During collision repair, you must remain focused on the goal: Return the vehicle to its original structural integrity and appearance in a cost-effective manner. Here is the plan.

From the moment a vehicle comes into your shop for repair, the clock is ticking. The insurance company has its agenda, the customer wants his or her car back, and you have to make them both happy. With new insurance and EPA regulations, it seems you don’t have a moment’s rest from running your business, keeping your people employed, and turning a profit. You must return the car with the same crash-worthiness and finish it had before the accident. This is certainly possible, but nothing can reduce profits more than having to go back and do something over, or realizing that there is more damage than you’d seen before. To prevent this from happening, you need to come up with a plan the moment the vehicle comes in for repairs. This is not always easy depending on the damage. Mercedes-Benz vehicles have higher monetary value than ordinary cars, and as a consequence are more likely to be repaired instead of totaled, so it’s very important that you get it right the first time.

From the moment a vehicle comes into your shop for repair, the clock is ticking. The insurance company has its agenda, the customer wants his or her car back, and you have to make them both happy. With new insurance and EPA regulations, it seems you don’t have a moment’s rest from running your business, keeping your people employed, and turning a profit. You must return the car with the same crash-worthiness and finish it had before the accident. This is certainly possible, but nothing can reduce profits more than having to go back and do something over, or realizing that there is more damage than you’d seen before. To prevent this from happening, you need to come up with a plan the moment the vehicle comes in for repairs. This is not always easy depending on the damage. Mercedes-Benz vehicles have higher monetary value than ordinary cars, and as a consequence are more likely to be repaired instead of totaled, so it’s very important that you get it right the first time.

Step One

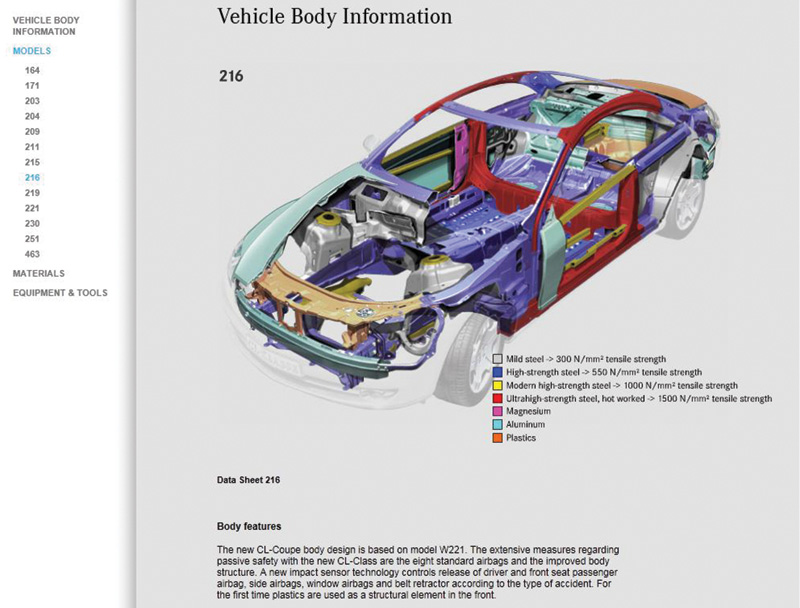

The first step before performing any repair work is a visit to www.mbcollisioncenters.com for a look at the vehicle’s construction materials. This is an essential safety step and will let you know when magnesium or ultra-high-strength steel is used. Repair procedures will be different as a result.

Of course, every accident is different, but you should focus on what is similar about every one. There are accidents where only the body is contacted, others that include suspension pieces. Either way, you need to check for structural damage. The front and rear crumple zones are collapsible structures. They are meant to absorb the energy of an impact and not pass it on to the occupants. Even if the impact appears light enough and one or two corners are written off, you must get this vehicle on a lift. Mercedes-Benz insists on the use of a chassis alignment jig when frame straightening to assure accuracy. Traditional measurement methods, such as those taken off the centerline of the chassis to various pick-up points, are simply too crude for “the best engineered cars in the world.” In fact, the company doesn’t even publish these dimensions.

Crash Analysis

The use of jig sets prevents any surprises when the bodywork is complete, such as finding that wheel alignment can’t be accomplished because there isn’t enough range of adjustment to make up for dimensional discrepancies. This is especially true if a wheel, upright spindle, or suspension arm has been bent. Also, be prepared to remove fenders so the adjuster can look at possible damage under the surface paneling.

This prevents any surprises when the bodywork is complete, but wheel alignment cannot be accomplished because there is not enough range of adjustment. This is especially true if a wheel, upright spindle, or suspension arm has been bent.

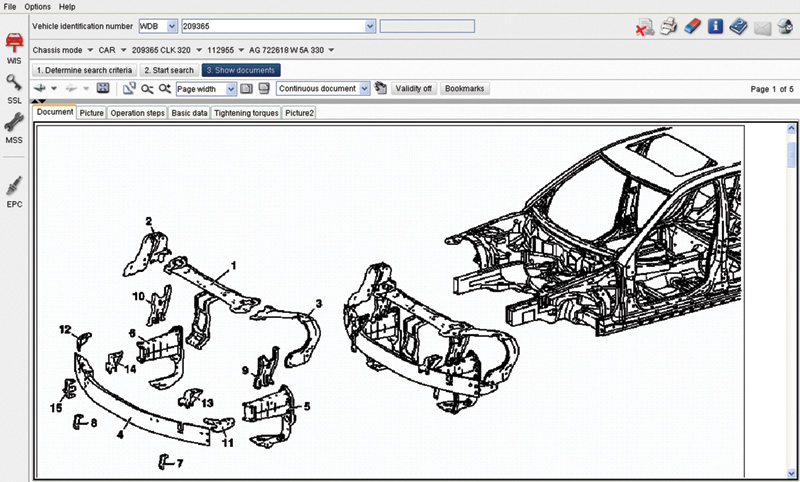

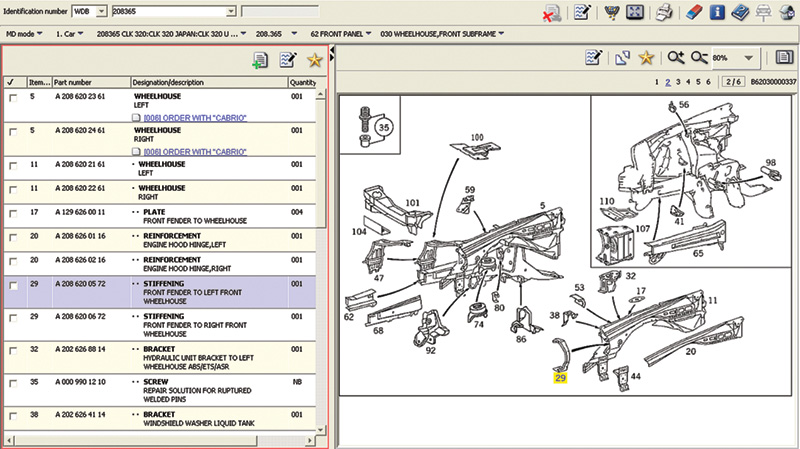

Your goal is to not miss any needed work on the original estimate and reduce the cost of any supplements. Use WIS (Workshop Information System, available with a paid subscription to www.startekinfo.com) to identify any repairs and procedures not included in the estimating guides (and, of course, to fix the car right). It gives detailed repair instructions for the job, and tells you the materials involved in the vehicle’s construction that may necessitate the use of special tools, equipment, and repair processes. This information will allow you to give the adjuster a truly accurate account of the time involved. EPC (Electronic Parts Catalog) is also an essential tool for doing estimates. You can look at the repair parts that Mercedes-Benz makes available to make sure you’re ordering exactly the right things.

Also, be prepared to remove fenders so the adjuster can look at possible damage under the surface paneling. Your goal is to put as much needed work on the original estimate and reduce the cost of any supplements. WIS gives detailed repair instructions for the job so you can give the adjuster a truly accurate account of the time involved. EPC is also an essential tool for doing estimates. You can look at the repair parts that Mercedes-Benz makes available.

Using Your Tools

Before you start to take the damaged section apart, look at the repair instructions at www.startekinfo.com, and the parts information on EPCnet (). This will help you generate an accurate estimate. Also, by quickly removing panels, you can look for further damage to the structure. [Edit: New EPCnet is ISPPI (https://www.startekinfo.com/home).]

Our example here is a 2002 208 chassis CLK that has been in a front-end collision. It appears on the surface that it will need a hood, upper radiator support, center support, and a front bumper cover. A deeper inspection, however, showed that the crossmember support, lower radiator support, and passenger side headlight stiffening support were all damaged. After reviewing the cost of the components and the cost in labor of straightening them, it was agreed with the adjuster that each damaged component should be replaced instead of being repaired. This saved a significant amount of labor time and ended up being cost-effective for everyone involved.

Looking at EPC, you can see the many stiffening support brackets in the front crashbox that can be replaced instead of worked straight. It may be cheaper and faster to replace components instead of straightening them, and you get O.E. crashworthiness, too.

If you are a Mercedes-Benz collision shop, your next step should be to visit the Mercedes-Benz Collision website, www.mbcollisioncenters.com. Here you will find specific information, especially about tools and body construction materials. This is an important safety step. Mercedes-Benz uses hybrid construction in many models. This means panels may be made of several different materials.

Even with light hits, using OEM parts like this ML rear bumper cover will reduce labor time. You will not have to modify the part to make it fit. It comes already primed so all you have to do is prep it for painting.

Hybrid Construction

Checking what materials are used is critical before starting any repair. Mercedes-Benz uses ultra-high-strength, high-strength, and mild steels, aluminum, magnesium, and plastics to build a vehicle. If you decided to cut an inner door panel on a 215 chassis CL-Class, for instance, you need to know that it is made of magnesium. This material burns a bright hot white and may ignite while being cut. The panel is also only available as a whole piece, so it does not make any sense to work it. In the case of the 208 chassis CLK320, the body is constructed of mild steel. If you have looked at EPC for parts ordering and Startekinfo for work instructions, you know the materials you may cut and reform, and you can now begin tearing down the crash damage. Following the steps outlined in Startekinfo, you can begin with the front crash box. If there had been frame damage, you may need to put the vehicle on a CarBench or Celette bench and reposition it.

We realize you probably don’t get paid for the time spent coming up with an efficient repair plan. While in negotiations with the insurance adjuster, you should not let him or her dictate how this particular vehicle will be repaired. By investing some time and researching Mercedes-Benz Startekinfo, EPC and the collision website, you have armed yourself with the specific information about what the manufacturer requires to restore this vehicle to its previous crashworthiness, fit, and finish. With an accurate assessment of time and money, jobs remain profitable and customers are happy.

0 Comments