A look at the remanufactured engines offered, some example prices and the warranty, helping you decide what’s best for your customer

What do Wall Street, the economy, government administrations and the automobile market have in common? (Don’t worry, this isn’t a political commentary.) Well, for one thing, they are all influential in some way when deciding to repair or replace that engine in the Mercedes-Benz you are working on. Not only does the customer have to consider these, but you as an informed advisor have the responsibility to help inform them so they can make a better decision.

Having been in the industry for over 45 years, I’ve seen my share of market fluctuations, economic ups and downs, and administrations come and go. I can tell you they all have an effect on whether to replace an expensive engine, repair it, or to cut your losses and get rid of the vehicle. There have been times when the customer says, “Absolutely not, it’s not worth it”—the vehicle is worth considerably less than the repair estimate. Other times, the customer won’t bat an eye, asking, “When can you get it done?” The current auto market, with used car values at lofty levels, has customers getting serious about keeping the vehicle in top condition, almost regardless of the cost.

How Much Engine?

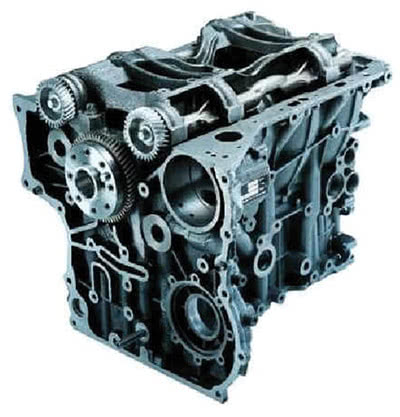

When considering a replacement engine, you often have the options of a complete engine, a long block, a short block and what’s called the basic engine. While most replacement engines are remanufactured, certain specialty engines may be only available new, particularly specialty engines and those recently introduced to the market. Get in touch with your Mercedes-Benz dealer to find out which options are available.

Short blocks are the lowest-priced engine option and an excellent alternative to having the complete engine replaced. The short block price is generally around 40% of a complete engine. If you have engine damage but have good functioning components such as the cylinder head, injection system and turbocharger, you can transfer these parts over and save on overall cost. The short block is available for selected variants of the OM642, OM646 and OM651 engine model series.

The long block is a remanufactured engine featuring a completely remanufactured crank assembly and preassembled cylinder head, including valves. It also has an attractive price point. Compared with replacing the complete engine, you save around 50%. You can keep all the injectors that are still intact from your previous engine. If you find that you need to replace the injection system as well, you might want to save on the cost of buying and installing the injectors. A basic engine, complete with a preassembled injection system, is available for a range of models. The difference between a basic engine and a complete engine is that the complete engine comes with additional items such as the EGR Valve, exhaust heat exchanger, exhaust manifold, turbocharger, wiring harness, oil, and filter, depending on model.

Engine Lineup

Let’s take a look at some current engines offered in the Mercedes-Benz parts lineup and maybe some of the more popular ones.

The complete gasoline engines generally available are the M112, M113, M120, M137, M156, M254, M256 M266, M270, M271, M272, M274, M275, M276, M277, M278 and M279. For diesels, we can get OM601, OM602, OM603, OM604, OM605, OM606, OM611, OM612, OM613, OM628, OM629, OM640, OM642, OM646, OM647, OM648, OM651, OM654, OM656 and OM668.

The basic gasoline engines available are the M102, M103, M104, M111, M119, M166, M254, M256, M266, M270, M271, M272, M273, M274, M275, M276 and M278. For diesels, they include the OM601, OM602, OM603, OM604, OM605, OM606, OM607, OM611, OM612, OM613, OM626, OM640, OM642, OM646, OM647, OM648, OM651 and OM668.

Short blocks are available in the OM642, OM646 and OM651 only.

According to our local Mercedes-Benz parts dealer, a couple of the most popular items are the OM647 and OM642 engines.

The OM642 is a 3.0-liter turbocharged V6 diesel engine that became available in 2005, replacing the five- and six-cylinder OM647 and OM648 inline engines. The OM642 was offered as an engine option for many cars and vans produced by Mercedes-Benz and also sold under the Dodge, Jeep, Chrysler, and Freightliner brands.

Also a popular mover is the OM647. A 2.7-liter, five-cylinder in-line common-rail diesel injected (CDI) overhead valve diesel engine. This engine utilizes a cast iron cylinder block and an aluminum cylinder head. The engine is turbocharged and intercooled. This engine also has four valves per cylinder and dual overhead camshafts.

Both of these engines were popular in the Sprinter Vans and, as such, have many fleet applications. This in part might be reason for the popularity of these engine replacements. In speaking with our local parts manager, there isn’t any one particular failure in these engines that is known for trouble. They just usually have a lot of hard miles on them and they are worn out. Certainly some cases can be strictly from poor maintenance or failure to use quality parts. Going cheap on a simple thing as the oil filter can lead to premature engine failure.

Warranty

All Mercedes-Benz replacement engines and long blocks are warranted for 48 months or 50,000 miles (36 months or 36,000 miles for Sprinter), whichever cones first, from the date of installation. Short blocks carry a 24 month, 24,000 mile warranty. As expected, there are some limitations, so read the warranty statement at www.mbwholesaleparts.com/warranty for yourself. Of course, the warranty also applies to commercial customers, including fleets. The warranty provides for replacement, including the labor, of a failed part, which is a big added value for your customer.

The Remanufacturing Process

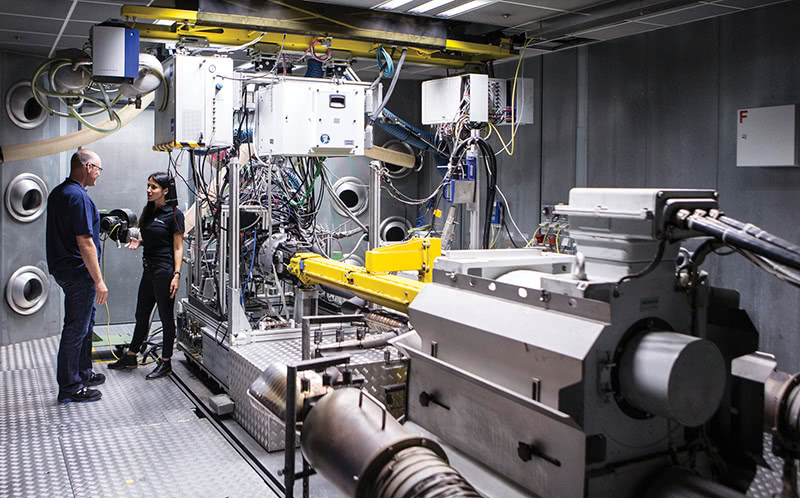

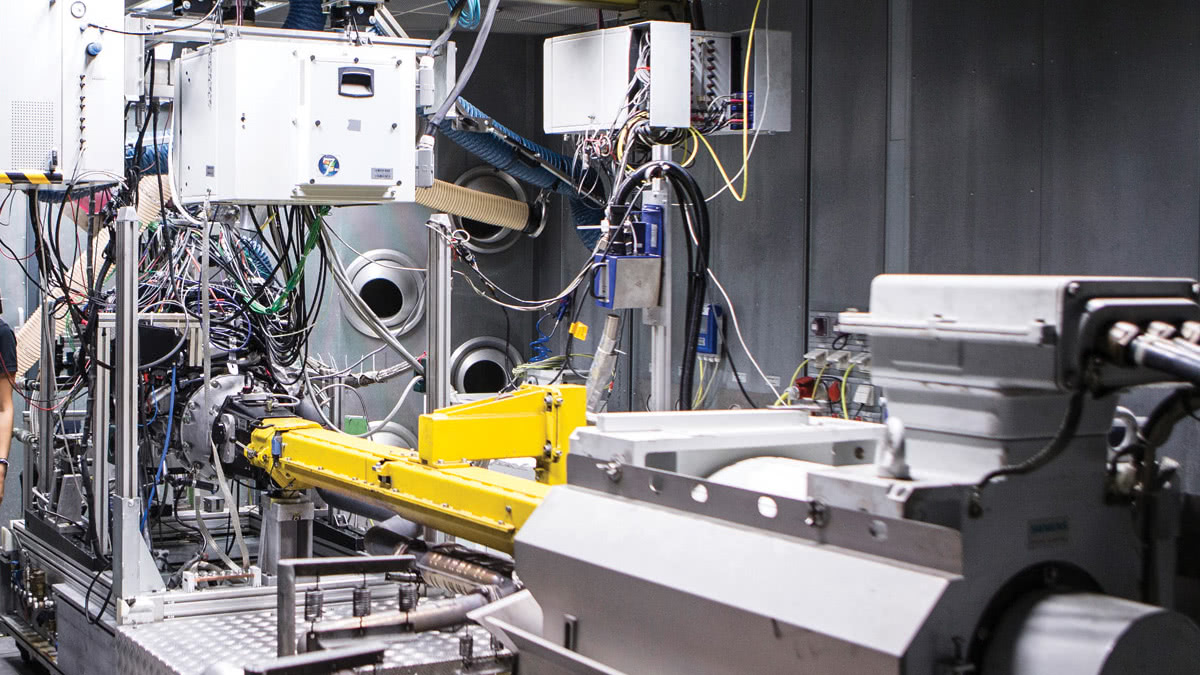

The warranty is so generous because Mercedes-Benz has great confidence in their remanufacturing process. The resulting ‘experienced’ engines are considered by some to a brand new engine, since they’ve often had hundreds of thousands of miles of pre-testing.

In the first step of the remanufacturing process, the used part is professionally disassembled into its basic components, and recyclable materials are separated out and sent for recycling when called for. Compared with new parts, Mercedes-Benz Genuine Remanufactured Parts utilize considerably less energy and raw materials. This means that 99% of the parts can be reused or sent for recycling.

Next comes the cleaning process, which is tailored to the specific workpiece. Sometimes it’s a special washing process and solvent bath for large-scale cleaning, other items call for ultrasonic cleaning for degreasing, or sand and glass bead blasting for cleaning specific areas. One thing’s for sure: the parts for reassembly are as spotless as brand new.

All parts are examined and inspected to meet or surpass the highest quality standards. To this end, each part is subjected to a careful visual and functional examination that allows any damage to be identified immediately. Microscopic damage detected on highly stressed component parts, using a special crack test procedure such as fluorescent magnetic particle inspection, identify any hairline fractures or leakage. Complex measuring methods are applied to check dimensional accuracy. Any parts that do not meet all test criteria are rejected.

All inspected parts are handled in accordance with strict engineering criteria and assembled to create a complete Mercedes-Benz remanufactured engine. Also, any changes identified in series production are automatically incorporated in the process to ensure the most up to date finished product. (As a side note, it is important to use the engine serial number when specifying replacement parts in the future to ensure that the correct version parts are ordered). Many of the remanufacturing techniques are unique to Mercedes-Benz, such as cylinder heads undergoing an induction hardening process, which cannot always be duplicated in the aftermarket. The crankcases are even wire-arc sprayed to ensure they are restored to their original dimensions.

Before any engine gets shipped out, the quality and performance of each remanufactured engine is tested on a special test stand, using the same criteria as in series production, to ensure maximum reliability. Also equipped with integrated and updated control units, they can be installed into your customer’s vehicle without any problems.

Decision Making

The process of deciding when to replace an engine with a remanufactured component versus repairing the engine you have is a complicated one. There is really no tried and true formula to tell you when one choice is advisable over another. It’s a matter of common sense and dollar figures, more than anything. Of course, the customer’s wishes are important considerations, but remember, you’re the expert. The advice you give should always be in his/her best interest, at least if you want to keep them as a customer. You may occasionally have that customer that says, “Hey, just fix it as cheap as you can; I’m gonna sell it.” We’ve all been there and know that often ends poorly. They might decide to keep it and wonder why it didn’t last more than a year, or worse, they sell it to someone and claim that you completely rebuilt the engine!

The mileage of the vehicle is a huge factor. Why try to do a major repair on an engine with 200,000 or more miles on it? You’ll be placing all those high mileage worn components back in service with a bunch of new parts. It doesn’t make sense. We’ve seen OM647 engines with over 200K that we literally could not get the head off (thanks to the Black Death) so a replacement engine was the only logical choice.

Of course, the condition of the vehicle is also an important factor. A near-pristine example that lives a pampered life is often a better candidate for the expense than an abused rust bucket. Then there are the collector models, where owner emotion influences the decision and reduces the importance of cost.

Let’s look at some possible situations and compare repair and replacement:

You have a Sprinter with an OM647 that was chip tuned and it caused a hole or crack in the piston. It has low enough miles that you may consider just a repair.

The labor guide gives 31 hours for an overhaul, which is essentially what you’ll be performing. You may inspect the cylinder head and find it’s perfectly fine and as such you might want to subtract some time. This job includes: replace rings, main and rod bearings, camshaft(s), crankshaft and timing components. Remove cylinder ridge, burnish cylinders, grind valves and clean and test or replace lifters. Includes (where applicable): adjust valves. This does not include pin fitting or rebore and align rods, which would be separate machine operations. At a minimum, you’ll need a piston and pin ($350), gasket set ($194), head set ($232) as well as main and rod bearings ($500). If your labor rate is $110/hr, this estimate puts you at around $4,700. Clearly, there are several other items needed on a job like this, but this is just a general example to help you see what’s involved and to make comparisons.

Now let’s look at a long block replacement. A long block consists of a cylinder block fitted with pistons, rings, connecting rods, crankshaft and all bearings, cylinder head(s), camshaft(s), timing chain and sprockets or gears. Labor includes (where applicable): clean and transfer fuel and electrical assemblies, engine mounts, manifolds, valve cover(s), oil pan, oil pump, timing cover(s), water pump, clutch and flywheel. Adjust valves.

Suggested retail for the MOPAR version of the OM647 (Part number R2527545AA, used in the Freightliner model 603 Sprinter) is shown online as $15,785 (although it can be had for less) and the labor guide pays 12.9 hours. At $110/hr that’s $1,419 for a total of $17,204. Same as before, there are other items to consider when building a complete estimate, but you get the picture.

Obviously, the repair here is likely the better option compared to a complete replacement, but this makes several assumptions: First, the engine must actually be repairable—a hole in the block might be a game-changer. The engine ideally has relatively low mileage. If it has really high mileage, repair might not be the wisest decision. The cylinder head, crankshaft, rods and timing components should be in very good condition or better, or you need to add them to the estimate. If you start to approach the cost of the replacement, and factor in the available warranty coverage, then you need to consider that replacement might be the better option.

Here is a classic example: the M272 engine. These were in many models in the 2000s and a good many are still on the road today. M272 engines have aluminum engine blocks with a 90° V-angle with silicon/aluminum lined cylinders. The aluminum DOHC cylinder heads have 4 valves per cylinder. All have forged steel connecting rods, one-piece cast crankshaft, iron-coated aluminum pistons and a magnesium intake manifold. A balance shaft is installed in the engine block between the cylinder banks to deal with vibrations in the 90° V6 design. Anyone who has serviced these models is aware that some early versions can wear out the balance shaft sprocket. This would be a prime candidate for an engine replacement.

Balance shaft replacement labor pays around 32 hours. You’ll need the balance shaft kit (about $500) plus the timing chain and guide rails, and possibly the camshaft phasers (VVT adjusters) for at least about $2,000 in parts.

Mercedes-Benz part number A 272 010 79 44 80 has a suggested list price of $6,600 (and can be had for under $6K) for the basic engine (assuming you return the core) and pays about 21 hours to install. At $110/hr you have $2,310 in labor for a total of around $6,300. Again, the overall estimate would generally be higher with all the incidentals, but those are also needed for the repair. You can see here the overall value is greater when the complete engine is replaced ($6,300) versus the repair ($5,500), especially considering the remanufactured engine warranty coverage.

Bottom Line

So what’s the bottom line? Genuine Mercedes-Benz remanufactured engines, whether they be a complete engine, basic engine, long block or short block, are extremely reliable, meticulously assembled and have a great warranty. It is absolutely worthwhile to consider and compare replacement with repair to find which is best for your customer. You might be surprised, so give your Mercedes-Benz dealer a call. For any of your high mileage repairs they are an excellent choice and will help your bottom line.

0 Comments