When a misfire is imperceptible, you may need to use the ECM as your “eyes” and “ears”. Learning to use freeze frame data and pending codes will speed diagnosis and reduce comebacks.

The misfire detection monitor, found on all 1996 and newer Nissan and Infiniti vehicles, will detect misfires long before they become noticeable from the driver’s seat. This was a great advance for those who like to keep their cars running at peak efficiency with minimal emissions (and who wouldn’t?). But, the sensitivity of misfire detection can make diagnosis frustrating, because a car that seems to be running fine may repeatedly set a misfire code. When diagnosing an imperceptible misfire, a technician must rely on the ECM for help with confirmation and diagnosis. Before jumping into a discussion of diagnostic techniques, let’s talk a bit about the reasons for misfire detection and how it works.

One of the most important reasons for misfire detection is to protect the catalytic converter. When a cylinder misfires, it sends all or part of its air/fuel charge into the converter, causing the temperature to rise. If too many misfire events take place, the catalyst will overheat and suffer permanently damage. The amount of acceptable degradation on modern catalysts is very low, due to ever-tightening emissions standards. Catalytic converters are quite expensive, so rapidly detecting and correcting a misfire is very important!

If the air/fuel charge does not ignite fully, its potential energy is not converted into motive force. If fuel is being used, but is not pushing the car down the road, the MPG will decrease. With current fuel prices, a typical driver with a typical car might spend $3000 per year on gasoline assuming it’s running properly. This is a pretty compelling reason to ensure a car runs as well as possible.

Another reason for early detection and elimination of misfires is engine wear. The unburned fuel in a cylinder with an ignition misfire or excessive fuel delivery may wash the oil film from the cylinder wall, causing the piston ring to contact the cylinder wall and result in accelerated compression loss, as well as oil dilution, further increasing wear on bearing surfaces.

Early detection

So how does the ECM detect misfires that go unnoticed by the driver? Simply, it monitors crankshaft speed. With each power stroke, the crankshaft will accelerate as the piston is forced down in the cylinder. The ECM monitors this acceleration using a crankshaft position sensor. If the acceleration is slower in one cylinder than the others, it stands to reason there was less power being generated on that cycle (a misfire). Thus, the ECM is able to detect a single misfire, even at 3,000 RPM. For us, this is too fast to detect. For example, on a four cylinder, that would mean picking one irregular power stoke out of 100 that had just occurred in a single second.

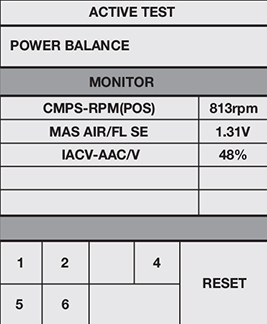

If you’re lucky enough to be assigned a car with a consistent misfire, the Power Balance Active Test is handy to verify the misfiring cylinder.

A severe misfire will provoke a different ECM response than a mild misfire. A severe misfire will trigger One Trip Detection Logic. A less severe misfire will trigger Two Trip Detection Logic. “Trips” are measured in key cycles for the misfire monitor. As long as the car is warmed up and has adequate fuel, the misfire monitor will run continuously while the engine is running. There is not a drive pattern that must be followed to get the monitor to run, although a specific drive pattern may be necessary to duplicate the misfire. It’s important to note that the key must be cycled off for at least 10 seconds to complete a trip.

If a misfire is severe enough to cause rapid damage to the catalytic converter, the ECM will blink the MIL as soon as the problem is discovered. This is called One Trip Detection Logic. If the misfire condition subsequently becomes less severe, the MIL will be turned off provided a misfire has not been detected on a previous trip.

If you monitor live data with the CONSULT, it will alert you when a pending code sets, and automatically start a data recording that you can review frame-by-frame.

If the misfire won’t cause rapid damage to the catalytic converter, the ECM will “remember” the misfire on the 1st trip, but will not turn the MIL on. Then, if a misfire is detected on a 2nd trip, the MIL is illuminated steadily. A Pending Code will be set after the 1st, so even though the MIL will not come on, you’ll have access to the pending code with the CONSULT or a generic scan tool.

Analyzing codes and freeze-frame data

The key to quick diagnosis lies in planning a logical attack based on available information. When faced with a MIL, the first step is to talk to the ECM and find out what it knows. The trouble codes and freeze frame data don’t hold the answers, but they do hold important clues. At the start of a diagnosis, they contain the information you’ll need to plan your next steps. So instead of rushing to start “checking stuff,” or blindly following a flow chart, take a few moments to look at the codes and the freeze frame data and see if you can think like an ECM, applying what you read in the manual about the DTC detection logic, and combining it with your unique human intelligence and knowledge of internal combustion engine operation. A diagnostic flow chart, no matter how well thought out, will never provide the fastest path to the right conclusion; in fact it may lead to no conclusion, or even worse, the wrong conclusion. Step one: put on your “thinking cap”.

Seeing patterns

Sometimes, misfire codes come in bunches. Looking for patterns in the cylinder numbers can sometimes lead you to a more fruitful diagnostic path. Nissan cylinders are numbered as they are laid out on the crankshaft. On a V6, the cylinder closest to the crank pulley is #1, and the farthest from the pulley is # 6.

If codes P0301, P0303, and P0305 were stored, it would be a clue that there is a problem common to all of the cylinders on Bank #1. Perhaps this is caused by a stuck VVT sprocket, or a clogged B1 converter, or a bad B1 A/F sensor, or a wiring problem particular to the injectors or coils on Bank #1.

If codes P0302 and P0304 were stored, you’d want to think about problems that would affect only those two cylinders, such as a head gasket blown between cylinders, or a leaking injector on cylinder #6 (driving cylinders #2 and #4 lean).

Like a flow chart, these few examples do not cover all possibilities, and there are many different engine designs and control strategies, so a pattern that might have possible meaning on one car may not on another. The point is that by looking for patterns and thinking about what might be causing them on your particular vehicle, you can eliminate unnecessary testing and jump straight to the tests that are most likely to yield useful results.

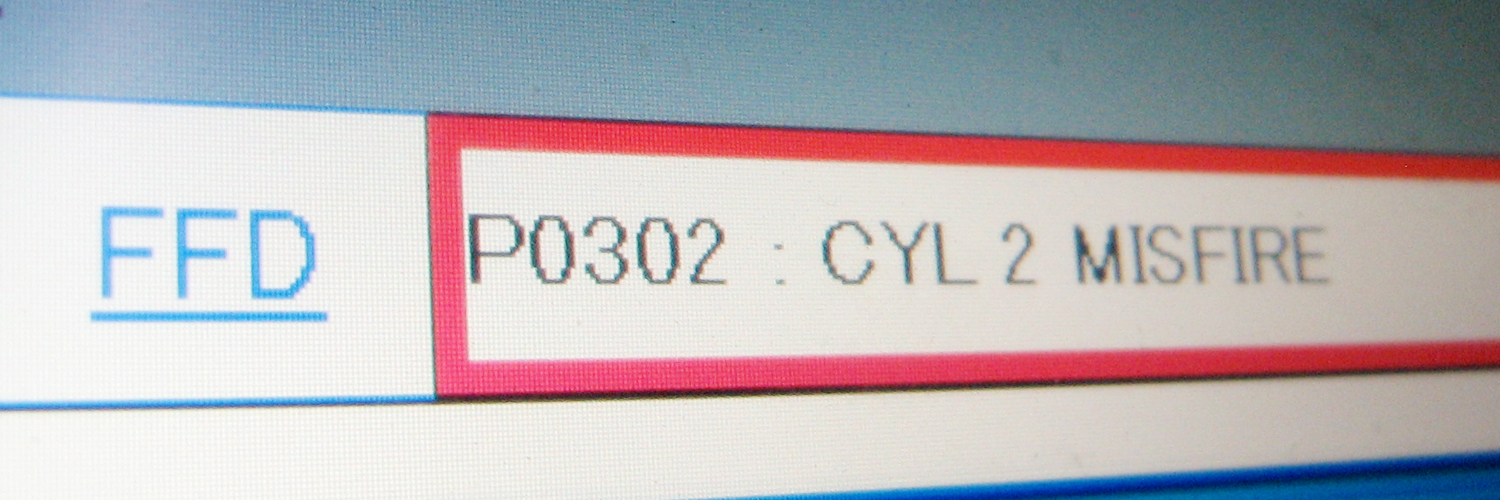

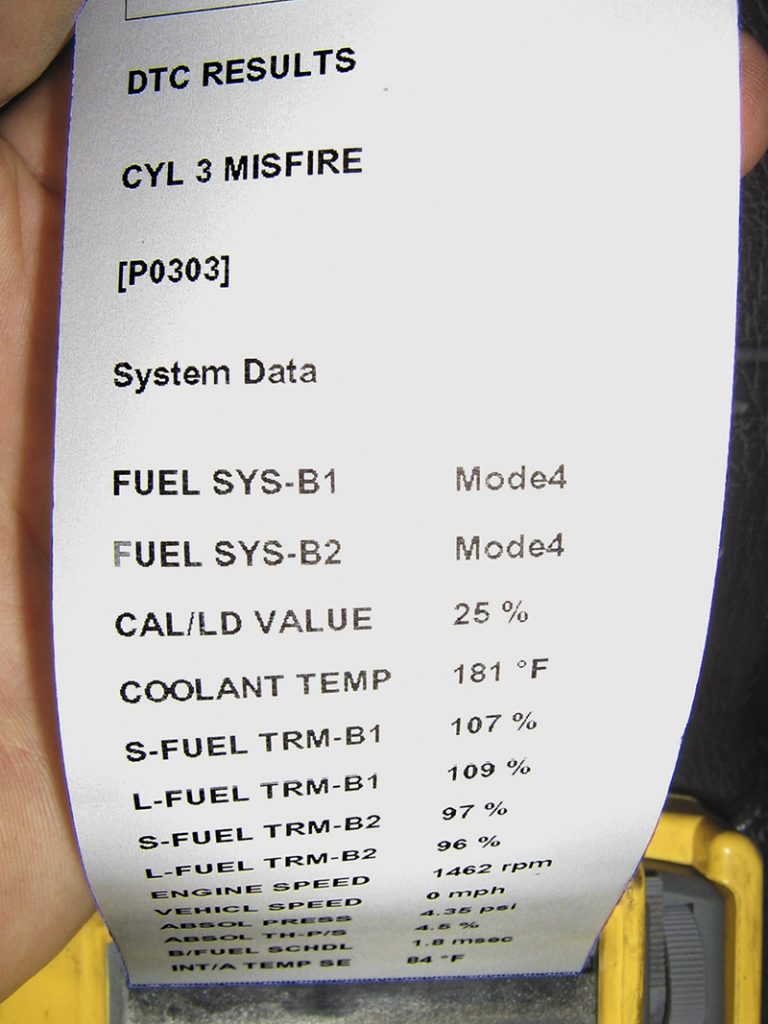

Freeze-frame data

Freeze frame data (FFD) is very important when diagnosing the cause of a misfire code. A cursory glance and printout will not do. Really examine the FFD. Read each PID and try to imagine what the car was doing when the code set, then verify your imagined operating scenario by driving the car and watching the same PIDs in live data.

Knowing the operating conditions that cause the misfire is not only important for trying to duplicate the conditions when the codes set, it’s also important for determining the likely cause of the codes. If a code was set at idle, you might lean towards checking for vacuum leaks or compression. If a code was set at light cruise, you might want to look at injectors or EGR. If a code was set at high load, the secondary ignition or fuel delivery become prime suspects.

It should be noted that the FFD is sometimes a bit delayed, especially on older models, so the FFD captured may be a second or so behind the event that resulted in the code setting. For instance, if the driver was at wide open when the misfire counter reached the threshold, then suddenly decelerated, the FFD may be misleading. It’s not a perfect world; it’s better to have access to information that is usually right than to have no access at all. If diagnosis were always easy, our paychecks would be a lot smaller.

Driving by the numbers

The other important use of freeze frame data is to duplicate the conditions that caused the misfire. There are three reasons you’ll need to do this.

First, you’ll need to confirm that the misfire can be duplicated now. If the misfire was caused by a transient condition, water trapped in a spark plug tube for instance, then you will not be able to confirm the cause or any repair. You may be able to find the cause and fix it without current symptoms through inspection and guessing, but you’ll never know for sure without a before and after confirmation.

Secondly, once the misfire is confirmed, swap testing is an excellent technique for isolating the cause. Swapping parts from cylinder to cylinder, and applying logic, can lead to a rapid diagnosis and a confirmation that you have come to the correct conclusion. Many engines have limited access to coils, plugs and injectors. When working with engines like this, it makes sense to reposition multiple parts at the same time.

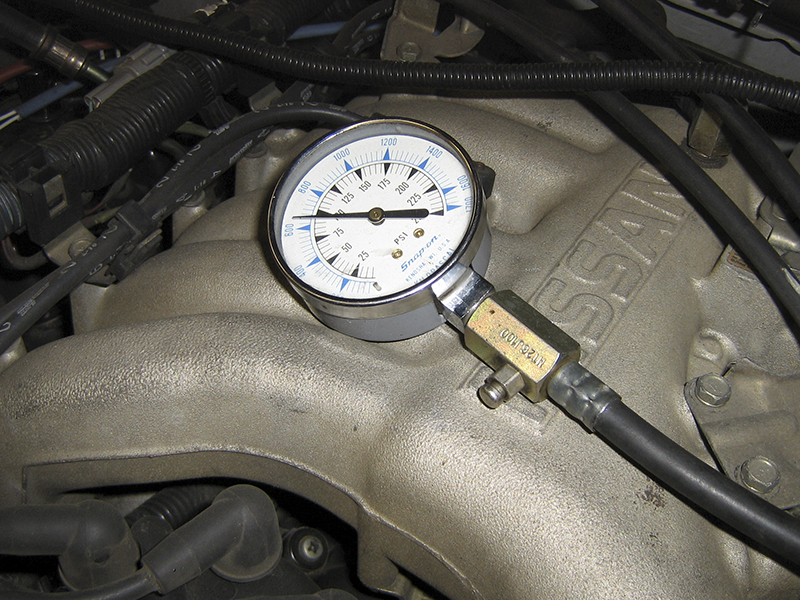

For example, let’s say a V6 engine has a P0303, and the coil and injector are buried under an intake plenum. Once you’ve confirmed the misfire is still present on cylinder #3, you’ll want to get maximum value for the time you spend removing the plenum. If you swap coil #3 to cylinder #1 and vice versa, injector #3 to cylinder #5, and plug #3 to cylinder #2, the misfire will follow the bad part. (It also makes sense to check compression on cylinder #3 while the plug is out). After the swap, confirm the misfire again. If it moved to cylinder #1, the coil is bad. If it moved to cylinder #5, the injector is bad. If it moved cylinder #2, the plug is bad. If it stays with cylinder #3, it’s not the coil, plug or injector, so focus on engine mechanical problems like vacuum leaks, valve sealing, etc.

Ignition and spark problems may be the most common cause of misfires, but don’t neglect your compression and vacuum gauges.

The final reason to use FFD in misfire diagnosis is confirmation of the repair. Once customers have paid the bill, they aren’t likely to want to spend any more money fixing the same code. Running a DTC confirmation procedure takes some time, but it’s time that can be billed. Time spent ensuring the car is indeed fixed is always time well spent. It protects your reputation, time, and avoids inconveniencing your customer.

Looking through the ECM’s “eyes”

If a tree falls in the woods, and there is no one there to hear it, does it make a sound? Likewise, if a cylinder misfires imperceptibly, is there really anything in need of repair?

If the misfire monitor is there to tell the tale, then yes, there is. Because the ECM is detecting what we cannot, we should let it guide us in our diagnosis. The FFD will tell us which road to take, and pending codes will tell us of our success or failure. When confronted with a P030x, we’re working for the ECM. It both guides us and judges our success.

0 Comments