Even though these systems are relatively new, you’ll get tire work on them any day now. Don’t embarrass yourself.

What drove the development of TPMS was governmental concern that the average driver underestimated the critical role of the tire/pavement interface, and rightfully so. Data gathered over the years from crash analyses indicated that a fair percentage of the blame for many accidents could be fully or at least partially assigned to reduced handling or braking performance due to under-inflated tires, or tire roll-offs and blowouts due to chronic, long-term under-inflation.

Race drivers know better than most the critical changes that occur in tire contact patch and vehicle performance as tire pressures vary. At speed, the total square inch area of tire-to-pavement contact is frighteningly small at best, and if you consider that that tiny bit of rubber is all that connects a two-ton machine to terra firma (thus allowing control of said machine), you begin to understand why government attention turned to systems to help alert a motorist to this common and potentially life-threatening condition. It’s a natural progression of systems that have included ABS, variable steering and dynamic stability controls.

Low tire pressure generates poor cornering response because of reduced tire stiffness. At low tire pressures the vehicle wants to go straight — understeers, or “pushes” in racing parlance — thus tires running at low pressure require a greater steering angle to generate the same cornering force for any given curve. The maximum speed at which a ramp can be negotiated with a test vehicle while staying in the lane is reduced as tire inflation pressure is decreased. Testing done by Goodyear demonstrated that with all tires correctly inflated to the door placard pressures the maximum speed attained on the ramp was 38 mph (baseline). Reducing pressures just three PSI dropped maximum speeds to 37 mph and at 20 PSI the car came out of the lane at speeds over 34 MPH. Obviously, tire inflation pressure is a critical factor in vehicle handling… but how much of a factor? According to the NHTSA, estimates for skidding and loss-of-control crashes for light vehicles with under-inflated tires total 247 fatalities, 23,100 injuries and 53,130 property-damage-only crashes per year.

The problems low tire pressures create aren’t confined to on-ramps. Think about lane changes or quick maneuvers designed to avoid accidents, obstructions or wildlife on the road. On a quick lane change maneuver, under-inflated tires result in poor handling and slow steering response. Depending on whether the low tires are on the front or rear axle determines the vehicle’s sensitivity to steering inputs (along with a myriad of other design and wear factors), but under the right conditions compromised directional stability will result in a spin or total loss of control.

Flats and Blowouts

Flat tires are always inconvenient and can be dangerous if there’s no safe place to pull off to change the tire. Blowouts can be quite another matter, jerking the wheel out of your hands, or causing a rear skid, which, contrary to popular belief, is the worst kind of skid to recover from for most drivers. How big a factor? From the NHTSA: 414 fatalities and 10,275 non-fatal injuries occur per year in light vehicles due to a flat tire or blowout.

Whoa!

Predictable stopping distances are another huge factor in control and avoidance. Low pressures increase stopping distances, and while a driver might not get completely stopped in an emergency situation, scrubbing off speed can be a critical factor in reducing injuries and property damage. Small reductions in stopping distance will often result in a significant reduction in the impact velocity and greatly lessen the “felt” severity of the crash. In other instances, predictable stopping distance will prevent a crash from occurring altogether.

Low pressure also affects a tire’s profile, closing up sipes (those little cuts on the tread face) and water channels, thus increasing the risk of hydroplaning. And don’t forget that the load rating of a tire is greatly dependent on its inflation pressure. Reducing the pressure dramatically lowers the load rating, putting the tire into overload, increasing tire temperatures, shredding sidewalls and pushing the tire closer to blowout.

Low pressures also reduce fuel economy and tread life. Recent data provided by Goodyear indicates that fuel efficiency is reduced by one percent for every 2.96 psi of under-inflation, and tread wear decreases by 1.78 percent for each one-psi drop in inflation pressure. Surveys indicate that the over 90% of drivers will respond to a warning light indicating low tire pressure, which is why this system is being mandated for installation on all light vehicles over the next few model years.

Indirectly Inaccurate

There are two different types of TPMS systems and a hybrid version combining some features of each. The indirect method uses the wheel speed sensors for the antilock brake system to report wide variations in rotational speeds. There are problems with this technology. First of all, it doesn’t measure tire pressure, but instead measures rolling circumference, and compares four tire/wheel assemblies to one another. A car with four nearly-flat tires will never turn the low tire light on unless there’s at least a 25-30% difference among tire speeds reported. The driver may be in danger and not know it because the reporting criteria are based on relative data, not specific data. There is no way for the car to report actual tire pressure, and the trigger point for the light has to be artificially high to avoid spurious illumination due to something as routine as replacing a pair of tires instead of all four at once. It is cost-effective, and it does work for flat or nearly-flat tires, but a dangerously low tire can go undetected longer than deemed safe.

Direct

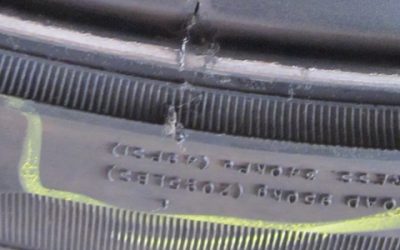

The direct methods use a sensor mounted inside each tire/wheel assembly to report each tire’s pressure to an on-board receiver, which adds an estimated $80 to the cost of an average automobile or light truck. The sensors may also report tire speed, temperature and relative humidity. Powered by a lithium ion battery with a service life of about ten years, sensors made by several manufacturers —Siemens, Beru, Schrader, Denso, Pacific — are mounted to the rim in such a way that they can directly sense and report the status of each tire on the car. Weighing in at about an ounce, the tire inflation stem is integrated right into the sensor on most designs. There are some older units out there that placed the sensor in the valley of the rim, belted in with a strap. At about $125 (retail) per wheel, second generation sensors are equipped with an integral seal and a gland nut that has a torque specification, typically in the 35-65 inch-pounds range. You must refer to the manufacturers’ information to get the correct data. Over- or under-tightening can cause the sensor to fail, and at the previously mentioned price of about $125 each, we can pretty much guarantee that you won’t have a happy conversation with a customer when you start talking about snapping off his sensors due to sloppy handling. Even the valve stem core has a torque spec, and at least one manufacturer, Vacula, offers a ratcheting breakaway valve core tightening tool for a street price of about $20. Obviously, this is no longer work for the biggest, dumbest guy you can hire for $5.15 per hour.

There are other service concerns as well. Typically, the valve stem is the antenna for the sensor and doing something as simple as replacing the original equipment valve cap with a set of those really cool dice or skull caps so popular at the checkout of discount auto parts stores can interfere with sensor transmission and trip a “service tire monitor” error message. There are also bulletins from various manufacturers warning of dissimilar-metals corrosion with replacement valve stem caps causing such tenacious seizure that the sensor is destroyed during valve cap removal.

SERVICE TIP: Don’t lose the original caps, don’t replace metal with plastic or plastic with metal — don’t try different caps, period. Remove all the O.E. caps prior to service, and keep them in a clean, dry, safe place. So, how can you tell if you can install a set of those neat custom caps? The presence (or absence) of the gland nut tells the story. We’d really hate to think we might keep anyone from buying a set of those neat little skulls with the fake ruby eyes, but…

“Car to Wheel, Come In…”

There is no way we can cover all the electronic variations for all manufacturers in a magazine article, but we can give you the basic concepts. There are two major variants to consider: integrated systems that piggyback onto existing electronics and dedicated systems that rely on a stand-alone tire pressure monitoring control module that reports over the controller area network (CAN) to the instrument panel (IP). The latest GM system, for example, borrows portions of the PCM, the BCM, the instrument panel cluster (IPC), the remote control door lock receiver (RCDLR) and the communications lines among modules, while the Mazda system uses a dedicated TPMS module, CAN and the IP. You will need the correct diagnostic information and flow charts to begin the troubleshooting process for the vehicle in your bay.

For a 2006 model year GM, if the internal accelerometer is inactive the sensors enter a stationary state. They sample every thirty seconds, but only transmit if there a significant pressure loss has been detected. Once moving, the sensors enter rolling mode, and sample at the same thirty-second interval, but transmit every minute to the RCDLR. The sensors continuously compare new readings to the last sample for reference and will transmit in re-measure mode if a 1.2 psi change is detected. Low-pressure messages that appear can be cleared by adjusting tire pressure. The sensor working range is 0-116 PSI with an accuracy of plus or minus two psi. Sensor relearn is initiated with the Kent Moore J-46079, or equivalent. The tool pings a transponder coil in the sensor at 125 kHz, which then transmits in learn mode to the RCDLR. When the RCDLR receives a transmission in learn mode and the sensor position is retained, it commands the IPC to chirp the horn to indicate “sensor learned,” so you can proceed to the next wheel. Learn sequence is left front, right front, right rear then left rear and must be done in that order. Learn mode will cancel after two minutes if no other sensor transmits in learn mode, or if five minutes pass from learn initiation. Procedures for earlier model GM cars vary from this procedure; again, make sure you’re using the correct service information for the year, make and model of the car.

The relearn procedures should be something we all pay attention to; they have to be performed after a simple rotation in order for the low-pressure message to be able to refer to the correct tire positionwise. The sensors will still work; they’ll just be reporting as though they were in their last learned position. The dash indication will be wrong, causing confusion with both driver and technician.

Sensor activation on our GM example can be done via a Tech 2 (most O.E. scan tools will command the TPMS system on their respective products), magnet (early GM), or via transponder ping. We found references to two types of transponder signals: one at 125 kHz with a continuous wave signal, and another at the same frequency with a pulse-width modulated signal. The diagnostic response channel can be at 315 mHz or 433.92 mHz, again depending on year, make and model. Modern universal testers such at those offered by OTC (www.otctools.com) or TIPS (www.tipstool.com) are upgradeable from your computer and will work on nearly everything o ut there, with the possible exception of current model year vehicles using a new protocol.

Be advised that there are also aftermarket TPMS out there, some using what looks like an overgrown valve stem cap as the sensor/transmitter, and others using a wheel sensor very similar to O.E. versions. If you run into one of these, hope that the vehicle’s owner will have kept the service information that came with the system, or perhaps you can find the manufacturer on the Internet and go from there.

Even Busting Tires Isn’t Simple Anymore

Although the sensors are streamlined and tucked in, you can easily destroy them if you aren’t careful loosening the bead and positioning the tire for removal. Old fashioned top-shovel tire machines should not be used if the bead shovel tends to tip inward and follow the rim contour as it’s drawn down. Your best bet is to purchase a new-generation table-type tire machine — if you’re mounting/dismounting stiff sidewall, low-profile tires, you need one anyway. It’s just about the only type of machine that can get the job done without damage. Some of the latest types have power-assisted accessory arms that manipulate the rim and bead for damage free handling, mounting and demounting.

No matter what you’re using, never position the shovel over the sensor when breaking the bead. The safest method is to remove the gland nut and let the sensor drop into the tire and then push the bead open far enough to retrieve the loose sensor before tire removal. Remember that the sensor can be damaged by either the shovel or by the bead itself if it’s drawn tight across the sensor as the removal shoe pulls the bead up over the rim. Just go slowly and use common sense. If you’re not happy with how it’s going, drop the sensor into the tire.

New and different is here to stay, and it’s going to permeate every system on the car. Who would have ever thought that tire changing or tire rotation could become so complicated?

0 Comments