sensor) is lower than a designated value [approximately 20 kPa (2.9 psi) under normal boost pressure — signal too low].

If the air mass (from mass air flow sensor) is higher than a desired value (signal too high), it is interpreted as a fault and DTC ECM-6806 is stored.

Substitute value

Reduced boost pressure

Possible source

Signal too high:

- Air leakage after turbocharger

Signal too low:

- Hoses between the turbocharger and the turbocharger control valve, or between the turbocharger control valve and the pressure servo, are loose or are blocked/damaged

- Faulty turbocharger control valve

- Faulty boost pressure control valve pressure servo

- Sticking boost pressure control valve

The ECM 6800 code was for a signal missing, permanent fault, and the data pointed to an open circuit or a defective turbo control valve.

Volvo’s test procedure for this code is as follows:

Check turbocharger control valve connector for intermittent contact resistance or oxidation. Check signal cable between engine control module #A38 and turbocharger control valve #2 for an intermittent open circuit according to Checking Wiring and Terminals.

Intermittent faults

Check power supply turbocharger control valve between turbocharger control valve #1 and system relay for an intermittent open circuit according to Checking Wiring and Terminals. Intermittent faults.

Remedy as necessary.

After an initial visual inspection of the engine compartment, the tech could not find any obvious signs of damage to the turbo control system or hoses.

Since the code ECM 6806 could be caused by an air leak or unmetered air in the intake system, the tech decided to perform a smoke test to see if there were any leaks in the system.

The most effective way to try to isolate the intake system during a smoke machine test is to disconnect and seal the intake tube right behind the air mass sensor. This will ensure that you can build enough pressure in the intake system to find even the smallest air leaks.

After running the tests for both the ECM 6800 and ECM 6806, the problem turned out to be a loose wire connector in the turbo control valve harness connector. One side was pulling out of the connector.

Download the PDF to see one of the few turbo related TSBs or TJs that Volvo has issued: TJ22295.

0 Comments