Intake air leaks, unmetered air leaks, false air, vacuum leaks or whatever name you use for this problem, it all means the same thing — air is leaking into the intake system behind the air mass sensor, air that is not being properly measured and calculated for.

All makes and models of cars on the road today that use an internal combustion engine can suffer from this very common problem, and the factors that cause this problem are as many as the problems that unmetered intake air leaks can cause.

Volvos are not immune to this problem either. Different years and models of Volvos can have common issues with intake system leaks.

Even a tiny amount of unmetered air can have long-term consequences for the powertrain of an engine.

We all know that larger vacuum leaks can cause problems like poor running, stalling and poor fuel economy. These types of leaks are usually easy to spot and are usually accompanied by a Check Engine light. But the most common types of intake leaks on Volvos are small ones, the type that won’t always be easy to spot. Most customers won’t even notice the subtle differences in their cars’ everyday performance.

This is, of course, by design. All cars sold in the United States, starting around 1994, were required to be OBD II compliant.

All manufacturers were required to design fuel and ignition systems that would self check and have the capability to “adapt†to small issues in the powertrain systems. The main reason for this was to keep the emissions of the vehicle below a specified level.

The earliest versions of OBD II were pretty basic and, compared with modern emission systems, they were Stone Age.The powertrain system “adapts†to problems like a small vacuum leak by changing things like fuel trim, valve timing, and much more in some cases.This is all done by the car’s powertrain systems to keep the engine performing as efficiently as possible and to protect the car’s catalytic converter from being damaged.

A lot of systems are able to adapt the engine’s management systems enough to account for smaller vacuum leaks without setting a lean code in the ECM. But the adaption was only designed to be a temporary fix for problems like small intake air leaks.

What are some possible long-term effects of small, unmetered intake air leaks?

We all know that when a car rolls into the shop with a large intake air leak, in a lot of cases with Volvos you can hear a larger vacuum leak when the engine is at idle. These larger leaks are usually accompanied by symptoms like stalling, uneven idle, loss of power and a Check Engine light on or flashing. But there are a lot of cars that will come into your shop with small vacuum leaks and no apparent symptoms or warnings.

Think about unmetered intake vacuum leaks as a high-fat diet for a car’s engine. In most cases, a normal engine management system will interpret a small vacuum leak as a lean condition and add extra fuel to compensate.

Over time and miles, this condition could begin to prematurely wear some of the engine’s internal and external parts and sensors.

Probably the most common part to be affected by this long-term abuse is the catalytic converter.

Ever wonder why some catalytic converters are still going strong at over 200,000 miles and some fail at 50,000 or 60,000 miles? Of course there are a lot of factors that can contribute to a catalyst’s early demise. Lack of proper maintenance by the car’s owner is probably the leading cause.

How many times has a customer come into your shop with a Check Engine light, and when the service writer asks them how long has it been on, they either look at them with a blank stare or say, “I don’t know†or “a few months†or similar response.

In most cases, early catalyst failure could have been avoided by proper care and regular maintenance.

Unmetered intake air leaks can contribute to early cat failure, but are usually not the sole cause. Oxygen sensors and air/fuel ratio sensors can suffer from unmetered air leaks too. Extra fuel and oxygen in the exhaust can cause things to heat up and damage the delicate parts of these sensors.

CASE STUDY 2005 VOLVO XC90 2.5T

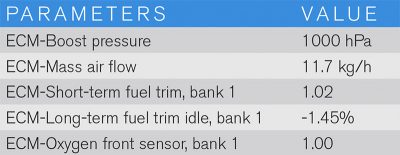

With the engine fully warmed up and pretested to confirm that there were no existing unmetered intake leaks, we hooked up this Volvo to VIDA and went into ECM Communication. We selected five different parameters: air mass sensor, short-term fuel trim bank 1, long-term fuel trim idle bank 1, boost pressure, and Oxygen sensor bank 1.

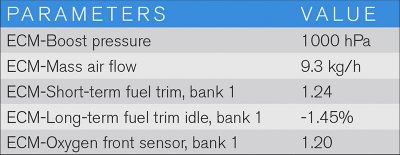

After making a note of the normal parameters, we introduced a small intake vacuum leak and rechecked the data.

The boost pressure and long-term fuel trim don’t immediately change, but look at the difference in the air mass, short-term fuel trim, and O2 sensor numbers.

Even a small vacuum leak can cause big problems.

Of course, the most common problem caused by intake air leaks is reduced fuel economy because the oxygen sensors will interpret the extra oxygen as a lean condition and richen up the fuel mixture.

The moral of this story is that you should always make checking for intake air leaks part of your diagnostic strategy on Volvos and all other makes.

WHAT ARE THE BEST WAYS TO PINPOINT INTAKE AIR LEAKS?

In the old days, you could walk into almost any shop and see someone testing for an unmetered intake air leak by spraying some sort of flammable aerosol on and around a running engine’s intake manifold to see if the engine’s idle speed would be affected by a vacuum leak allowing this extra fuel source to be burned in the combustion chamber.

This method was effective in finding vacuum leaks, but spraying highly flammable aerosols onto a hot running engine has its obvious problems.

When your customer calls you to ask, “Is my car done?†Your response should not be, “No, it’s well done!â€

These days the most popular way to find intake and other leaks is to use a smoke machine. Most shops have them. If your shop does not, it’s time to get one.

The best ones are set up for EVAP testing because the pressure is regulated to a safe pressure. Most of these smoke testing machines have a way to measure the size of the leak as well as generating a non-toxic smoke that make spotting leaks very easy.

COMMON VOLVO INTAKE AIR LEAKS IN PLASTIC AIR INTAKE PIPE FROM AIR MASS SENSOR TO TURBO INLET

1999-2007

5 cylinder turbo engines

(B5244T ThROUGH B5244T7)

This one is a very commonly overlooked intake air leak, because in most cases the amount of unmetered air that enters the turbo inlet is a small amount. But over time, these plastic pipes can begin to show signs of wear, and with everyday driving, the expansion and contraction of these pipes can cause a vacuum leak. Most times these pipes start to leak around the fitting that holds the PVC heater (also known as the PTC valve). They can also crack at the lower flange that attaches to the turbo’s inlet.

NOTE: When replacing these hard plastic turbo pipes, you should always order and replace the hose clamps with Volvo Genuine clamps from your local Volvo dealer’s parts department.

DON’T TRUST THAT OLD HOSE CLAMP!

Always replace those clamps. They were only designed to be used one time.

In many cases, you can get a comeback from a turbo hose or pipe popping off if you reinstall the old clamp. It may have felt like it was tight but the screw and grooves of the clamp may be stripped. It’s not worth the risk. Just make it part of the job.

EARLY T-6 2.9L TWIN TURBO INTAKE PIPE LEAKS (B 6294T)

If you work on Volvos on a regular basis, you are bound to see a few of these cars roll into the shop. This engine only came in the XC90 (2003-2005) and a few S80s (2001-2006).

When you open the hood on one of these Volvos, you will know it by the design of the air intake plumbing and pipes that cover most of the top of the engine.

This 2.9L twin turbo engine turned out to be pretty reliable for Volvo even though some of the transmissions that came in these cars turned out to be less than stellar. The air intake plumbing is where you will experience problems with vacuum leaks.

This one can drive you crazy. The intake system on this car is a work of art and resembles a set of bagpipes more than an intake manifold. As the plastic pipes age, they can shrink, crack, and distort, causing small leaks.

But the real problems can be caused by you. This is because every time you touch one of these intake pipes, you can create problems that may have not been there before.

Every time you remove this intake plumbing to perform services like replacing the spark plugs, checking or replacing ignition coils, or even replacing the upper engine torque mount, it can be difficult to reassemble with no leaks.

So what’s the answer? You could replace the intake pipes and clamps every time you service one of these engines, but in most cases that’s not needed. The best practice to ensure a sealed intake system on one of these is to use your smoke machine to check for leaks after reassembly.

In most cases, adjusting the position and tightness of the hose clamps will stop the leakage and, in some cases, you will have to replace the clamps.

OLDER VOLVO VACUUM LEAKS (1993-1999 850, S/V/70, 960, S/V 90)

Small, unmetered air leaks don’t affect these older Volvos as much, but any unmetered vacuum leak will not allow your customer’s Volvo to operate at its peak efficiency, regardless of its age.

The main problem you will experience on these older Volvos is the deterioration of the silicon and rubber vacuum hoses and elbows that are hooked up to different parts of the intake manifold.

A quick visual inspection of these hoses can usually turn up a few cracked or collapsed hoses.

The main thing to remember is if one hose is leaking, there will be more. So you should recommend that your customer replace all of the older vacuum hoses because a lot of these Volvos will still have the original hoses on them.

Use Volvo Genuine hoses and elbows to replace these hoses. You can purchase different size vacuum hose in bulk from your Volvo dealer, and it can be ordered in lengths.

OIL TRAP AND CRANKCASE BREATHER LEAKS

Starting in 2005, Volvo started using a diaphragm-based crankcase breather system. These systems were more efficient and less prone to clog than older PCV systems.

Some vacuum leaks on Volvos can be checked with a smoke machine; that’s because they are leaking intake air directly into the crankcase.

Theses oil traps are designed to recirculate unburnt crankcase gases back into the intake for combustion.

These systems work well, but with any plastic and rubber engine parts that are constantly exposed to heat and pressure, they will fail over time and need replacement.

When these oil trap breather systems start to fail, the customer may hear a whining or whistling noise when the engine is at idle. Some technicians refer to this noise as the “flying saucer noise.â€

On the P2 Volvos (2005-2010 V50, S40, and C30) the oil trap and oil trap diaphragm are part of the oil filter stand assembly bolted to the front side of the engine block.

This assembly comes from Volvo in one piece that includes the oil filter cup, oil filter, oil trap, oil trap diaphragm, and PTC heater.

If you have a failed oil trap check valve, you can check it by carefully removing the oil filler cap while the engine is at idle. If the oil trap needs to be replaced, you will have a hard time removing the cap because, if the check valve is ruptured, the crankcase will be generating a lot of vacuum, holding the oil cap in place.

0 Comments