by John Anello

I was called in to a shop to program an electronic throttle body on a 2003 Nissan 350ZX (Figure 1) after some mechanical repairs were performed on the vehicle. This is a common practice in the field whenever an electronic throttle body is cleaned or replaced, or the battery has been disconnected too long. The PCM loses the throttle plate learned position and it must be relearned using a manual procedure, or requires the use of a factory scan tool. When the ignition key is turned on, the PCM will usually force the throttle plate closed to check for full throttle stop, and then open the throttle slightly to make sure it is not binding. These checks are usually performed by the PCM using two sensors within the throttle motor assembly. If the motor is not working and the PCM cannot achieve a predetermined throttle position, then the PCM will set a trouble code and put the vehicle in failsafe mode with very limited throttle response when the driver goes to accelerate. If the throttle motor is working and the TPS sensors check okay, don’t be too quick to condemn a throttle unit with throttle error codes stored before performing a throttle relearn procedure.

The shop was hired to remove the automatic transmission from this vehicle and replace it with a standard transmission from a salvage vehicle. This was not easy on today’s cars because for every alteration there is a cascading effect that requires a lot of careful thought with many more changes to follow. The flywheel needed to be replaced so it could accommodate a clutch assembly. The entire engine harness, dash harness and PCM were also replaced from the salvage vehicle (Figure 2) to accommodate the different components and wiring used for manual transmission operation. The salvage PCM was the same year application, but would not start the vehicle because the PCM was locked out due to the onboard immobilizer system not recognizing it as the original PCM from the car. This particular vehicle used immobilizor keys that were paired to the BCM and the BCM was paired to the PCM. The shop had to install the BCM, ignition lock cylinder and the immobilizer keys from the salvage car to get this vehicle to run.

This was one major operation that the installer deserves credit. I just ask one question: Why? If it were me, I would have opted to sell the car and buy another one with a manual transmission. I guess it’s all about the challenges a vehicle can present.

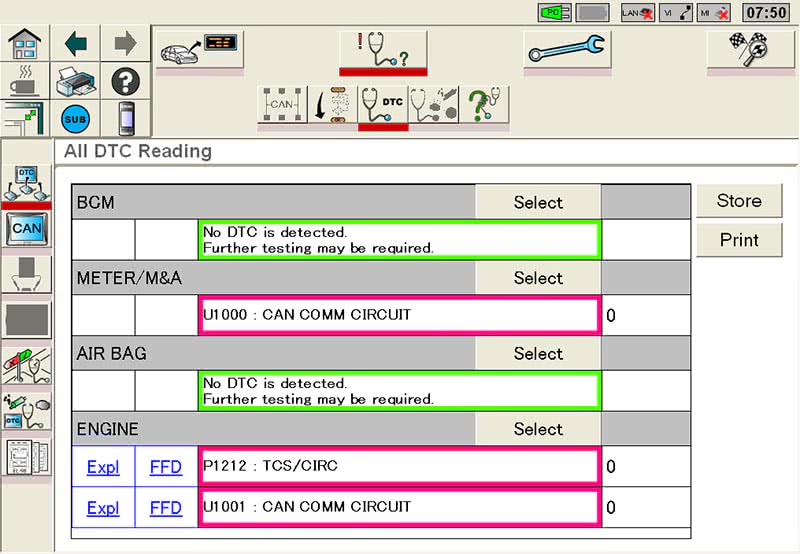

When I arrived at the shop, the engine started and ran, but would not throttle up properly. There was also a check engine light (MIL) on. I hooked up my Nissan Consult III scan tool and pulled codes from the entire vehicle (Figure 3). The PCM stored codes P1212 (TCS circuit fault) and U1001 (CAN communication circuit). These codes were related to the ABS unit missing off the network, but there were no codes related to the throttle control unit. This vehicle had a working throttle, but it just had no power on acceleration. Whenever I get a no-power complaint without a misfire, I steer myself in the direction of checking for lean operation, clogged exhaust, or ignition/valve timing issues. Most of my no-power complaints fall into these categories.

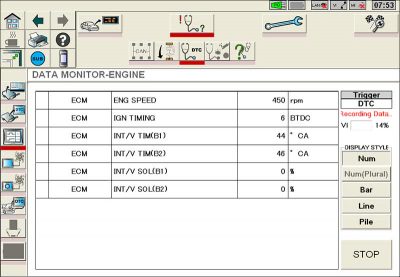

It was simple enough for me to look at scan data just to see if the valve timing was an issue. This engine has variable cam timing and uses two cam sensors to calculate the movement of the cam gear actuators on each bank. With the variable timing solenoid commands off, the cam gear positions should be near zero degrees. When I viewed the data (Figure 4), I could see that at idle each cam gear was off by at least 45 degrees. I then asked the shop if maybe the timing chain had not jumped and if he checked it. He told me that the engine ran perfect before the transmission was put in. I knew that the PCM had to index its readings off the flywheel to determine banked cam timing, so I made the suggestion that the shop pull the transmission so that we could check the flywheel together.

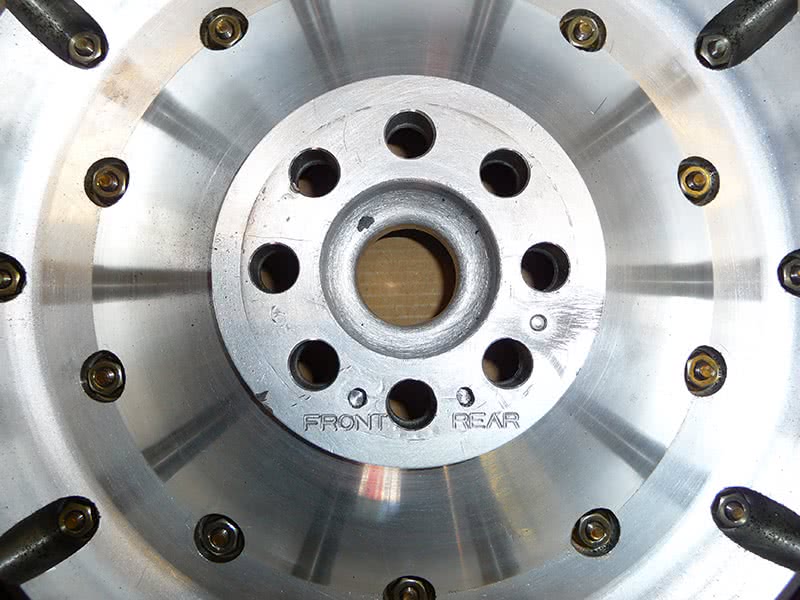

I came back to the shop the next day and the transmission had been removed from the vehicle. I looked at the flywheel that had been installed (Figure 5) and I stood there wondering how it could ever have been installed correctly. It was not a factory flywheel, but one purchased through the aftermarket. There was no dowel hole visible from the front. I removed the flywheel to inspect where the dowel actually was located on the end of the crankshaft (Figure 6). I carefully did not lose the position the shop had installed the flywheel in, and flipped the flywheel over (Figure 7). You could probably play Russian roulette and install this flywheel in eight different positions, but the maker of this flywheel must have included installation instructions. You know, the kind of instructions you throw out because you feel you can wing anything without them. We have all been here before.

If you look real close (Figure 8), you can see that there are three indentations in the flywheel. One was marked FRONT, another was REAR, but the third was created by the shop when they forced the flywheel in place using the impact gun. Oh yes, the almighty power of the impact gun. By comparing the crank trigger wheel on the back of the original flywheel (Figure 9) to the aftermarket flywheel, I was able to determine that the dowel should have been placed inside the indentation marked REAR. By doing the math on a 360 degree roulette wheel, each hole-to-hole position represented 45 degrees. The shop was one complete hole off, or 45 degrees, thus giving me the 45 degree deviation of cam gear position as seen on the scan tool.

This was an error that can happen to any tech during an installation process. It is so important to not ignore those installation papers you find in the box. They are there for a reason — so a job can run smoothly. We are in a fast-paced world, and I will admit that I move very fast during the course of handling close to 10 cars a day, but I still use caution and safety during each job I encounter because we can’t get paid to unravel the mistakes we make. It only becomes a learning experience not to do it again. My only hope is that this one will touch home with one of you techs out there who decides to do a clutch job on one of these Nissans.

0 Comments