By Bob Freudenberger

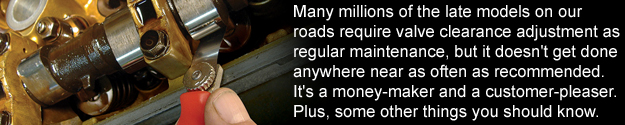

With no valve cover, adjusting clearance in this 1910 Buick is just a matter of pulling the pin and threading the yoke up or down on the pushrod. Aren’t you impressed that it’s got overhead valves?

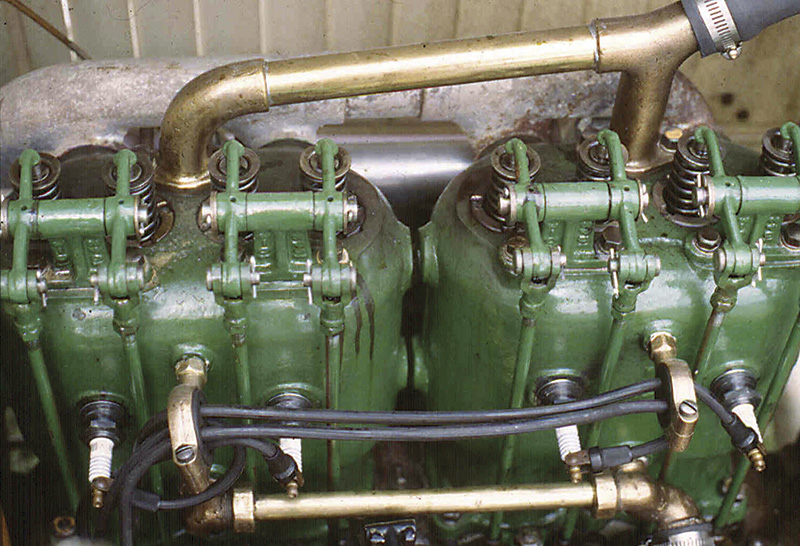

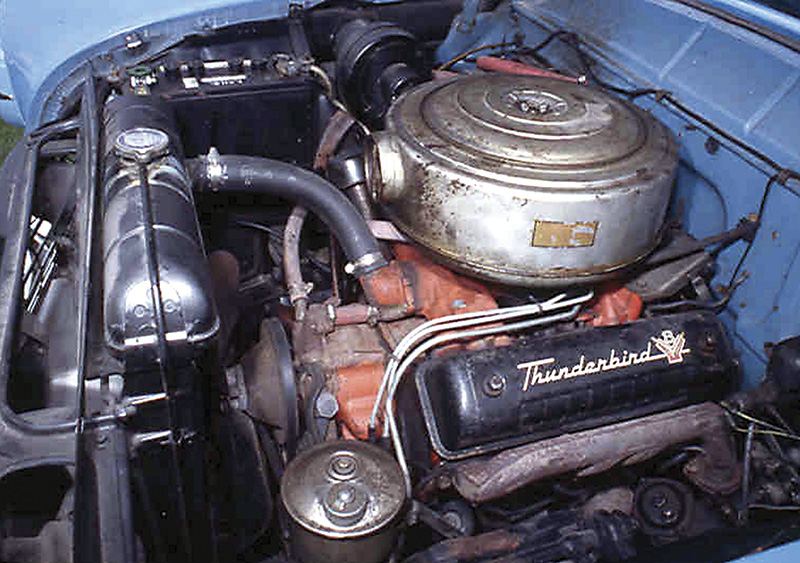

The earliest example we’ve been able to find of a mass-produced engine with hydraulic zero-lash valve lifters is the 1936 Cadillac Monobloc V8. Before that, on OHV engines from Chevy and others, you turned screws that threaded into the rocker arms until you were happy with the drag on the feeler gauge. Or, in a Ford flathead V8, for example, you had to grind the tip of the valve stem until you achieved the correct clearance. That is, unless you happened to have hot-rod “adjustables.” America got accustomed to most engines having hydraulic lifters after the Ford Y-Block with its solid mushroom tappets faded away in the early ‘60s, and valve adjustment looked like it was going to be relegated to the historical dustbin, where it would keep company with rod bearing cap shims, grease cups and water pump shaft packings.

Wave Upon Wave

After the Ford Y-Block with its solid mushroom tappets faded away, we as a nation got used to hydraulic lifters in most engines.

Except for imported engines. There was the VW Type 1, of course, and, as much as we hate to admit it, we well remember the English 1.6L in the Ford Pinto of 1971, which had pushrods, solids and adjustable valve clearance, a big departure in the Ford dealership where we were working. With the introduction of early Toyotas and Datsuns, and the continuation of throwbacks such as the slant six, we began to realize that we had to reacquaint ourselves with adjusting valves. Some were done static, others with the engine running (a messy proposition). Regardless, the maintenance schedules in those early days required that we do this job along with a tune-up, which was then required every 15,000 miles or so.

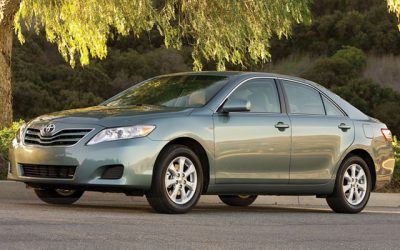

Now, of course, Japanese carmakers dominate the import market. Unless you’re an independent who specializes in makes that don’t include these conveyances, you deal with these vehicles every day. So, you have the responsibility of recommending the best maintenance practices to your customers who own Toyotas, Hondas, Nissans, Mitsubishis, Isuzus and Subarus. Since many, many of the engines that power these vehicles have manually-adjusted valves, you should be recommending lash checks as part of a normal bundle of maintenance services, which you can continue to call a tune-up, if you must use that anachronistic term.

What are the benefits of doing this job? You’re making money, of course, but there’s also the appreciation motorists will have of a quieted clatter, often to a high degree. There may even be a little improvement in performance.

Getting this right requires careful technique. First, of course, it’s easier if you take all the plugs out so you don’t have to fight compression, but you’ve probably already done that in preparation for the installation of new ones.

Next, use your head in choosing the specs. For example, if the range for an intake is .003 to .005 in., we naturally choose .004 in. We have two handle-type feeler gauges labeled “I” and “E” so we can put the blade for the intake clearance in one and the blade for the exhaust in the other.

Cold, Please

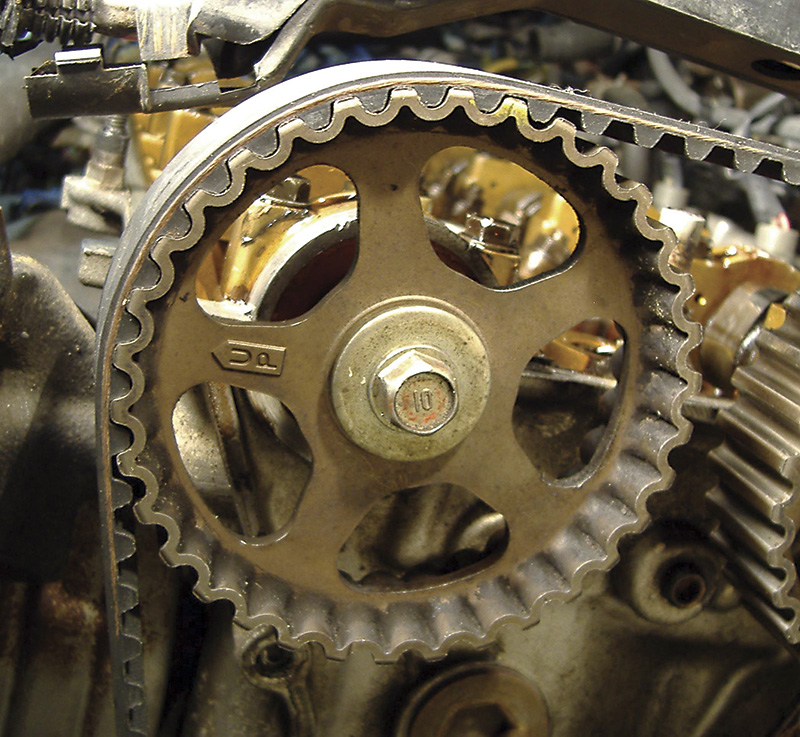

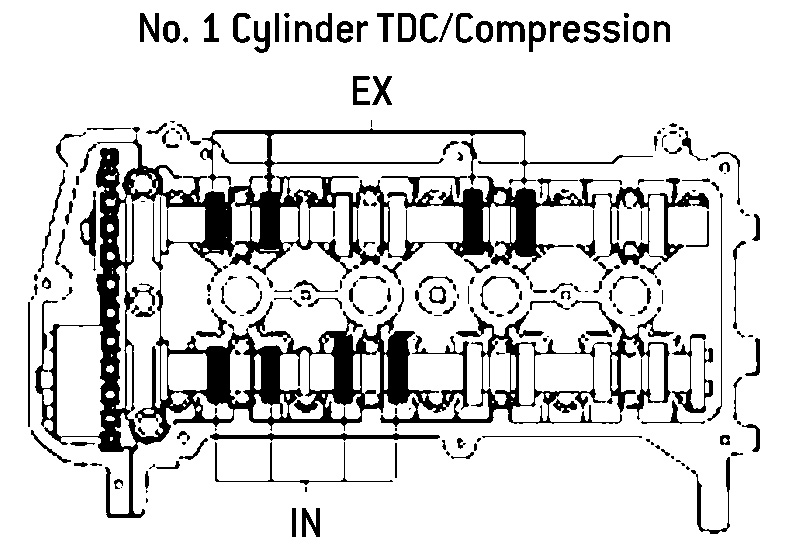

Follow those marks and the instructions exactly. This is the sprocket position for #3 in this firing order 1-3-4-2 engine . . .

How about temp? Specs are usually given for a cold engine. Well, waiting for that condition to obtain could really throw a monkey wrench into a busy shop’s schedule. Ideally, you’d do it after the car sat overnight, and that’s a definite requirement if the adjustment is being done to address a noise (too loose?) or idle misfire (too tight?) complaint. But otherwise, who can arrange workflow so that you’re always servicing a cold engine? No, you’ve got to deal with the time realities of modern life.

So, use the most powerful fan you’ve got on a hot motor while you remove the valve cover, etc. to get it down to no more than 100 deg. F. Then, choose the gauge that matches the max clearance given — in our example of .003 to .005 in., use .005.

You’ve got to make sure you’re measuring lash at the recommended area of the lobe, too. Don’t just assume that having the nose straight up and the heel down produces the most clearance. On the DOHC Honda shown, for example, the measurement is taken on the leading flank. Follow the procedure.

How much drag is too much? We can’t imagine how you’d put that into words. It comes down to the tactile judgment of a craftsman. Then, remember that as you tighten the locknut, you’re opening up the clearance by the amount of the play in the threads even if you hold the adjusting screw stationary. Take a few seconds to recheck.

Tighter and Tighter?

Although you may think it sounds strange, there are some engines wherein the valves recede into their seats faster than the mechanism that opens them wears, resulting in the counter-intuitive situation of the clearance getting tighter instead of looser. If neglected, this situation will result in misfires, then burned valves.

Wayne Pasicznyk, Honda Specialist with Identifix-Direct Hit, tells MT, “That will happen on certain engines. For example, the 3VZ Toyota V6 in the ‘88 to ‘95 4Runner. They’d get tight and a valve in #6 cylinder would burn. And, there were a lot of problems with the ‘98 to ‘01 Honda CRV 2L. The seats were soft, so the valves receded faster than the valve train wore, and the valves would get tighter and tighter. There’s a TSB on it.”

Indeed there is, and here are excerpts:

| Bulletin 03-038, November 5, 2004 Applies To: 1999-01 CR-V, ALLSYMPTOM: The engine idles roughly, is hard to start, performs poorly, or has the MIL on with DTC P0301, P0302, P0303, P0304 (cylinder misfire), or P0172 (fuel system too rich).PROBABLE CAUSE: One or more exhaust valves have receded into the cylinder head.

CORRECTIVE ACTION: Inspect the valve clearance and, if necessary, replace the cylinder head. INSPECTION PROCEDURE:

REPAIR PROCEDURE: Replace the cylinder head. |

Suba HLAs

Certainly, manually-adjusted valve clearance isn’t universal in Japanese vehicles. Take Subaru, for instance. The company went to HLAs (Hydraulic Lash Adjusters) many years ago. These have proved to be mostly trouble-free, but there are occasional instances of air trapped inside them causing tapping and loss of performance. If you encounter a Subaru with these symptoms, remove the valve cover on the noisy side and try to push in on the rockers against the lash adjusters. Does one move? If so, you’ve found air and you’ll have to extract the HLA for bleeding.

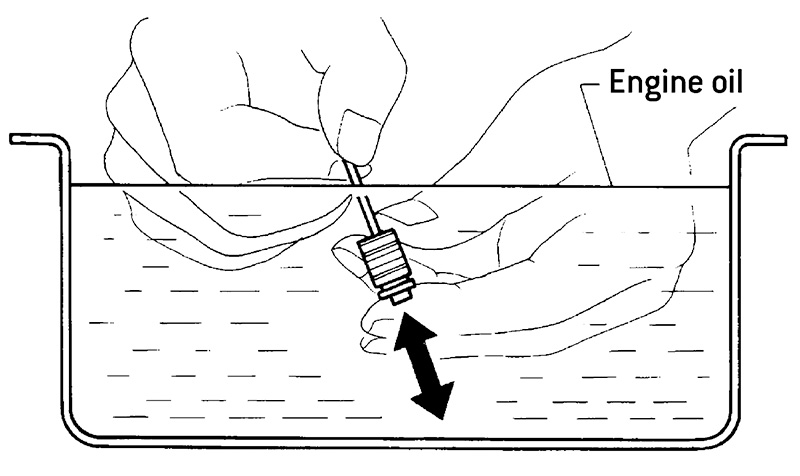

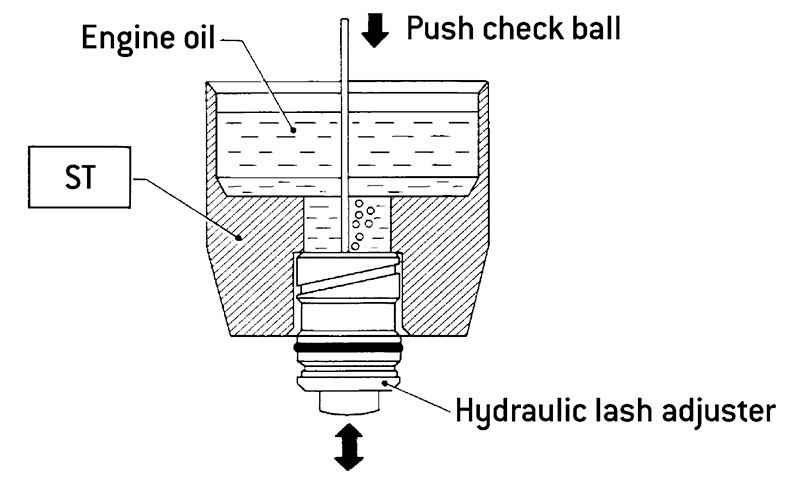

Or, you can do it by submerging them in a pan of oil and pumping while you depress the check ball (courtesy Subaru).

Loosen the bolts that retain the rocker assembly in a criss-cross pattern starting with the center four, but leave an upper center bolt engaged by a few threads, and pull out the offending lash adjuster. Submerge it in engine oil and depress the check ball with a thin rod or wire (0.08, or 2mm in diameter) while you move the plunger up and down slowly until you don’t see any more bubbles.

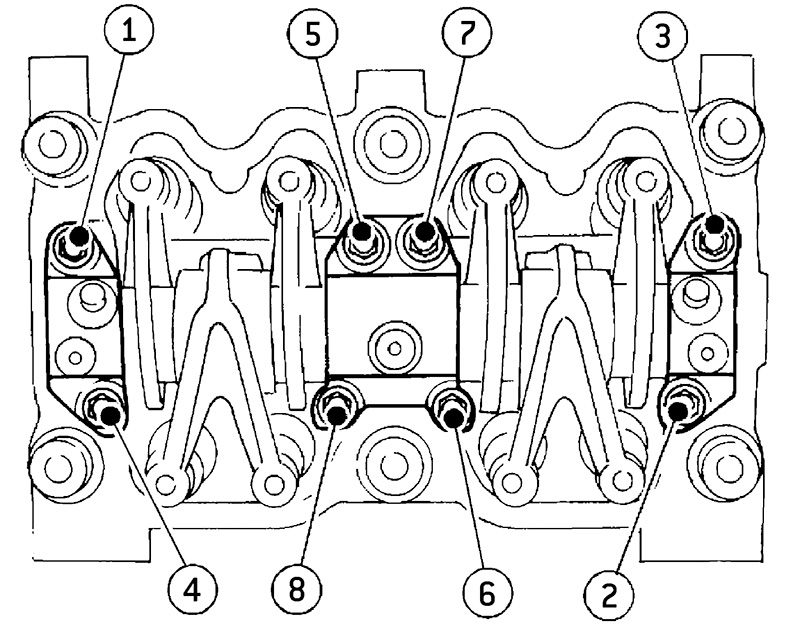

For reinstallation, fill the rocker reservoirs with oil and keep the bleed holes up. Tighten the rocker assembly bolts to 9 ft. lbs. in the pattern shown.

By the way, Subaru is the only Japanese carmaker we can think of that still relies on timing belts to drive the cams of most of its engines.

Cross-Wise Pushrod

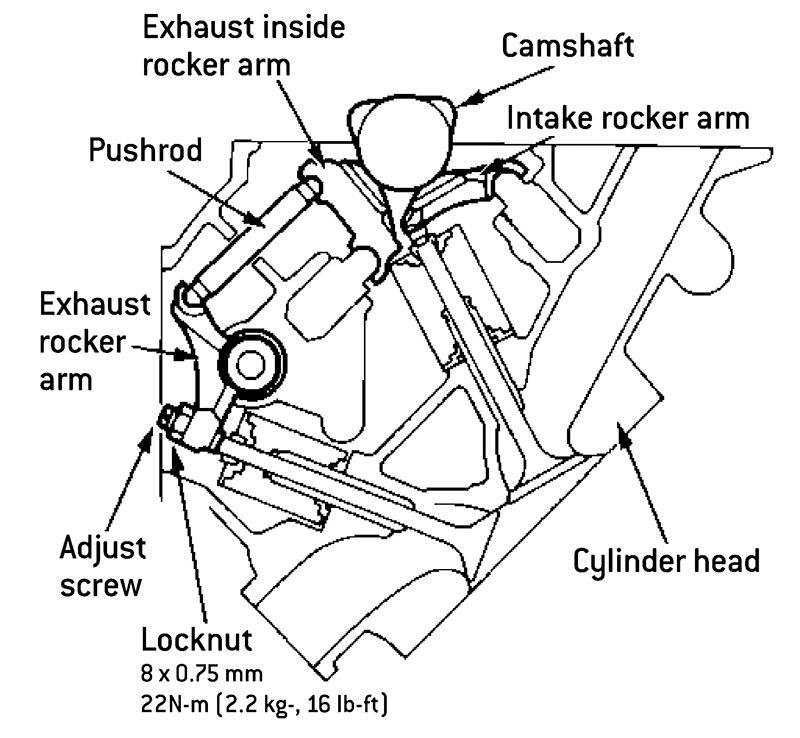

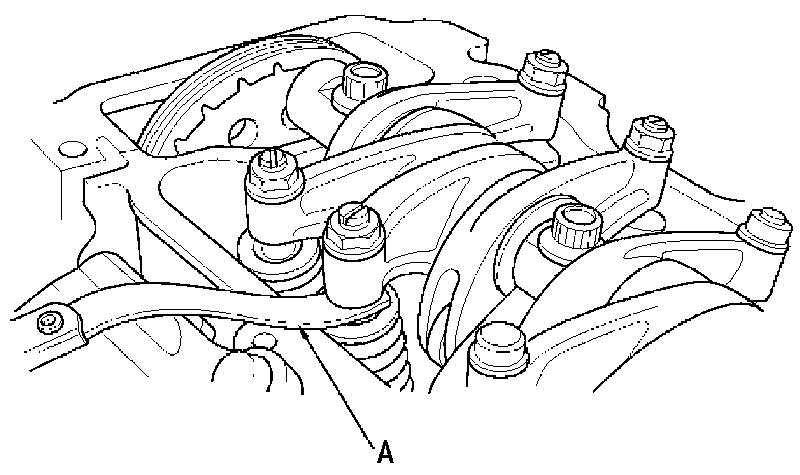

When we first saw the original Acura Legend 2.5L SOHC V6 that was introduced in ‘86 (that’s 20 years ago!), we were surprised at its innovative valve train with that stubby cross-wise pushrod. Never been a problem, though (courtesy Alldata).

We should mention one unusual configuration that surprised us when we first saw it: The ‘86 to ‘90 Acura Legend 2.5L/2.7L SOHC V6, which uses a stubby pushrod to transfer opening force cross-wise to the exhaust valve rocker arm. While there’s an HLA involved, you should know how to put it in the middle of its travel in cases where the head’s been disassembled, to wit:

- With the crank at TDC of #1’s compression stroke, turn the adjusting screw in until it just contacts the valve stem, then give it 1.5 more turns. Torque the locknut to 16 ft. lbs.

- Do the same on #2 and #4.

- Rotate the crank clockwise exactly one turn, then do cylinders #3, #5, and #6.

This 1.5L Scion engine has bucket lifters with shim adjustment. You can check the clearance of the eight valves shown at TDC of #1, then rotate the crank 360 deg. to check the other eight (courtesy Alldata).

Of course, there are many electronically controlled valve timing and lift systems out there on Japanese vehicles, but there’s so much to the subject that we’re going to save it for a future issue of Master Technician.

The job of adjusting valve clearance isn’t going away any time soon. Our research into the recent models found that even some of the latest Hondas, such as the Fit and the Ridgerunner, still require it. Also, many of the newest Toyotas still have shim-adjusted bucket lifters. So, get used to it and exploit it. Valve adjustment is not only an honest maintenance requirement, it’s also a customer pleaser.

0 Comments