You can’t just choose “Round and Black” anymore…

Tire and wheel selection used to be much more simple. All you really needed to know about tires was the diameter and aspect ratio, and pretty much anything “round and black” would fit and work just fine. You could select any brand you liked, and any tread pattern that suited your customer’s taste.

Similarly with wheels, all you needed to know was bolt pattern and rim diameter, and you could choose a rim width you liked and hope that the wheel would fit over the brake components. Your customer might like the OE look, or aftermarket bling, but it didn’t really matter.

The situation is very much different today, certainly with Mercedes-Benz vehicles. Discriminating motorists choose Mercedes-Benz vehicles because they want the finest in comfort, luxury, and performance. And the vehicle’s wheel/tire package is an integral part of the vehicle’s ride and handling characteristics, as well as a critical component in the vehicle’s safety systems.

As with every other system in Mercedes-Benz vehicles, engineers have carefully designed wheel/tire packages to conform to exacting standards of ride and handling, as well as assuring precision interface with safety systems including ABS and stability control systems. So when choosing or recommending replacement tires or wheels, there’s much you need to know.

There’s “MO” than meets the eye

“MO” on the sidewall stands for “Mercedes-Original.” It means that the company has tested and approved the tire.

We’re all familiar with what have become conventional tire sidewall markings. They include the usual tire size and maximum inflation specifications, and also speed ratings, load index, UTQG rating, and mud/snow designation where appropriate. But all of this is supporting information for tire selection and recommendation, and these features alone are not sufficient to restore OE-level ride, handling, and safety systems to their original specs.

And while these specs and markings are useful, they don’t necessarily provide assurance that tires meet the exacting standards designed into the wheel and tire package by the engineers who carefully designed these vehicles.

In order to assure compliance with OE ride and safety standards, Mercedes-Benz has established strict criteria for replacement tires. Such tires, offered by virtually all of the leading tire manufacturers, can be identified by an “MO” designation on the sidewall. These tires, certified as Mercedes Original, have been developed in collaborative efforts between Mercedes-Benz design engineers and tire manufacturer engineers. They are designed and tested to assure compliance with as many as fifty different parameters, including lateral force performance, directional stability, performance verification in a wide range of driving conditions and road surfaces, and even sensitivity to vibrations on a tire oscillation test bench.

MOE tires are Mercedes Original Extended tires, commonly referred to as “run-flat” tires, and are built with reinforced sidewalls and other design features which allow a driver to continue up to 50 miles on a flat tire, depending on vehicle load. These tires, like MO tires, are tested to very high standards similar to those for MO tires.

You might be surprised to learn that Mercedes-Benz has a very aggressive tire program available to independent repair shops through Mercedes-Benz dealership parts departments. They offer very competitive pricing, they normally stock a deep inventory of MO and MOE tires, and typically offer same-day or next-day availability.

Cars in your shop may be on their second or third set of tires, depending on miles driven, and so the original size, make, and style of tire for a particular vehicle may not be apparent. Your local Mercedes-Benz dealer’s parts professional can help. By entering a vehicle’s VIN into his system, he can often identify which tires a vehicle was born with. This way, you can install tires exactly like the originals to restore like-new performance.

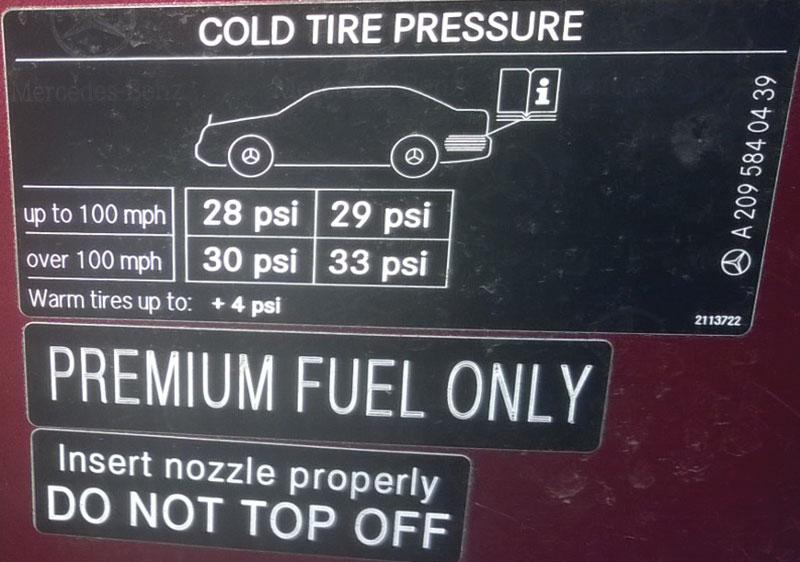

While nobody in this country should be driving over 100 mph, Mercedes-Benz gives us the right info for the chassis.

Note that sizing, and even tire brand and model, may not be sufficient information for selecting replacements. Tire manufacturers may offer a particular tire both with and without the MO or MOE rating. So it is important to specify this rating when purchasing tires for your customers, and your dealership parts department will supply you with such tires from their extensive inventory.

You might ask, “What should I expect from MO/MOE tires compared to those without these ratings?” The answers are many, due to the design, construction, and rubber compounds built into these tires. Your customer can expect better wet and dry traction, longer tread life, smoother ride, and low tire noise. These are substantial benefits.

Surely you’ve had customers who want to “move up a size or two” when choosing replacement tires, usually in a misguided attempt to “improve” ride and handling. This is wrong on many fronts. First, moving to a larger tire rarely provides improvement in either ride or handling. Rather, it most likely will compromise the R&D efforts that went into making a Mercedes-Benz handle so well in the first place.

But deviating from the OE tire size can lead to the proverbial unintended consequences, independent of the impact on ride and handling characteristics. Today’s Mercedes-Benz vehicles are designed with advanced electronic control systems that rely on a variety of inputs from the four corners. These inputs are likely to be compromised by a change in tire size or aspect ratio. Such inputs may include wheel speed, drive ratio, and even suspension travel. Plus, the situation is even more critical on vehicles equipped with 4Matic all-wheel-drive systems, where the interrelationship of all four wheels is even more critical.

What about wheels?

As you might expect, there are many factors to be considered when it comes to wheel replacement. You may need to replace a single damaged wheel. Or perhaps your customer wants to spring for a fancy set of alloy rims. There’s much to think about.

If you’re replacing a damaged wheel, then you can appreciate the need to choose a replacement of the proper size and style. But no so fast! You can’t just look up make, model and year in a generic chart or catalog and hope to come up with the proper wheel.

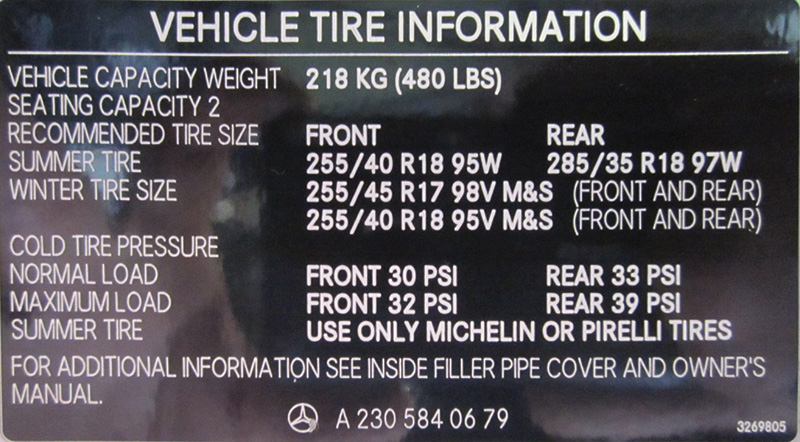

Each vehicle will have its own label indicating acceptable wheel and tire sizes. Of particular note here is the notation that summer tires are of the “staggered” configuration, with larger tires on the rear. However winter tires should be of the same size front and rear.

Many Mercedes-Benz vehicles are factory-equipped with a “staggered” wheel setup in which the front wheels are a different size and/or offset from the rear wheels. So you can’t just pick a new wheel from a catalog or, worse yet, buy a used wheel from a scrap yard. And having a Mercedes-Benz wheel repaired, or exchanged for a repaired wheel, is not a good option. The company specifically recommends against any type of wheel repair, since a repaired rim is not going to provide the same level of safety and performance as a new OE wheel. By far, the best option is to provide the VIN to the parts professional at your local Mercedes-Benz dealership so they can determine exactly which type and size of rim is correct for the car you’re working on.

If your customer is interested in switching to aftermarket wheels, the issue becomes more complicated. Certainly rim width, diameter, and offset/back spacing are critical for providing acceptable levels of ride and handling. But there are other factors to consider as well. Offset that varies from OE can cause inordinately high loading on wheel bearings and suspension components. There can be fitment issues with brake calipers and rotors, as well as hub centers. And it’s possible that such wheels can affect alignment enough that caster, camber, and toe may exceed the limits of adjustability in the vehicle. If alignment remains beyond specifications, the result will be an ill-handling vehicle, increased turning radius, accelerated suspension wear and, of course, accelerated tire wear.

But it goes much deeper than that. The advanced electronic systems in late-model Mercedes-Benz vehicles rely on accurate inputs from all four wheels. Systems involved include anti-lock brake systems (ABS), ESP stability control systems, Distronic Plus (DSR) systems, and Brake Assist (BAS) systems. Faulty or out-of-spec inputs to any of these systems will compromise their performance and effectiveness.

There are other concerns with aftermarket wheels. Mercedes-Benz factory wheels are hub-centric, not lug-centric. This means that the wheels are indexed axially by the fit of the center of the wheel to the hub, and not by the lug bolts and holes. But because the manufacturers of aftermarket wheels try to consolidate wheel designs so that a given wheel can fit many different makes and models, the center hole may not be precision-machined for proper indexing. Absent such precision, these wheels are almost guaranteed to cause unwanted, annoying, and possibly dangerous vibration.

While this tire and wheel combo may look stylish, it will definitely cause problems. Advise your customers to stick with stock.

As with tires, your customer may want to move to larger diameter wheels with lower-profile tires. Again, not a good idea. Lower profile tires with shallower sidewalls are less able to cushion road bumps and irregularities, resulting in a harsher ride. At the same time, they are less able to protect rims from relatively minor pothole damage. Such wheel and tire packages can also negatively affect speedometer accuracy, as well as the adverse interaction with electronic control systems as described above.

Larger diameter wheels raise the vehicle’s center of gravity, leading to increased body roll when cornering, and also impact acceleration and responsiveness due to their effect on the final drive ratio. Other problems associated with larger wheels and tires include potential interference with wheel wells and suspension components, increased turning radius, bottoming-out of the suspension, and premature wear of suspension components.

Bear in mind that cars factory-equipped with AMG options will likely have equipment that will affect wheel and tire selection. An example would be larger brake rotors and calipers, which typically require different wheels that provide additional clearance for these larger brake components.

Service procedures are key

When it comes to mounting wheels and tires, MBUSA has specific procedures that they recommend in order to prevent wheel and tire damage and to assure the integrity and performance of the wheel/tire assembly.

To begin with, Mercedes-Benz recommends against mounting cold tires, since they will be too rigid to flex during the mounting process. They recommend that tires be at least 60 degrees F (15 degrees C) for mounting. And no heating procedure should be used other than allowing tires to warm naturally to room temperature. So you should never use a heat gun, hair dryer, or radiant heater to warm cold tires.

Wheels should be cleaned in the bead area to assure proper sealing, and valve stems should be replaced every time. If a tire has a light spot, the tire and wheel should be selectively matched during tire mounting to assure radial trueness of the wheel/tire assembly. Genuine Mercedes-Benz wheels are often marked to indicate light spots. MO tires are likewise often marked accordingly.

Factory alloy wheels are typically lightest at the valve stem hole, and tires will have a color dot on their outboard side.

If a vehicle has the same size tires at all four corners, Mercedes-Benz recommends installing a single new tire or a pair of new tires at the front of the car. Naturally unidirectional tires should be mounted accordingly. Torquing and re-torquing procedures for lug bolts varies by model, so consult STAR TekInfo for specifics.

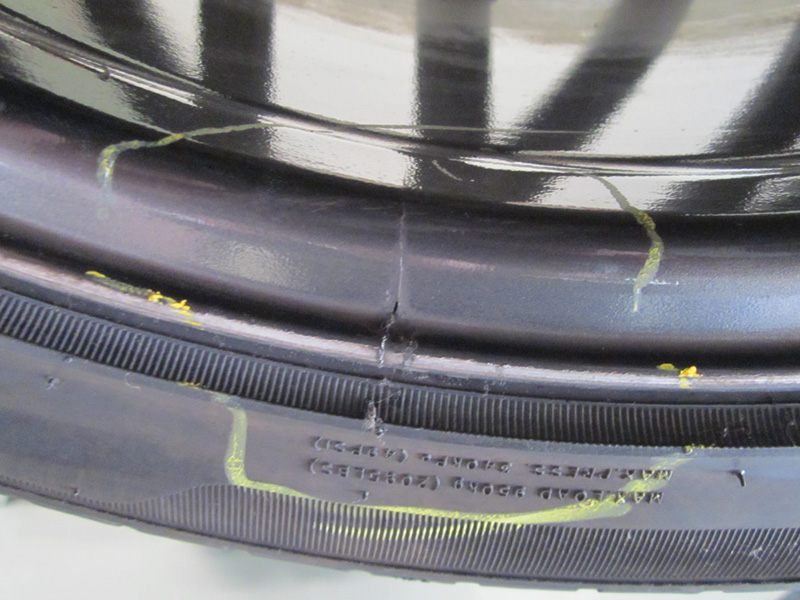

This aftermarket rim is cracked! You’re not likely to see that with Mercedes-Benz Original Equipment wheels.

Mercedes-Benz specifically recommends against any kind of repair to any wheels or tires. Repairs to wheels can compromise their integrity, and plugging puncture holes is specifically not approved by the company, regardless of the location of the puncture. Also, the company recommends that tires older than six years old be taken out of service, and tires classified as M&S should be taken out of service after four years from the date of manufacture.

If tire rotation is called for, it can only be performed if the wheels and tires at all four corners are the same. If so, Mercedes-Benz recommends rotating from front to rear on the same side of the car. However if the wheels/tires are “staggered” with different sizes front and rear, then rotation is not recommended.

Wheels can be cleaned using commercially-available mild cleaning products. When deeper cleaning is called for, your local dealership can supply a special alloy wheel cleaner, part number A 001 986 3471 that is very effective in removing stubborn dirt. After cleaning, you should treat the surfaces with polish and gloss preserver.

Tires can be cleaned with appropriate cleaning products. But Mercedes-Benz does caution against the use of high-powered cleaning machines or pressure washers on tire surfaces. The very high pressures put out by these machines can damage sidewalls.

If tires must be stored, it is recommended that they be cleaned thoroughly first and marked with position on the vehicle and direction of rotation. Tires should be stored indoors to avoid possible damage from sunlight, heat, moving air and ozone, which can degrade the elasticity and strength of the tire. Best to store tires in a cool, dry location, and avoid contact with gasoline, oil or greases, which can dissolve the rubber.

But what about TPMS?

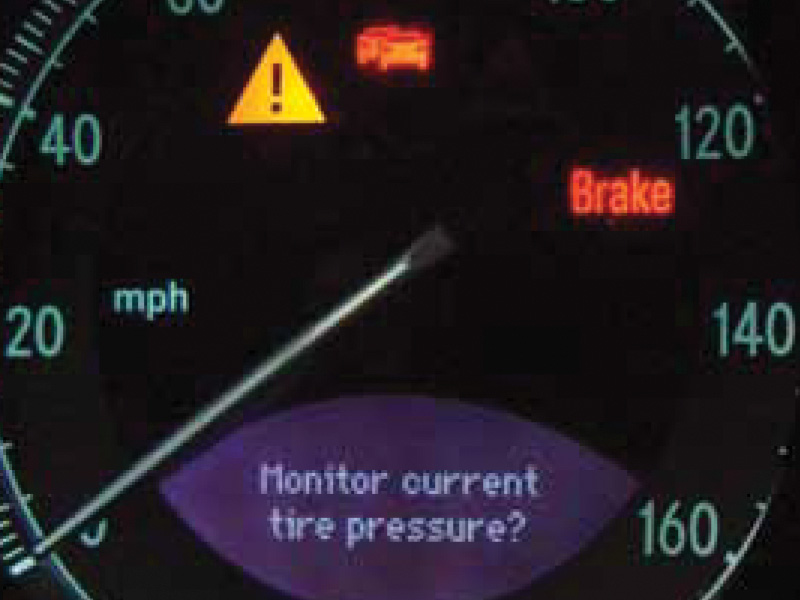

Tire Pressure Monitoring Systems may be referred to as TPM (Tire Pressure Monitor) or TPC (Tire Pressure Control) systems, but they all refer to the same system, whose role is to monitor the air pressure in each tire and relay that information through CAN-B, which can alert the driver when pressure in one or more tires falls below a pre-established threshold. Powered by an internal battery, these sensors send a signal about once a minute under normal operating conditions, and about once a second when a low pressure is detected.

It is important to avoid damage to TPC sensors when mounting or dismounting tires. Make sure your tire-changer’s apparatus is oriented away from the valve stem and the sensor within.

These systems tend to be largely trouble-free, as are the sensors inside the wheels. But a few servicing cautions are in order. If you’re unsure whether an older model is equipped with TPC, a quick look at the valve stem will tell the tale. TPC-equipped vehicles will have an aluminum valve stem, not rubber or steel, and if TPC-equipped, will have a sensor mounted to the valve stem inside of the tire. Note that TPC valve stems should have plastic valve stem caps in order to prevent galvanic action and corrosion that can develop between a metal valve stem cap and the aluminum valve stem.

After wheel and tire service it will be necessary to re-activate the TPMS/TPC system, and then test-drive the vehicle to allow the system to re-learn pressure settings and parameters.

Also, you may not be aware that TPC radio signals cannot penetrate wheels nor the steel belts in the tread area of tires; they can only pass through the sidewalls of the tires. And, in model years 2006 and earlier, Mercedes-Benz vehicles used different types of sensors than vehicles made after that. So it is important to always order replacement sensors and valve stems using the vehicle’s VIN. The parts professional at your local Mercedes-Benz dealer will be happy to help assure that you get the correct part for the vehicle you’re servicing.

When mounting or dismounting tires on TPC-equipped rims, you want to be sure that your tire changing machine does not contact or interfere with the TPC sensor. You’ll want to orient the tire/wheel assembly to avoid such interference.

Following related parts replacement or depressurization, it will be necessary to re-activate the TPC system and have it “learn” the new readings. This will require a test drive of as little as a couple of minutes, or as much as 20 miles or 20 minutes.

0 Comments