From the nimble 3 Series to the luxurious 7 Series, BMWs are bred to perform. Skilled drivers know that when you are behind the wheel of a BMW, you can use all of the car’s power to the limits of tire adhesion and your driving ability.

The level of performance that BMW offers requires the careful design and integration of many systems. One of the most important is steering, which is why BMW is a leader in steering technology.

Rack and pinion steering is found on BMWs that get driven the hardest. Compared to the other common steering system, recirculating ball, rack and pinion provides a more sensitive road feel and quicker response to driver inputs. In addition, rack and pinion steering is compact and lightweight, important considerations in any car.

Evolution

BMWs have sophisticated suspensions that keep those fat tires in solid contact with the road surface. But responsive driving characteristics still wouldn’t be possible without equally-sophisticated steering systems.

Over the years, rack and pinion steering has evolved through several generations of development.

- The originals were simple, manually-powered units.

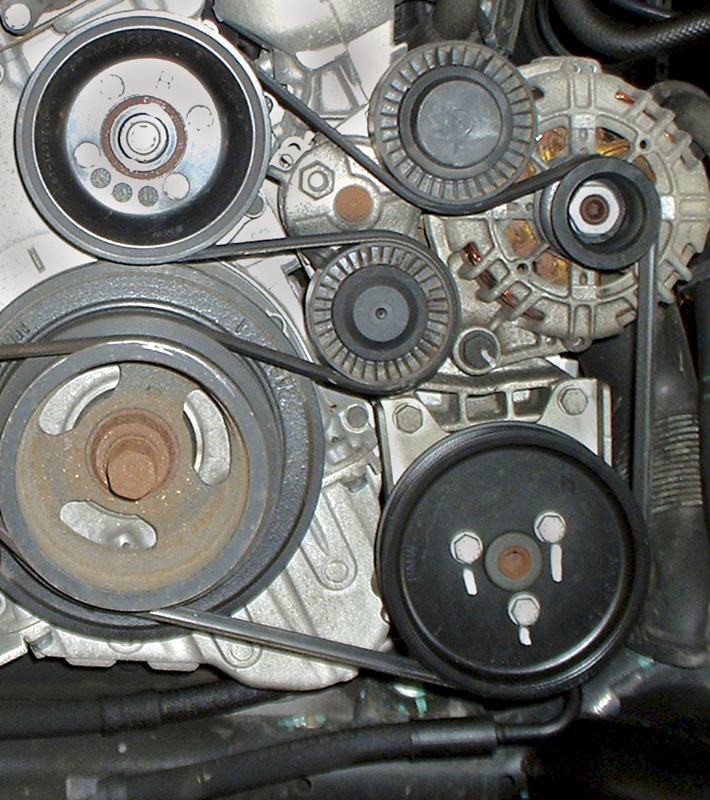

- The first major advancement was hydraulic power assist. A belt-driven pump, powered by the engine, provides hydraulic pressure through a spool valve to the steering assembly, making the steering wheel very easy to turn.

- The ZF Servotronic assembly represents the third generation of rack and pinion technology. The unit is linked to the onboard computer systems. Vehicle speed inputs to the steering controller govern how much effort the driver must employ. Reduced effort is required during standstill or slow-speed maneuvers, such as pulling into a parking space or making a tight turn at an intersection or drive-way. More effort is required as vehicle speed increases for better stability.

- The BMW Z4’s version of rack and pinion steering is electrically powered and electronically controlled, eliminating the need for hydraulic components and their bulk, weight, and leak potential. On 3 Series, 5 Series, and 6 Series vehicles, the optional Active Steering system combines Servotronic assist with a planetary gear reduction system to adjust the steering ratio based on vehicle speed. Active Steering offers the driver a faster effective ratio for low-speed maneuvers, and a slower ratio for high-speed stability.

Basic anatomy

Even at its current level of computerized sophistication, the basic rack and pinion steering design has remained the same as it’s been for decades. At the end of the steering column, inside the housing, is a pinion gear. The teeth of this gear mesh with the teeth on a straight metal bar, the “rack,” that is set at 90 degrees to the steering column.

Attached on the left and right ends of the rack are inner tie rods. The inner tie rods connect to the outer tie rod ends. The outer tie rod ends are attached to the steering arms. The inner tie rod ends and the rack and pinion housing are protected by rubber bellows that seal out road contamination.

To put the action as simply as possible, as the driver turns the steering wheel, the pinion gear teeth turn and engage the rack gear teeth. In response, the rack moves either left or right, which in turn changes the direction of the front wheels.

The advances in BMW steering technology include variable ratio steering, elimination of “bump steer,” and the newest, all electronic/electrical system that eliminates hydraulics.

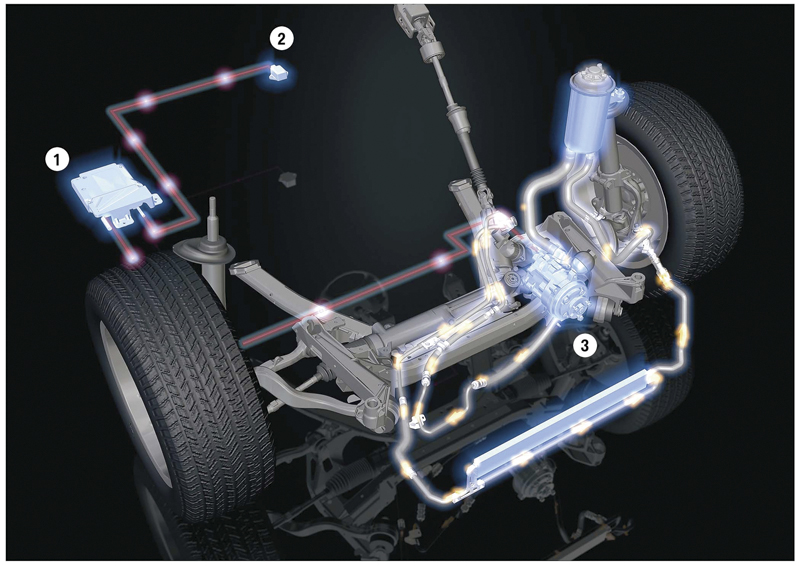

One of the latest innovations combines hydraulic and electric assist. (1) Electronic control unit, (2) Yaw rate sensor, (3) Hydraulically-assisted power steering unit with combined planetary gear and electric control motor.

Variable Ratio

Steering “ratio” is the measurement of how much you must rotate the steering wheel to turn the front wheels a given distance. It is measured in degrees—the number of degrees that the steering wheel must turn in order to pivot the front wheels one degree. The higher the first number, the less effort it takes to turn the steering wheel. The trade off for reduced steering effort is that the steering wheel must be turned farther to change the direction of the front tires.

Early rack and pinion steering had a fixed steering ratio. BMW and other carmakers later added “variable ratio steering.” When the front wheels are straight or turned to no more than about 40 degrees, the steering ratio is low for faster response. This offers more control of the car, especially at highway speeds.

As the front wheels are turned more, the steering ratio increases, reducing the effort required to turn the steering wheels. This makes it easier for the driver to make tight maneuvers such as parking or turning a corner at an intersection.

On rack and pinion steering, variable ratio steering is accomplished by changing the cut of the rack teeth. Near the center of the rack, when the front wheels are straight, the teeth are cut at approximately a 20 degree angle. Away from the center and closer to either end of the rack, the gears are cut at 40 degrees.

Several BMWs incorporate engine speed into the steering control, via the onboard computer system. The system takes input from vehicle speed sensors and front wheel angle sensors to adjust the amount of assist applied to the steering system. At higher speeds, less assist is provided for more precise control. At lower speeds, more assist is given for increased driver comfort.

All rack and pinion steering units suffer from “bump steer,” which is movement of the steering wheel when the tires hit a bump or dip in the road. Although the tires and suspension are designed to absorb most of this force, many rack and pinion assemblies are so sensitive, there can be noticeable movement in the steering wheel. For drivers, bump steer is at least an annoyance and, in severe situations, a safety risk.

Goodbye Bump Steer

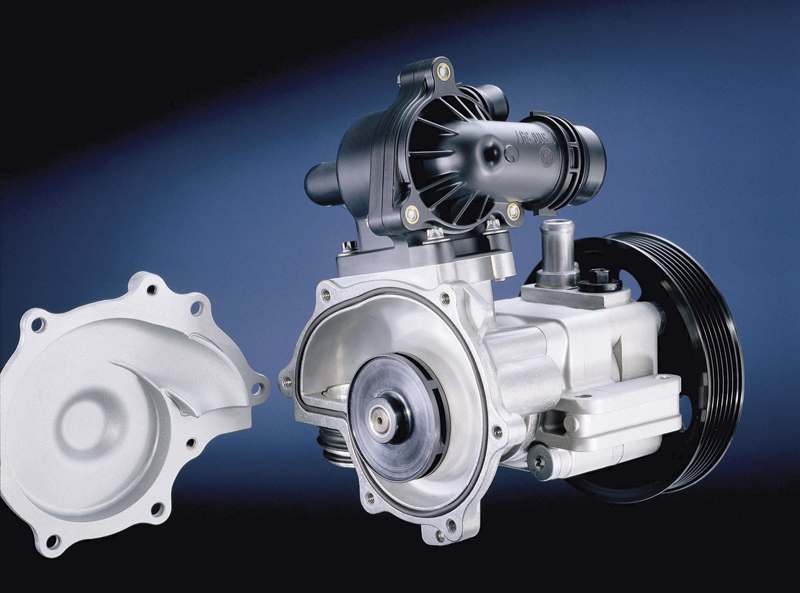

Some late-model BMWs have the power steering pump combined with the water pump, which may come as a surprise.

To eliminate bump steer on its power steering units, BMW incorporates a special valve assembly into the power steering system. This rotary valve has a motor, six control grooves, and a sleeve that is connected to the pinion. The valve body has axial grooves that are matched to the control grooves.

A torsion bar connecting the valve motor, the pinion, and the valve sleeve keeps the valve motor centered. Driving down the road, torque can be transmitted to the valve body either from the steering or from the front wheels (bump steer). This torque twists the valve motor relative to the valve sleeve. The twisting motion shifts the position of the motor’s control valves relative to the axial grooves in valve body.

When the torque and resultant twist comes from the steering wheel, the grooves direct pressurized power steering flow in the correct path to turn the front wheels in response to inputs from the steering wheel.

But when the force applied to the valve body comes from the opposite direction —up from the front wheels instead of down from the steering wheel — power steering flow is directed to counter the bump steer input. Even if the steering wheel is rigidly held, the valve body rotation corrects for “bump steer” without causing steering wheel movement.

As soon as the bump steer influence is over, the valve assembly re-centers itself to return to the straight-ahead position.

Electric Steering

Hydraulic assist, better known as power steering, makes it comfortable to drive any vehicle, even the biggest car or SUV, because steering is so easy. Put a person who has only driven vehicles with power steering in a manual steer car and you are guaranteed to hear complaints of “I can’t turn the wheel” or “There is something wrong with the steering.”

The comfort and convenience of hydraulic assist steering has its price, however. Hydraulic units are large, heavy, and help increase underhood temperatures.

Until recently, a driver’s choice was manual steering or hydraulic assist, but the BMW Z4 now offers something completely different: Electric assist power steering from ZF. The ZF Servolectric system is new to BMW. It probably won’t show up in your shop for a year or two, but the first time you see the system under the hood, you will appreciate its advantages.

ZF Servolectric uses a controller that monitors steering wheel movement. When driving straight ahead, Servolectric remains in stand-by mode and requires no electrical power. When the steering wheel is moved, sensors measure the steering torque and steering speed. This data becomes input to the engine control module. The ECM then signals the Servolectric unit to provide the correct amount of power assistance. Based on the ECM’s signal, the Servolectric motor transmits the required torque to the pinion. All this is done virtually instantly.

The Servolectric system totally eliminates all the components associated with hydraulic power steering. Gone are the belt-driven pump, fluid, hoses, and connections, replaced by a compact electronic controller and a small electric motor provided to BMW as part of the steering column assembly. With the size and weight reduction, and the elimination of a belt-driven pump, Servolectric boosts engine performance and fuel economy.

Unlike hydraulic units, Servolectric is completely independent of engine operation. Full assist is also available at idle speed, making it more convenient when parking or making tight maneuvers in a congested area.

And because it is electronically controlled, Servolectric is easily incorporated into sophisticated dynamic stability control and crash avoidance systems.

With all of its advantages, you can expect electrically-powered electronically-controlled power steering to quickly replace the old-school hydraulic systems on coming models.

Service and Troubleshooting

Any power steering pump takes up a lot of space in the engine compartment, needs a belt and pulley, and has vulnerable pressure and return hoses.

Despite its relatively small size and weight, BMW’s rack and pinion steering unit is very durable and typically lasts the life of the car, even under the aggressive driving conditions that are common for many BMWs.

However, nothing is perfect and steering problems can occur. Common complaints include:

- The car pulls to one side, or the steering wheel must be held off center to drive straight.

- The steering is stiff or tight.

- The steering is loose. The car tends to wander or the driver has to turn the wheel more than normal to get a response.

- Leaks.

Complaints about pulling to one side, stiffness, or looseness are usually symptoms of suspension, tire wear or underinflation, or alignment problems. Stiffness in a BMW with hydraulic power steering can also be caused by a worn pump, loose belt, low fluid, or leaks. Only after checking the tires, alignment, and the suspension system should you consider the rack and pinion steering assembly as the source of the complaints.

Leaks and torn bellows are the most common problems with rack and pinion steering. External leaks are obvious because you can see the fluid. Internal leaks are detected by pressing on the rubber bellows protecting the inner tie rods. If any fluid is felt inside the bellows, there is a leak.

Servicing the Servolectric units will require following the trouble code and troubleshooting procedure similar to any electronic/electrical device on the car.

Shop level repairs or rebuilding of rack and pinion steering assemblies is not recommended because in-shop service has a very high failure rate. In fact, it is nearly impossible to find repair kits because there is little or no demand for them. It is faster, easier, and you have a much lower risk of a comeback when you replace a bad rack and pinion steering assembly.

To provide the best service for your customer, pull the old rack and pinion unit, flush the power steering fluid thoroughly, install a new BMW assembly, fill with the recommended P.S. fluid, replace any worn suspension components, and do a complete wheel alignment. Then you can send your customer back on the road with the taut, precise steering that BMWs are known for.

0 Comments