Threaded fasteners — It’s not just length and thread count!

Tips for decision-making about non-reusable bolts and joining technologies.

This 2013 Beetle GSR TSI engine includes TTY bolts for greater clamping force, encapsulated bolts for corrosion resistance in water-immersion applications, and many other different types of fasteners.

It’s a fact: automotive bolts are application-specific. We make sure we have the correct length bolt for the application. If a bolt is too short and only engages a few threads in the component, it may pull the threads out of the joint. If it is too long, it may bottom out when installed in a blind opening.

If a bolt is reusable, we measure to check that it has not already been stretched beyond its factory-specified length before reusing it. We torque a bolt to a factory-specified amount in an effort to ensure a durable assembly.

Newer bolt designs feature differences beyond length and torque specification that require a bit more attention to detail.

Torque-to-Yield bolts: A stretch beyond

Torque-To-Yield (TTY) bolts are designed to be stretched to a degree that requires greater precision than can be achieved using torque measurement alone. The benefit is a more uniform amount of clamping force being applied to the materials being joined.

A great example of where this is important is use in cylinder head installation. The fact that some head bolts may need to be a different length than others, possible variations in friction between individual bolts, compressibility of the head gasket — or in the case of newer Multi-layer Steel (MLS) gaskets, non-compressibility — and other factors must all be taken into account when determining the amount of clamping force required for a strong seal between the cylinder head, gasket and block.

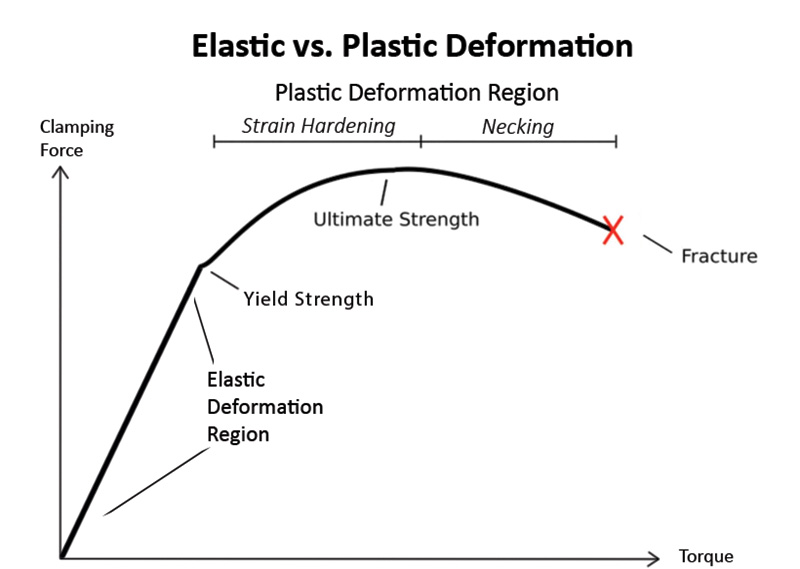

Elastic deformation offers a linear relationship between torque and clamping force. Each additional unit of torque generates clamping force at the same rate as the prior unit. In the plastic deformation region (above the yield strength limit on the graph), additional torque generates incremental clamping force at a nonlinear rate that peaks (strain hardening) and then tapers off. Volkswagen engineers calculate precisely how much beyond its torque yield limit each TTY bolt can be rotated to maximize its clamping force.

All bolts stretch slightly when tightened. Like with rubber bands, stretching increases the clamping force, for more durable holding power. In the past, bolts were typically tightened to a torque amount intended to stretch the bolt to just below the point at which it would permanently deform. This amount of torque caused elastic deformation, or stretching of the bolt, but not so much that it could not return to its original shape once the load was released. The bolt retained its shape and strength, and was thus reusable.

TTY bolts are intentionally tightened beyond their elastic limit. The bolt stretches and changes its shape permanently. It cannot bounce back to its original length when uninstalled. A TTY (or other) bolt that has entered this state, called plastic deformation, cannot be reused. Further stretching would weaken it and reduce performance.

TTY cylinder head bolt design eliminates threads wherever they are not necessary along the shank length. This reduces shank diameter and bolt weight, which contributes to fuel economy improvement and materials cost reduction. These non-reusable TTY cylinder head bolts fit many Volkswagen models, including the 1999-’05 Beetle, 2000-’06 Golf, and the 2000-’05 Jetta and Passat.

When properly installed, TTY bolts provide their intended clamping force whether the engine is hot or cold, and maintain it after many thousands of heat cycles. The original Volkswagen application of TTY bolts was to lock down the cylinder head. Due to their reliable clamping performance, you now will find TTY technology in many applications on Volkswagen vehicles. The list has expanded beyond cylinder heads to include crank pulley, flywheel, brake caliper, and oil filter housing bolts, suspension, sub-frame, and drive axle-to-hub bolts, ball joint nuts, strut-to-body nuts, as well as transmission assembly and transmission/engine mount bolts.

Your Volkswagen repair information may not identify a TTY bolt using that acronym or name. Be on the lookout for installation procedures that state that the bolt cannot be reused, and must be replaced. Additionally, your parts manager may inform you that the component or system being repaired requires a new replacement bolt which also may simply be labeled a “bolt,” even though it most likely features TTY technology.

Torque plus angle of rotation

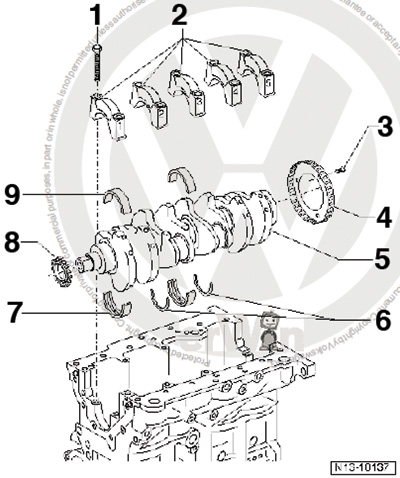

The bearing cap bolt (#1 in this image) on the 2004-‘12 Golf and 2006-‘14 Passat is a TTY bolt that must be replaced if removed. The new replacement bolt must be torqued to 65 N-m, then rotated an additional 90 degrees (1/4 turn) to achieve its optimal clamping force.

TTY bolt installation is a multi-step operation, and typically requires an angle gauge as well as a torque wrench. You first torque the bolt to near the high end of its elastic deformation range. This extracts all of the clamping force you can get from that portion of the torque-clamping force curve that is linear, and therefore, predictable.

Next, you rotate the bolt through a factory-specified angle. This ensures that the bolt is stretched near to its “ultimate” strength. Extensive testing has verified that the clamping force generated is directly proportional to the amount of rotation. Factory engineers and bolt manufacturers can therefore specify an angle amount with confidence that it will generate the precise amount of clamping force desired.

Many different types of TTY and other bolts can be used on the same model Volkswagen vehicle. Some may be different for the same model, due to running changes during the model year. Look for technical bulletins, repair manual updates, and other recent information sources for the latest specifications for the vehicle in your bay.

Each application may be different, with torque and angle specifications customized for the component and joint. Some bolts are mandatory — the only type that can be used for a specific application. Some aluminum bolts can be reused, but only once, and only for the same application as originally specified and used. Refer to your Volkswagen repair manual or technical bulletin for the specifications for a given bolt or fastener.

Encapsulated bolts

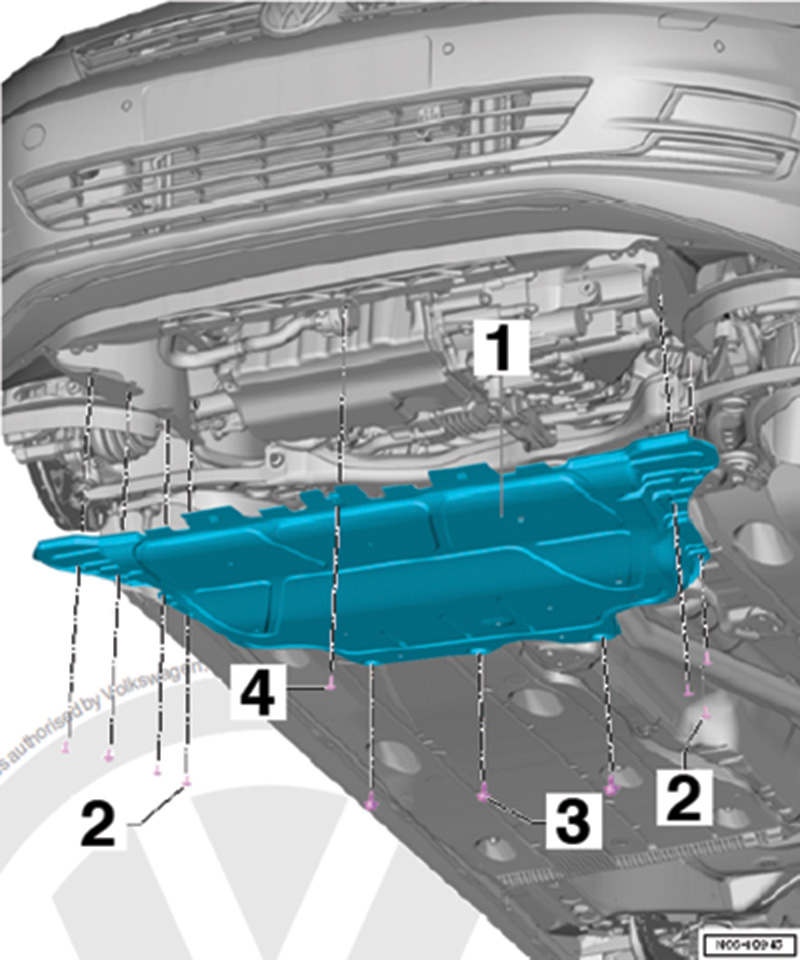

Three of the eleven bolts holding the Long Noise Insulation Cover under the engine (#3 across the rear of the cover) on the 2015 and newer Golf are microencapsulated, and not reusable. They must be replaced with new bolts

if removed.

Another category of bolt that is often not recommended for reuse is those that come from the manufacturer with either a thread locking coating compound or an anti-corrosion coating on the threads. The issue is not that thread locking and corrosion resistance coatings cannot be applied in the field. Rather, using new, pre-coated bolts is simply a better way to maintain quality control.

By installing a new pre-coated bolt instead of applying thread-locker or corrosion coating to the existing bolt for reinstallation, you can be assured that the adhesive or corrosion protection is on the fastener in the correct amount and at the exact location needed. The coating is applied by the bolt manufacturer in a manner that is carefully controlled. It ensures a level of bonding or corrosion protection that enables the joint to meet clamping or corrosion resistance requirements.

Always check the information in the ELSA repair manual and in technical bulletins to confirm whether the bolt you are removing is recommended for replacement or reuse.

Friction and torque

Friction absorbs most of the torque used in tightening a joint. As you tighten a bolt, torque is divided among three main functions. Fifty percent or more of total torque is absorbed by underhead friction, the tension between the underside of the bolt head and the top surface of the material being joined. Forty percent of torque is soaked up by thread friction, which is resistance to tightening due to the presence in the threads of any irregularities, damage, or debris. Only ten percent of torque is available to stretch the bolt and develop the clamping force that keeps the joint together.

This is the reason many repair procedures specify cleaning any debris from the thread area, and applying lubricant to the threads and underside of the bolt head. Just a five percent increase in friction in either the underhead or thread areas can cut in half the amount of torque remaining to develop clamping force.

Mechanical thread lockers such as lock washers and nylon inserts work by increasing friction between the mating threads in a joint. Sure, it may help resist vibration-related damage over time, but based on how friction affects tightening torque, it may be undesirable. Unless the factory specification calls for a mechanical thread locker, use of one may actually prevent achieving the precise level of fastening power required.

More durable

There are many additional factors that introduce the potential for variation in the amount of tension created in a bolt when torque is applied. To ensure more durable assembly and repair, follow the Volkswagen recommended repair procedures when using fasteners. Your repairs will provide their intended clamping force over many thousands of start and stop cycles.

Download PDF

0 Comments