Whether for emissions controls or for brakes or for other vehicle systems, parts from the original manufacturer have features available nowhere else.

Emission Components

As more localities make emissions inspections a prerequisite to registering or renewing a car’s license, more diagnostic and repair work focuses on emissions-related technologies in the vehicle. Though some inspections are relatively perfunctory, in other places the vehicle must come very close to the emissions standards it met the day it rolled out the factory door. That not only means all the emissions-related systems must be functional, but they must work almost identically to their original condition. OBD II CEL standards for many parameters allow a variation of no more than 50 % from the set values. Let more than one component wander from its original performance by some fraction, and the total can easily be enough to trip the emissions standards.

It is enough of a problem to determine just what is amiss if a vehicle should fail a test, especially factoring in the nagging suspicion there are an irreducible number of false-failures. The last thing you need, if you’re doing emissions work (or any other, for that matter), is to complete your testing, settle upon a component and replace it only to still have the same problem. On those memorable occasions when that problem turns out not to have been anything wrong with your diagnosis or work, nothing additional with the car you were working on, but instead a defective replacement part, it’s easy to feel a certain irritation at the parts manufacturer.

Your chances of feeling that irritation, to say nothing of your chances of wasting all the time it takes to diagnose and repair the car in the first place and then repeat a diagnosis only to find the defective new part – those chances are minimized if you use a part not just similar to but identical with the one that the car had in the first place, the part they used at the factory. It is not merely that short cuts and manufacturing economies could undercut the quality of a part.

When a part is manufactured by a group of people who not only understand its role in the complete vehicle system, but who invented that complete vehicle system in the first place, who take pride in their invention of a long series of such systems – you can count on that part to work the way you expect. Besides, while carmakers provide complete information about their emissions systems, their diagnosis and repair, they are not inclined to broadcast all the manufacturing technology and testing that went into the design and construction of the components. Somebody else, however skilled, trying to make a copy of the part is guessing and hoping to a large extent.

This is a particular concern when it comes to emissions parts, because there is rarely a way you can tell what the components do by a visual inspection since most emissions components eventually work chemically. Unlike brake disks or connecting rods or steering knuckles, you can’t necessarily tell by looking at an EGR valve or a charcoal canister purge valve when it’s supposed to do what. You have to work within an understanding of the whole system to diagnose and repair it, and the parts manufacturer requires the same understanding you do to build the part in the first place. Mercedes-Benz consistently builds emissions components to that level of understanding.

Besides their role in keeping the car’s exhaust and vapor emissions within the standards set by air quality regulations, emissions components are now so closely integrated with the rest of a vehicle’s engine and drivetrain management systems that what some time ago would have been an isolated emissions fault can now have effects on driveability and other vehicle aspects far removed from the tailpipe. Emissions control could even extend to the elimination of blue language on the part of an otherwise disappointed customer.

Dependable Brakes

Brake hydraulics lie at the heart of the deceleration system. A car that can’t stop perfectly dependably every time should be parked until a skilled, professional mechanic sets its brake system back to a reliably functional state. Of course, brakes are, with steering, almost the highest liability work you can do. Your partner in that work is the manufacturer of the parts you use. Do you know who that is? Could you find the person responsible for the quality of the part you installed if you had to? Do you know the extent, if any, of the vehicle testing and manufacturing experience they have?

When you’re working on high-liability systems like braking, there’s much to be said for working in partnership with the manufacturer of the vehicle, with a company that’s built their products in the same city for over a hundred years. They’re not going to disappear; they’re not disguised behind a blank white label. Get a master cylinder or a brake caliper from them, and you’ve tapped into a century of technical research and competence. This depth of resources is just not available anywhere else for any price, never mind at a discount.

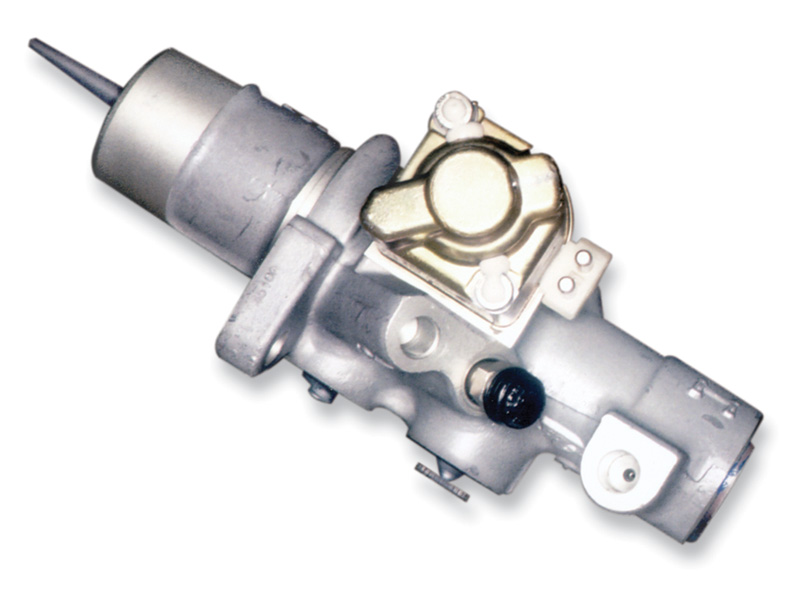

Besides the effectiveness and suitability of the part for its hydraulic role, another factor to consider is how easy it is to work with the component. A master cylinder like the one in the photo, for instance, that includes its own dedicated bleeder port can save many hours of brake bleeding, while you try to get the last bubble of air out of the system. In the absence of that bleeder, a master cylinder replacement could be a much more frustrating job, taking longer and with a much greater risk of unsatisfactory results, both for the motorist and for the shop. When you find parts that lend themselves easily to the intended application, you can depend on high levels of mechanical experience on the part of the parts maker. That’s experience just like your own and on the same vehicles.

Brake hydraulic components, however competently produced, require extended testing and an accurate, precise assembly procedures. What you have to achieve is a hydraulic system absolutely without compressible bubbles of air anywhere in the system and sealed against the absorption of moisture from any source. When the vehicle manufacturer built the parts, they thought these problems out and arrived at solutions to them, or continued testing until they did. Get the technical information as well and follow the recommendations of the vehicle and component designers and builders. What better partnership can you form with a supplier?

0 Comments