Volvo is one of those brands that rarely sees the tow truck.

Volvos tend to be able to limp into the shop in most cases, unless the battery is dead or the owner has been severely neglecting the regular maintenance.

When it comes to Volvo, the majority of no start complaints will be battery-related. Non battery-related no start conditions on a Volvo are the exception to the rule in most cases. That being said, ALWAYS CHECK THE BATTERY!!

Some of the more common causes for no starts on Volvos are:

- Battery

- Alternator

- The rare starter motor

- Ignition lock sticking

- Immobilizer and key communication problems

- Fuel pumps (more common in pre-2005 models)

- Broken or shorted wiring (commonly caused by rodent activity under the hood)

- Out of gas!

- Camshaft or crankshaft position sensor

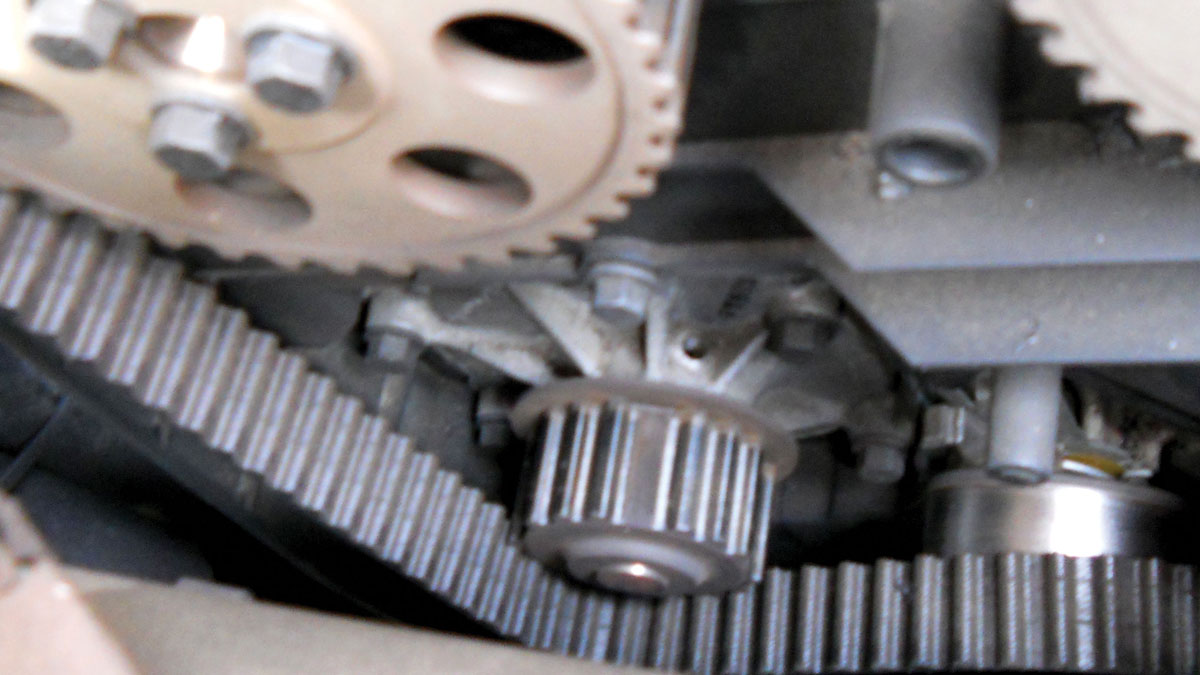

- Broken timing belt (ouch!)

These are just a few, and most of these issues are fairly easy to diagnose — that’s if the car has a solid symptom when the car is towed in.

Of course, starting issues can come in a wide variety of flavors; the majority that we see come into our shops today are of the intermittent variety.

The word “intermittent†can strike fear into the hearts of a lot of technicians, but with training and experience that word will become less daunting.

When a customer comes into your shop and says, “My car doesn’t start,†or some version of that, the first step should always be a detailed customer interview. This is especially critical in the case of an intermittent symptom or symptoms.

If the person that brings the car in is not the person that drives the car, it is important to try to interview the person who does. This will help avoid confusion and misleading information about the problem.

Ask the right questions. The average customer will not be able to accurately describe all the symptoms, especially if the problem only happens once a year on a cold Tuesday at noon.

What are the right questions?

It depends on the problem. If the car comes in on a tow truck with a solid no start condition, the list of questions can be shorter than in the case of an intermittent issue.

If your service writer is not that technical, it will help if a technician asks the questions. If that is not possible, your shop can develop a symptom form that the customer can check boxes on.

Questions like: Where, when and how often are just the beginning. The right kind of customer interview process will save a lot of time, confusion and money.

Here is one case where a good customer interview process would have come in handy.

Has this ever happened to you?

A 2000 Volvo XC70 got towed into the shop one day with a crank but no start condition. The customer said the car just stalled out. The technician started his testing with the basics; he checked for spark and checked for fuel pressure. There were both. The tech then hooked up his scan tool and checked for stored codes. Again nothing. The tech then checked the live data while cranking, and still no joy.

After a few hours of hair pulling, the tech went and asked one of the other techs what they thought. The other tech asked, “Is it out of gas?†The tech that was working on the car said, “Of course not. I checked the fuel pressure, plus the gauge reads a quarter full.â€

Q: Is it possible to have fuel pressure and no fuel volume?

A: Yes.

So the other tech walks over to the car that was up on the lift and taps on the gas tank. Of course the tank sounds empty.

They add some gas and voila, the car starts.

The service writer calls the customer and asks, “Does your fuel gauge work?†The customer then says, “Nah, it’s been broken for years.â€

Could the right questions have helped save all that wasted time?

ASK THE RIGHT QUESTIONS!

In the case of “very†intermittent customer complaints, like the type that only occur every other month or so, you would probably have a better chance of winning the lottery than experiencing the symptoms while the car is in your shop. In a lot of these cases, there will be no stored data or codes to work with. And if you don’t experience a symptom, how can you know you fixed the problem?

It’s up to you to educate your customer on how difficult it can be to pinpoint a very intermittent no start condition. When it comes to no start and other diagnostics, have a game plan and a standard step-by-step procedure.

If you follow the same systematic way you diagnose problems, especially intermittent ones, you will become better and faster at finding the root causes.

Check those TSBs, or, as Volvo calls them, Technical Journals (TJs or RTJs). Volvo has issued several that deal with starting problems across all their years and models. Some of the starting issues that are covered in these bulletins may surprise you.

One example is RTJ 21487; this bulletin only covers a problem with one production year — 2010. The problem that is covered is a no start caused by the key fob not being recognized due to electromagnetic interference caused by a chrome plated lock bezel.

Information is probably the greatest tool in the modern auto technician’s arsenal. Luckily for us, all that valuable info is at our fingertips on the web. If you want the most up-to-date repair and service information on Volvos, the best site is volvotechinfo.com, and the best tool for the job is Volvo’s VIDA software.

| Part Number | Description | Comments | Size (kB) | Download Time (min) |

| 30677016 | CCM upgrade | 178 | 1 | |

| 30677017 | CEM upgrade | 308 | 1 | |

| 30677018 | DDM upgrade | 60 | 4 | |

| 30677021 | ECM gasoline upgrade | 741 | 1 | |

| 30785453 | ETM/ECM p upgrade | 741 | 1 | |

| 30677027 | PDM upgrade | 57 | 4 | |

| 30677030 | REM upgrade | 53 | — | |

| 8691415 | Service 2.0 upgrade | 389 | — | |

| 30677038 | Total upgrade CAN | 1782 | 14 |

Don’t Forget to Check the Basics

As these cars have become more and more complex, so have our testing tools and procedures.

If you perform a lot of diagnostic work at your shop, you are not alone; now and into the future advanced diagnostics will become more a way of life for us. Your shop needs to keep up with new technology through continued training and investment in new tools and equipment.

CHECK THAT BATTERY!

The rules have changed. In the old days, the good old 12 volt battery only had to perform a few basic jobs, including turning the starter and storing power.

Of course we all know that, but did you know how sensitive the modern CAN network cars are to 12 VDC battery’s condition, capacity, and state of charge?

In the old days the average battery could last 5 to 10 years or more in rare cases. Today’s cars demand so much from their battery that the average lifespan of the 12 volt battery in the U.S. is 3.5 years, and that’s in normal conditions.

When it comes to Volvo batteries, the same rules apply.

The rules have changed when it comes to testing and charging batteries too. Like everything in life there is a right way and a wrong way. Don’t just roll the old VAT 40 over and crank the knob to full until you see the smoke.

To perform an accurate battery test on a modern Volvo you need to access the battery posts and use a modern battery testing system. Some lazy techs think that they can test the battery from the positive post connector in the main fuse box…

DON’T DO THIS!

Your shop should have a modern battery testing system, especially when checking AGM (Absorbed Glass Mat) batteries.

If you don’t have a newer style battery testing tool, it’s time to get one; this goes for your battery charger too.

There are two Volvo-approved methods for testing when addressing a customer concern regarding the 12 volt battery: The VIDA Battery Test and the hand-held batter tester 9513030 (Midtronics BT3300). These testers are very accurate if used correctly and also have the ability to test the starter and charging voltages. And they have the ability to print out the results of the test so you can show the customer.

You should always perform a battery and charging system test with the battery fully charged if possible. Of course, if the battery will not take a charge, that’s where you should start.

Tools of the Trade

What tools do you go for when diagnosing a no start condition?

That all depends on what type of no start you are dealing with. Is the symptom consistent or intermittent? And how intermittent?

Of course in any no start diagnosis, tools should include a scan tool such as Volvo’s VIDA, a battery tester, and a fuel pressure gauge. But you may have your own favorite tools to help you get to the bottom of these types of problems.

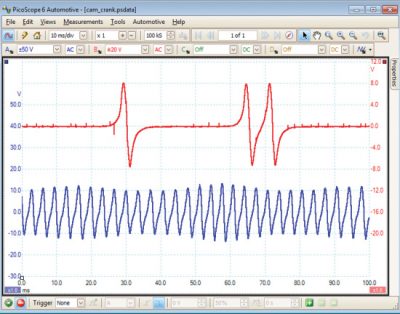

Some old tools are becoming popular again for diagnosis of difficult-to-find issues. Four-channel oscilloscopes can be very useful in the hunt for intermittent problems and can be used to compare waveform patterns to verify the function of multiple systems and components.

And some new tools that were not designed specifically for automotive repair can be very useful. Some technicians are experimenting with tools like the FLIR (Forward Looking InfraRed) gun. This very cool tool can be used for checking multiple systems and issues on cars.

One of the more interesting ways to use this tool is to help find a key-off parasitic battery draw. The way to do this test is to let the vehicle that you are testing, for key-off drain, sit in the shop overnight, so the whole car is at ambient temperature. You can then use the FLIR gun to scan around the vehicle to see if there is an area that is warmer than the rest of the car. The area that is warm is usually the area that is energized and drawing amperage.

This test can be very effective in the fuse box area.

NOTE: A FLIR gun can help point out an affected circuit, but you should always confirm the fault by performing the appropriate testing.

It can be easy to forget to check the basics and jump down the diagnostic rabbit hole.

The Smoking Gun — A Case Study: 2008 Volvo XC90 3.2L Towed in With a Crank But No Start Condition

In some cases, diagnosing a no start condition can be relatively simple. In the case of this XC90, the customer reported that when the car was started in the morning, smoke started coming out from under the hood, and the car stalled and would not restart.

The customer, of course, thought the worst and was expecting the shop to tell him that the engine blew up or something like that. After a quick check of the oil and coolant levels by the technician, it was apparent that such was not the case. The tech confirmed that the engine did crank normally but would not start.

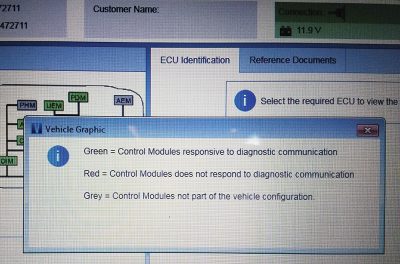

The tech then hooked up the car to a laptop equipped with Volvo’s VIDA software and checked for live data and stored codes.

The codes that were related to the no start were ECM P0302 and ECM P035211. The tech then removed the cover on top of the engine to inspect the ignition coils and there it was – literally – “the smoking gun.”

The number 2 coil had internally shorted out and blown the fuse for the ignition system.

It’s common for higher mileage Volvos to have coil failures, but to have one melt down is a lot less common.

NOTE: If you have a higher mileage Volvo in the shop with one or more failing ignition coils, you should always recommend that the customer replace all the coils at the same time. This will help avoid a comeback due to the fact that all the coils are the same age and have the same mileage on them. A new set of genuine Volvo spark plugs would be a good idea too.

The point is, that with changing technology and older Volvos on the road, we are going to see issues in the shop that even the most experienced Volvo technicians may be surprised by.

RATS!!

Yes folks, they and all their little rodent friends love nothing better than to crawl up into a warm, cozy engine compartment for the night, and not only do they get a warm bed but there’s an all-you-can-eat buffet included.

If you get a Volvo in your shop with mysterious electrical problems, make sure to inspect the engine compartment for signs of rodents. If you see a lot of droppings and debris, you should ask the customer if the car is parked for long periods in places like forest areas, barns, or garages with known rat activity. Rats love hoses and wire insulation.

Is the Network Awake?

Some early Volvos from 1999-2001 with CAN bus networks can experience a no start condition if the battery voltage drops below 9 VDC because some of the network nodes have gone to sleep and need to be awakened, and replacing or charging the battery won’t always do the job.

There are two common ways to do this. The best way is to use Volvo’s VIDA software program to ping the nodes that are offline. When you are in VIDA, go to the Network tab; the modules that are offline are in gray. If you can’t wake them up with VIDA, you can go to the next step.

You can disconnect the positive and negative battery terminals and short them together for 15 to 30 minutes.

This should clear the memory out of all the modules and reset the adaptions to factory default settings.

And if a module such as the ECM has gone into some sort of limp mode, this should clear that too.

0 Comments