One of the first tests that should be performed during a no-start or drivability diagnosis is for proper fuel pressure. But there’s more than just pressure to think about.

Have you checked the fuel pressure? When we discuss a symptom that a vehicle is exhibiting, this is one of the first questions we have to answer. It would be disheartening to perform all sorts of time-consuming scoping of ignition waveforms, sensor specifications and voltage readings of signals only to find the culprit was a problem with fuel pressure. In the age of OBD II diagnostics, CAN communication among modules and pulse-width modulated signals, we often overlook the most basic tests such as that for fuel pressure. But there is so much more we can test about a fuel pump. Also, there are many more factors we have to think about besides the pump that affect the fuel supply to the injection system. Let’s see what some of those problems might be.

Under pressure

As long as they have been called Nissans, they have used a fuel pump mounted inside the tank (not true with the previous Datsun nameplate). Of course, Infiniti vehicles have always had it there. The pumps these days are mounted in “fuel pump modules.” These include the pump assembly, level sensor and supply and return lines. They also may include the pressure regulator on “returnless” systems.

Going back to “Fuel Supply 101,” the function of a fuel pump is to draw gasoline from the tank and send it through lines to the injection system mounted in the air intake manifold. A fuel pressure regulator makes sure that an adequate and consistent supply of fuel is available at the injectors. It keeps the fuel at the specified psi even if engine demand increases or decreases. It does this by maintaining spring pressure on a diaphragm against which the excess pressure from the pump pushes (the supply pressure from the pump is always higher than the required pressure). Most pumps are capable of putting out double the operating pressure. The 80 or so psi hits the diaphragm and forces a bypass valve open to allow the excess pressure to return to the tank, thus keeping the pressure at the specified level.

Fuel rail-mounted pressure regulators are often vacuum-assisted. Manifold vacuum is applied to the spring pressure side of the regulator. This pulls up on the diaphragm and lowers fuel pressure slightly. While under acceleration manifold vacuum drops, which allows fuel pressure to increase. This additional fuel is helpful in high-demand situations.

Keeping in mind exactly how EFI operates will provide you with more ways of testing it, and allow you to arrive at accurate diagnoses, especially in those hard-to-find intermittent problems.

Tapping in

Nissan/Infiniti does not typically provide a Schrader valve on their fuel rails for checking fuel pressure. Also, the rail on the V6 is underneath the upper intake plenum, so it is difficult to get to. Tapping into the feed line from the fuel filter is the right way to connect your gauge. Nissan/Infiniti uses a flange-style fitting starting in about 1999, so make sure you have the necessary adapters from fuel pump kit J-44321, available at your local Nissan/Infiniti parts counter.

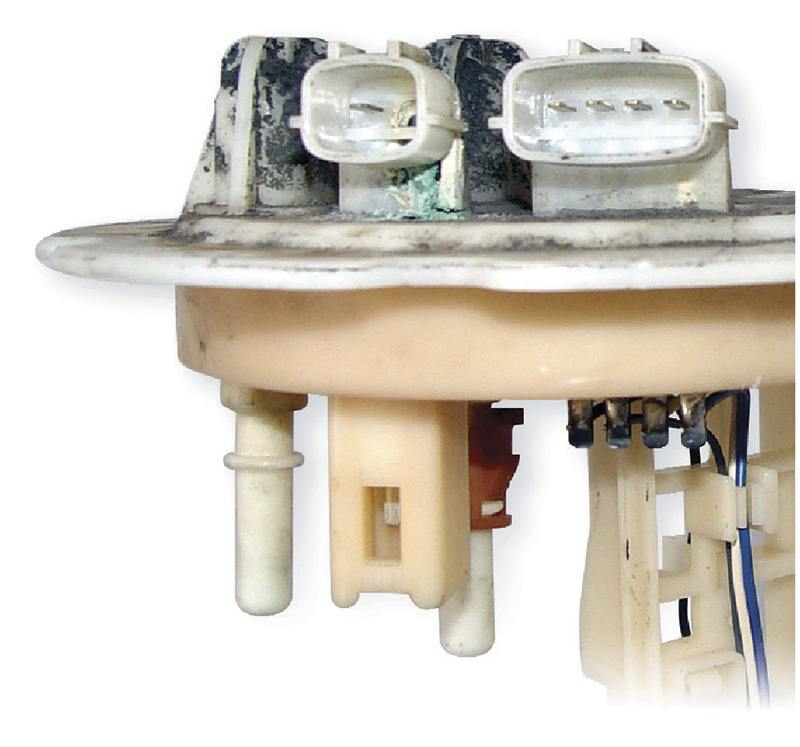

If fuel pressure is not up to spec, it doesn’t necessarily mean the pump is bad. In this assembly, you can see green copper oxide corrosion forming in the wiring to the pump, which causes high resistance and poor pump performance.

Always remember to play it safe and reduce pressure before disconnecting any fuel line. This can be achieved by using the Consult II, going into “Work Support” and selecting “Fuel Pressure Release.” Or, you can remove the fuel pump fuse, run the engine until it stalls, then crank it two or three times. Just don’t forget to put the fuse back when you’re done connecting your gauges.

Pressure can be checked with the fuel pump relay jumped and the engine not running, or by simply running the engine. Of course, with the engine running manifold vacuum is applied to the regulator so pressure will be 5 to 10 psi lower than with the engine off. If monitoring fuel pressure while driving, have someone else at the wheel for safety’s sake. Watch pressure carefully. Nissan and Infiniti provide fuel pressure specs with and without vacuum applied to the regulator. Under acceleration, fuel pressure should increase. If under hard load you see the pressure dropping you can suspect that something is going wrong with fuel volume.

Another test is that of “dead head” pressure. Here, you clamp off the return line from the pressure regulator back to the tank. As mentioned earlier, almost all pumps put out just about double the regulated pressure. By blocking the return line you can see the maximum pressure the pump is capable of producing, which should be almost double the engine-running pressure. If the psi does not increase significantly, then you may have a weak pump. We recommend that you do not leave the return line blocked for very long. Only perform this test long enough to read the gauge.

You can measure voltage at the pump control module, which is mounted in the trunk. In this case, the relay is providing 13.8 volts and the module is grounding the pump completely to get maximum output.

Fuel volume is another helpful test. Remove the fuel feed line and safely run the fuel into a measuring container. Crank the engine for 15 seconds and measure the quantity of fuel delivered. You should get about a pint. If you prefer, you can jump the pump relay with the key on — expect about one quart in 30 seconds.

estrictions in the system such as a collapsed fuel strainer in the tank or a clogged fuel filter can reduce fuel volume and cause drivability problems.

Don’t just throw in a pump

There are other factors involved in fuel pump performance than just the condition of the pump itself. Fuel pumps are electromechanical devices that rely on proper power and ground to function. If there is a problem with either, you could install several fuel pumps and still not have the necessary pressure or volume. So, you should perform electrical tests on the system, such as monitoring voltages to the pump.

You don’t need access to the fuel pump to check its amp draw. An inductive ammeter and a loop of wire installed in place of the fuse works fine. Or, you can use a scope and a low current probe.

This can be tricky since the pump is not always easy to get to. You can check voltage at the relay or fuse, but it could drop across connectors after the relay. You need to verify proper voltage at the pump, which will probably require removal of the pump. Luckily, Nissan and Infiniti have typically installed a fuel pump inspection cover either underneath the rear seat, or in the trunk, which makes life much easier. You can check voltage at the top of the fuel pump module and verify the ground without having to drop the tank. If you find a problem with voltage drop between the fuel pump module and the fuel pump inside the tank, you may need to replace the unit as an assembly. It makes sense to always do an amp draw test, which can let you know if the pump is working too hard (a clogged filter or a blocked return line, perhaps?), or is on the way out. Most Nissan and Infiniti fuel pumps draw about 5 to 5.5 amps. This can easily be checked with an ammeter between the switched contacts of the fuel pump relay, or at the fuel pump fuse. Most quality digital multi-meters (DMMs) can measure safely up to 10 amps, so this shouldn’t be a problem. Keep in mind that when you start the vehicle the “in-rush” created by the pump starting up will increase amp draw until it settles down into its true operating amperage.

Additional fuel pump controls

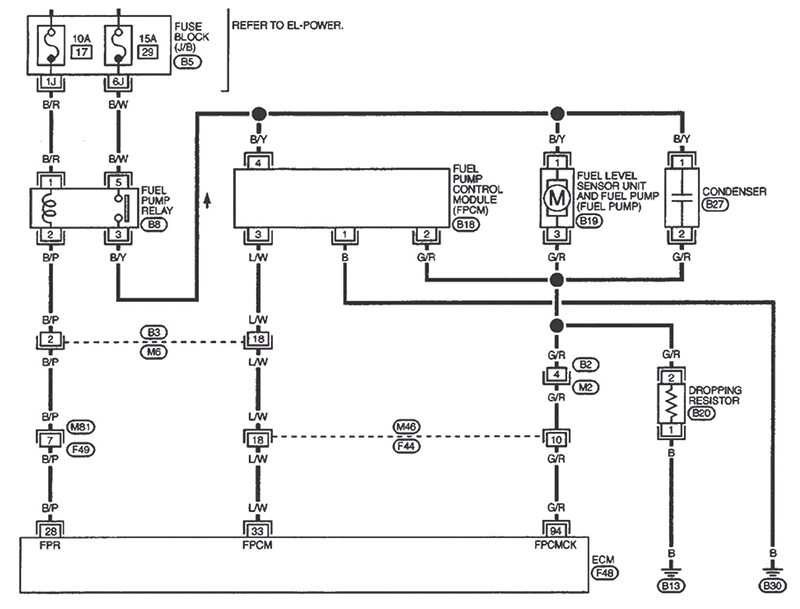

Nissan/Infiniti has also incorporated an additional control of the fuel pump. Under low-load situations, the engineers felt that the pump didn’t need to be operated at full power. So, they installed a dropping resistor in the ground side of the pump wiring. This reduces the voltage through the pump for low demand situations to about 9 volts. The addition of a fuel pump control unit can also ground the pump directly in higher demand situations, bypassing the dropping resistor and producing full fuel pump operation. You can bypass the relay and send full battery voltage to the pump by placing a jumper wire between the fuel pump ground and the ground of the module. So, if you see slightly lower pressure and volume numbers on some Nissan and Infiniti vehicles.

Finally…

Remember that the control module may be reducing voltage to the pump.

With the sensitivity of computerized fuel injection systems, something as simple as incorrect fuel pressure can cause everything from an illuminated MIL to a drivability concern. If your tests point to a worn-out pump as the cause of the problem, replace it with a genuine Nissan/Infiniti O.E. pump, which was not only designed to work with the control module, but will also have predicable pressure and amp draw specifications. Its long life is another benefit that customers will appreciate.

Here is a wiring diagram of a fuel pump control module on a 2000 Nissan Maxima. The module receives a signal from the PCM. Depending on this signal, the module either grounds the fuel pump directly, or allows it to ground through the dropping resistor only.

0 Comments