A look at servicing the system, problem areas including diesel particulate filters and countdown to zero

If you want to really get into the science behind BlueTEC and AdBlue® technology, take a look at the June 2018 issue of StarTuned. In this article today, we will take a look at servicing these systems in your shop and, in particular, some problem areas that may pop up. The dreaded countdown to zero is one of them. This is where your customer says “my dashboard indicates I only have 6 starts left on my vehicle and it needs to go the workshop.” Even worse, they’ve ignored it and are stuck 30 miles from nowhere and the vehicle will no longer start. Unfortunately, Europe has begun the ban on diesel vehicles and they may be on their way out, but you are still going to see them in your shop for some time.

Service Recommendations

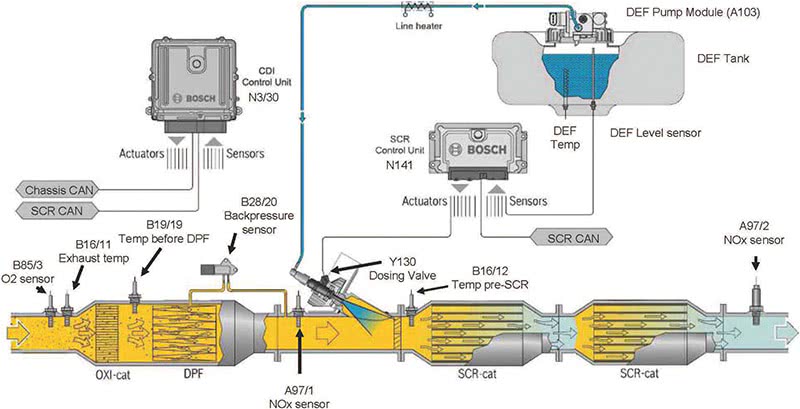

Servicing the diesel vehicle in your shop is pretty much the same as servicing the gas engine vehicles, with some obvious exceptions. You will follow the A and B service recommendations with the difference being the addition of the Diesel Exhaust Fluid (DEF). Always top off the tank with a high quality DEF (such as the trademarked AdBlue) at regular service intervals. Your Mercedes-Benz parts department carries a handy container of genuine fluid with the added benefit of a nifty little fill valve. Also at the B service, Mercedes-Benz recommends a drain and fill of the DEF tank in order to eliminate any contaminants. According to most sources, DEF has a shelf life of one to two years. Since it has no preservatives, it can lose its effectiveness over time. Your dealer will always make sure you’re getting fresh product.

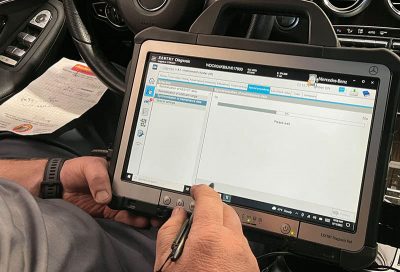

Always conduct a full scan or quick test of the vehicle with a factory-compatible scan tool so that you can have a clear picture of the whole vehicle. The technology behind BlueTEC is complicated to say the least, and knowing what’s working properly and what isn’t is the first step to keeping your customers cars on the road safely and trouble free. When it comes to more complicated troubleshooting, such as Diagnostic Trouble Codes (DTCs) and solving them, you won’t get far without a XENTRY Diagnosis system. There are sometimes many adaptive resets and programming platforms that need to be applied that just aren’t available on most aftermarket scan tools. Plus, the XENTRY has many guided test steps.

Recalls

There are a number of emissions-related service campaigns and recalls issued regarding the diesel particulate filters and the AdBlue technology. Some go back as far as the days of the Dodge-branded Sprinter vans, so always check for campaigns, bulletins and recalls whenever you encounter a DTC or emissions and drivability complaint. Indeed, in our shop we check every VIN for recalls as standard operating procedure.

For example, service campaign No. P-SC-2012070004 issued August 2012 performs an update for the Selective Catalytic Reduction (SCR) Control Module Software. This affects models 164, X164, 212 and 251 models from Model Years 2009–2011. This service campaign software update addresses fault codes 203C11 and 20BA1A. (The AdBlue fill level sensor has a short circuit to ground, or the output for heating element of AdBlue pressure line has a malfunction.)

There are actually three different SCR updates in just a short time span if you look up these models, so you get the picture. You need to look up the model you are working on and save your customer some hassle if there is a campaign or recall on their vehicle.

You Have Zero Starts Left!

So what happens when the instrument cluster tells your customer there are a limited number—or worse, no starts left? The dashboard readout may also warn you: Check AdBlue. Well, in simplest terms one or more fault codes concerning the AdBlue system are stored in the engine control unit. It is important to understand that there is a distinction made in the fault codes between system fault codes and cause fault codes. The cause fault code must first be rectified in the engine control unit with the guided XENTRY Diagnosis guided test(s) in order to enable the AdBlue system fault code to be erased. This has caused many a technician to pull their hair out trying to clear a code for the system. These system fault codes are always shown together with at least one cause fault code in the engine/SCR control unit. The quick test results must not be erased; otherwise, the information on the cause fault code will be lost.

XENTRY Tips document LI49.20-P-053539 makes this statement: “Important: If an active system error is present, the AdBlue tank doesn’t necessarily need to be filled. Keep in mind you may have to empty the tank for a repair to rectify the cause.” It makes sense to this writer and technician that making sure the tank isn’t empty, however, is prudent before proceeding further. After processing the cause fault(s), the AdBlue fill level should definitely then be checked. If the fill level is correct, then it does not need to be topped up to rectify the fault.

We’re going to address this issue on a 2015 Mercedes-Benz E250 BlueTEC 4MATIC Diesel with engine type OM651.924. This will also apply to any Model 164/166/212/221/251 with engine OM642 and SA code U42 (BlueTEC (SCR) diesel exhaust treatment), Model 166/204/212 with engine OM651 and SA code U42 (BlueTEC (SCR) diesel exhaust treatment) or Model 463 with engine OM642 and SA code MC7 (Engine OM 642 D 30 BlueTEC).

Possible system fault codes include 16D300, 16D400, 16D500, 15EA00, 15EB00, 15EC00, 16CE00, 16CF00, P13DF00, P13E300, P13E400, P13E500 and P13DF09.

These system fault codes are always shown together with at least one cause fault code in the engine/SCR control unit. Once again, remember the quick test must not be erased; otherwise, the information on the cause fault code will be lost. Once all the cause faults have been rectified, the quick test faults can be erased.

The Procedure

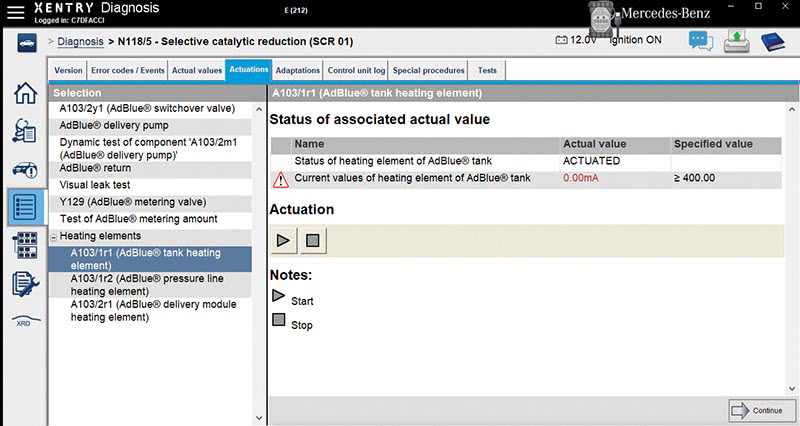

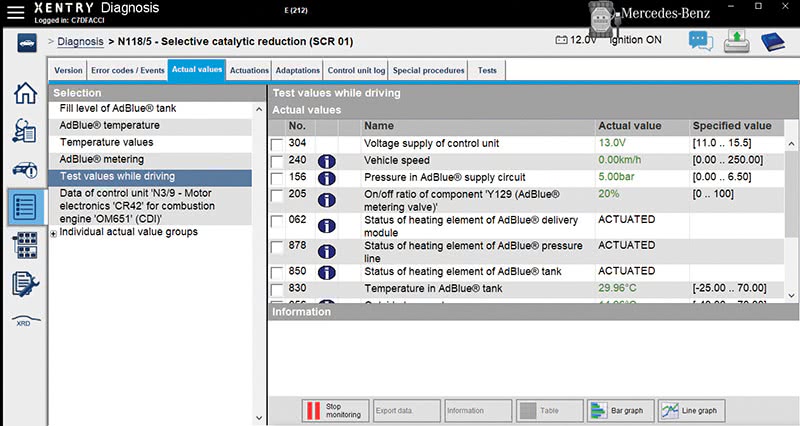

Let’s say in the above vehicle you have scanned the CDI control unit and have a 16D400—the remaining driving distance is limited due to a malfunction in the AdBlue system. A scan of the SCR control unit displays a P20E800 reductant pressure low code. So the system fault is in the AdBlue system and a possible cause is the pressure of the reductant (a fancy name for the DEF). This is where you need a factory-compatible scan tool because you’re going to have to activate some components.

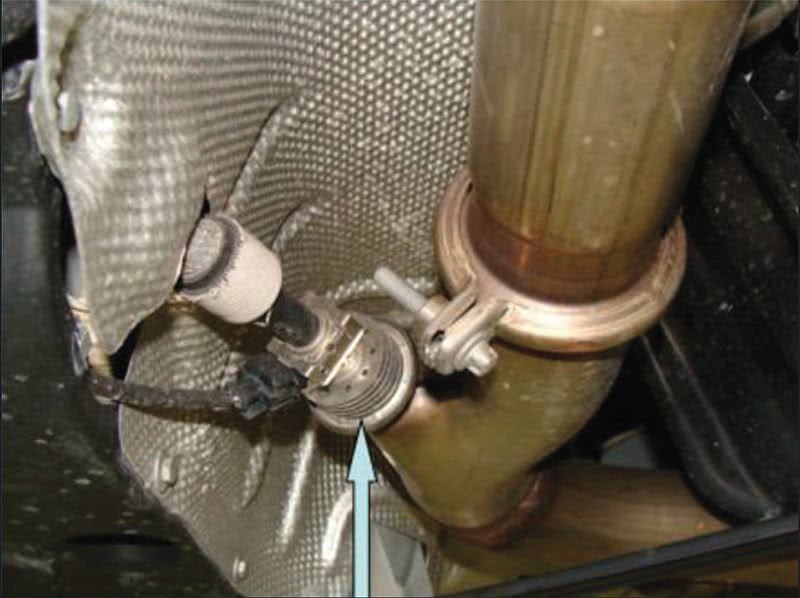

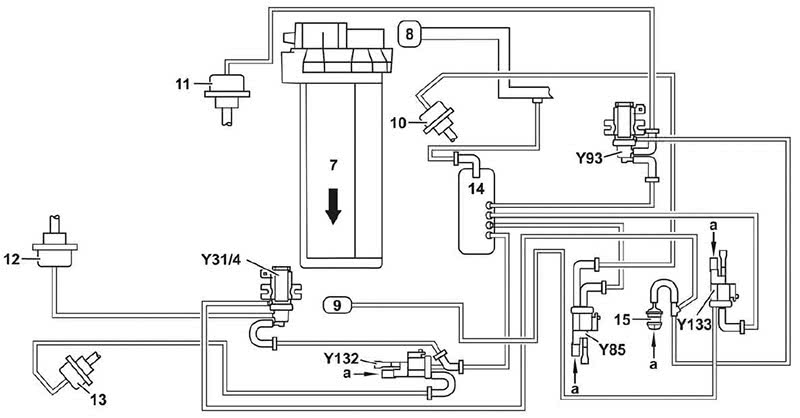

Follow the screen prompts for the test plan. Your scan tool will need to provide an activation test of the DEF pump. While doing this, verify that the pressure sensor data reaches specified values of 5000 hPa or 5000 mBar. If the pump test fails and the AdBlue tank is not empty, your pump may be faulty. If the pump runs yet fails the test there may be a blockage to the pump inlet inside the tank. Remove the injector from the exhaust and run the pump test again. Check for any fluid leaking out of injector, pressure line or pump to line fittings. If your tests prove that the pump has failed then it is a matter of replacing it and following the procedure to reset the system. It should be noted that techs in the field have sometimes gotten air locked in the pump when filling, so be sure use a syringe to fill all the openings and lines with DEF to prime the pump. Also, fill the tank all the way to the filler neck; failure to do this will result in setting the fault code.

Be aware that when the quick test has been erased, the existing system fault code and the combined message “Check AdBlue” or “No start in XXX km” will remain active. To erase the system fault code and the combined message, you will need to proceed as follows:

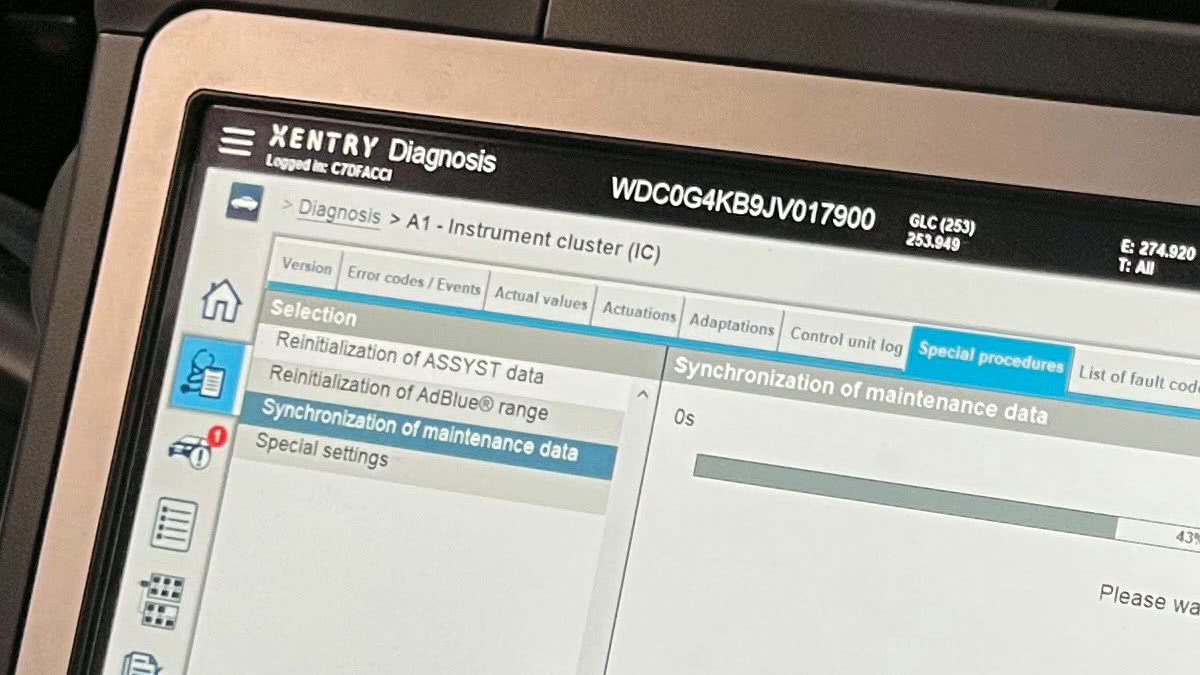

Check that the engine and BlueTEC control unit software is up to date, then proceed with the guided test plan and click on the link “Reset warning message…” If “Completed successfully” is shown, the system fault can be erased and an additional adaptation test drive is no longer required. This particular model we are looking at actually has a service campaign No. P-SC-2012100005 issued November 2012 attached to it that calls for a SCR control unit update. If you can’t perform this update the dealer should provide it for you.

It is only necessary to perform an adaptation test drive to erase the system fault code if the message “Reset not completed successfully” appears.

The adaptation test drive must be performed according to the following criteria:

- Warm up the vehicle for approx. 10 minutes (coolant temperature at least 80°C/176°F, catalytic converter temperature at least 250°C/482°F).

- Drive for 30 min as consistently as possible between 80 km/h (50 mph) and 120 km/h (75 mph) with occasional coasting phases.

Then check whether the fault is set to “stored.” If so, erase the fault; the message in the instrument cluster should disappear.

Diesel Particulate Filters (DPF)

Let’s take a look at one of most critical elements of a diesel emission system—the DPF. In the June 2018 StarTuned article, you can read about its construction and function. Today, we will look at the lifespan, how you tell if it’s restricted and what to do about it. First off, there are dozens of possible codes that can set that might be an indication that your DPF is plugged. You will need to use your brain, scan tool codes and data, and some strategy based diagnostics to narrow down your possibilities.

Why does the filter get restricted? We all know that the filters undergo passive and active regeneration but sometimes it’s just not enough. Restricted diesel particulate filters might be caused by short trip driving at low speeds. Vehicles operating at low speeds on short trips are unable to meet the requirements for the filter to clean itself. Soot and ash are two major byproducts of combustion that have to be cleaned up. Regeneration typically removes most of the soot by converting it to carbon dioxide. Ash, on the other hand, is already a byproduct of combustion, so no amount of heat from the engine can convert it. Over time, the ash will build up to the point where the filter has to be physically cleaned or replaced. More on this later.

Looking at a test case on the same vehicle we addressed earlier we have a customer concern of a lack of power and a DTC, P0299FA (boost pressure of turbocharger 1 is too low). At first glance, we might think the turbocharger is at fault but let’s list some possibilities and eliminate them.

- Air filter or restriction of the air entering the system. Using a visual inspection, check for any blockages of air properly getting to the intake.

- Vacuum leaks. Pull up the vacuum diagram and verify you have proper vacuum at all points. Check all switch over valves and check the waste gate for actuation when applying vacuum. Here you can narrow this field down even more. No vacuum? Possible faulty pump, intake issue or a leaky hose or valve. A smoke machine is handy in this situation. Thoroughly check the integrity of all vacuum hoses.

- Sensors. Possibilities would include boost or air charge sensors, backpressure sensor, etc. A faulty sensor may give the system a bogus reading. With the Key-On/Engine-Off the pressure sensor values should all match.

- Leaks in the charge air system. Pressure test the charge air system with at least 7 psi. Again, a good smoke machine can do this. Verify connections of pipes and make sure there are no leaks.

- Road test while watching sensor data. If no or low boost pressure is produced, then remove the exhaust and charge pipes from the turbo. Inspect both impellers for damage. If you get some pressure but it goes flat on heavy acceleration and you see an increase in the backpressure sensor reading, remove and inspect the exhaust for blockage. Yes, you may have a blocked DPF.

You may ask “wouldn’t the blockage show up with some additional codes?” Maybe a P200200 (the efficiency of the diesel particulate filter—cylinder bank 1—is not sufficient) or P245900 (the soot content of the diesel particulate filter is not OK).

There are several other codes as well that should indicate a problem with a restricted DPF, but in the real world we know this isn’t always the case. Don’t assume anything and follow where the evidence leads.

A blocked or restricted DPF should be replaced. Your Mercedes-Benz parts department carries a line of brand new replacement filters and also takes your old one in exchange. This way the components are recycled and environmentally sound, and safe practices are used. After replacing the DPF you will need to perform the “teach-in process” to complete the repair. As always, be sure the latest software is installed in the vehicle as well.

There are options for cleaning a DPF as well that some techs in the field have reported success with. A solution especially made for the process is sprayed in upstream of the filter by removing a sensor and a purge solution is injected afterwards. There are also some industries that clean DPFs using an ultrasonic cleaning method. The drawback here is you have to remove the part, ship it out and wait for shipment back. Meanwhile, your customer’s car sits on your lot taking up space. It should also be noted that as of this writing cleaning the DPF is not considered a Mercedes-Benz approved repair.

In this article, we’ve offered some practical advice on the care and feeding of BlueTEC models and the associated anti-pollution controls. Diesels will still be around for a while and you should familiarize yourself with all the components of the AdBlue system. These engines are solid and run for a long time, so you will benefit by staying informed on all the technology to be able to service and diagnose, quickly and efficiently, real world problems in your shop.

Very Good information with the cars that have AdBlue Systems. Where can more information be obtained on the pre Adblue cars?

Thanks for your comment, Mark. Are you looking for something specific on pre-AdBlue/BlueTEC vehicles? You can try the search bar at the top of the page or let us know what you’re looking for and we’ll help you find it.