After 55 years the Corolla has not only survived, but thrived. Join us as we take a look at the history, common issues and technology of the world’s best selling car.

Despite all the difficulties and unknowns of 2021, it was a good year for Toyota; in fact, it was a great year. As usual, sales numbers and profit margins were high. In addition, Toyota dethroned General Motors to become the automaker with the highest sales in the U.S. They revealed plans for a new electric vehicle battery factory in North Carolina and the joint Mazda Toyota Manufacturing plant in Huntsville, Alabama began production. In December, Aiko Toyoda, global president of Toyota and grandson of the company’s founder Kiichiro Toyoda, announced a bold new electric future for both the Toyota and Lexus brands. This announcement steps up Toyota’s commitment to electric vehicle production and sales.

Last year was also a great year for the Toyota Corolla. The compact sedan celebrated a huge milestone with its 55 year anniversary. The first production Corolla rolled off the assembly line of the Japanese Takaoka Plant way back in 1966. In 1997, the Volkswagen Beetle handed off its crown to a new king and the Corolla became the “best-selling vehicle of all time.†Then last July another milestone – the 50 millionth Corolla sold, holding its place as the top selling car.

The Corolla Chronicles

The name Corolla has latin roots and means “a small crown of flowers.†This follows in Toyota’s tradition of using crown-based names for their sedans, a tradition which started with the Toyopet Crown as the original sedan in 1955. The name Camry comes from a Japanese word for crown “kanmuri,†and the naming pattern continued with the Corona (wreath of flowers). The Corolla has been designated as an E chassis, starting with the first generation E10 in 1966, all the way to the twelve generation E210 released in 2018.

Originally built in Japan and sold exclusively at Toyota Corolla Stores, the Corolla has since been built and sold all over the world. In the United States, the Corolla’s maiden assembly plant was at New United Motor Manufacturing, or NUMMI in Fremont, California. In fact, the first Toyota vehicle built in the U.S. was a white Corolla FX16 that came off the assembly lines at NUMMI in 1986. Production continued thereafter.

As of 2011, U.S. production of the Corolla has been at Toyota Motor Manufacturing Mississippi (TMMM) set in the rolling hills alongside Interstate 22 near Tupelo Mississippi. The plant is officially located in the village of Blue Springs, whose population was last estimated at 241 people. The 2 million square foot factory employs nearly 10 times that number. Originally intended to produce the Prius, TMMM now exclusively produces the Corolla and all replacement service parts for North and South America. It takes approximately 20 hours for the production lines at TMMM to complete one Corolla vehicle, starting with stamping the body panels all the way through to final assembly.

Powertrain

The Corolla powertrain has come a long way from the original K series engine family. These early 4-cylinder engines had push rods, 2 valves per cylinder and a single carburetor. There were various options for twin carburetors, high octane fuel and California emissions.

As with Toyota’s principle of continuous improvement, the Corolla powertrain has gone through countless improvements over the last 50 years as well. The latest model years offer two power plants, the 1.8L 2ZR-FAE and the 2.0L M20A-FKS.

The main point of interest for the 1.8 liter engine is the Valvematic system, which allows the intake valve lift to be precisely adjusted by an electronic control actuator on the back of the intake camshaft. There are several notable features of the 2.0 liter M20A-FKS. Like most new engines, there is variable valve timing on both camshafts. The exhaust camshaft is adjusted traditionally with hydraulic oil pressure but the intake camshaft is actuated with an electric motor. This is referred to in service data as VVT-iE or Variable Valve Timing – intelligence by Electric Motor. Additionally, the M20A engine uses Toyota’s D-4S fuel system which combines direct fuel injection with port fuel injection. The engine controller can switch between the two injection options based on engine temperature, engine load and various other conditions. The port injectors can also be used to help keep carbon from building up on the intake valves, which is an unfortunate side effect of direct injection. To round out the powertrain, there are two CVT transmissions and an optional six speed manual transmission. The K120 CVT comes with the M20A-FKS engine and has a unique CVT. Toyota added a ‘launch gear’ to deal with the low-speed efficiency issues and acceleration lag that are inherent to CVTs. This design is essentially a two speed automatic transmission coupled with a traditional CVT.

The Skinny on Corolla Lean Codes

When Lean Isn’t Good

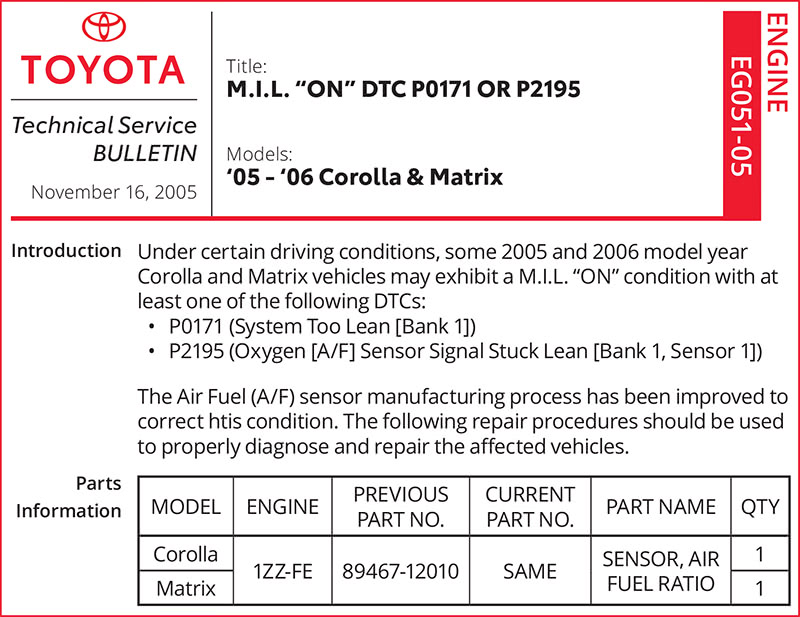

Toyota created the Lean Manufacturing ideals that have influenced companies the world over, but lean isn’t always good, at least not for air/fuel mixture. One common issue with many of the Corolla engine families has been lean fuel mixture faults, the main code being the familiar P0171. In later model years, there have been more specific fuel trim and air fuel imbalance faults added because the P0171 covered such a broad range of possible issues. The most common customer complaints related to lean conditions would be the check engine light being illuminated or low power issues.

While the following points about lean fuel system faults are not specific to Corollas, they can be used to quickly and accurately diagnose any OBD II era and newer Corolla.

There are three main categories that a lean fault can fall under:

- Unmetered Air

The first type of lean fault is when unmetered air finds a way into the engine. This may happen through a torn air snorkel tube or a cracked vacuum hose, for example. If air enters the engine without first passing through the mass air flow sensor (MAF), then the ECM isn’t aware of the extra air and doesn’t add the necessary fuel, driving the mixture lean. - Fuel Delivery

The second type of lean faults are fuel delivery issues, or not enough fuel getting into the cylinders. This may be the result of low fuel volume from a weak fuel pump or restricted fuel injectors, which can drive the mixture lean even if the inputs, ECM, and outputs are all good. - Measurement Errors

The third type of lean faults are feedback issues from a faulty air/fuel sensor or oxygen sensor. In the case of feedback issues, the engine controller is being tricked into setting a lean fault code not by an actual problem with the air intake or fuel system but by a skewed sensor input.

Sneaky Leaks

There are a few other items to consider when dealing with lean faults:

- When an evaporative emissions fault is stored along with a lean code, it’s a strong indication that the purge control valve is stuck open. The purge valve is normally closed until the engine controller grounds the solenoid causing the valve to open. Having the purge valve stuck open creates an internal vacuum leak that is not obvious during a visual inspection or smoke test. An easy way to test for this condition is to block off the hose from the purge valve to the intake and observe the fuel trim numbers.

- The brake booster is another source of an internal vacuum leak that can create a lean condition. While not commonplace, booster leaks did occasionally occur on the 8th and 9th generation Corollas. Holding the brake pedal down while monitoring short term fuel trims is a quick test to check for a booster leak. If the fuel trims climb consistently while the brake is applied, the booster needs to be inspected for leaks. There may also be a hissing sound when stepping on the brake pedal.

- Be sure to check Mode 2 freeze frame data for the lean code. This will provide valuable information in determining the cause of the lean condition. A cold engine temperature can indicate an intake manifold gasket leak, while a lean fault that set under acceleration or cruising speed would point to a fuel volume or air flow sensor issue.

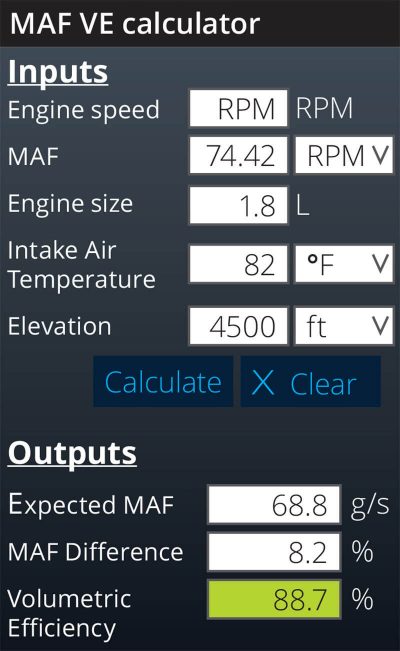

- Focus on any Air Fuel, Oxygen, or Mass Air Flow sensor faults that may be present along with the lean code. Performing a Volumetric Efficiency test is a good way to verify if the Mass Air Flow sensor is reporting correctly. Check to see if either of the oxygen sensors are biased lean over a longer road test, or if the sensor voltages go above or below normal operating range. Also check to confirm that the correct sensor has been installed in the correct location.

On certain model years the connectors were similar, and it was possible to install an oxygen sensor in place of an air fuel sensor or to install an upstream sensor in the downstream location. Either of these scenarios will cause all kinds of drivability issues. Be sure to check for California emissions standards as well, since there may be different sensor applications for the same model year Corolla.

There are also several service bulletins related to updated Air Fuel sensors and Engine Control Module programming for a select number of Corollas.

- One final note regarding the fuel system. Restricted fuel injectors have been reported on many Corolla engines over the years. This is especially true of higher mileage vehicles that have been run on budget fuels without any additives or detergents. Fuel trims being elevated throughout all driving load ranges indicate a fuel delivery problem and possibly clogged injectors.

Lean Vehicle Study

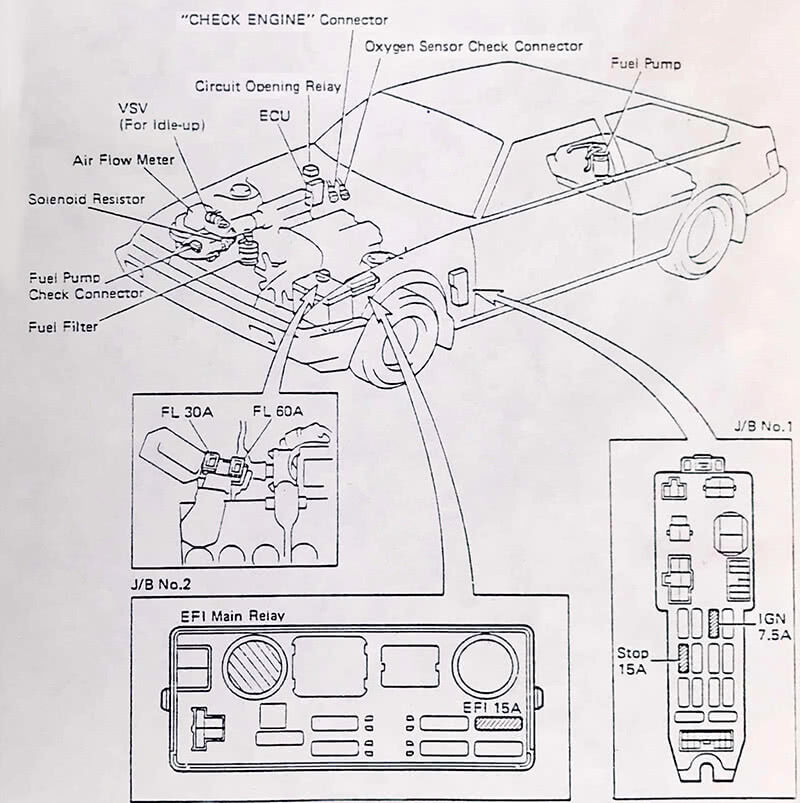

The following vehicle study is a typical lean condition diagnosis on a 2005 Corolla S with a 1.8 liter 1ZZ-FE. This NUMMI built Corolla was brought in to the garage due to the MIL being on. After verifying the check engine light was displayed, the vehicle was scanned for faults. One fault was stored: P0171 System Too Lean (Bank 1).

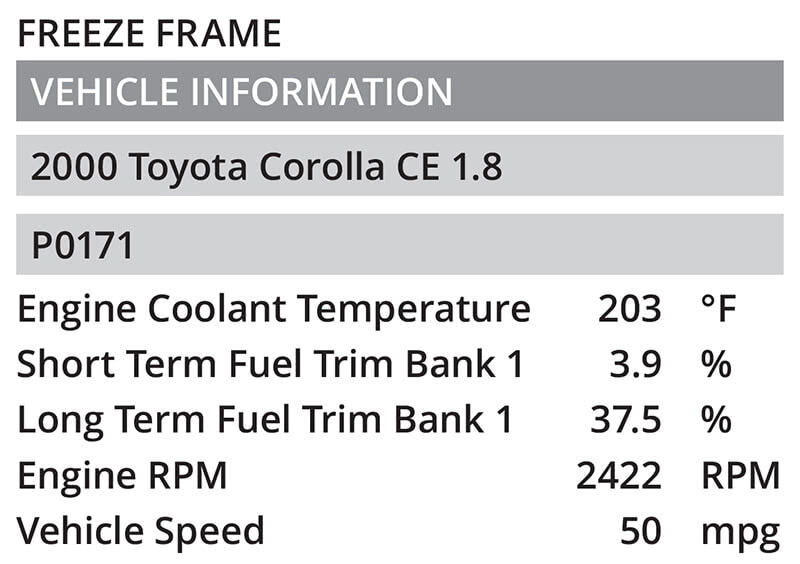

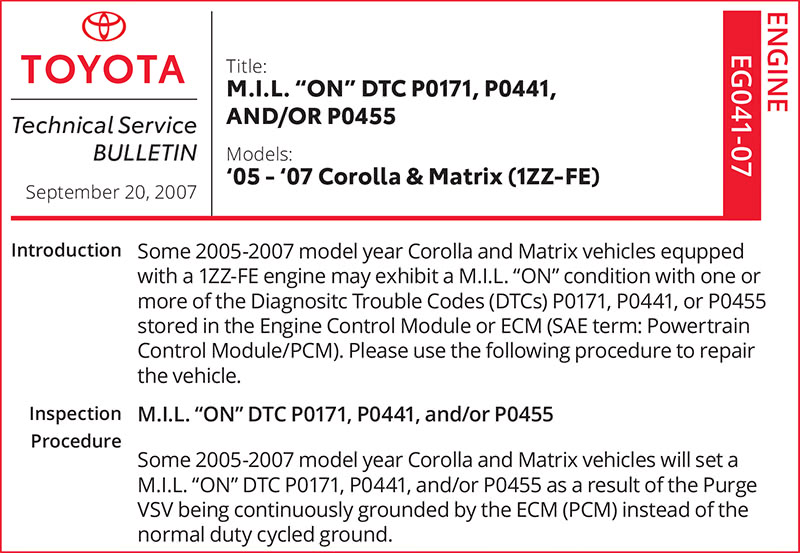

A visual inspection did not reveal any issues other than a recently installed MAF sensor. While reviewing service information it was discovered there were three Technical Service Bulletins for a lean fault on this Corolla. Bulletin EG051-05 listed an updated Air Fuel Sensor to remedy a lean fault code, while

EG041-07 described a situation in which the Engine Control Module continuously grounds the purge valve creating the lean condition.

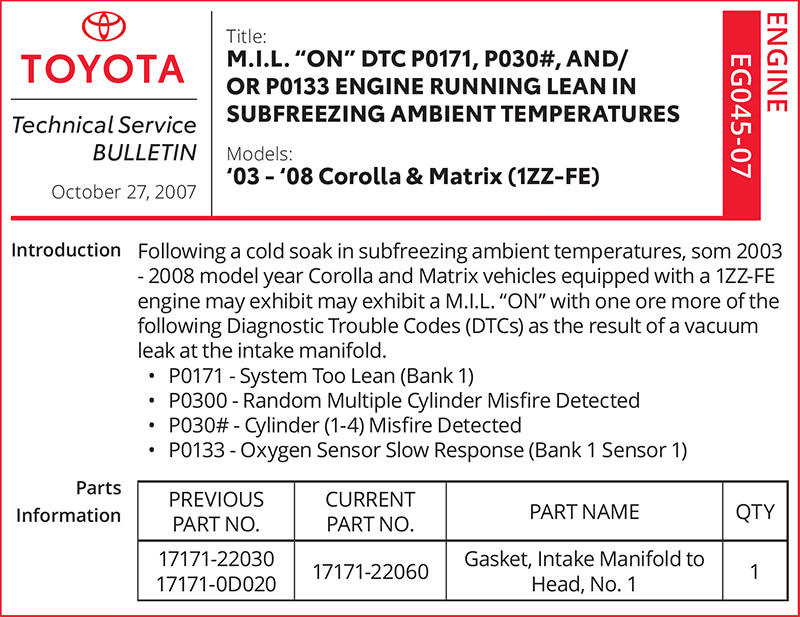

In the final Service Bulletin, EG045-07 a vacuum leak at the intake manifold gasket is guilty of creating the lean code.

With multiple potential causes identified for the lean fault, it was time to begin testing. A Volumetric Efficiency test confirmed that the aftermarket MAF sensor wasn’t the problem.

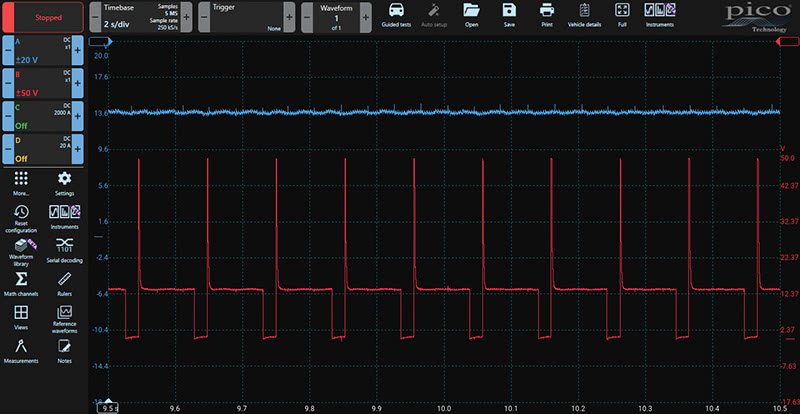

While on a road test, the air/fuel sensor operation was monitored via scan tool and found to be working correctly. A quick check of the purge valve using a lab scope showed that it was functioning normally as well (next page). The waveform showed that the purge valve ground was being duty-cycle controlled by the ECM and the electric solenoid was responding with a voltage spike each time the magnetic field collapsed.

That left an intake gasket leak as the most likely cause of the lean fault. A smoke machine was attached to the air intake system when the engine was cold and there was indeed a large leak from the intake gasket just above the oil dipstick. The vacuum leak was further confirmed when propane was injected near the intake manifold and the fuel trims rapidly dropped from positive to negative numbers.

A new intake manifold gasket was ordered and installed, and the throttle body was cleaned at the same time because carbon build up had accumulated and it was easy to clean while removed from the car.

After cleaning the throttle body, it’s a good practice to clear the learned idle data stored in the ECM, otherwise the idle speed may be too high while the ECM gradually relearns. The same holds true for the long-term fuel trim. It’s best to erase the ECM’s memory to reduce the time it will take to relearn.

Some Corollas allow memory to be cleared with the Techstream, but not all. If there isn’t a utility to clear memory, disconnect the battery cables from the battery and jumper them together for 15 seconds. This will discharge any capacitors in the ECM that might provide power to retain volatile memory when the power is disconnected.

After these repairs, the vehicle was monitored for several cold starts and road tested to verify the fuel trims were within an acceptable range. The fuel trims were normal and the Corolla was returned to the owner.

New Technology

The Corolla has come a long way in technology as well. Toyota Safety Senseâ„¢ comes standard on new Corollas. Toyota Safety Senseâ„¢ or TSS for short includes a Pre-Collision System, Pedestrian Detection, Dynamic Radar Cruise Control, Automatic High Beams, Lane Departure Alert, and Road Sign Assist.

Forward Recognition Cameras and Millimeter Wave Radar Sensors are becoming standard features. There’s no time like the present to gain the knowledge and equipment needed to calibrate these Advanced Driver Assist technologies.

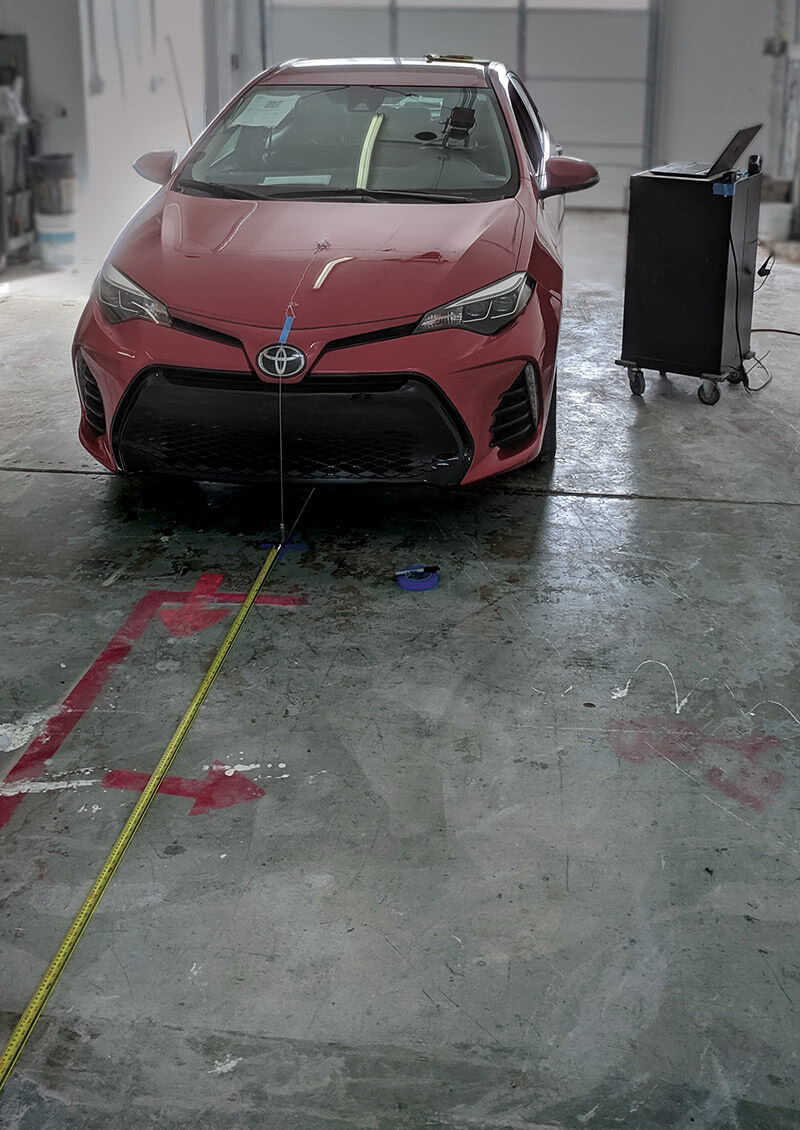

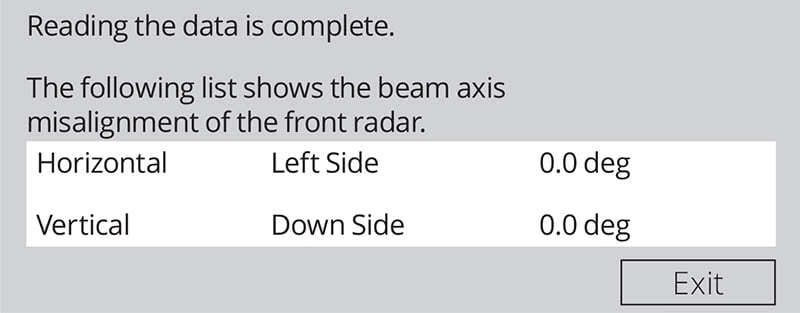

The windshield mounted front camera needs to be recalibrated after a windshield replacement or any time the camera is removed or disturbed. In the event of a front end collision or front bumper removal, the radar sensor adjustment procedure must be performed. Bumper removal is often necessary for radiator, condenser, or headlight replacement, so this isn’t just a body shop issue. The front radar sensor assembly is located directly behind the Toyota emblem.

Toyota has also started offering a hybrid version of the Corolla sedan. The 1.8 liter 2ZR-FXE Atkinson cycle engine paired with Toyota’s Hybrid Synergy Drive is a reliable powertrain that has been used on Prius models and the Lexus CT for years.

New technologies are not limited to the vehicles themselves though. New manufacturing technologies are playing a vital role as well. Toyota introduced the Corolla Cross in 2020 as a compact SUV larger than the C-HR but smaller than the popular RAV4.

The 2022 Corolla Cross will be the first vehicle produced at the recently opened joint Mazda Toyota Manufacturing plant in Alabama. It is built on the same platform as the twelfth generation E210 Corolla using the Toyota New Global Architecture or TNGA. The Global Architecture production system incorporates advanced new technologies and allows Toyota to build multiple vehicle models using the same platform base. This technology fits with Toyota’s one piece flow mentality and allows an assembly line to quickly switch between quantities and models being produced.

The Corolla’s Future

Toyota shows no signs of retiring the Corolla anytime soon. On the contrary, they have revitalized the best-selling compact sedan with a variety of new options, including the iM hatchback, Nightshade Special Edition and the anticipated GR Corolla. The GR is rumored to be a high performance tuned Corolla hatchback due out in 2022. With Toyota’s new commitment to battery technology and carbon neutrality there will likely be a fully electric Corolla available in the not too distant future also.

Toyota has built its name on quality, dependability and affordability. The Corolla has played a huge part in helping to build that reputation from the first production vehicle in 1966 to the latest models, and every year in between.

By Jordan Hill

0 Comments