The Supplemental Restraint System (SRS) for Volvo started with the 1987 Volvo. This system consisted of some with dual air bags and a crash sensor.

The Supplemental Restraint System (SRS) for Volvo started with the 1987 Volvo. This system consisted of some with dual air bags, on both driver’s and passenger’s sides, and some with just a single driver’s side air bag. The system had a crash sensor and, if enough force was experienced, the air bag would deploy and the occupant would be secured for their safety. An air bag is an inflatable cushion designed to protect occupants from serious injuries.

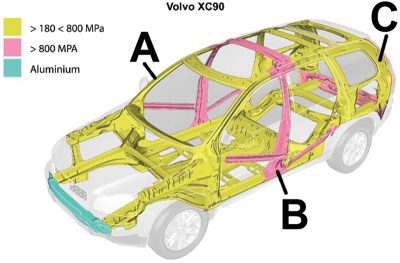

The crash sensors or collision sensors were located near the front and rear bumpers. These sensors would send a signal at impact to deploy the air bags. Through the years more collision sensors were installed for better safety, eventually being located in the front and rear bumper area and on both sides B and C pillars.

Volvo worked with air bags and seat belts through the years to make the safest vehicle on the road. The three point seat belt was one of Volvo’s innovations and they wanted to use both seat belts and air bag systems to help reduce fatalities in the world. At first people thought that air bags would take the place of seat belts, but Volvo wanted to use both seat belts and air bags to make the vehicle even more safe. Not wearing a seat belt is like believing it’ll never happen to me. Volvo believes no child should sit in the front seat. Children should be in the back seat with a booster seat secured properly.

Getting the air bag to deploy at the right time was the challenge early on. The first air bag technology started with many drawbacks including the use of pyrotechnical charges to inflate the air bag and the nature of the gas that would inflate the air bag. Another concern was the choice of material that would be used for the bag itself. Many aspects would be analyzed and tested many times.

All of this evolved into technology in which a quantity of non-toxic nitrogen gas is produced, filling the air bag in a few hundredths of a second. Woven nylon is the material commonly used for the air bags.

By the 1990s air bags were standard equipment in the 850 and soon Volvo would introduce a side impact protection system. This system would help in protecting the passenger from a side impact.

The control module for the air bag system was located under the seat in the early years and moved to the center console behind the parking brake in 1993 with the Volvo 850.

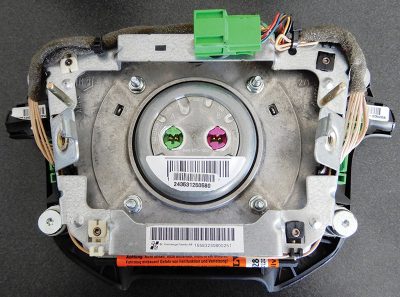

The air bag module is designed to inflate extremely rapidly then quickly deflate during impact. It consists of the air bag cushion, a flexible fabric bag, inflation module, and impact sensor. The purpose of the air bag is to provide the occupants a soft cushioning and restraint during a crash to prevent or reduce injuries between the occupant and the interior of the vehicle.

The air bag provides an energy absorbing surface between the vehicle’s occupants and the steering wheel, instrument panel, as well as A-B-C-pillars, headliner, and windshield.

Volvo soon developed the IC Inflatable Curtain. The Inflatable Curtain would help protect against head injuries for both passengers front and back in case of a side impact. The system was introduced in the 1999 S80 Volvo. Volvo would be the first to introduce the inflatable curtain and many vehicle manufacturers would follow in their steps for safety.

The Volvo convertible in 1998 would have the curtain inside the door, and the curtain would deploy upward and stay deployed for safety in case of roll over. Through the years the curtain would be refined, making it longer to protect children in the rear seat. This application was in the Volvo V70 and XC70.

A new generation of air bags would follow and were known as smart bags and would add another level of safety. They would sense body weight, impact speed, and impact angle. These bags could sense the impact force and step down the force of the air bag deployment, reducing the risk to its cargo.

Components and their function in today’s Volvos

The wiring for the SRS system is orange and should never under any circumstances be checked with ohmmeters or any live measuring tool due to possible accidental deployment.

The SRS warning light should light up when ignition is in the number 2 position, and after start-up should go out within ten seconds. If it stays lit there is an issue with the system and should be diagnosed properly. If the light doesn’t come on with the key in number 2 position the bulb is faulty or there is a wiring issue.

When removing air bags for storage always place the air bag metal side down or rear side down. This will help prevent the air bag from “popping up†in the event of an accidental deployment.

Air bags have three main parts: the air bag, the inflator, and the propellant. The air bag is made up of a woven nylon fabric and has different shapes and sizes. There is a heat shield coating to protect the fabric from scorching. Talcum powder is used to coat the air bag so the fabric doesn’t stick together.

The inflator canister is made from stainless steel or cast aluminum. Inside the canister is a steel wire mesh with ceramic material sandwiched in between. When assembled, the inflator assembly is surrounded by metal foil to maintain a seal that prevents propellant contamination. The propellant is in the form of black pellets and is primarily sodium azide combined with an oxidizer, and is typically located inside the inflator canister between the filter assembly and the initiator.

Air bags are typically located in the steering wheel and in the dash above the glove compartment. They are designed to deploy during certain frontal or front-angular collisions, impacts, or decelerations, depending on the crash severity, speed, angle and object impacted. The complete process of deployment takes about two tenths of a second.

When an accident occurs and the air bags deploy, a small amount of powder appears that might look like smoke. Do not to be alarmed; this is normal.

The dual stage air bag, depending on the severity of the impact, will deploy at a less severe 70 percent of capacity, and full capacity at the most severe level.

The front seat belts are equipped with pyrotechnical tensioners. If the vehicle is involved in an accident and the deceleration rate is high, the collision sensor will send a voltage charge to the seat belt tensioner. A gas charge will be set off and the seat belt will become tightened to hold the passenger against the seat back. On impact the seat belt will tension the passenger snugly into the seat so movement is limited and the passenger is secured in the seat. For the seat belt to work properly it must be worn correctly. Make sure the belt is not twisted and it should sit low on the hips.

Never have more then one person per belt. Never sit so far back that the belt doesn’t touch your body. Never wear the belt under your shoulder. If the belt doesn’t retract completely, replace it, and never try to repair a seat belt. Never put a child booster seat in the front seat; it should always be installed in the back seat.

Collision sensors or crash sensors send messages to the control unit to deploy air bags when the vehicle is in an accident. These sensors are located near the front and rear bumpers and B and C pillars of the vehicle. Collision sensors also function as diagnostic monitors. Collision sensors continuously monitor the SRS operation and record any faults in SRS system. The sensor is a piezoelectric sensor that detects deceleration and collision forces. To ensure correct operation of collision sensors the sensors must be secure and grounded properly.

The vehicle’s passenger occupancy sensor detects whether a passenger is in the seat and decides whether or not to direct the air bag to deploy in the event of an accident. If the sensor determines that the weight on the seat is not a person, the air bag does not deploy. Volvo says any person under 4ft. 7in. should sit in back since the air bag might not otherwise provide full protection.

SIPS (Side ImPact Sensors) are located in the seats and, depending on the severity of a crash, speed, and angle, deploy when the vehicle is impacted on the side. Not all side impacts deploy air bags, depending on the severity of the crash. The bag will only deploy on side impact. These air bags are in the back rest of each seat on the side.

Seat track sensors (STS) are magnetic sensors that detect the position of the seat.

An inflatable curtain doesn’t sound like a life saving component, but it is. Volvo’s Inflatable Curtain is located in the headliner and stretches from the front windows to the rear windows. This air bag is designed to protect the heads of both front and rear passengers from side impacts. The inflatable curtains are not designed to inflate from a front or rear collision or a roll over.

The steering column has a pyrotechnical tensioner with a contact reel or clock spring. This single wire type contact reel design ensures the most reliable contact possible between air bag module and the crash sensor.

The SRS control module is located in the center console behind the parking brake. Volvo changed this location from under the seat in order to be centrally located.

The whiplash system is integrated into the front seats and is mechanical. This function reduces the risk of whiplash injuries in the event of a collision. The whiplash system includes specially designed hinges and brackets on the front seat back rests and head restraints designed to help absorb some of the energy generated in a collision from the rear. Any objects behind the seat could impede the function of the system.

On some Volvo models there is a rear compartment and child seats can be installed where children are between 50 and 88 lbs. and up to 55 inches tall. There are the three point seat belts and latches. There are also anchors on the back of the rear seat to strap down and hold booster seats or child seats.

Before touching the SRS system or any of its components, be sure you know what you are doing by reading the Volvo OEM SRS manual which is available from Volvo.

You should always switch the ignition off and disconnect the battery negative lead; then, before doing any work on the system, wait an additional ten minutes. Do not pound or hammer anywhere near the SRS crash sensor, for example, while under the car, if the ignition is on even if you are not working on the SRS system. Do not use an electrical welding unit on the car without disconnecting the battery negative lead. Not doing this could result in air bag deployment and possible injury. Do not under any circumstance use an ohmmeter or live electrical measurement instrument to measure resistance in the air bag seat tensioner or wiring while these components are connected, as this may cause them to activate.

If the SRS light stays on while driving, there is an issue with the system and the vehicle will need to be diagnosed. If the light is on the system will not work correctly and needs to be addressed sooner than later for occupants safety. This must be done by a qualified workshop due to the pyrotechnical SRS components.

Checking mechanical components such as seat belt and whiplash unit in seat

Check to see if the seat belt extends and retracts properly. Pull the belt out and hold, then jerk the belt repeatedly to make sure it locks correctly. Make sure the seat belt buckle opens and closes correctly.

Checking a seat for whiplash, move the seat forward and tilt back up with controls. Remove the side panel and press the catch for the seat belt end to remove the belt. Take off the protective panel. On the side of the seat check that the rod has no play. If there is play in the unit or visible space, both sides need to be replaced with new units.

Precautions when servicing SRS system

Never apply power to SRS if the collision sensor is not mounted on the vehicle.

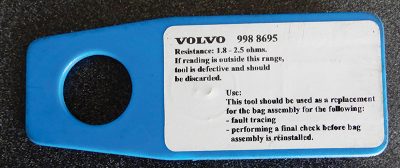

Never make any measurements on air bags or seat belt tensioners. A process of elimination will determine fault by using tool resistor 9988695.

Wiring repairs should never be done on the wire harness of an SRS system.

When handling air bags always have the trim cover facing away from your body.

Always wear safety goggles and gloves when handling a deployed bag or seat belt tensioner because it might have sodium hydroxide deposits that could irritate the skin.

Make sure to tighten all components and brackets to correct tightening specifications.

Never use a meter to check air bags or seat belt tensioners since the electrical stimulation might cause them to deploy.

Download PDF

0 Comments