There is a lot of confusion in the industry regarding differential gear ratios. Some Nissan trucks may have one of more than five different gear ratios. Fortunately there are many ways of determining gear ratios, and this article will teach you how to determine them economically and efficiently.

Differentials serve an important purpose on every vehicle, but they can be complex, and many technicians have trouble understanding them fully. In this article we will learn all about differentials, with a focus on determining gear ratios. We will discuss the purpose of a differential, the main components that all differentials include, some tips to remember when servicing differentials, and most importantly, how to identify differentials and their gear ratios.

We will look at a few different vehicles, but the focus will be on 4WD Nissan trucks of the last 15 years. These vehicles have both front and rear differentials, and have the most variations in design and gear ratios. Remember that the factory service manual is your best friend when servicing these vehicles, and the dealership parts department can clear up a lot of confusion if called upon. Just make sure you have the vehicle’s VIN handy and a fax machine or email ready for printouts of parts diagrams.

Sometimes it is very difficult to determine which “little washer” you are talking about, and simply circling it on the parts explosion can save everyone a ton of time and money. Remember, this article is not an all-inclusive cure-all for differentials, but rather a guide on how to approach servicing them and identifying proper parts.

First, some terms and basics of differentials. This will be review for most, but some may learn a thing or two and this information is required to properly identify and service a differential.

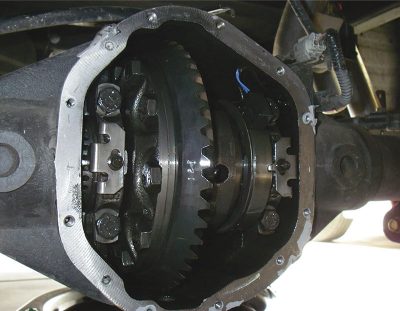

Differentials consist of a pinion gear, driven by the output from the transmission, and a ring gear (which Nissan calls drive gear) which drives the axles. Differentials also include other components that allow the drive wheels to spin at different speeds, which happens whenever the vehicle isn’t travelling in a perfectly straight line.

The most common type is an open differential which utilizes spider gears to allow this difference in speed, but there are also limited slip and locker-type differentials available. We won’t focus on these aspects of differentials in this article, but it is important to know they exist.

Every vehicle has at least one differential, but there are different types. Front-wheel drive vehicles have a differential that is almost always integral to the transaxle and does not change the direction of rotation. Rear-wheel drive vehicles have a differential that is located in a rear carrier and changes direction of rotation 90 degrees.

Four-wheel drive vehicle design varies, but most trucks use a front differential carrier, similar to the rear differential carrier, that is modified or offset to fit in the front of the vehicle where space is at a premium. Some all-wheel drive SUVs have a different setup, especially those that have the option of either FWD or AWD on the same chassis. They typically have transverse mounted engines and a FWD differential setup, but with a transfer case bolted to the transmission and a driveshaft connecting to a conventional rear differential carrier.

Differential gear ratio, or final drive ratio, is determined by dividing the number of teeth on the ring gear by the number of teeth on the pinion gear. For example, if the ring gear has 47 teeth and the pinion gear has 16 teeth then the gear ratio is 2.937:1. This is usually expressed as simply 2.937, as the 1 is assumed.

Differentials are often referred to as “final drive” because they are the last set of reduction gears before the drive axles and wheels. All differentials on production vehicles are reduction type, which means the input shaft will rotate multiple times for each rotation of the output shaft. This means there will be an increase in torque, but at the cost of a decrease in speed. This final reduction is on top of any reduction that has already taken place in the transmission.

Let’s take a look at an example of the extreme reduction that occurs in first gear on the 2012 Nissan Xterra 6-speed manual with M226 rear differential. The gear ratio for first gear is 4.368:1 and the final drive gear ratio is 3.538:1 Therefore the engine spins 15.454 times each time the drive wheels spin once!

Now let’s look at ways of identifying common Nissan differentials. Knowing which differential a vehicle is equipped with will narrow down the potential gear ratios and make ordering parts considerably easier.

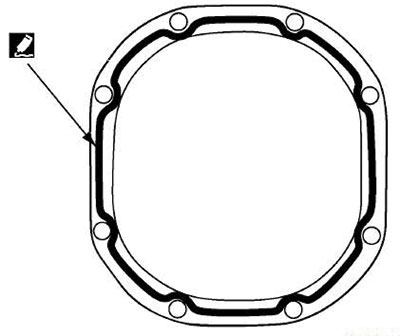

C200

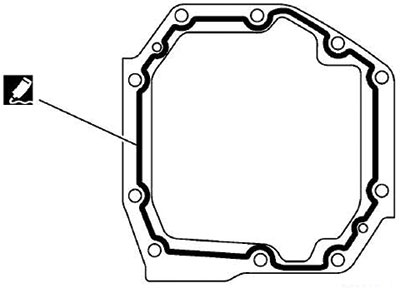

A fairly common rear differential in many Nissan Frontiers and Xterras, the C200 has a 200mm ring gear, fully enclosed axles, and quite a few different possible gear ratios. It can be identified by its removable rear cover that is symmetrical and has 8 bolts securing it to the differential case. Equipped gear ratios include 2.937, 3.133, 3.357, 3.916, 4.083, 4.363, and 4.625.

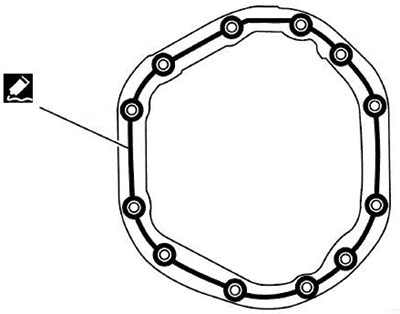

M226

A bit more heavy duty than the C200, the M226 rear differential can also be found on Frontiers and Xterras, and is the only differential used on most Titan models. It has a 226mm ring gear, fully enclosed axles, and is available with or without an electronically locking differential (ELD). It can be identified by its removable rear cover that is not symmetrical and has 12 bolts securing it to the differential case. The cover has a bulge towards the left side which provides clearance for the ring gear. Equipped gear ratios include 2.937, 3.133, 3.357, 3.538, and 3.692.

H233B

A “third member” type differential, the H233B rear differential, is mostly found on older Nissan hardbody trucks and early model Frontiers and Pathfinders. It was very popular in the 1990s and early 2000s, but has been phased out in recent production vehicles. It has a 233mm ring gear, fully enclosed axles, but no removable rear cover. The entire final drive assembly is assembled together and then bolted into the differential case. Equipped gear ratios include 4.363, 4.636, and 4.900.

R180A

The R180A is the most common front differential and can be found on Frontiers, Pathfinders, and Xterras. It has a 180mm ring gear and is mounted offset to the left with an enclosed side shaft on the right side. It has a removable cover with 9 bolts, 8 of which are arranged in a mostly symmetrical pattern. Equipped gear ratios include 3.133, 3.357, 3.538, and 3.692.

R200A

Basically a bigger version of the R180A, the R200A front differential is fairly uncommon but can be found on Frontiers and Xterras of the late 1990s and early 2000s. The removable cover is symmetrical with 8 bolts, and is similar to the C200 cover. The ring gear is 200mm in diameter. Equipped gear ratios include 4.363, 4.636, and 4.900.

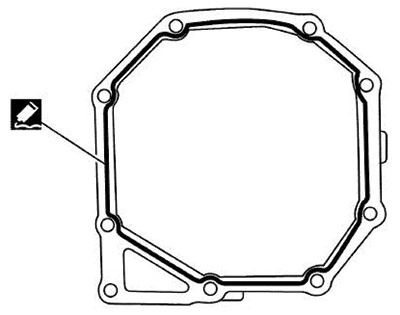

M205

This front differential is found on the largest vehicles in the Nissan line such as Titans and Armadas. It has a removable front cover with 10 bolts arranged asymmetrically. It, like the previously mentioned front differentials, is offset to the left with an enclosed side shaft on the right side. However, unlike the other differentials, there is a small extension housing at the right end of the side shaft tube. Equipped gear ratios include 2.937 and 3.357.

Ways to determine differential gear ratios

The easiest way to determine differential gear ratio is by consulting the factory service manual. There are multiple options for many vehicles, depending on transmission, trim level, and whether the vehicle is 2WD or 4WD. However, every possible OEM gear ratio is listed in the service manual, and can be located with a little patience.

First go to the “Driveline” section of the service manual, abbreviated as “DLN.” Skip to the “Service Data and Specifications (SDS)” section and all available gear ratios are listed along with the number of gear teeth on both ring gear and pinion gear. There is also lots of other useful information in this section including clearance, preload, backlash, and runout specifications. Also included is a list of adjustment washers including their part numbers. Keep in mind that most dealerships don’t stock all, or any, of these washers so be sure to allow a day or two to get them if you are rebuilding a differential.

The VIN tag, typically located on the driver side door jamb, will list the axle code which can be used to determine differential gear ratio. The code will be listed as two letters and two numbers. The letters will indicate the type of rear end and the number will indicate gear ratio. For example, an axle code of CA31 indicates a C200 rear differential with 3.133 final drive ratio, while an axle code of CC35 indicates an M226 rear differential with 3.538 final drive ratio.

Bear in mind axle codes will only be listed on the VIN tag for the rear differential. There is also a sticker located on the rear differential near the companion flange that will list the gear ratio, but chances are that sticker will be long gone on most vehicles that are a few years old.

The differential ring gear will also be stamped with the number of teeth that are on it and the pinion gear. So if you are working with a differential that has a removable rear cover and are unsure of the gear ratio, then the cover can be removed and the differential spun until the stamp is visible. While removing the cover is not ideal, it is not terribly difficult or expensive to do. This is not a viable option on “third member” type differentials, however, as they do not have removable covers and it takes a lot of work to get a good look at the ring gear.

One of the best ways to identify differential gear ratios on any vehicle is the “mark and spin” method. While it is not the most exact method of gear ratio calculation, it is an excellent test that will definitely get you in the ballpark at the very least. It is important to know what the different possible gear ratios are before starting the test.

For example a 2012 Nissan Xterra with a C200 rear differential will have either a 2.937 or a 3.133 final drive ratio. To perform this test we must first lift the rear end of the vehicle and make sure the transmission is in neutral. Before we start the procedure we should determine whether the vehicle has an open differential or some form of limited slip or locking differential. Simply spin one of the wheels and watch the other. If it spins in the opposite direction then the differential is open, if it spins in the same direction then the differential has some sort of locker or limited slip.

Now mark the tire at the 12 o’clock position and mark the propeller shaft and a non rotating portion of the differential carrier in a place that can be easily seen. If the differential is open, then one of the tires will need to be secured so it will not spin. Now slowly spin the tire two complete revolution while watching the propeller shaft. The tire is spun twice because the other tire is secured; two revolutions of one tire will equal one revolution of the ring gear.

Count the number of revolutions the propeller shaft makes. It will never end up spinning an exact number of times, so any partial turns will have to be estimated (which is why this procedure is imperfect). If it spins just under 3 revolutions then the ratio will be 2.937, and if it spins just over 3 revolutions then the ratio will be 3.133.

If the differential is a limited slip or locker type, the procedure is similar. The only difference is that one tire will not need to be secured, and the tire will only need to be spun one revolution. One revolution of both tires equals one revolution of the ring gear.

As you can see, determining gear ratios can be very confusing and difficult. This is especially true when working on vehicles that have many different possible gear ratios, or have potentially been modified from their OEM packages. Hopefully you will find some of the information in this article useful in finding the final drive ratio of the vehicle that you are repairing. It is by no means a panacea of final drive gear ratios, but it should get you enough information to confidently order parts and repair a front or rear differential on Nissan vehicles.

The reality is that most vehicles only have one or two possible final drive ratios, so determining which one you are working with isn’t very difficult. But for those few vehicles that have many possibilities, you will need all the help you can get. Remember that it is always cheaper and easier to spend a little extra time thinking, testing, and researching, than making assumptions and ordering the wrong parts. Patience and clear, logical thinking are required when working with these complex modern vehicles.

0 Comments