Function, testing, tips and tricks

Ah yes, EVAP system diagnosis, every technician’s favorite!

It’s because the EVAP system is so easy to diagnose, right?

Actually these systems can be some of the most challenging to diagnose. The main reason is that, in a lot of cases, EVAP system problems can be very intermittent and hard to pinpoint. But with a good understanding of how these systems work and a good diagnostic strategy, it can become a lot easier to troubleshoot the Volvo EVAP system.

Volvo EVAP systems are normally very reliable, but as these cars get older and begin to clock a lot of miles, the stresses of the road start to wear on the hoses and various EVAP system components.

There are also many situations that can lead to early EVAP system malfunction, such as cars that are operated in areas with high heat or freezing temperatures.

Another common cause of EVAP system damage is a driver who has a habit of topping off the gas tank after the pump stops. This can cause excess fuel and fuel vapors to damage the vent valves and saturate the charcoal canister.

And if the car you are working on has recently been in an accident or just got out of the body shop, it very common to find damaged EVAP parts that were not replaced or hoses that are cracked, misrouted or even missing.

When you get a Volvo in your shop with EVAP codes stored in the ECM, you should always start your diagnosis with information gathered from the customer.

Questions like, when did the Check Engine light come on?

And when did you last put fuel in the car?

Has the car been in an accident or in a body shop recently?

These types of questions can help you to take your diagnosis down the right path.

After you read the codes and check for freeze frame data, make sure to check for TSBs or Volvo TJs that can often be related to a specific code or symptom. Volvo has issued many that are specifically related to the emissions system.

The most common EVAP system failures on Volvos are hoses that are cracked, broken or clogged.

A complete EVAP system visual inspection can sometimes quickly uncover causes for the codes stored in the ECM. You may often find a cracked or broken hose right away. But don’t make the mistake of assuming that a cracked hose is the only problem in the system without testing the system function after the hose is replaced, because it’s very common to have multiple EVAP issues in higher mileage Volvos.

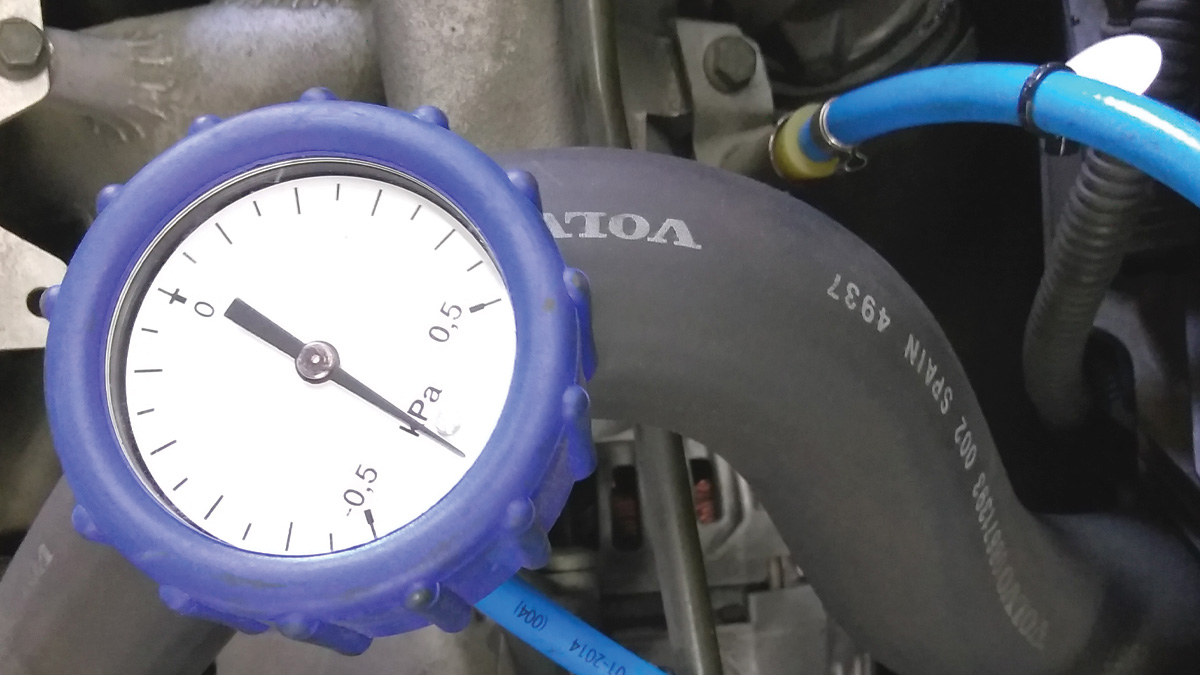

One of the most valuable tools to have when performing EVAP system diagnosis next to a scan tool (preferably Volvo’s VIDA) is a smoke machine made for EVAP system testing and is regulated for tank system pressures.

Depending on the year and model of the Volvo you are working on, there are several ways of commanding the EVAP system to run a self test.

On 1995-1998 Volvos, you can use the Volvo System Tester or a scan tool that is capable of bi-directional control to run a self check of the system. And on 1999- 2017 Volvos, you will have the best results using Volvo’s VIDA diagnostic software to perform accurate diagnosis.

If you don’t have these scan tools, you can confirm your repairs by driving the car on two complete drive cycles and check to see if the EVAP monitors have run and passed. But this method can be very time consuming and hard to run correctly unless you have access to a closed race track.

On 1995-1998 Volvos, the following is what the ECM needs to see before it will even start the EVAP system test.

- There can’t be any diagnostic trouble codes stored for: Vehicle speed signal, canister purge valve, EVAP canister shut-off valve or the fuel tank pressure sensor.

- The fuel trim must be active.Â

- The engine should be idling.Â

- The car can’t be moving during the testing (0 mph).Â

- The car needs to be below 2500 meters (about 8,000 feet) and above sea level.Â

- The outside air temperature should be above -8 degrees C (17.6 degrees F).Â

- The engine coolant temperature must be above -8 degrees C (17.6 degrees F) and below 120 degrees C (248 degrees F).Â

- The pressure in the fuel tank should be above 1 Kpa (0.145 psi).Â

The diagnostic test will start at the earliest about 17 minutes after the engine has started when all conditions have been met, and takes approximately 30 seconds to complete.

If the diagnostic test is interrupted for any reason, the engine control module will try to start again the next time all conditions are met. The engine control module performs a maximum of four diagnostic attempts during an operating cycle. If no faults are detected, the diagnostic procedure is not active again until the engine is switched off and on again.

If a fault is detected, the ECM will make two further attempts to evaluate the fault.

On most of the early Volvo models the most common EVAP codes seen are ECM 611 and ECM 612. And the most common causes of these codes seen in independent Volvo shops are:

- Cracked hose at roll over valve

- Cracked J hose at canisterÂ

- Sticking or leaking EVAP canister purge valve

- Clogged fuel tank vent at filler neck (usually with spider webs)Â

- Leaking gas cap or cracked gas cap seal

- Leaking fuel tank seals

Of course, there are a few less common possibilities for EVAP system problems on these cars, like the fuel tank pressure sensor or a broken or cracked canister.

And of course, these are the most common EVAP system problem seen on the early Volvos. But these cars are getting older every day, so we will begin to see problems that we have never seen before.

Download PDF

0 Comments