Some people consider the vacuum gauge a lowly instrument that might have been part of a DYI tune-up kit decades ago. Think about it for a minute, though, and you’ll realize how basic and important the info it gives you really is.

Torque Benders, Part 2: Detailed Procedures

Last time, we discussed the basic design, failures, and what it takes to freshen up a differential. Here, we’re going to get deeply hands-on.

Don’t Play with Fire

There’s no such thing as a “minor fire†at an auto service shop. Beyond the obvious loss of...

Round and Round? Nascar Events Never Moved Me

Then, many years ago, Monroe introduced its Reflex shock to the press at Atlanta Raceway…

McConiga’s Axioms: They Aren’t My Clowns and This Isn’t My Circus

I don’t know about you, but I’m fed up with political correctness, partial truths, and our...

Flat Tappet Oils & Additives

In spite of the wholesale O.E. switch to roller lifters that started a couple of decades ago, if you’ve got a vintage rod chances are it has flat tappets, and maybe you don’t want to go to the trouble and expense to retrofit to rollers. Plus, some racing venues only allow flat tappets. These operate at higher temperature and pressure levels at the lobe/lifter interface than rollers do, so require greater wear protection. The primary anti-wear additive for flat tappet camshafts and lifters is ZDDP (zinc dialkyl dithiophosphate), but that’s been phased out of ordinary motor oils mostly because of fears that it’ll foul the cat. Racing oil and additives provide zinc in adequate quantity to provide the protection you need to prevent catastrophic lobe and lifter wear.

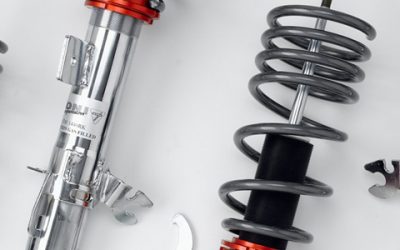

Handling the Change, or Changing the Handling, Part 3: Suspension Upgrade

In the past two installments we discussed how the dimensions of a car and its overall weight distribution can affect cornering and handling. Let’s see how we can utilize this information and begin to upgrade the suspension.

Protecting Your Eyes and Hearing

Protecting your eyes and hearing is your responsibility. It’s easy to do, but many technicians do not make the effort to protect themselves. Change that habit!

CC Rider, Part 2: Step-by-Step

Last time, Greg explained static and dynamic compression, the factors that determine them, and how to calculate what you’re going to get. Now, he gives us the proper procedures for measurement.

Starting Line: (What’s) Under The Hood

You may have noticed that HOT ROD Professional has morphed into Performance Technician. What does that mean? Initially, it means a renewed commitment to a wider variety of performance-related topics of interest to you, our tech-savvy readers.