We offer tips on how to spot a flood-damaged vehicle, and suggest that an extensive pre-repair damage assessment could present opportunities for an above-average repair estimate.

Help your customers prevent flood damage from harming the performance of Nissan’s smooth 270 hp, 3.0 liter V-6, shown here in the 2013 Altima sedan.

Flood damage assessment is more like the diagnostic process for collision than mechanical repair. Rather than a single point of failure, there is the high probability of damage to multiple vehicle systems in many different areas. Your job as detective is much broader than of a mechanical problem diagnosis. And your shop should have strict guidelines to determine when the extent of damage indicates that you should declare the car not repairable and decline to service it.

The first thing you need before tackling the repair of a flood-damaged vehicle is an awareness of the fact that it has been up close and personal with water. You don’t want to find out after you’ve sold a non-flood repair that the vehicle has significant water damage and requires a major increase in the estimate. Worse, you don’t want a comeback (or series of comebacks) due to corrosion or other water-related damage that doesn’t show up until a few months later. It can be difficult to convince even a good customer that this must be billed as a new repair.

Warning signs

Some flood damage is obvious. Water marks up the sides of interior door panels and trunk side wall linings, saturated carpet and backing, and leaves, debris, and water puddled in indentations on the top of the engine are but a few indications of flood damage that are easy to spot. A thorough inspection is your friend.

It’s easier to catch if the car comes in the day after a flood in your market area. Or the tow truck driver tells you that the customer tried to muscle through a two-foot deep wading pool created by flash flooding of a low bridge underpass.

The smell of desperation

Unscrupulous operators sell used cars without identifying them as having been flood-damaged. The customer that notices the phrase “sold as-is” on the purchase agreement only after he or she discovers flood damage may try to push some of their pain onto you as the repair service provider.

They may bluster their way through an argument that something must be defective on the vehicle, hoping that it can be covered by warranty. That may be a sign that you need to get the customer to tell you more about the vehicle’s repair history. If you get a feeling that the vehicle has been shopped around to multiple service providers, dig deeper. The smell of desperation is a big red flag.

What is that new carpet hiding?

Even without intentional deception, some flood damage may be difficult to spot. Mold and mildew in the vehicle interior may not be visible, although the odor can be detected – and you won’t need a trained dog. Look for a musty, dirty sock smell or rotten egg odor.

Another warning sign of flood damage is new carpeting or carpet backing (jute) that has been removed or recently replaced. The replacement may have been an attempt to eliminate a moldy smell.

The chemistry of corrosion

A battery moves current from its anode (negative terminal) to its cathode (positive terminal), and in this discharge process provides electrons to perform work in the attached device. The electrolyte in the battery connects the anode and cathode, allowing the flow of current between the two terminals.

When moisture is in contact with exposed iron or steel, it creates an electrochemical pathway that encourages electrons to move from one place (anode) on the surface to another (cathode). Electrons transfer from iron or steel molecules to nearby oxygen molecules, changing the composition of the metal. We see the result as corrosion, rust, or a loss of surface material in the metal.

The process can begin within minutes of exposure of metal to moisture. Once begun, it doesn’t take much moisture to keep corrosion progressing. As little as 60 percent relative humidity can create an electrolytic condition and continue corroding exposed metal surfaces. You probably know this from the surface rust that forms almost immediately after steel parts have been sand-blasted or stripped.

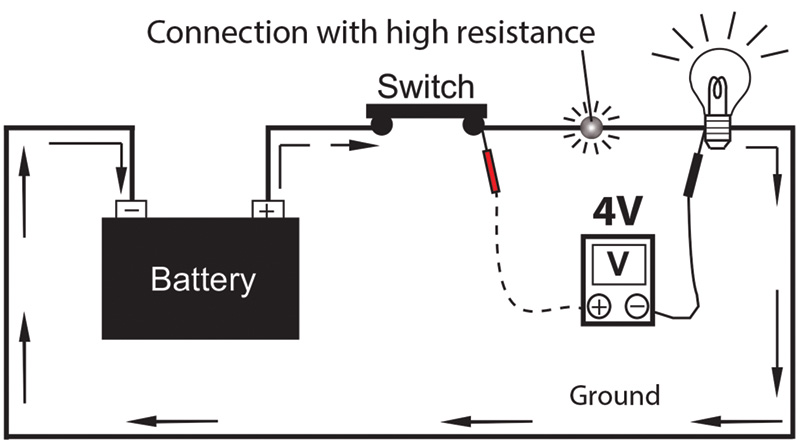

Corrosion in a wiring connection can increase resistance and voltage drop, leading to slower than normal electric motor speeds, dim or intermittently flickering bulbs, wire overheating, and other problems.

In automotive applications, corrosion aggressively weakens the structural integrity of metal panels and components and lessens the ability of paint and coatings to adhere to the metal surface. Look for surface corrosion on steel body panels, and weakened or deteriorated flanges and areas where metal layers overlap.

Inspect rocker panels, frame rails, exhaust systems, and other exposed underbody metals. Check support brackets, door and trunk hinges, and other areas where metal components are joined using bolts, rivets or other metallic fasteners.

Paint job

Corrosion under paint will eventually cause a bubble or irregular surface area. If you see imperfections or variation in surface height, a recent paint job could be hiding corrosion damage.

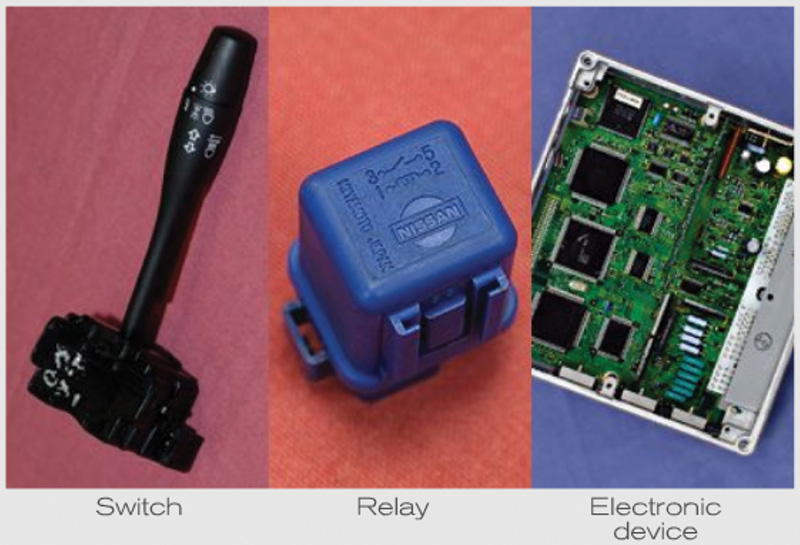

Sensitive modules and connectors

Corrosion also reduces the conductivity of electrical connections. Many electronically-controlled systems rely on low voltage signals that are extremely sensitive to corrosion in connectors. Even if water reached only a little above the bottom of the vehicle, there is enough wiring under the seats and in the floor that exposure may have caused corrosion to affect many systems and multiple connections within those systems.

Wheel speed sensors and other ABS brake components, crash sensors, seat belt pre-tensioners and buckles, body control modules, yaw rate sensors, and other safety-critical components are often built into the floor or near it, depending on the Nissan model. Full of sensitive electronics and located by necessity near the exterior of the vehicle, these components are especially vulnerable to flood damage.

Are any exterior or interior lights not working? Are any warning lights lit on the dash? Do the ignition and starter motor circuits function erratically or not at all? Water helps create new paths to ground for secondary ignition parts. Are other systems not working? Water intrusion into connectors may prevent CAN communication between various control modules.

Voltage drop testing can help you find corrosion-caused excess resistance in a connector or circuit.

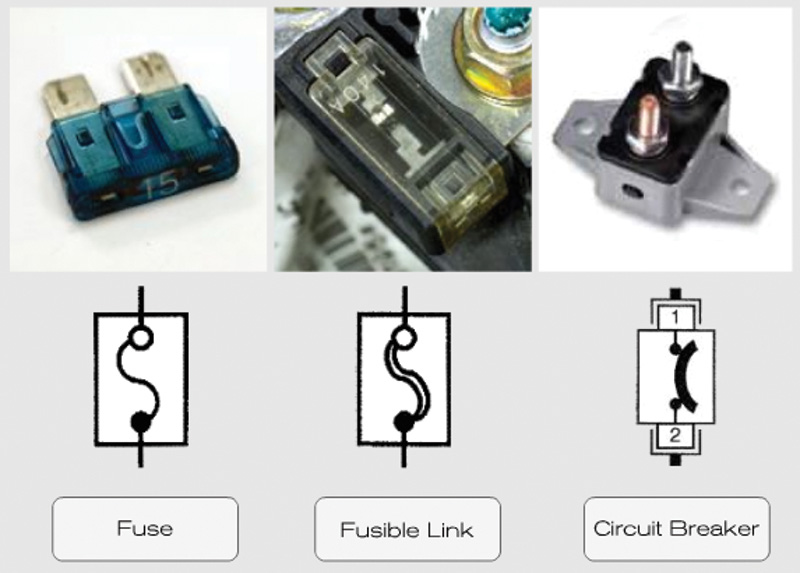

Perform visual checks for corrosion in wiring harnesses and connectors. Then do pre-repair scans for trouble codes indicating performance problems with sensors, actuators, and control modules. Although corrosion in connectors and wiring harnesses may not be readily visible, trouble codes can help point you to diagnostic procedures that will reveal corrosion-related shorts and intermittent faults. They will help focus your search to the most likely problem circuits, fuses, and wiring harnesses, saving you diagnostic time.

If the ABS light is on and you find a code for a wheel speed sensor (WSS), check the sensor wires for breaks or a loose/corroded connector. Broken wires are probably the leading cause of WSS failures. Water rising to the height of the wheel speed sensors may not occur as often as wiring harness damage, but once it happens, it is equally deadly. Flood water can corrode the teeth of the wheel speed sensor tone ring, even on vehicles in which the tone ring is built into the hub assembly. Hub assembly seals protect against rain and/or road water splashes, not wheels that are submerged for minutes or hours.

Check the threads of ground connections. Corroded grounds are a common cause of reduced power and intermittent failure of electrical devices.

In from the cold

If the customer comes in with a cold weather complaint of an intermittent problem that goes away after the car warms up, the cause may be water freezing in an electrical component or its wiring harness. If you think it could get cold enough overnight for the problem to repeat, you could keep the vehicle parked outdoors and in the morning have your technician diagnose those components you suspect may be affected.

Alternately, you could place the component you suspect is the cause in a freezer for a couple of hours. Once chilled enough that any water inside has re-frozen, re-install the part on the vehicle and check whether or not the intermittent fault re-occurs. If it does, then you can determine whether to repair (dry out) or replace the component.

Salty dog

Reconditioning experts recommend that if you do tackle a flood repair, you should limit your efforts to only those vehicles that have been exposed to fresh water. Salt water accelerates the development of corrosion and electrical problems at a significantly higher rate than fresh water. The high concentration of salt makes the water function more like the electrolyte in a battery, encouraging the electrochemical reaction that produces movement of electrons in the metal.

Engine and transmission

If water rose halfway up the side of the engine or transmission, the potential for damage is greater. Engine and transmission seals and gaskets are potential entry points for water, especially if there was an oil leak from those areas before the flooding event. And water and dirt can get into bearings and accelerate wear.

Water in the engine

Before attempting to start an engine that you suspect has suffered flood damage, check all fluids for water. Cranking the starter motor could cause hydrostatic lock in an engine. If the engine has sat in moist or flooded conditions for a while, corroded pistons or bores could cause it to seize up. Attempting to start it could lead to a bent connecting rod or more extensive damage.

Remove the spark plugs or fuel injectors and rotate the engine by hand to ensure that it turns over freely. If water comes out of the ports, continue rotating the crankshaft manually until no more water exits. Then use compressed air or other technique to remove any water that may remain in the cylinders. Inspect the spark plugs and fuel injectors and replace as needed.

Water in the engine oil can cause oil foaming, loss of power and sludge formation. Drain a little oil from the oil pan. If you detect water or the oil has a milky discoloration, drain and replace it, change the oil filter, and refill the system with new oil.

Drain a small amount of fuel from the fuel tank and test it for water. If there is water in the fuel, drain and replace all of the fuel in the tank and hoses. Replace the fuel filter. Drain some fuel from the fuel pump and check for water. If you find water in the pump, drain the fuel and replace it with fresh gasoline.

Remember that water does not mix with gasoline or engine oil, so any water that’s present will settle to the bottom of the sump or fuel tank. As such, it will be the first liquid to come out when you drain oil or fuel, so look closely right from the start.

Remove air filters and check for the presence of moisture. If the filters are or have been wet, replace them.

Transmission (clutch, final drive and hydraulic systems)

An outwardly visible sign that a transmission has been submerged in water is the presence of a powdery white film on its exterior. This is due to oxidation of the aluminum case, and will be more severe than normal after a flooding event.

On the inside, transmission clutches are hygroscopic, meaning they absorb water. The water will displace transmission fluid, pushing it out of clutch linings. Once it’s absorbed, you cannot remove water from the clutches. The only safe choice is to replace them.

Water in transmission fluid deteriorates the friction modification properties of the clutches and results in chatter and harsh shifts. Even a small amount of water can damage the clutches. It won’t always be enough to create the milky appearance that is a warning sign of transmission fluid contamination.

There are test strips available that can simplify the task of determining whether the transmission fluid has been contaminated. There are different types, including one that tests for antifreeze contamination and another that identifies plain water in the ATF.

Using both reveals a lot of useful information. No reaction from either strip is the best news; that would show that the transmission fluid is not contaminated. If the coolant strip reacts, that is a sign of a cooling system leak. If both strips react it is also coolant contamination; the coolant has enough water in it to cause a reaction from each separate test strip. If only the water strip reacts, that rules out coolant contamination and confirms the presence of water in the ATF.

Rear differential

Water in the rear differential could eventually cause corrosion on the ring gear, leading at minimum to a noisy rear end. If the vent on the rear axle differential was submerged, water has likely mixed with the gear oil. And the vehicle does not have to be submerged long. Just driving through high water could allow water in if the axle seals were not in good shape.

Insurance considerations

State law and insurance company guidelines play a large part in whether repair is an option, or the car must be declared a total loss and sent to salvage. Vehicles are typically declared a total loss when the cost of repairs exceeds the vehicle’s pre-accident actual cash value (ACV).

However, two other factors often come into play. First, many states have laws that specify when an insurer can total out a vehicle. The laws are based on a number called a total loss ratio, created by dividing the cost of repairs by the ACV. Some states set a lower limit for that ratio, below which an insurer cannot total out the vehicle.

This total loss ratio minimum is called a Total Loss Threshold (TLT). As of 2016, 29 states have set a TLT ratio.

The second factor affecting the total loss decision applies only in the 21 states that do not set a TLT. In those states, insurance companies typically add the cost of repair plus the salvage value of the damaged vehicle and compare that number to the ACV. If repair cost plus salvage value exceeds the ACV, the insurer will likely declare that vehicle a total loss. That calculation is called a Total Loss Formula (TLF), and the 21 states where there is no government-mandated TLT use it.

You can search online for the phrases “Total Loss Threshold” and “Total Loss Formula” to see which applies in your state.

Money and time

The solution to most vehicle problems is just a question of money and time. If you have done good detective work to identify the problems on a flood-damaged vehicle, you will earn more of that money from the customer that wants his or her vehicle restored to safe operating condition.

Thanks and a tip of the hat to Neal Barnes and David Edwards, both part of the Nissan Aftersales Division, for contributing real-world insights from market areas that have been heavily impacted by major floods in recent years.

0 Comments