Checking pushrods are available from several manufacturers and in lengths from as little as six ins. to as long as thirteen ins. They come in ball-to-ball and cup-to-ball configurations, with at least three cup sizes to accommodate the different sizes of ball adjusters commonly found on stock engines and on racing rockers adjusters. They are a must-have if you intend to get the right pushrod length the first time every time. Can’t do without ‘em.

A discussion of resonance, clearances, length, geometry, and lubrication.

A pushrod selection consideration is the tuning effect of size, length, and stiffness of the components in the valve train. Pushrods dance, jiggle, and vibrate as they operate and the “tuning” factor we need to consider has to do with resonance and harmonics. Any part has a natural resonant frequency at which it will vibrate and a point at which a small periodic input or disturbance coincides with the resonant frequency will cause the vibration to increase with each excitation input. Essentially, the small input becomes additive. Think about bouncing a basketball. If you were to apply a constant amount of pressure over and above that needed to compensate for the losses from the ball hitting the floor, gravity, and any wind resistance, each bounce would be higher and higher and higher.

It’s still possible to buy the tube and make your own pushrods. Here are just a few of the pushrod end types available should that be something you need to do.

An example of a problem with natural resonant frequencies and input disturbances matching arose some years ago as auto bodies became stiffer. The auto makers managed to make the car body’s natural resonant frequency the same frequency as that of an unbalanced tire at 60 mph. Suddenly, the smallest tire disturbance shook the car like crazy. In a single model year, we had to have a completely different tire mounting and balancing system to quell the shake.

What introduces input disturbances into the pushrod? The spring, the cam, the crankshaft, and the firing impulses it transmits via the cam drive system (another reason that belt drives are found on so many racing engines today), and the valve itself as it bounces on its seat at close. It’s interesting to note here that there are two reasons we use high-tech dampers on racing engines. One, to control the torsional twist that might fracture the crank, and, two, to reduce or dampen out those varying frequencies generated by the engine as it changes rpm that might be shared with the valve train and put it into resonance.

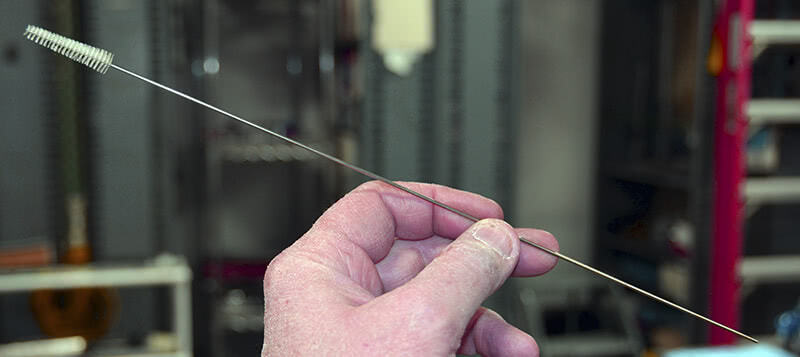

This is an example of a pushrod cleaning brush. Cleaning the oil passageways in a pushrod is just as critical as cleaning the oil galleries in an engine block. The first time I pulled one of these brushes through a new pushrod I was stunned at how much swarf was trapped inside that tiny little passage. The brushes are a little fragile, so order a couple of them. If you have heavy-wall pushrods and the oil passage is small, I’ve had good luck pushing the metal rod in first and pulling the brush through backwards.

When ordering pushrods, you must specify if you are running them with guideplates. Most come hardened and will be guideplate-compatible, but there are some that lack case hardening and will wear rapidly on the guideplate. Now you’ve got two problems: a damaged pushrod and metal in the engine. This three-piece is a street-only part in my opinion. I only run one piece in high-performance applications.

| Here you can see the difference between a pushrod with standard clearance and one with 210 degree clearance for a high-lift application. If the pushrod contacts the rocker body, it will try to push the pushrod out of the cup and dump the valve train. | |

Made for high-horsepower engines like those found in ProStock, Top Sportsman, and the mountain motor classes, the pressed-in bronze seat helps prevent galling when opening the valves against extreme pressure.

Space jam

Beyond clearance issues around the intake runner, what other installation considerations are there? Clearance issues at the rocker and lifter end are also something to think about. Putting a larger diameter pushrod down into a lifter to reach the seat might create side contact so tip clearance options might be needed. If lift is high enough, you may need to go to a ball end rocker and a cupped lifter to accommodate the pushrod-to-rocker angle and to keep enough oil in the joint to prevent galling. The cup acts like an oil reservoir that holds oil and cools and lubricates the interface, and offers more clearance than even a high-clearance conventional pushrod.

All pushrods need to be cleaned thoroughly before installation. Pushrod brushes are available from Trend and Goodson that do the job nicely. A high-quality high-pressure assembly lube is applied to both ends of the pushrod on assembly to prevent galling, and, last, but certainly not least, the pushrod must be the correct length.

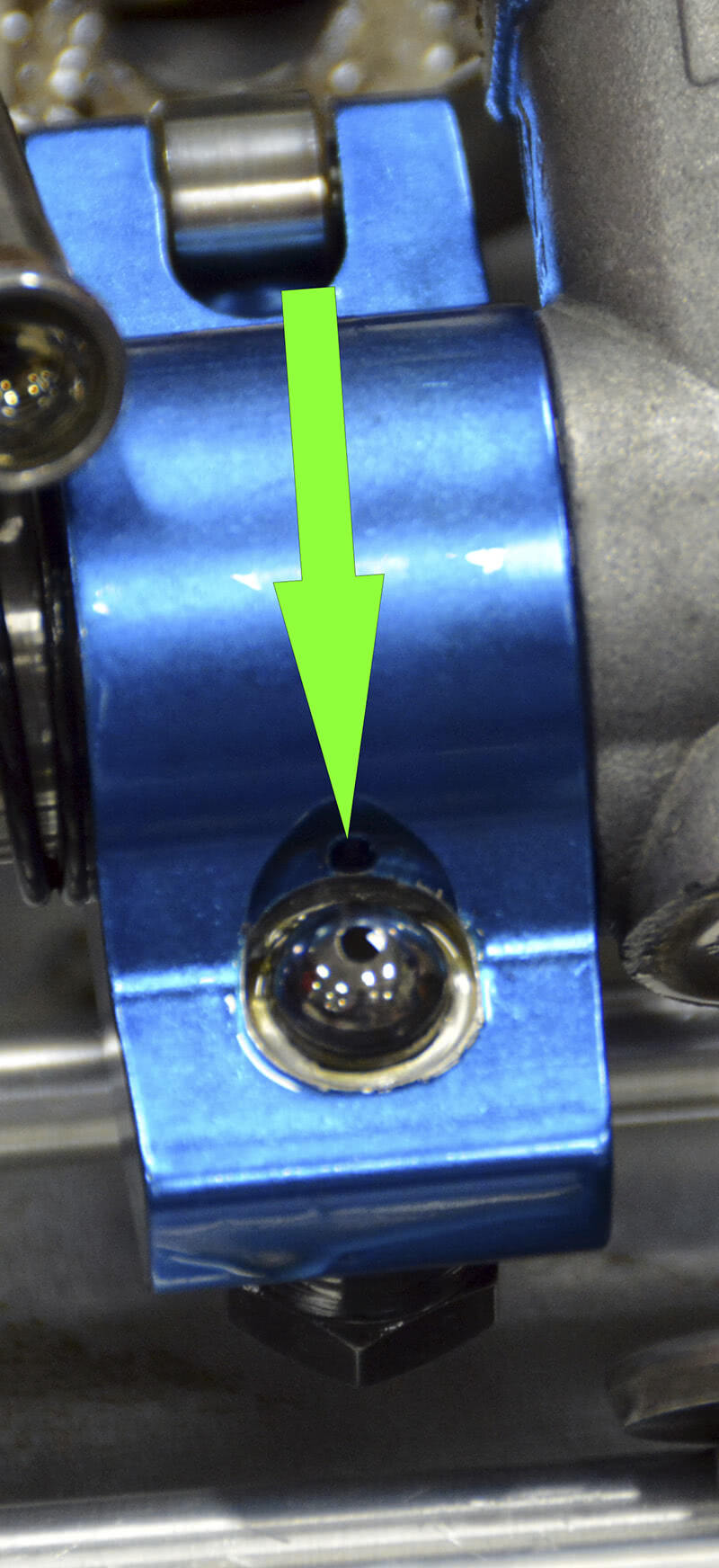

| At the arrows you can see where the adjuster screw has been drilled to allow oil to pass from the pushrod up into the rocker body. You can also see where the rocker body has been drilled to move oil into the needle bearings that ride on the trunnion shaft. If you order the wrong length pushrod, you will possibly misalign these passages to the point where there is no oil being delivered to the bearings and they will fail in short order. Read your rocker arm literature! You may have as little as three turns of adjustment. | |

Here’s an economy roller rocker mounted on a Ford FE engine. This is a shaft-lubricated system with solid pushrods so the rocker ball on the adjuster and the pushrod cup should be lubricated by pumping oil through the rocker body and adjuster screw and into the ball/cup interface. Since drilling all that is expensive, they just drilled a small spray hole that is supposed to somehow get oil into the space between the ball and cup. I suppose it might work if the spring pressures are very low, but this is not the kind of system I’d recommend for any serious engine.

Geometry

Rocker stand mounting height and pushrod length work hand-in-hand when trying to get the correct valve train geometry. Ideally, you would like the roller tip of the rocker arm to roll across the center of the valve tip — say about the middle third. The roller should start out slightly on the exhaust side, move to the center at mid-lift and move slightly inboard at full lift. The narrower the pattern the better, and getting it right means adjusting the rocker stands or trunnion mounts up and down and then ordering the correct pushrod to fit the finished application. More than that, the pushrod must be right-sized to allow oil flow, either from the pushrod up through the rocker cup to the rocker bearings, or from a pressurized shaft system through the rocker to the upper pushrod cup.

There are two major considerations in play. First, the rocker pushrod cup must not be extended out so far that it becomes unsupported by the rocker body and gets rocked back and forth and weakened. Second, the rocker adjuster cannot be turned out so far that it shuts off the oil passage from the cup up and into the rocker body. On both T and D and Jesel systems, as well as many others I’m sure, you’re limited to an operating range of as little as three turns total from seat, and you should be at one and one half turns at the end of the build so that you have some room to adjust the valves during the season. I can’t tell you the trouble I’ve seen from people not reading the directions that come with their rocker systems regarding how far in and out the adjusting screw can be in the rocker body. If you don’t have a set of length-checking pushrods, buy them — and use them. Set your rocker adjuster to the middle of the specified operating range, put the correct feeler gauge between the roller and valve tip, tighten up your checking pushrod, and read the length off the scale on the pushrod.

When you order your pushrods, take advantage of your supplier’s technical service department. Talk to the salespeople about your specific application, the power levels, rpm, spring pressures, and power output, and they will help you find the right product for your application. If you have questions pre-build, they will also help you find solutions to problems you might not be able to foresee. The people I’ve talked to are more than willing to help you with pre-build engineering.

The pushrod might be a simple-looking device, but it has big responsibilities. It is a key component in translating the cam into valve lift and duration and it is subject to far more stress than we imagine. Recent discoveries made with the Spintron have made quantum leaps in pushrod technology possible, but you still have to take a craftsman’s view of what you buy and how you install it. If you follow the few basic suggestions here, your pushrods will last you through several successful seasons.

0 Comments