With very few exceptions, the catalytic converter has been on every gasoline-burning car sold in the U.S. since 1975. Over those 36 years, we’ve sometimes seen them clog and lower engine performance, or lose their efficiency, setting codes and/or preventing a vehicle from passing an emissions test. Here’s how to make sure that cat’s really dead before replacing it.

To start the catalytic process, fresh oxygen-rich air is injected into the exhaust stream during engine warm-up for approxima tely two minutes. Combined with the rich mixture of a cold engine, this gets the converter hot enough to initiate the oxidation process quickly.

The goals engine designers strive for are basically maximum fuel mileage, minimum emissions, and performance that makes the vehicle fun to drive, but trade-offs must be made to achieve them simultaneously. When the catalytic converter was first adopted, critics warned that this restriction in the exhaust stream would decrease fuel mileage and horsepower, but just the opposite happened. Since the engines of cat-equipped vehicles could have much more efficient calibrations than the previous “leaner and later” emissions-reducing strategies and still meet regulations, performance and driveability actually improved markedly.

At about the same time, many high-population states and municipalities started emissions inspection programs to verify that vehicles were not gross polluters. These tests took a diluted sample at the tailpipe and measured percentages, parts per million, or grams per mile of HC, CO, and NOx directly. Since 1996, of course, we’ve had an OBD II monitor that tests the efficiency of the catalytic converter by means of oxygen or A/F sensors both upstream and downstream of the converter, and the diagnostics in the PCM (Powertrain Control Module).

Capacity

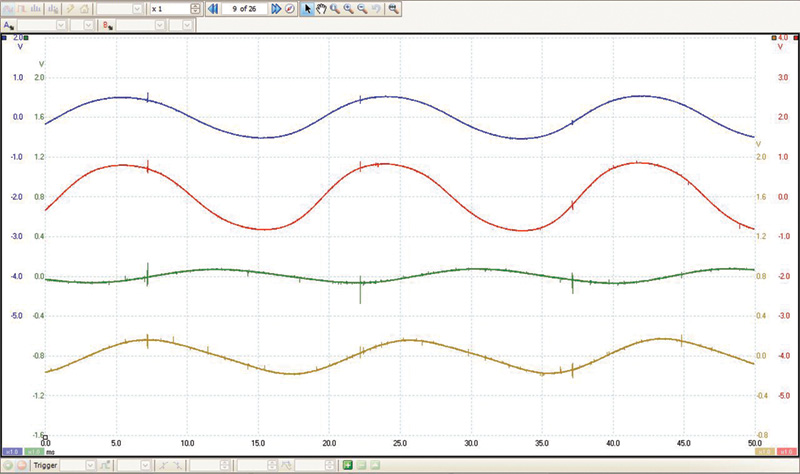

What’s actually being tested here is the cat’s ability to store and release the oxygen needed to complete its reactions. If the engine’s air/fuel ratio is rich for too long, the stored oxygen can be used up, and this situation is called catalyst “punch through.” So, the PCM compares the activity of the upstream HEGO or A/F sensor to that of the one downstream. A good cat will have large oxygen storage capacity, so it will absorb fluctuations in the oxygen content of the exhaust, somewhat as an electrical capacitor smoothes voltage variations.

The PCM expects to see a big difference between the amount of voltage change activity in the upstream sensor and the one downstream. If, instead, it sees that the ratio between the two is close to one, the catalyst fails its monitor.

Construction

Always look at fuel trims first. You may find a fuel control issue that is adding to the problem. Exhaust leaks can also contribute to the setting of a P0420, P0430.

The core of a catalytic converter is a ceramic honeycomb substrate that maximizes the surface area that comes into contact with the exhaust gasses. It has a “washcoat” that contains the catalytic material. The irregular surface created by the washcoat further increases the area, which gives the converter the maximum chance to burn up the HC and CO, and break down the NOx, in the exhaust. Expensive “noble” metals are suspended in the washcoat, chiefly platinum, palladium, rhodium, and cerium.

And here is where a big difference in quality between OEM units and aftermarket replacements makes itself known. To keep materials costs down, non-OEM units use as little of those metals as possible, and we’ve seen where they often don’t last even a year, or can’t pass the monitor or a emissions test when new. There are often complications with the physical installation, too.

Mercedes-Benz does not engage in this type of cost-cutting with its genuine replacement catalytic converters, choosing instead to supply units that meet as-new standards of performance, durability, and fit. Such adherence to quality will not only help you avoid comebacks and dissatisfied customers, but also make your job easier.

Feline fatalities

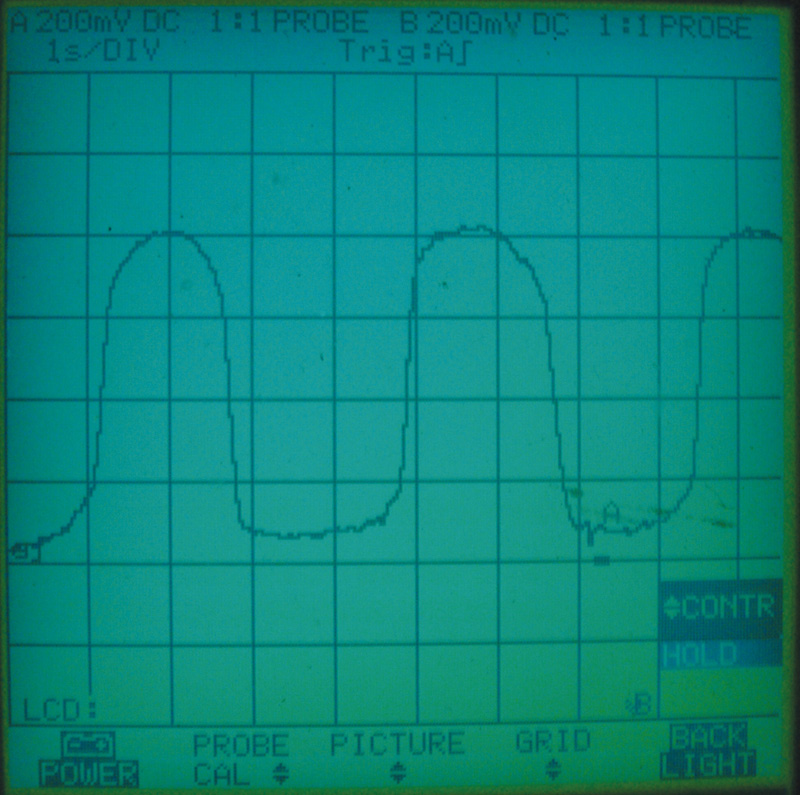

When using the O2 or A/F sensors to evaluate the functioning of the converter, you’re obviously assuming that the sensors are good. Shown is an O2 sensor switching rich to lean at about 800mv at a rate of one switch per second.

Mercedes-Benz catalytic converters are engineered to last for the life of the vehicle, so make sure you answer two questions accurately before you replace one. First, has it really failed, or is some other problem reducing its efficiency and causing a code to set? Second, if it is indeed ruined, what condition caused its destruction?

Cat failures start with the obvious: mechanical damage such as a shattered substrate (does it rattle when you hit it with the heel of your hand?), or perhaps corrosion or metal fatigue in a very old unit, Next, there’s lack of catalytic action, which may be due to contamination of the metallic elements from oil burning, an internal-engine coolant leak, or silicone from non-sensor-safe RTV. Or, in the case of the oxidation section, insufficient fresh air whether or not an air-injection system is present. For the reduction section, poor catalysis may be due to an air/fuel ratio that’s not being held at stoichiometry (14.7:1 air to fuel by weight) because of some electronic engine management problem. Finally, there’s melt-down and clogging, which is typically caused by overheating from misfiring or continuous running in open loop.

The most common DTCs (Diagnostic Trouble Codes) are P0422 and P0432, which indicate that efficiency is below specs for banks #1 and #2, respectively, on a “V”-type engine. But the presence of codes doesn’t necessarily mean the cat is wrecked, or even significantly degraded, so it behooves you to do further testing.

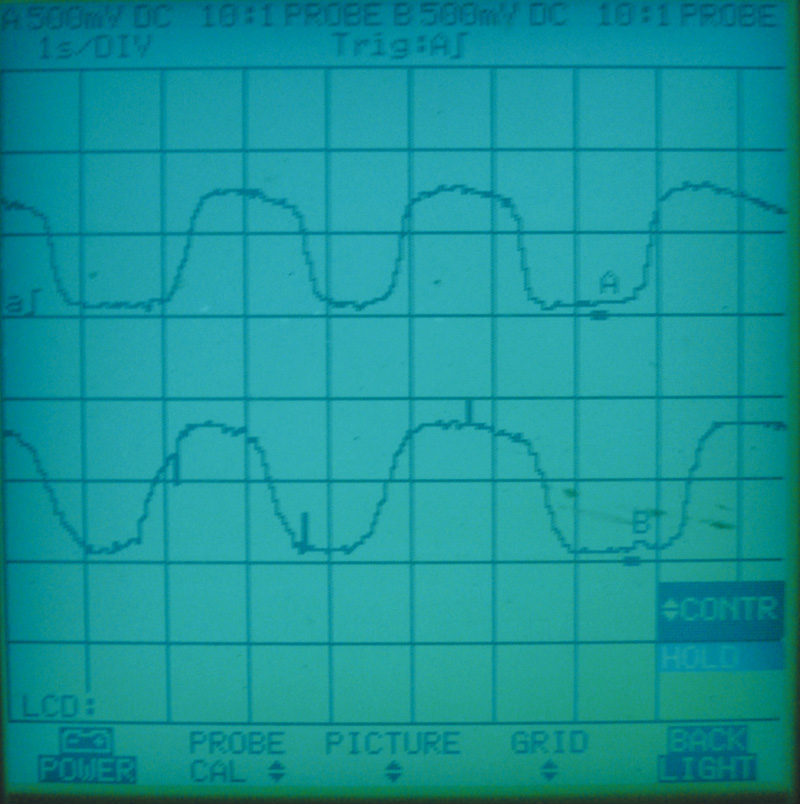

You can compare the front and rear O2 sensor signal voltages, as we are here. This was taken with the engine in the warm-up phase and at idle. The catalytic converter has not reached operating temperature, so they are both about the same.

A false converter DTC is often the result of a slight misfire that’s below the misfire monitor’s reporting threshold. This may add enough extra gasoline to the exhaust stream to exceed the cat’s oxygen storage capacity, thus making the signal from the downstream sensor jagged enough to set a code.

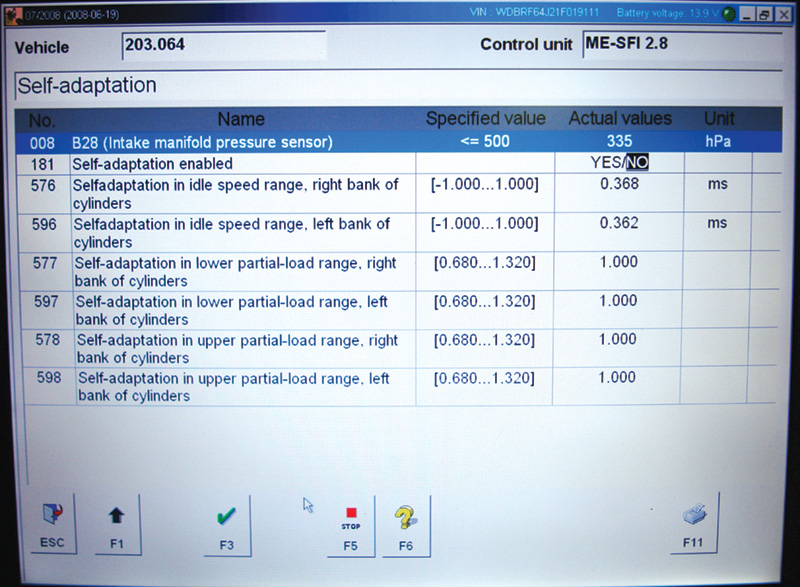

If you’ve invested in an SDS, under actual values you can evaluate the engine’s “smooth running” to isolate any problem cylinders. Check the spark plugs and compression of any indicated. The next thing to look at is fuel adaptations of the misbehaving bank. If the mixtures are too lean or too rich, the PCM will compensate. If the adaptation limits are reached, you should get fuel trim codes, but you may see cat efficiency codes first. Try to correct any fuel trim issues to get the adaptation number as close to 0.0 as possible. Also “smoke” test the exhaust to make sure you don’t have any air leaks. False air can change O2 or A/F sensor readings and lead to converter efficiency codes.

Also, you can use your SDS to monitor catalytic converter operation. You can plot the oxygen sensor voltage scan data in the “Lambda” values. Front O2 sensors will switch above and below .5V with a normal mixture. At idle, you will also see the rear sensors toggle in a similar fashion. The converter has not “lit off,” so you will see little to no change from front to rear readings. Bring the rpm up to a steady 2,000 and wait. If the cat is working, you should see the rear sensor signal start to stabilize . Of course, here we are relying on properly-functioning sensors. You should also verify that the O2 sensor heater has a 12V supply and is properly grounded. You can also easily measure the heater element’s amp draw.

Plugged

The two upper traces are from the pre-converter O2 sensors, and the lower traces are post converter. Bank #1 is the upper trace and bank #2 is the lower. Bank #2s cat is apparently struggling to clean up the exhaust.

The symptoms of a clogged catalyst are usually anemic power, poor fuel mileage, and, in serious cases, backfiring through the intake.

The easiest test for plugging is done with a vacuum gauge. Note the reading at idle, then hold rpm at 2,500. The needle will drop when you first open the throttle, then stabilize. If the reading then starts to fall, excessive backpressure is the probable cause.

But don’t stop there. The next step is to check backpressure directly. If the vehicle has air injection, disconnect the check valve from the distribution manifold, and plug in a pressure gauge (you want one with a low scale). Or, remove the upstream O2 or A/F sensor and take your reading at its hole in the manifold. Check the specs for the car at hand, but if you see over 1.25 psi at idle, or more than three psi at 2,000 rpm, there’s a restriction in the exhaust system.

There’s yet another direct means: Remove the converter and shine a light through it. You should be able to see breakage and meltdown. If there are too many bends in the pipes for a clear view, put your shop vac in its blow mode and use a tapered adapter to force those CFM through the unit. If you hear the sound of the vacuum’s motor change, flow is being strangled.

One final note: If the vehicle is still under the federally-mandated eight year or 80,000 mile emissions warranty and hasn’t been abused or tampered with, the cat is definitely covered. While sending your customer back to the dealership will mean losing the work, it will make you a hero.

0 Comments