Diagnosis, service, repairs, tips and tricks from the world of the independent Volvo shop.

This will be part 1 of a series of articles that will cover volvo brake systems from basic service to advanced traction control diagnostics.

Brakes, yes brakes, every technician’s favorite job! Well, most technicians like to do them. It’s an easy job, there’s not much chance for problems and when you’re done, you and the customer can see and feel a real difference.

Most technicians have done more brake jobs than they can count. Doing brake jobs every day becomes so second nature that it’s easy to forget the true importance of these systems and why it’s critical to do brake repairs the right way every time.

It is important that your shop has an inspection procedure for every car that includes a complete brake inspection, because next to the tires, the brakes are the most important safety system on the car.

Most of your customers won’t notice when their Volvo is experiencing brake symptoms like pedal fade or brake pulsation until these symptoms become too pronounced to ignore. And in most cases when customers bring their cars in to have the brakes checked, it’s because they hear a noise or squeak when they apply the brakes.

The service writer needs to get as much information about the symptoms as possible. Sometimes they will have to ask leading questions, like “do the brakes only squeak when the car is turning?†or “at what speed do you feel the vibration and did the ABS light come on?â€

Taking some extra time to interview the customer and asking the right questions will help you to more accurately diagnose and repair your customer’s Volvo the right way the first time.

If it’s possible, take a test drive in the car with the customer, to make sure you are addressing the noise

or symptom that the customer is describing.

Since most noises develop slowly over time, most of your customers tune them out or think the noises are normal. In fact, most of your customers will only notice when there are dramatic changes in their car’s behavior.

That’s where we come in. If you’re like most technicians, you will hear multiple noises, clunks and rattles on a routine test drive, most of which the customer probably has tuned out or thinks are normal.

If you can manage your customers’ expectations by educating them about how their brake systems work and about the testing and repair process, it will go a long way towards avoiding confusion and comebacks due to lack of communication.

Make sure you can duplicate the customer’s complaints. If you cannot duplicate the symptoms and you don’t see any obvious problems with the brakes, you need to explain to the customer that, without a symptom, you can only make an educated guess.

BRAKE INSPECTIONS

Most of the Volvos that come into independent shops tend to be at least 5 years old or older with at least 30K miles on them. And in a lot of states that don’t use salt on the roads for snow removal, shops often see Volvos that are much older and may have well over 100K miles on them.

When test driving for brake problems, “around the block†just won’t get it. Volvo’s definition of a brake system test drive should include “normal†driving, with multiple stops at different speeds and, whenever possible, a freeway test drive with speeds above 50 mph with light and hard braking.

At least one braking should activate ABS control from a speed of above 50 km/h (31 mph). Make a note of any unusual noise or abnormal behavior. Listen particularly for clicks or bangs, see if the car pulls to one side or if the brake pedal does not seem to be responding properly.

If you experience brake pedal pulsation, don’t automatically assume that warped brake rotors are the cause. Yes, in a lot of cases the rotors turn out to be the cause of pulsations, but testing should always be done to ensure that you replace the right parts the first time.

Make sure to measure the rotor runout with a dial indicator. You should start by removing all four wheels and making sure that the rotors are pressed flush against the wheel bearing hubs. On Volvos, the maximum allowable lateral runout of the hub should not exceed 0.02 mm. You should also check the wheel hub’s lateral runout before installing new brake discs. Although rare on Volvos, the bearing hub could be bent from a serious pot hole encounter or a past accident.

NOISE FROM REAR BRAKES?Â

Under certain conditions while driving in reverse and applying the brakes, a groaning noise may be heard from the new rear brakes. A rear brake pad and a grease retainer are available as a service solution, should it be determined that this is the cause. Here is the repair procedure:

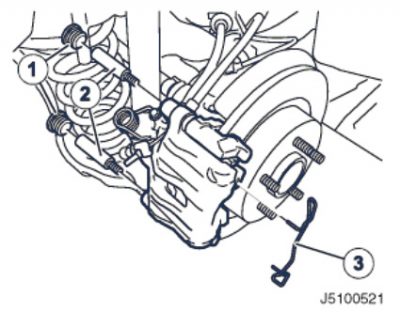

- Remove the spring (3).

- Next remove the protective caps (1).

- Next remove the caliper pins (2) with a 7mm hex socket.

- Use a bungee cord or wire to hang brake caliper so the brake hose won’t get damaged.

- Remove the old brake pads

Note! Do not depress the brake pedal while the brake pads are removed. - Clean the brake caliper 2.

- Clean and check the brake caliper and the dust cover.

- Clean and check the brake pad mating surfaces in the brake caliper and caliper holder.

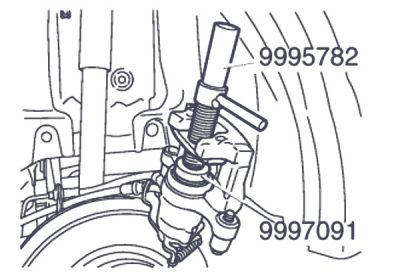

- Press the piston back into the cylinder on the brake caliper. Use: The press tool 9995782 with the Key 9997091.

- Check that the dust boot is correctly positioned.

- Install the new brake pads.

Note! The brake pad with the spring must be placed against the brake caliper piston.

INSTALL:

- The brake caliper.

- The locating pins (2). Tighten to 30 Nm (22 ft lbs).

- Lubricate the locating pins using silicone grease.

Note! Check the rubber sleeves of the locating pins. Replace if necessary.

INSTALL:

- The protective caps (1).

Check those brake hoses!

As Volvos age and clock all those miles on the odometer, the original parts will begin to wear and deteriorate. This is especially true of rubber and plastic parts, like the hydraulic brake hoses, and you will often see older Volvos with high mileage come into your shop with the original brake hoses on them.

The brake hoses on older Volvos with high mileage can start to develop cracks, usually at the pivot point where the hoses move and flex the most during normal driving and turning.

In some cases the brake hoses can develop bumps or bubbles on the outer skin of the hose. This is a serious condition! The bumps indicate that the inner part of the brake hose has ruptured and is bleeding brake fluid into the outer hose wall. You will usually only see this condition on Volvo 240/740/940 (1978-94) models.

If you get a Volvo or any other car in your shop with brake hoses that have this type of rupture, you should insist that the customer have all the soft brake hoses on the car replaced along with a full brake fluid flush. Although it is rare on Volvos, some shops have had cars towed in with one of the brake hoses ruptured

and leaking.

This is most commonly seen on the first generation of the S/V 40 series Volvos (1999-2004). When checking these brake hoses, be sure to pull back the spring that protects the top of the hose.

Don’t go cheap on these brake hoses or any other brake parts, it’s just not worth the risks. Use only genuine Volvo parts from your local dealership’s parts department

BRAKE FLUID

Check your customers’ brake fluid on every inspection; brake fluid is often overlooked. Since brake fluid is hygroscopic (water absorbing), it can absorb moisture from the atmosphere under normal humidity conditions.

Don’t judge the fluid just by its color. Use an electronic fluid tester to measure the moisture content of the fluid in the master cylinder. If the fluid has more than 2 percent water content, you should recommend replacement.

Of course if the brake fluid looks like muddy bilge water from a cargo ship, the entire brake system probably needs to be flushed out too. Volvo recommends brake fluid replacement every 20K miles or every 2 years. All Volvo models use only DOT 4 brake fluid.

BRAKE ROTORS

When you work on a lot of Volvos you will start to see a pattern, and not just the one scored into the rotors. The pattern is that most Volvos use up their brake discs as they wear down their pads, especially in city stop and go driving.

When you measure the rotor thickness, a lot of times the rotor will be very close to the minimum thickness, and if you machine the rotors you may still be barely above or at the discard limit. But you’re probably going to have a comeback due to warpage in a few months after the brake job is performed.

A lot of independent Volvo shops and dealerships never turn rotors. In some rare cases, mostly on older Volvos like 240s and 740s, you can just replace the brake pad set and reuse the rotors, if they are still within specifications and have less than 0.02 mm runout. But if the Volvo is driven mostly in city traffic, in most cases you’re better off replacing the rotors on every Volvo brake job, especially on the XC70 and XC90.

VOLVO TECH TIP FOR BRAKE ROTORS

When you want to order new brake rotors for some later model Volvos, you will need to measure the old brake disc, because a lot of models will have 3 rotor size options available, and the size that was installed from the factory can’t be determined by the VIN. So do yourself a favor, get a tape measure that can measure in millimeters, so you can get the right parts the first time.

COMMON VOLVO BRAKE ISSUES AND REPAIRS

ABS CONTROL UNIT FAILURE (850S/V 70 1996-2000)Â

Most of these early Volvos have had their ABS control unit replaced at least once, but you will still see the occasional car come with a malfunctioning control unit.

Most of the early versions failed because of poor solder joints on the circuit board where the connector pins are attached. The replacement ABS units have had this defect corrected, but there are a lot of Volvos out there that have used or rebuilt units in them. These are the ones that you will see more recent failures on.

REPLACEMENT REAR BRAKE PAD SHIMS FOR LOW SPEED BRAKING VIBRATION AND NOISE (850-S/V 70 1993-2000)

If you have ever had the joy of feeling that these shims are the fix for the symptom, you probably did not believe that a modified shim could fix such a heavy vibration and noise resonance. The symptom usually only happens after repeated braking at very low speeds, 10 mph and below.

When you replace the rear brake pads on these cars make sure you use the updated shims (Part #272272). Â

BRAKE VACUUM PUMP FAILURE

If you get a Volvo in that feels like the brake booster is bad because the pedal is hard and has very little vacuum assist, don’t just throw a brake booster at it. Check to see if it is equipped with a brake vacuum pump. These pumps can fail without warning and not store any codes in the BCM. You can test the pump by applying power and ground on the bench or activating it with your scan tool or VIDA.

When the vacuum pumps malfunction, the symptom is felt more after a cold start. Also if the vacuum pump has failed on a P1 Volvo, there is an updated overload relay and wire harness that needs to be installed with the new pump (this is covered in Volvo TJ 20293).

Volvos can be sensitive to the quality of their brake parts; a lot of brake noise complaints have been attributed to the customer’s having someone install cheap aftermarket brake pads or missing brake hardware. If you want a happy customer and no comebacks, only install OE Volvo brake parts; you won’t be sorry you did.

Some technicians say, “What’s the difference as long as I use a ‘good quality’ brake pad set?†Well here’s one difference you may not have thought about.

Volvo performs many months of performance and safety testing on all of their parts while they’re installed on the cars they were designed for, at Volvo’s $81 million safety center that happens to be the most technologically advanced crash-test facility in the world.

Most aftermarket brake manufacturers test their version or “copy†of the brake parts on a bench mounted brake testing machine in their factories.

VOLVO TJs

Read those Technical Journals!!!! Volvo has issued multiple TJs about brake systems on almost every model they make, so take some time and read them; the time spent will always pay off.

Download PDF

0 Comments