This may be a subject of interest for technicians and the driving public that have VW and Audi models that incorporate traction control with ESP (Electronic Stability Control). This version of enhanced ABS generally comes standard in most VW and Audi models.

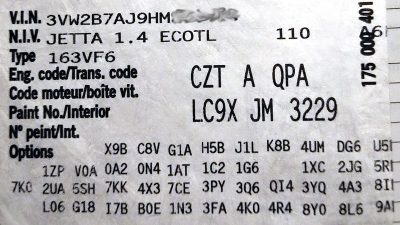

Within this specific article and adaptation, a 2017 Jetta from a northern community is used to install a traction control switch with the accompanying harness.

The vehicle owner inquired about the possibility of adding a traction control switch that was not factory installed in this particular model. The inquiry led to the possibility of a kit purchase and installation. The major concern with the customer was likely “ESP intervention” when climbing a hill (driveway) in winter (heavy snow) conditions. Another worry was options if the vehicle became stuck in mud or snow.

Definitions to think about and remember:

| ESC | Electronic Stability Control |

| ESP | Electronic Stability Program |

| ABS | Anti-Lock Brake System |

| EDL | Electronic Differential Lock |

| ASR | Anti-Slip Regulation |

| TC | Traction Control |

| SVM | Software Version Management |

| Tools Needed |

| VCDS, 90 amp power supply, screen capturing software, installation kit, pen with paper and a simple camera. |

| One definite approach to see if this type of ABS with ESP system is installed is by using the Ross-Tech VCDS. Below is the actual ABS sample of the model during the first scan. |

| The other option was to view the PR code attached to the vehicle. View the last pages to understand how this model was built. |

Address 03: ABS Brakes (J104)

Labels\User: 1K0-907-379-CC.LBL

Part No SW: 1K0 907 379 CC

HW: 1K0 907 379 CC

Component: ESP MK60EC1 H46 0175

Revision: 00H46001

Coding: A14B400C492300FD850F02EB921E004120100010

Shop #: WSC 00066 790 00293

About traction control (1)

(a) Depending on the “flavor or version” of ABS with ESP, it is completely dependent on the model and model year. One may see a traction control switch at the center console.

(b) The ABS scan will identify the ABS version with its “flavor or version.”

(c) If the ABS scan does identify the correct flavor, the instrument cluster warns of traction control intervention and, without a switch, many of these models can have the traction control switch kit installed.

(d) If statement “c” is true, then the ABS control module requires coding to enable the switch to operate “on-the-fly” and illuminate the warning lamp within the instrument cluster.

About traction control (2)

If for some reason (make all your customers aware) that the model(s) in this article fits the criteria – “ABS with ESP with a warning lamp and no traction control switch,” there is a way to temporarily disable traction control if the vehicle owner is stuck in mud or snow. This feature is called “roller mode,” and also offers the ability to have the vehicle tested on a dynamometer. Therefore the front wheels will turn without ESP and disable rear wheel speed activity. This ensures that the ABS and ESP are not active during the dyno test.

That will also mean that violently forcing the steering wheel may also disable traction control. The “roller mode” test is still used to test the emission control systems for these models.

How to, and what to expect – Advise the customer how deactivation behaves.

- The ignition switch must be off with vehicle in a safe and driveable condition.

- No pedestrians and occupants should interfere or be at risk for any harm.

- Turn the ignition switch ON and do not start the engine.

- Apply the 4-way flashers.

- Apply the throttle five times to the floor and release at each application.

- Start the engine, place in gear and attempt to move the car with traction control temporarily disabled.

- ABS with ESP will NOT allow the vehicle to remain in this condition because, at approximately five feet of travel, the traction control system will be reactivated.

- Depending on the conditions, repeat steps 1 through 7 if required to move the vehicle.

Remember that this is ONLY a guide to help your customer understand how this system works and an aid when stuck in mud or snow. Not all models offer this feature.

Offer hand written notes for the customer, not this article.

How about convincing your customer to “update” their traction control system?

The installation is not difficult by any means. Complete kits can be found with aftermarket suppliers or accessing the dealer network for the correct parts and wiring connections.

A personal choice is through the aftermarket suppliers because “everything is in the box.”

Another personal choice is using crimp and shrink connections. Scotch lock, quick splice or whatever term that is used, is not a professional adaptation to the harness.

You are your own warranty company so don’t destroy your reputation for a ten cent part.

Use these key words to find a reputable supplier with the correct connections/tools:

- “Crimp and shrink connectors”

- “VW traction control switch kit”

- “Heat/shrink tool”

- “VW and Audi PR codes”

Many aftermarket suppliers will use similar language, the identical parts, and precise images. The suppliers generally list the models affected that do not have the factory traction control switch installed.

Choosing suppliers with a reputation is the key for a proper and perfect installation.

If this type of service and installation is offered to the customer, they will certainly appreciate those times when ESP intervention was holding the vehicle back when “vaulting” up a snow covered or muddy hill.

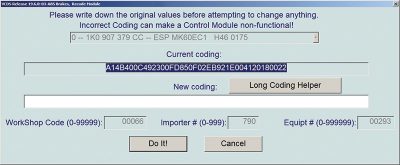

After the installation of the additional harness and the added switch with final connections, it’s time to code the ABS with ESP. The completed adaptation will allow the driver to enable or disable traction control at will.

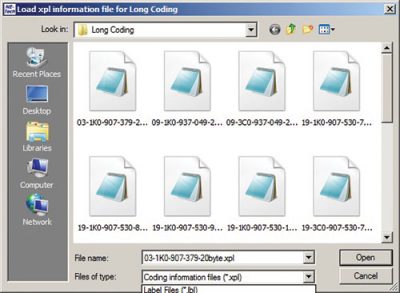

When using the Long Coding Helper, the original code can be copied from the original log file and pasted into the empty field. The coding value can be inspected. Be aware that there may not be sufficient explanations with the coding values. In most cases, the correct coding value with replacement ABS components must use the SVM protocol.

Identical part numbers between original and used test components is possible providing the original long coding is saved.

To test your coding without engaging VCDS, find the file in the folder as in the following example and execute it: C:\Ross-Tech\VCDS\ LCode.exe

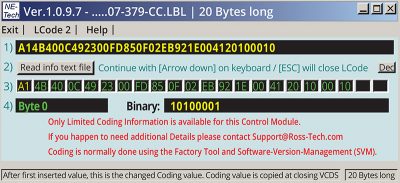

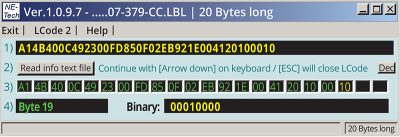

Both of these first images have the same original coding. The first image describes the warning at Byte 0 (A1 is the first one in yellow). The first (SVM Warning) and second (Byte 20) images below do have the identical coding, but Byte 20 (10 in yellow) does not describe the function of that specific Byte.

Column 3 is numbered 0 to 20.

Column 4 offers the Byte position and Binary translation of hex 18.

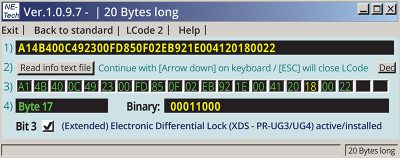

Editing the revised coding in Bytes 18 and 20 offers more information, especially for Byte 18.

It can be argued that the PR code in this case does not even match the vehicle, but an added switch was installed to activate traction control.

Listed here are the changes made on this specific model:

Original:

Coding: A14B400C492300FD850F02EB921E004120100010

Revision:

Coding: A14B400C492300FD850F02EB921E004120180022

Using VCDS

(a) Access the entire scan and save it for future use.

(b) Directly access the ABS System Address 03.

(c) Choose the Coding Function 07.

(d) Copy and paste the original code (from the scan) into the long coding template.

(e) Change the digits highlighted in red and save the new/revised coding.

(f) Scan the entire vehicle again and keep those copies for future use.

(g) Exit the ABS system within VCDS and cycle the key once.

(h) Press the new switch momentarily and test the dash lamp.

(i) A short drive test and cycling the new switch should offer TC on-the-fly.

After the coding is saved and key cycled, the current coding status is in the display as proof of the coding change. Using the new switch does light the Traction Control Warning within the instrument cluster. A quick road test on a snow or wet covered parking lot proves that traction control is inactive (enabled switch) for the short test.

Invoice the customer accordingly for this update/addition.

Note 1: When requesting data to identify the meanings of each Byte, the choice can be used with a label (*.lbl) or an *.xpl file. Use the “Read info test file” button for access and explanations.

Note 2: The file extension *.clb (encrypted label) is not permitted with NE-Tech when used off-line.

Homework anyone?

Another choice, and with decent editing skills, one can use MS Notepad. Using and saving with the correct extensions, you can create a library as in this example. Much of the data can be found in non encrypted labels.

This option is used to check and test coding values and options without the vehicle connection while keeping the data in a recognizable form such as:

- 03-1K0-907-379-20byte.xpl

- 09-3C0-937-049-23byte.xpl

- 19-1K0-907-530-10byte.xpl

- 46-8P0-959-433-12byte.xpl

Breakdown example

- 03 = ABS

- 1K0-907-379 = Controller part number

- -20byte = bytes string

- .xpl = file extension that VCDS uses

This library was a creation over time to allow access to coding structures that were of value, for basic testing and a learning exercise. These files are maintained within a separate folder and occasionally edited/corrected for completeness/accuracy.

Within the C:\VCDS\Labels folder, these are perfect examples that can be viewed.

Remember the “VW Coding Mysteries” article that was published some time ago? Find it, read it and apply these articles together. If you can’t find it, contact this publisher for a copy.

VW Coding Mysteries Review

At the time that specific article was being created, there were a few odd mysteries the vehicle owner(s) made mention of. The mystery(s) were solved with a precise customer interrogation of how that vehicle came to the facility in that condition. With a schematic and using the VCDS network measured values screens, it was later determined that, in one case, the incorrect coding was repeated in a used part.

With the second customer, a mistake was created at the dealer level when programming an instrument cluster. The dealer coded the original Comfort Controller incorrectly and provided an incorrect replacement. The original was reused and this time coded correctly by searching for identical models that had the correct coding. The searches were accomplished using the library of saved scans from identical models that have been kept over a long period of time.

For the model that had the TC switch installed see the image below.

There are many sites and descriptions that offer the breakdown of the VW and Audi PR codes. Match this original PR Code to the description of the image named “Coding change” on the previous page. UG3 and UG4 are not listed within this original PR Code.

When the installation is completed, clearly describe to the vehicle owner how the switch operates after disabling ASR or Traction Control.

When the customer is aware of the new installation and how the switch behaves, describe the instrument cluster warning with the ASR (TC) disabled and how the light will illuminate if ASR (TC) is active in normal mode When ASR (TC) system intervenes.

With this specific installation complete and correctly coded, the customer appreciation will be evident.

Download PDF

0 Comments