Some European cities are outlawing diesels, but that wouldn’t be happening if they were all as clean as those with this Mercedes-Benz technology.

Most of the cars you see in your shop have gasoline engines, but with Mercedes-Benz you surely see a fair number of diesels, too. Sure, some are old 123s or 210s, probably needing glow plugs or at least an oil change, but Mercedes-Benz has long been a leader in diesel technology as far back as the 260D (W138) in 1936. Since then, quite a bit has changed: Instant-heat glow plugs, electronic fuel injection, and low-sulfur fuel. But the biggest change has been the treatment of diesel exhaust emissions.

Back in the Model 124 E-Class era, the Trap Oxidizer was introduced in an effort to cut down on diesel particulate matter, that black diesel smoke said to be harmful when inhaled. More recently, better Diesel Particulate Filters (DPFs), Selective Catalytic Reduction (SCR) catalysts, and Diesel Exhaust Fluid (DEF) have been introduced to keep diesels in compliance with emissions regulations.

Dry System

We’ll start with the so-called Dry System, which was introduced in the mid 2000s. This system does not use AdBlue® Diesel Exhaust Fluid (DEF), and has been proven to be extraordinarily reliable: For this reason, and because it was only installed for a limited time, we’ll only cover it briefly.

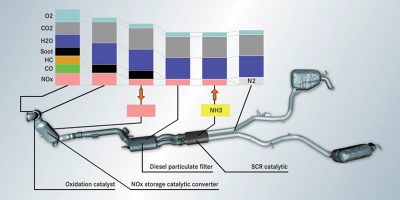

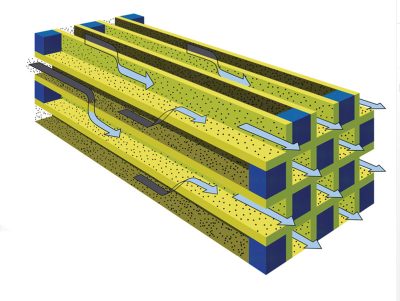

The dry system uses several exhaust components to manage the exhaust stream, and it operates in two phases. In the first, the so-called Lean Phase, unburned hydrocarbons and carbon monoxide are converted to carbon dioxide and water in an oxidation catalyst. The exhaust stream then flows through a nitrogen oxides storage catalytic converter, which, as its name implies, stores oxides of nitrogen (NOx) for later use in the second phase. This stores about 80% of the NOx passing through it.

Diesel particulate matter, or soot, is trapped in the Diesel Particulate Filter (DPF). Similar in function to those old Trap Oxidizers, they literally filter the ultra-fine soot particles from the exhaust stream. A differential pressure sensor compares the inlet and outlet exhaust pressures, and once the differential pressure gets too high, a Regeneration Phase is started, which burns off the soot, cleaning the filter.

Regeneration occurs by increasing the exhaust temperature, which can be done by post-injection and/or Exhaust Gas Recirculation with intake air throttling. A temperature sensor monitors the exhaust gas temperature. In the case of short trips, the regeneration might happen over several driving cycles. In any case, regeneration is not noticed by the driver.

The rest of the NOx is converted by the Selective Catalytic Reduction (SCR) catalyst, using the ammonia (NH3) that is stored within it, into Nitrogen and water. Note that about 78% of the Earth’s atmosphere is Nitrogen, which is not generally recognized as a pollutant. This means the exhaust stream has been converted into Nitrogen, water, Carbon Dioxide (CO2), and Oxygen.

But where did that stored ammonia come from, and what happens when it gets depleted? Good question, and that’s where Phase 2 of the dry BlueTEC system comes in.

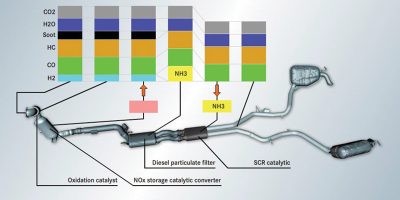

In this Rich Phase, the engine continues to operate with a lean mixture as before, but additional fuel is injected into the cylinder just before the exhaust valve closes. It simply burns, but without adding to the engine’s output energy. Any excess oxygen that was in the exhaust gas is consumed by this extra fuel, also increasing the percentage of unburned hydrocarbons. The relative share of NOx is significantly reduced in the exhaust stream, which still contains water as before.

Since there is no free oxygen, the oxidation catalyst has essentially no effect. The NOx storage catalyst releases NOx into the exhaust stream, which reacts with the water and forms ammonia, NH3. This passes through the DPF and refills the SCR catalyst, allowing the cycle to repeat. The dry system, by definition, does not use external materials such as AdBlue diesel exhaust fluid (DEF), leaving the engine management system to control the entire process.

While these dry systems have been found to be quite trouble-free, when something goes wrong it is most likely to be a sensor that has failed. A distant second is system wiring damage, followed even further by exhaust system failures. In the case of a sensor, it nearly always shows us as a DTC (Diagnostic Trouble Code) easily found using XENTRY, or a generic scan tool.

The regeneration times and intervals are dependent on temperature, and significantly decrease as exhaust temperature rises. The DPF regeneration occurs based on differential pressure, about once every 600 miles, and takes about 10 to 20 minutes to complete. The NOx regeneration happens about every two miles, and takes only a few seconds. Neither would be noticed by the driver.

Wet System

The BlueTEC ‘wet’ system, also known as BlueTEC II, is what is installed in current production models, as well as Sprinter vans. Just about every on-road Mercedes-Benz diesel vehicle built for the past several years has this system.

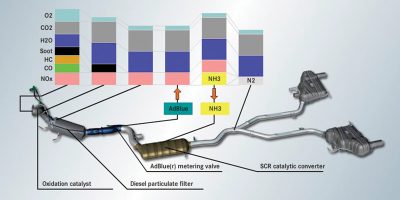

Although the dry system’s method of getting some ammonia for the catalytic reaction is brilliant, it’s not as effective as demanded by environmental regulations. To counter this ‘deficiency, the wet system gets its ammonia by injecting precise quantities of AdBlue® Diesel Exhaust Fluid (DEF) into the exhaust system. (Note: AdBlue® is the brand of DEF recommended by Mercedes-Benz, but other quality DEF may also be used). As with the dry system, the first stage is an oxidation catalytic converter mounted near the engine, and in the wet system it performs the same exact task as in the dry system. There is also a Diesel Particulate Filter, again for the same purpose as in the dry system. Further, the wet system also uses an SCR catalytic converter almost identical to the one in a dry system.

The NOx storage catalyst is not needed since we get ammonia from the DEF. Downstream of the Diesel Particulate Filter is the AdBlue Metering valve. This looks and functions a lot like a fuel injector, spraying a precise mist of DEF into the exhaust stream. This is not continuous, but intermittent, since any excess ammonia from each spritz gets stored in the SCR catalytic converter and used just moments later. A mixing plate, which helps the injected AdBlue distribute evenly and completely in the exhaust gases, is located inside the exhaust pipe, just downstream of the metering valve.

Let’s start with a look at the chemistry of the Diesel Exhaust Fluid. AdBlue is a solution of urea [(NH2)2CO], meaning it has two NH2 molecules (a compound known as amidogen) joined together by one carbon and one oxygen atom. This can be converted into ammonia (NH3) in either of two ways, known as thermolysis (heat-activated chemical reaction) and hydrolysis (water-activated chemical reaction). These chemical reactions cause the atoms and molecules to recombine into either ammonia plus HNCO (via thermolysis) or ammonia plus CO2. While it seems a little complicated, the bottom line is that you don’t really need to know the chemistry to believe that the system actually works.

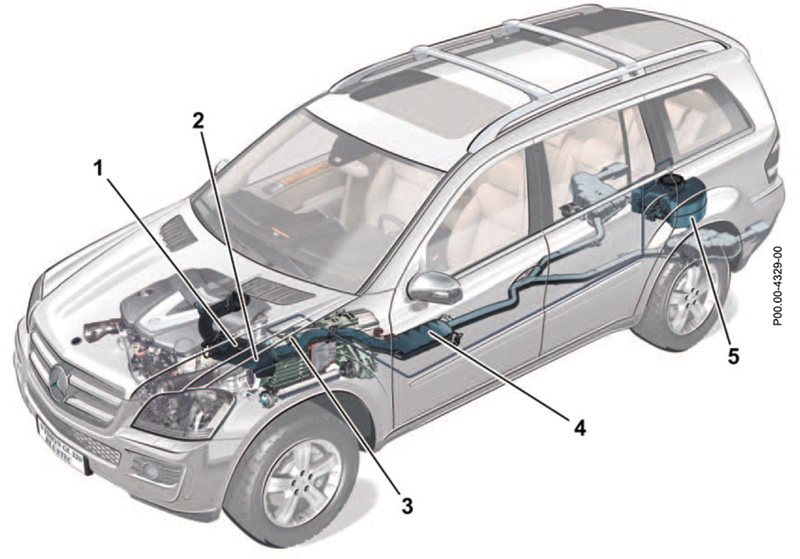

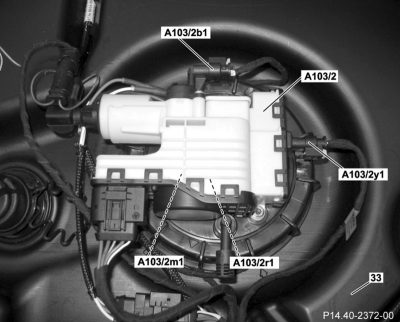

We are going to describe the system as it was in Model Year 2009, when the system was introduced in the 164 and 251 diesel models. Since then, some of the components have changed slightly, but the overall function of the system remains the same even today.

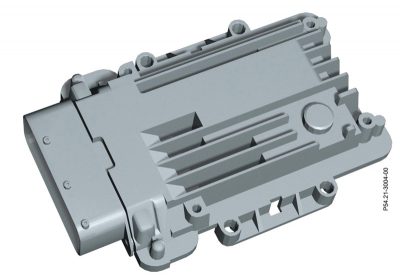

Although the CDI module has the controlling role in the injection and regeneration cycles, the AdBlue control unit is responsible for handling the AdBlue fluid itself. This includes the actual AdBlue feed and injection, as well as the anti-freeze function (AdBlue DEF freezes at about 10 deg. F.) and the return flow function: AdBlue can be damaged by excessive heat, so after every squirt, the pump is reversed briefly to keep the AdBlue in the injector and the pressure line away from exhaust system heat. Also, any AdBlue left in the lines at engine stop must be returned to the tank, otherwise it could freeze.

The AdBlue metering valve is operated via a Pulse-Width Modulation (PWM) signal from the AdBlue control unit. During pressure buildup, when the pump just starts pumping, the value is held open to let any air out of the lines. After the dose of AdBlue is delivered into the exhaust, the valve is again held open briefly during the return flow process to allow the fluid to be pumped back towards the tank. The duration of the reverse pumping action is determined by the CDI control module, based on the exhaust gas temperature as read by the exhaust temperature sensor. The PWM signal allows the valve to deliver varying amounts of AdBlue according to need.

The AdBlue pump operates at a nominal pressure of about 5 bar, which can be adjusted by the AdBlue control module’s software. At startup, the pump’s current draw is monitored for system diagnosis, setting a DTC for too much or not enough current. If the nominal 5 bar pressure is not reached, as determined by the pressure sensor, a DTC is stored in the CDI control unit fault memory. You’ll find the pump, along with the pressure sensor and one of three heaters, attached to the AdBlue tank at the service cover.

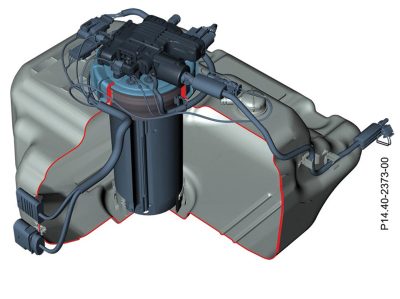

The pump must always be fed sufficient liquid to avoid drawing in air, so a second “removal” tank within the main tank is used. It is always kept completely full, by means of a bypass in the delivery module, to avoid all air. It is from the removal tank that all AdBlue is pumped.

The delivery module is heated, as are the tank and the pressure line. The three heaters are controlled by the AdBlue control module. The heaters are enabled at temperatures below about 14 deg. F.

The AdBlue tank is made of plastic, and has temperature and fill level sensors as well as a heating element. The tank is designed such that frozen AdBlue – which can occur if the vehicle is parked outdoors during cold weather – will not cause damage to the tank. The temperature sensor is of the NTC type, which means its resistance decreases with increasing temperature. The fill level sensor is actually three sensors: Full, Reserve Level, and Empty. These are simple electrodes that, when in contact with the AdBlue liquid, show a different resistance between them than when dry (i.e., not immersed in the AdBlue).

Workshop Tips

In practical terms, the chemistry of the system might not seem important, but an understanding does help when repairs are needed by helping narrow down which sensor must be at fault. We’ve written about diagnosis before, but as a refresher: If you really know how the system and each component operates, and truly know all the symptoms, then by careful thought a professional technician can use logic to determine the cause for a fault, and test to verify that conclusion. Of course, the CDI system’s DTCs will help narrow things down as well.

So, on to some practical tips. First, if for any reason you empty the AdBlue tank – replacing it, for example – it is critical that the removal tank is completely filled before allowing the system to operate. Otherwise, air can be drawn into the system and the nominal 5 bar pressure won’t be reached. The main tank must be completely filled before the removal tank is filled via the bypass in the delivery module. Be sure to read the WIS work instructions for this job to get it right.

If your customer needs a refill of AdBlue, normally you can just put more into the tank and be good to go. However, all DEF degrades with heat and time, which can be recognized by a strong odor of ammonia. Mercedes-Benz recommends that the DEF tank be emptied completely every two years, and refilled with fresh fluid. Of course, a small amount can’t be drawn out, but this shouldn’t matter.

When handling DEF, read the label and follow all warnings. Use gloves and eye protection without question, but also use shop cloths and other protection to ensure that even tiny splashes of DEF are kept off the vehicle and its components, particularly interior finishes. When AdBlue dries, it crystallizes, forming a white crusty residue that is difficult to remove from soft surfaces such as carpeting. Newer models have the AdBlue filler located outside the vehicle, next to the fuel tank filler opening, while some older models have the DEF filler under a cover in the cargo area.

If your customer admits to having put anything other than DEF into the filler, it is important that the vehicle not be driven. The AdBlue tank needs to be completely emptied of the contaminated fluid by removing it from the vehicle. As we mentioned, follow the WIS instructions for the initial fill of a completely empty tank.

We’ve found that some owners only use their vehicles for short trips, and the exhaust system doesn’t have enough time to get hot enough to regenerate the Diesel Particulate Filter. This is especially noticed in Sprinter vans because of the typical usage patterns of tradesmen. To regenerate the DPF, a decent highway run will go a long way.

If the DPF cannot regenerate properly, excessive soot can bypass it and cause damage to the SCR catalyst. One rule-of-thumb for diagnosis is to examine the tail pipe. If you can wipe with your finger enough soot to actually create a small cake or ball of material, it is likely the SCR catalyst is also affected. A light coating of black soot, which doesn’t form a “chunk,” but merely dirties your finger, means the SCR catalyst is likely okay. Get the DPF to regenerate and advise your customer to make sure every few hundred miles the vehicle gets a half-hour on the highway.

The BlueTEC wet system is now just about 10 years old, and considered a mature technology. The diagnostic routines in XENTRY and the repair instructions in WIS are pretty solid. It’s not a terribly complex system, but the occasional repair and, of course, regular maintenance will keep your customers stopping in from time to time. Armed with an understanding of not only the chemistry, but also the sensors and phases of operation will go a long way toward making each time you touch the system both agreeable and profitable.

0 Comments