In an effort to increase the safety of the driving public, Tire Pressure Monitoring Systems (TPMS, Mercedes-Benz TPC) warn the driver when tire pressure is low and may cause tire failure. When the system needs maintenance, it’s our responsibility to repair this important safety tool. In this feature, we cover the Beru system that first appeared in model year 2006, and will cover the newer Tire Pressure Monitoring Systems in the November issue.

Mercedes-Benz has always been an innovator when it comes to safety systems. In almost every chassis, high-strength alloys are used to protect the passengers in the event of a collision. Electronically-controlled driver’s aids help maintain traction when the tires are about to lose their grip on the road. These systems are designed to work at their peak efficiency with proper tire size, tread depth, and inflation pressure. If any of these characteristics does not meet the necessary standards, optimal performance will not be available. Tire size is important and owners should stick to the same size replacement tire to maintain the road-holding ability they are used to. Tread depth becomes vitally important with rain and snow. Tread design channels water out of the way of the rubber meeting the road. A good snow tire will keep the channels clean, but the sidewalls have to flex properly for the tread to conform to the road surface. Proper pressure is necessary to assure all these characteristics. In the case of under-inflation, there is also the danger of the tire overheating from excessive flexing, which can lead to tread separation and catastrophic failure. A blowout at Interstate speeds can easily result in a serious accident.

In 2000, recognition of these factors led the Clinton administration to push through the TREAD Act (Transportation Recall Enhancement and Documentation). This required that all vehicles built for the 2008 model year have a tire pressure monitoring system as an early warning to drivers that the air pressure in one or more tires is low. Besides leading to unsafe driving conditions, under-inflation reduces fuel efficiency. While this doesn’t amount to a large percentage of an individual vehicle’s overall MPG, on the national level it becomes significant.

In the Beginning

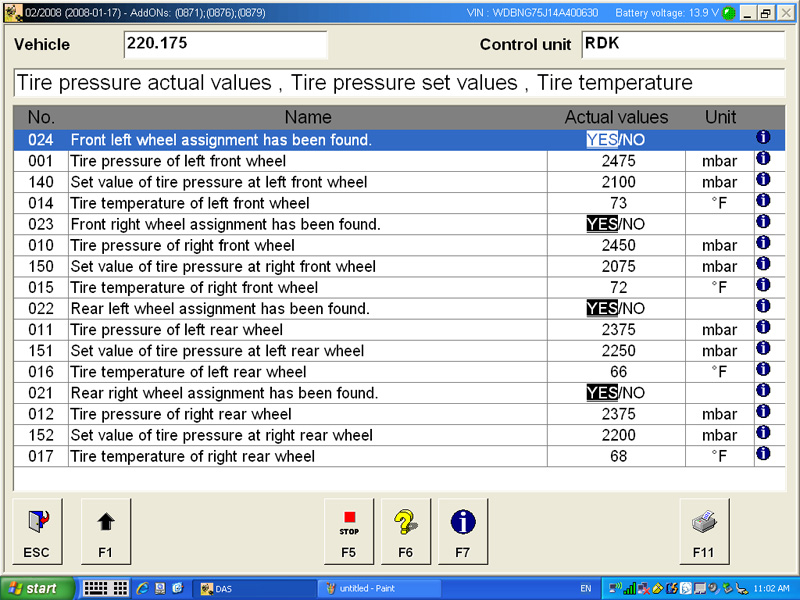

You can use your SDS to read the sensor identification, tire pressure and tire temperature. You can also see the proper tire pressure settings. This is a quick way to make sure the TPC control unit can read all the sensors.

Tire inflation can be monitored two ways. The first is the direct method. This uses a pressure sensor mounted inside the tire that reads the psi and transmits a radio signal to a control unit. Tire pressure can also be monitored by the indirect method. Since air pressure supports the weight of the car, any reduction in it will reduce the circumference of the tire. ABS and the traction control system already monitor and compare tires speeds in order to perform their functions. A tire with a smaller diameter will put out a different number of pulses over a given distance. If the difference is significant, the control unit can infer that that tire must be underinflated. This system relies on the wheel speed signals of the other three tires to help make the determination, and uneven tread wear can throw it off. Direct measurement, which all Mercedes-Benz vehicles use, is more inherently accurate, but brings the added complication of needing batteries for the sensors/transmitters. Even the advanced lithium-ion batteries used will only function reliably for about seven years. Of course, that is longer than the recommended safe life of a tire, so the sensors can be renewed during tire replacement.

To find the recommended tire pressures, look at the placard either mounted in the driver’s side door jamb, glove box, or inside the fuel filler door. These are the settings you can see with your SDS if you look in Actual Values.

What Kind of Pressure are We Under?

Under TPMS guidelines, sensors must transmit either a 433MHz, or a 315MHz signal. The Mercedes-Benz TPC system uses 315MHz on North American vehicles, and 433MHz for European. The signal is not sent continuously because that would drain the internal battery prematurely. Instead, the sensor reads the pressure every three seconds, and transmits the reading every 55 seconds while the vehicle is being driven. If inflation drops by three psi, the sensor will begin transmitting this information every .8 of a second. So, driving with chronic low tire pressures causes signal transmission roughly once a second instead of once a minute, which will shorten battery life significantly.

You can reactivate the TPC system though the instrument cluster. Use the folder keys to get to mph, then the arrow keys to choose TPC reactivation, and use the + or – keys to toggle to “Yes.” Then you have to drive the car for about 20 minutes over 20 mph.

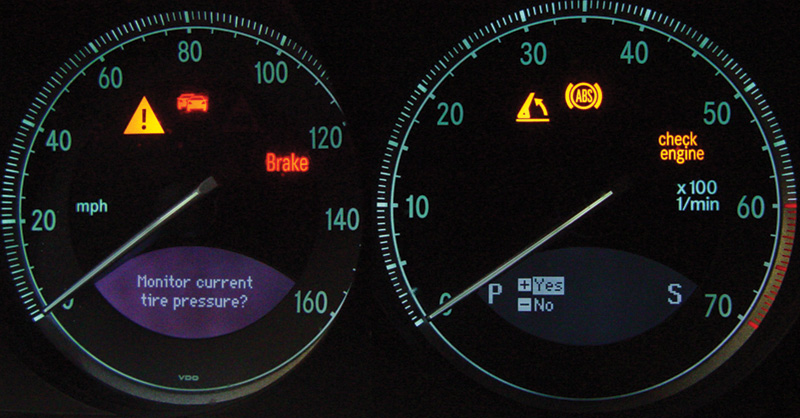

Explain to your customers that when they see the tire pressure warning light come on, they should correct the tire pressure as soon as possible not only for safety concerns, but also to extending the life of the sensor batteries. After inflation is corrected, the instrument cluster will instruct the driver to reactivate the TPC (a.k.a. RDK) system to check the new pressures. This does not require a scan tool, but can be done through the instrument cluster. Consult the owner’s manual to find the specific procedure for the vehicle at hand, but essentially you will be using the folder keys to scroll through until vehicle speed is displayed. Then, use the arrow buttons until a question referring to reactivating tire pressure is displayed. Hold down the reset button for a few seconds and you will be asked if you want to activate the TPC system for the new pressure measurements. Using the “+” or “-“ keys, scroll to highlight “Yes” and wait. The message in the cluster should indicate that tire pressure is now being monitored. Drive the vehicle over 20 mph for about 20 minutes. The instrument cluster will then display a pictogram of the vehicle and the individual tire pressures (one Bar =14.7psi), and the warning message should go off.

Here, the bead is being broken at the three o’clock position with the valve stem at the nine o’clock position. This prevents damage to the sensor when the bead makes it over the safety lip of the rim.

Warning the Driver

If a failure occurs in the system, a warning message will be displayed instead of the tire pressures. If it is in red lettering, it means there is an actual problem with a loss of air pressure in one of the tires. Immediately stop the vehicle and manually check and correct inflation. You can then return to your shop if the tires maintain pressure. If not, have the vehicle towed in. If the warning message is in white lettering, it means there is a problem in one of the three major components of the TPC system. With the system being mandated in 2008 (Mercedes-Benz started using this system much earlier), the sensors could be getting low on battery life. There is also the possibility of damage to the antenna in the wheel well that receives the signals and passes them on to the TPC control unit. The control unit sends any warning messages through CAN-B to the instrument cluster to warn the driver. With an SDS Star diagnostic system, you can interrogate the TPC control unit, pull diagnostic trouble codes, look at live data, and perform service procedures.

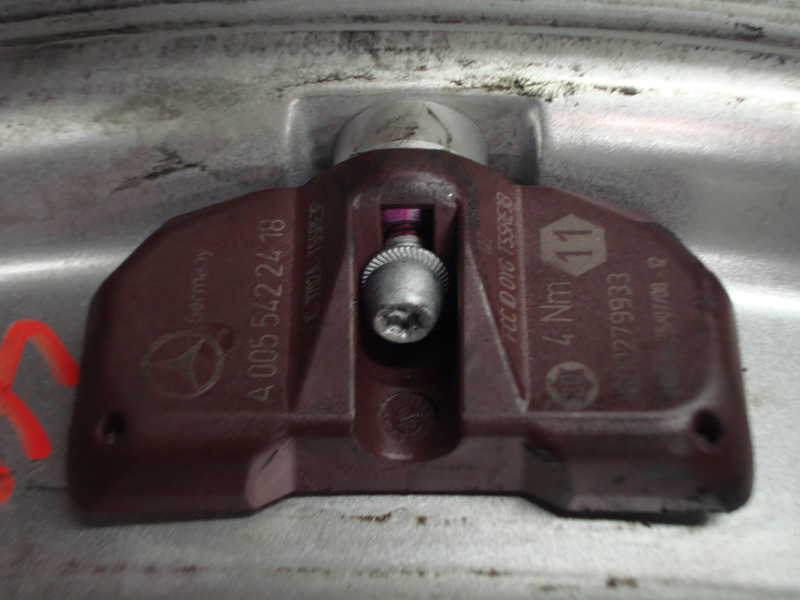

Whenever you replace a sensor, record the identification number pictured here vertically on the right. The number reads 600279933 on this sensor. The mounting screw should be tightened to 4NM.

Tire Service with Sensors

The presence of the sensors requires extra care during tire service. When breaking the bead, always have the tire stem 180 degrees from the anvil of the tire machine to prevent sensor damage. Also, when removing the tire, make sure the sensor is just in front of the anvil. This way the sensor rotates clockwise away from the anvil and the tire should not come in contact with the sensor while being removed.

You should follow a few simple rules when servicing tires and the TPC system. First, replace any sensor that is over five years old. Next, inspect the underside of the sensor. There is a white filter that covers the sensor element. If the filter is dirty, broken, or contaminated with tire sealant, replace the sensor. A damaged filter will shorten the service life of the sensor and/or give incorrect readings. The sensor sends a signal indicating battery condition with every transmission of tire pressure. This battery life reading can be called up with the SDS system. This allows you to accurately inform the customer about which sensors should be replaced along with the tires.

Replacing the Sensor

When installing a new sensor, you should order a new valve kit to go along with it. An aluminum valve stem is used with a lock nut. New sealing washers will come in the kit to prevent any valve stem leaks. The nut for the valve stem needs to be tightened down to 4 NM to form a proper seal. The new sensor also gets mounted to the inside of the vale stem with a special hollow screw, which also needs to be torqued to 4 NM. Always be sure to fit the plastic valve cap to complete the installation. This prevents corrosion in the Schrader valve. Inform your customers not to use metal valve caps as different metals will eventually react with the aluminum threads and become very difficult to remove. You should record the sensor’s ID number and the wheel it is being installed in. This will be important if you need to manually enter the sensor’s position in the TPC control unit. Your Mercedes-Benz parts department supplies an external sticker with the ID number printed on it, which you can tape to the wheel for future reference.

If the sensor does need to be replaced, there are still a few service procedures that need to be performed to speed up the reactivation process and prevent a customer from returning and complaining that the TPC warning message is still displayed in the cluster. Each sensor has its own electronic identification signal it transmits along with those for battery life and tire pressure. This information can be pulled up with most TPMS tools. You may need to activate the sensor before it will transmit while the vehicle is standing still. Simply remove five psi from each tire you want to test, and the sensor will transmit the new information. Remember to correct the pressure after taking the reading for each tire. When you drive the vehicle, the sensors will transmit their ID numbers, battery life, and actual tire pressure. The TPC control unit will eventually learn the wheel position of each sensor. This will be followed by the tire pressure. This process may take a while, hence the customer’s possible return. With the SDS, you can manually enter the ID number for each sensor into the TPC control unit. Now that the wheel positions have been learned, the learning of tire pressure will happen much faster.

The SDS has its Advantages

When you order a new wheel speed sensor, you should always replace the tire valve. The sticker taped to the sensor has the ID number on it. You can tape this to the rim to identify the sensor number if you are going to manually enter it.

Using your SDS, enter the TPC (Tire Pressure Monitor) system where you will have the options to retrieve diagnostic trouble codes, look at event history, actual values, actuations, initial startup, control unit adaptations, etc.. By choosing either initial start-up with manual entering of information, or control unit adaptations, and then selecting settings, you can enter the TPC sensor directly for each wheel. This speeds up the tire pressure learning process since wheel position is known. It can also be a valuable tool in your diagnostic process. If you suspect that a bad wheel sensor or antenna is not transmitting information, you can simply change the position of the wheel on the vehicle, then reactivate the system and see if the problem moves to a new wheel location or stays in the same wheel, which would indicate a bad TPC antenna. Other external characteristics can affect how the TPC control unit reactivates. If you live in a hot climate, air temperature inside the tire can go above 120 C. This will cause the sensor to stop transmitting information. Also, if tire pressure is three psi above specifications, the system will not finish the reactivation process.

The activation process must be performed any time components have been replaced, and new air pressure values need to be read. With the initial start up of a new TPC control unit, you can automatically retrieve car information, or manually enter the data. As an example of what information is necessary, you should know that the TPC control unit is usually powered up by the Rear SAM.

Additional weight in the vehicle has an effect on tire pressure. The central gateway gives vehicle-specific information and country code to the TPC control unit. The Front SAM sends charging system voltage and ambient temperature readings. Tire temperatures are affected by ambient and road surface temperatures as well. Look for the placard either in the fuel door, glove box, or driver’s side door jamb. These are cold inflation pressures, so the tire pressure needs to be checked before driving the vehicle and not after a long trip. These pressure settings can be changed if different tires are fitted and the tire manufacturer recommends it, but Mercedes-Benz strongly recommends that only the original tire construction and size be used to work with the other electronic systems in the vehicle such as ESP, ASR, and ABS.

The TPC system is not without its limitations. It cannot report on a sudden loss of air pressure (a blowout), so you will still need to carefully inspect the integrity of the tire with each service. With a working knowledge of the TPC system you can do more than just keep that warning message off. You can also provide your customers with the confidence of knowing their vehicles’ safety systems are ready to work as designed. It’s that confidence and trust in you that keeps them coming back.

|

Vehicle |

220.184 |

Control unit |

RDK |

|

Write wheel electronics identification number. |

||||

|

Wheel electronics identification number of left front wheel |

0600350357 |

|||

|

The wheel electronics identification number is printed on component A69/1 (left front tire pressure monitor sensor). |

||||

|

Wheel electronics identification number of right front wheel |

0600348488 |

|||

|

The wheel electronics identification number is printed on component A69/2 (right front tire pressure monitor sensor). |

||||

|

Wheel electronics identification number of left rear wheel |

0600279933 |

|||

|

The wheel electronics identification number is printed on component A69/3 (left rear tire pressure monitor sensor). |

||||

|

Wheel electronics identificaiton number of right rear wheel |

0600262161 |

|||

|

The wheel electronics identification number is printed on component A69/4 (rear right tire pressure control wheel). |

||||

0 Comments