It was supposed to be an estimate on an oil leak and suspension noise. We looked at the oil leak and suspension. It was later we learned that this vehicle had been “touched” by another shop.

History

Where do we start with this one? It was supposed to be an estimate on an oil leak and suspension noise. The X5 is owned by a customer we know and has a professional trust in us. We looked at the oil leak and suspension. It was later we learned that this vehicle had been “touched” by another shop.

Currently

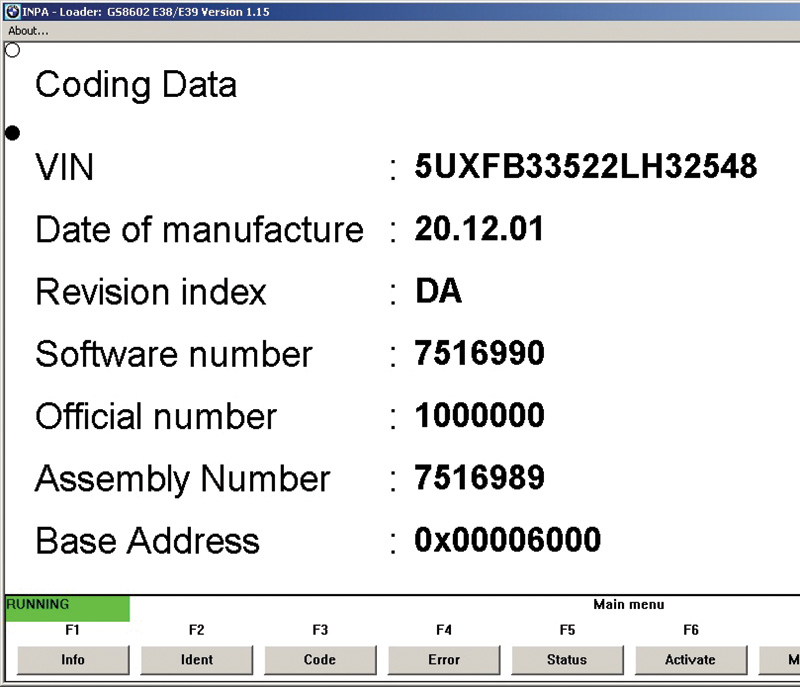

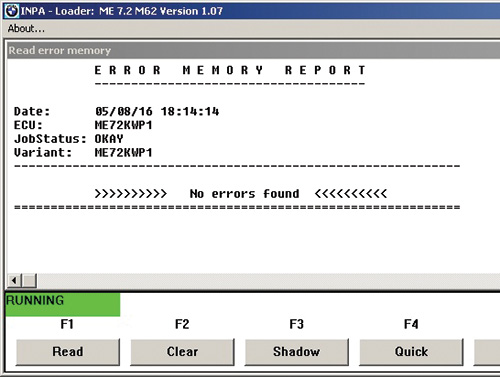

As usual, a system scan was performed and saved. The saved data was placed in a folder and all the fault codes were deleted. The suspension work was estimated, lower engine covers were removed and the engine bay and engine were cleaned. Time was an issue so we gave the X5 back and expressed to the customer, “Drive it for the weekend and we’ll look at it again at the beginning of the week when the suspension parts arrive.” How simple could it be?

Tools used

- BMW INPA with a “K” plus D CAN cable or ADS cable.

- Launch with the BMW software.

- 90 amp clean and stable power supply.

- A quality grease cleaner, water hose and compressed air.

Experience

INPA is a ridiculously quick and somewhat adjustable tool if you have the patience to translate the German language to English code. Software is required to accomplish this task but this article doesn’t discuss the changes made within the software. Many pieces can be found and added into the structure of INPA. For older models, this is our “go to tool.” The Launch Tablet version is surprisingly well made and the layout is quick and clean to use. There is no bi-directional control in this simple tablet version but the data is identical to INPA.

Method to test 1

The first issues addressed included the leaks found and suspension noise identified. In the service bay, one ball joint and a CV boot required attention on the passenger’s side. One leak was the transmission cooler and, while inspecting this, we also noticed an odd noise and found that

The water pump and one idler pulley required attention as well.

The remaining leak was yet to be discovered but for certain, the oil pan drain plug should have been sealed with a new gasket, not the mangled version still attached to the original plug. Oil sweating was also noticed at the timing chain covers. Quickly all this was noticed after a reasonably effective cleaning of the entire engine and undercarriage assembly.

One shop rule is; when a vehicle is in the service bay and the key in the vehicle, the driver’s window must always be in the open condition.

This proved to be a good rule, and when the window was closed in the parking lot, the window clip for the track broke and the glass became jammed.

The customer was notified and did comment “this happened at the rear windows,” and we did order new clips. Now we needed to get the window up and disable the window motor temporarily so we could return the car to the customer for the weekend.

Next shop rule; perform a road test, just to be sure and it was tested, ready to deliver for the weekend. That was a Friday, close to shop closing time. The next morning a call was received on my personal cell phone from the customer complaining about a lack of power and his “feeling unsure” about its drivability.

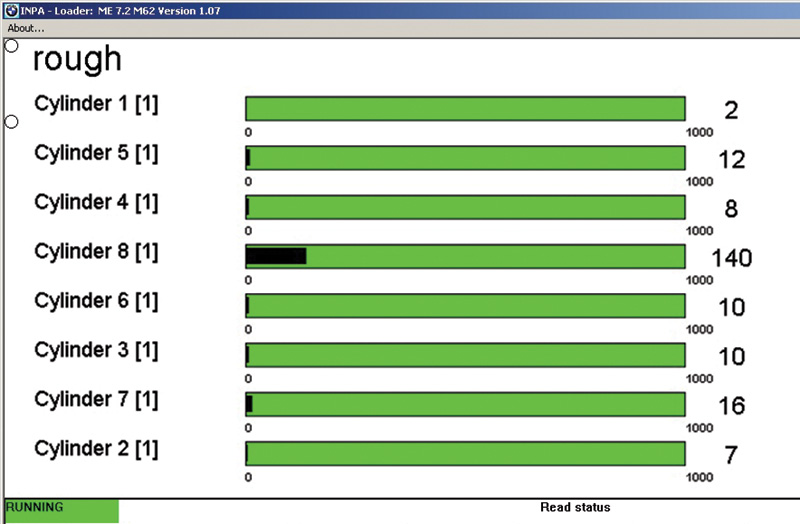

We met and one fault was found; this X5 did not behave like the day before. There were no recorded faults for the DME the first time it was looked at, and that included the previous day. I asked questions as to what the sensation was, his answer being “lack of power and seemed to run rough.”

So what were the chances that someone removed the cover over the coils and plugs, not ensuring that the seal in that cover was installed correctly and allowing leaking water into that one cylinder? 100 percent! Especially after we degreased and washed the engine. This seemed to work and, knowing full well this X5 did not arrive in this condition, it was checked, and double checked again, and the customer took the X5. Lucky for both of us, the X5 drove away and we watched it, very slowly down the street, and quickly returned with what would appear as higher idle. We heard the idle in this condition.

Next shop rule; Gather more information, and the customer was not happy because “it didn’t do this till you touched it.”

Then the customer said “see, look” as the throttle was pushed, no RPM increase and the customer turned off the key. We were horrified! Why was the key switched off in that condition, and would we be able to repeat it?

Yes it did recur, and we immediately heard something odd when the key was cycled to the ON position, then started the engine.

Method to test 1

We idled this X5 into the bay and got the customer back home. We got INPA ready while the fault was still affecting the X5. We looked for faults and recorded, then deleted, the codes.

An opera has structure; it has rules and is tuned to the music of the universe. It is an expression of the human condition through the eyes and heart of a genius. Thinking about this vehicle we realized the BMW wasn’t following any rules.

In the bay, there was no throttle control at all. With INPA running, that fault code was deleted, and we noticed that engine harmonics and RPM did change and we did feel the throttle react until the key was cycled again.

What we found

First, and because we had washed the engine, the drive by wire throttle control needed to be checked physically. The harness was inspected and no debris or water was found. To ensure a perfect connection, we used Stabilant-22 on the harness connection. Look it up, this is magic in a bottle and the scientific term would be “a long-chain organic block polymer that switches to a conductive state.” This is expensive and NOT to be used as a “mechanic in a spray can.” Do the research, it’s impressive.

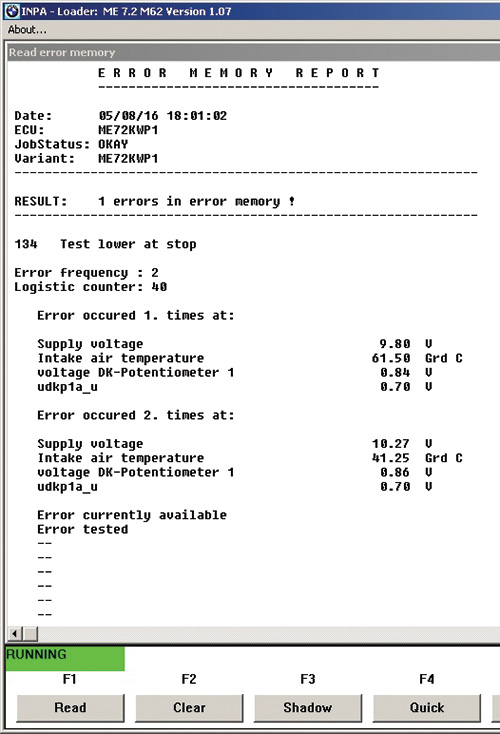

Second, we tried one more time and the fault returned with no throttle control until the fault was reset again. This time the scan tool software recorded the actual values and recorded the changes over time.

Recordings were screen images and a movie recording of INPA in use.

Third, we inspected the throttle blades because that noise appeared to be coming from the throttle control module.

When the air inlet and rubber seal were removed for inspection from the throttle body, the mystery of what happened was clear.

The clamp had to have been loose for some time. The clamp was loose enough to allow particles of dirt to enter between the hose and seal. With engine torque and movement, that small amount of dirt and debris would “grind” itself into the rubber seal.

When we washed and air dried the engine, we pushed whatever dirt was present through that loose seal, and that very small amount of dirt jammed near the shaft sides or the throttle. It took multiple tries and two more road tests to clean the throttle body to the point where throttle movement was perfect.

The values

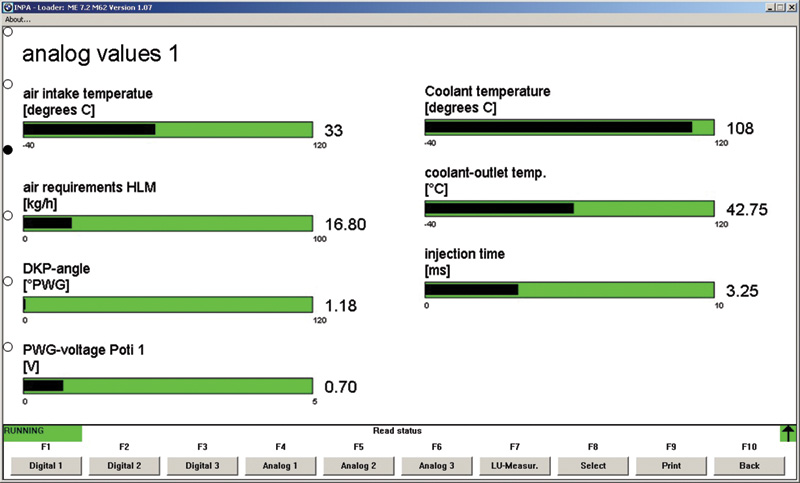

During the recording KOEO, there was a value of interest:

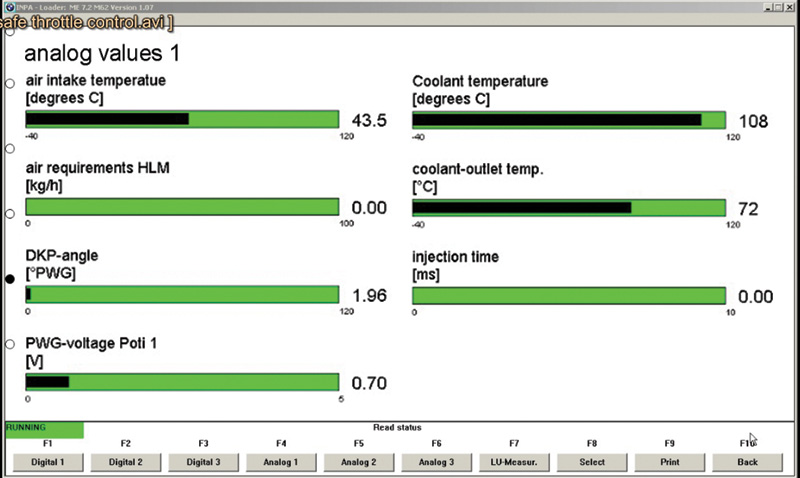

- DKP-angle would toggle between 1.57 degrees and 1.96 degrees PWG for no valid reason.

- WOT throttle worked to 100 degrees PWG when floored.

- At closed throttle, 1.57 degrees and 1.96 degrees PWG toggling resumed.

- This we considered in safe mode. The next image is a screen capture from a movie. 1.57 to 1.96 KOEO is not correct!

In the normal and cleaned operation, closed throttle is set to 1.18 degrees PWG with no load. That value remained stable.

If A/C was enabled, the setting would increase to 1.96 degrees PWG. If the rear defogger was enabled, the throttle degree increased to 2.35 degrees PWG. When consumers were turned off, the throttle returned to 1.18 degrees PWG.

The following image is a normal value/operation with no faults.

Note: These are values specific to this model at normal operating temperature and relative barometric pressure.

Once the cleaning was accomplished and the air inlet, air box and seals correctly assembled with a proper road test, the results were no faults, and the customer still maintains their trust in us. The image above is at normal temperature and idle.

So what was learned?

(a) Trust no one in Yoga pants that works on BMW models trying to imitate Pavarotti.

(b) Request to the customer that the local lube shop is just so.

(c) Murphy’s Law is 100 percent reliable.

Download PDF

0 Comments