Sensotronic Brake Control (SBC) Bleeding Procedure SL and E-Class, all years

The SBC brake hydraulic system must be bled with the menu-assisted STAR Diagnostics “Bleed Brake System” and “Inspect Brake System For Air” functions, or aftermarket equivalent, after the replacement or removal/installation of the following components: SBC hydraulic unit (A7/3), brake operating unit, suction line, pressure reservoir, brake lines or hoses, brake fluid reservoir, or brake calipers. Reference WIS documents AH42.10-P-0002-01T and AR42.10-P-0012R.

Further, when performing repair work on an SBC system, it is imperative that the brake system only be bled with Mercedes-Benz-approved bleeding equipment. The procedure requires that the unit must maintain a constant pressure of at least 2 bar, but not to exceed 3.5 bar. In conjunction with the approved brake bleeder, the electrohydraulic brake adapter (EHB) tool must also be utilized in order to ensure that the brake fluid receptacle bleeding hose is securely affixed to the brake caliper’s bleeder screw (reference WIS document AR42.10-P-0010-02R).

Approved Mercedes-Benz brake bleeders are available through the MBUSA Standard Service Equipment Program (SSEP).

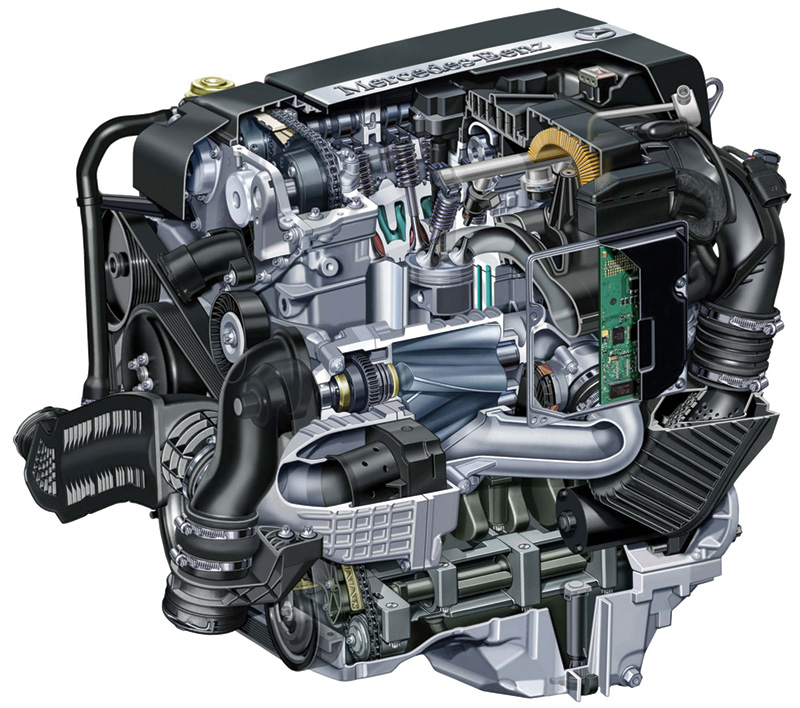

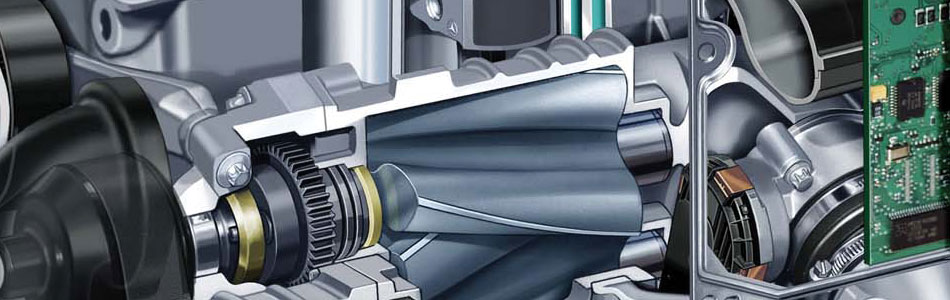

C230CL 1.8 Kompressor Engine Performance Complaint

C230CL 1.8 Kompressor Engine Performance Complaint

Engine vibration, rpm fluctuations at idle, or poor accelerator response along with codes P2020 (P0172), P2046, P201C or P201A may be caused by a tear in the partial load vent hose at the connection to the crankcase. Air will bypass the mass air sensor — i.e. unmeasured air will enter the intake — causing the engine to run lean.

The remedy:

- Remove the supercharger. Refer to WIS document AR09.50-P-4705QK.

- Remove and install partial load vent hose for crankcase ventilation.

- Install the supercharger according to the WIS document above.

Note: Use a “click clamp” as specified in parts information for securing hose. Ensure that the clamp is positioned as close to the end of the hose as possible and fastened tight.

Parts Information:

Click Clamp, 005 997 49 90

Partial Load Vent Hose, 271 018 04 82

0 Comments