A Little History

The exhaust-driven turbocharger was invented back in 1905 by Swiss engineer Dr. Alfred Büchi in Germany. And the first mass produced turbocharged car engine was used in the Oldsmobile turbo Jetfire in 1962. This turbocharger was fitted to a 215 cubic inch V-8 engine and was a small-diameter Garrett T5 model with an integrated wastegate.

Turbochargers were originally called turbo superchargers when all forced induction devices were classified as superchargers.

This could be confusing. Of course today, the term “supercharger” is usually only applied to mechanically driven forced induction devices. The main difference between a turbocharger and a conventional supercharger is that a supercharger is mechanically driven by the engine, often by a belt or gear driven by the crankshaft pulley.

The turbocharger, on the other hand, is powered by a turbine which is driven by the engine’s exhaust gases.

There are pros and cons to both systems. Turbocharger systems tend to be overall more efficient but are not as responsive at lower speeds. This is because that little turbine fan needs a lot of exhaust pressure to bring it up to speed; hence the dreaded turbo lag. Of course advances in turbo control systems over the years have all but eliminated this turbo lag.

Engines equipped with a mechanically driven supercharger can produce a lot of power at lower rpms. This is because the supercharger does not need that much engine speed to do its job. And since it’s driven directly off the crankshaft, there is no waiting for power.

Using a supercharger can also cost the engine some horsepower due to the extra load on the crankshaft pulley that is used to drive it. Since a turbocharger is driven off the engine’s exhaust pressure, there is very little loss of horsepower.

These days Volvo and some other automakers have found out that using both systems on the same engine can give the best of both worlds. For example, the Volvo 2.0 L T6 (twin charged) turbocharged and supercharged engine uses these devices sequentially. The supercharger is used by the engine from 0 to 3,000 rpm. After that, at 3,000 rpm, a large diverter valve in the intake manifold is opened to let the pressure from the exhaust driven turbocharger take over.

Turbo Control Systems

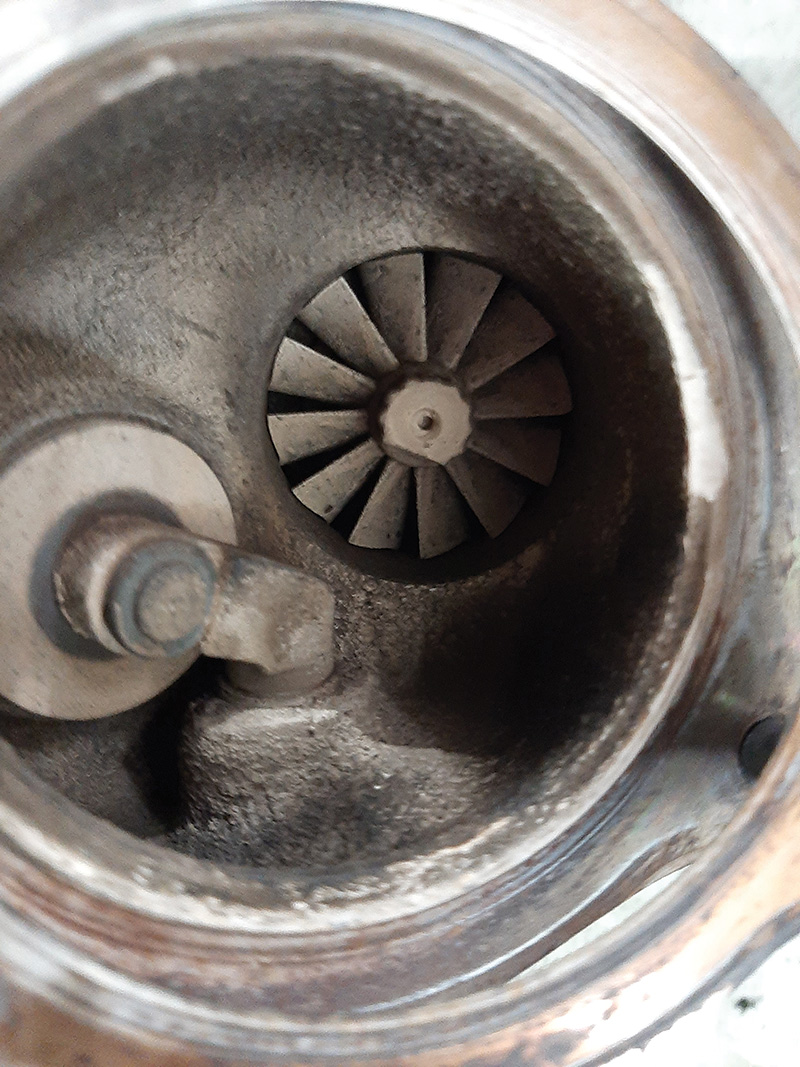

In the early days of turbocharging, the systems were fairly simple; engine exhaust would spin the compressor wheel on one side and the connected turbine compressor wheel would produce positive intake pressure on the other side.

This pressure needed to be regulated because, as the engine produces higher rpms, the engine produces more exhaust pressure, and some turbochargers’ compressor fans can spin at speeds of 80,000 to 250,000 rpm. Left unchecked the turbocharger’s potential pressure output can be more than the engine can take.

The most common type of turbo control is a vacuum-controlled wastegate valve.

The wastegate is used to divert excess exhaust gases away from the turbine wheel.

The primary function of the wastegate valve is to control the maximum amount of boost pressure that the turbo can deliver to the engine’s induction system. Wastegates can be external or internal, but pretty much do the same thing.

When the wastegate is commanded to open by either engine vacuum or the ECM, depending on the age of the car you are working on, a little flapper valve is opened and allows some or all of the exhaust gases to bypass the turbine. This causes the turbine wheel to slow down and reduces the positive pressure delivered to the intake manifold.

Overall, these systems work pretty well, but over time just like any other engine part, heat, vibration, and age will start to take a toll on them.

Here is how most of the turbo control systems work on the Volvos commonly seen in independent shops today.

The boost pressure in the intake manifold is controlled by the Boost pressure Control Valve (BCV).

The Engine Control Module (ECM) receives information about the actual throttle position via the Throttle Position Sensor (TPS) in the Electronic Throttle Module, or ETM.

The boost pressure is measured by the boost pressure sensor. That data is sent to the control module which, in turn, sends a command to the Boost Control Valve (BCV). This valve regulates the control pressure by using the turbocharger wastegate and bypass valves. The ECM also uses signals from the Intake Air Temperature (IAT) sensor, the engine coolant temp sensor, and the map sensor to help keep the boost pressure consistent during altitude and temperature changes.

Volvo Has Been an Innovator

Volvo was not the first automotive manufacturer to use turbochargers on a mass produced scale, but they were among the first to use forced induction systems.

The first Volvos to come with a turbocharger option were the legendary 240 series (1980-1984). These cars had a 2.1 L 4-cylinder engine with a mechanical fuel injection system (K-Jetronic).

These early Volvo turbocharged cars were not very powerful by today’s standards, putting out a whopping 131 to 163 horsepower, depending on year. But at the time these cars were pretty fast, and these cars represented Volvo taking baby steps into the high performance market. You might say the early Volvo 240 turbo cars were the grandparents of today’s R and Polestar series of Volvos.

If you have been around Volvos for a long time, you know that Volvo has gone through many engine variants over the years, some more successful than others.

About 40 percent of the Volvos produced after 1980 came equipped with a turbocharger, but after 2003 the number of turbocharged Volvos on the road has increased exponentially.

The latest Volvos are available with not only a turbocharger, but some variants come with both a turbo and a supercharger to maximize the potential power output of these relatively small 2.0 L engines.

0 Comments