Passive evolves into active, and the changes keep Mercedes-Benz vehicles ahead of the curve in regard to driving feel and handling prowess. Here’s an overview of electronic suspension, AIRMATIC, Magic Body Control, proper calibration of lane-keeping radar, and collision prevention.

Since the invention of the wheel 6,000 years ago, man has tried to find ways to smooth out the path it travels on, lessen the rolling resistance, and quickly adjust to changes in terrain. In the horse and cart days, of course, the roads were dirt, full of ruts and rocks. Changes to both the wheel and the surface it rides on helped to improve the ride and handling as carts were replaced by automobiles and the roads were paved. The invention of the rubber tire improved things immensely, but much more was needed for safety and comfort. Enter the suspension system – a flexible way of separating the carriage from the wheels. Even ancient Roman chariots had a sort of suspension system using leather straps, and centuries ago carts had some sort of spring system — steel leaf springs were used to isolate the rider from the road.

Since the invention of the wheel 6,000 years ago, man has tried to find ways to smooth out the path it travels on, lessen the rolling resistance, and quickly adjust to changes in terrain. In the horse and cart days, of course, the roads were dirt, full of ruts and rocks. Changes to both the wheel and the surface it rides on helped to improve the ride and handling as carts were replaced by automobiles and the roads were paved. The invention of the rubber tire improved things immensely, but much more was needed for safety and comfort. Enter the suspension system – a flexible way of separating the carriage from the wheels. Even ancient Roman chariots had a sort of suspension system using leather straps, and centuries ago carts had some sort of spring system — steel leaf springs were used to isolate the rider from the road.

Those early carriages weren’t fitted with shock absorbers, but as speeds rose, so did the need for suspension damping. Early shock absorbers, which persisted into the 1930s, were actually friction dampers. They don’t really absorb shock, but rather dampen the oscillations of the springs. Frenchman Maurice Houdaille is credited with inventing the first shock absorbers to take advantage of the excellent cushioning qualities of hydraulic fluid forced through an orifice. He received his first patent in 1907, and his products eventually became used on production vehicles.

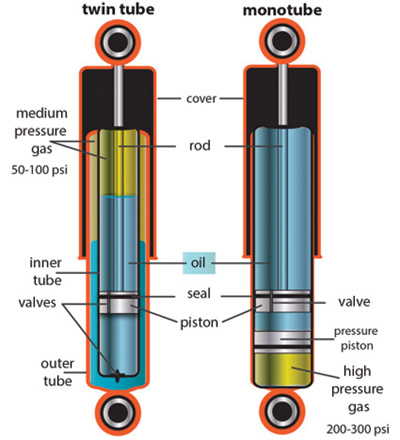

The simplest early versions consisted of a tube with a piston that moves up and down through a chamber filled with hydraulic fluid. Later, this fluid was augmented with pressurized nitrogen to prevent the formation of bubbles. The movement of the piston draws in or displaces fluid though orifices, the size and placement of which determine the damping characteristics. Over the years, both the mono-tube and twin-tube types were used. Both have compression and rebound strokes. In the mono-tube design, when the piston rod moves in, the separating piston compresses the gas cushion by the amount of oil corresponding to the volume of the piston rod. During the rebound stroke, the piston rod retracts and the nitrogen gas pressure pushes back on the separating piston. Damping occurs in both directions via the piston valve. In the twin-tube principle, when the piston rod moves in some of the oil flows from the lower to the upper working chamber through the piston valve. Oil is thereby pushed through the base valve in the reservoir tube providing compression and damping. On rebound, the piston valve takes over the damping function while a quantity of oil corresponding to the volume of the retracting piston rod flows back through the base valve.

Fully-active body control

The word “active” is the key here. Conventional systems can only react to road surface imperfections by resisting the changes encountered. Mercedes-Benz invented active body control (ABC) to do more than just resist, but actually makes corrections. A network of five sensors constantly measure each type of body motion, side-to-side, front-to-back, and up-and-down. These are acceleration body sensors at the left front, right front, and right rear. The lateral acceleration sensor is mounted on the tunnel under the center console, and another is usually mounted under the back seat area on the left side.

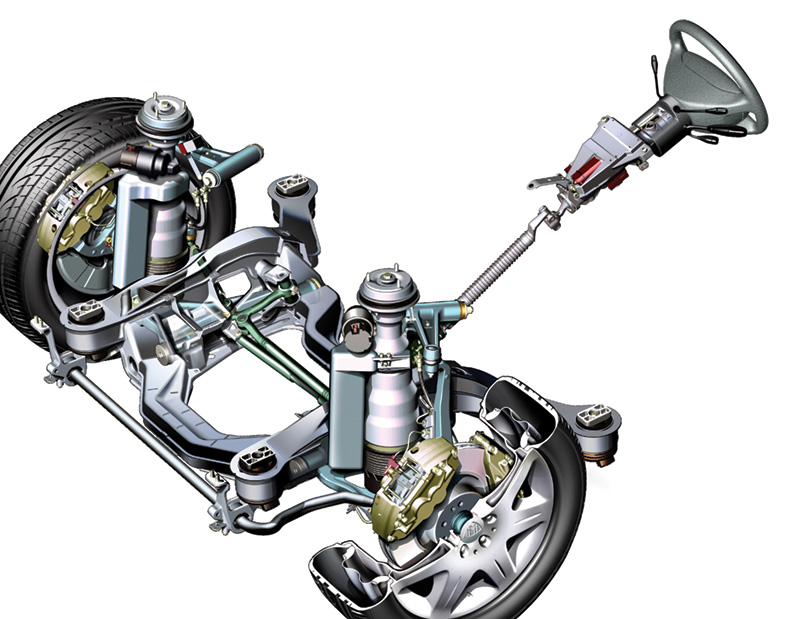

At each wheel, an advanced strut design incorporates a spring, a shock absorber, and an active hydraulic cylinder that can move up or down. A sensor in each cylinder monitors its position. Two microprocessors and a high pressure hydraulic pump are also employed. The radial piston pump is capable of producing pressures between 180 and 200 Bar while driving. Should the pressure fall to below 100 Bar, the ABC control light is activated and a limp-in mode is engaged. To complete the system, there is also an oil reservoir and filter, oil cooler, pressure storage device, pulsation damper, oil temperature sensor, and hydraulic lines.

ABC can change the length in each strut in as little as 10 ms as it detects movement in the sensors. The system also allows for a self-levelling feature, which raises or lowers the vehicle in response to changing load (i.e. the loading or unloading of passengers or cargo). Vehicles equipped with ABC have a “Sport” button that allows the driver to adjust the suspension range for different driving style preferences. So, the driver can adjust the suspension to maintain a level ride in more demanding driving conditions.

Caring for ABC

Service concerns of the ABC system will consist of many of the same maintenance requirements of conventional systems, such as leaking struts and worn bushings and components. First, always check the basics when troubleshooting faults. DTCs can be easily called up using Star diagnosis, XENTRY, or compatible scan tools. After replacement of hydraulic components, the system will need to be filled and bled. To do this properly:

- Fill the hydraulic reservoir with hydraulic fluid PN A 001 989 24 03 10 (Note: when changing the hydraulic pump, the engine must be run for two minutes before pushing the ABC button). The vehicle should be level and sitting on its wheels, not elevated.

- Check the dipstick. The level should be between the Min and Max marks with the engine stopped and vehicle unloaded.

- Start the engine, then push the ABC button until both lights go out. Be sure to keep the level above the minimum mark.

Bleeding:

- Charge the system manually with pressure. The special tool number is 124 589 24 21 00, however techs in the field have used a cooling system pressure system tester with an adapter to perform this task.

- Push the ABC button until both lights come on (car level high).

- Push the ABC button until both lights go off (car level normal).

- Repeat last two steps three times (15 times if changing valve blocks).

- Stop the engine and wait for 10 minutes.

- Check the dipstick and top up as necessary.

- Start the engine and check the valve blocks for noises.

If noises are heard:

- Stop the engine, lift the vehicle and open the bleeder screws until oil comes out. Close the bleeders.

- Repeat the process until the noises disappear.

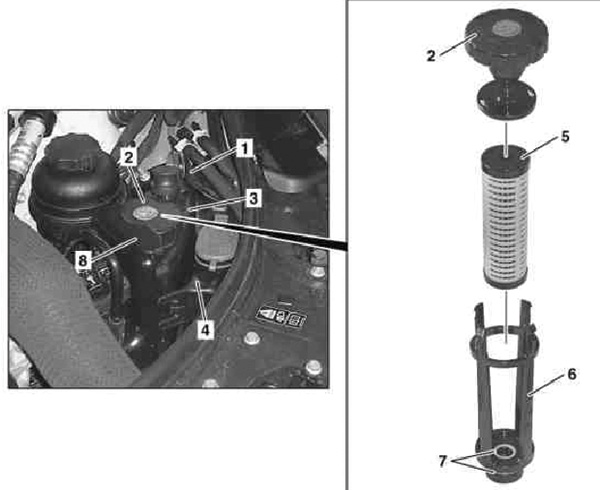

Also note that a new improved filter is available for the system and is located in the reservoir. Newer models do not have a replaceable filter– the reservoir must be replaced as the filter is integral.

AIRMATIC

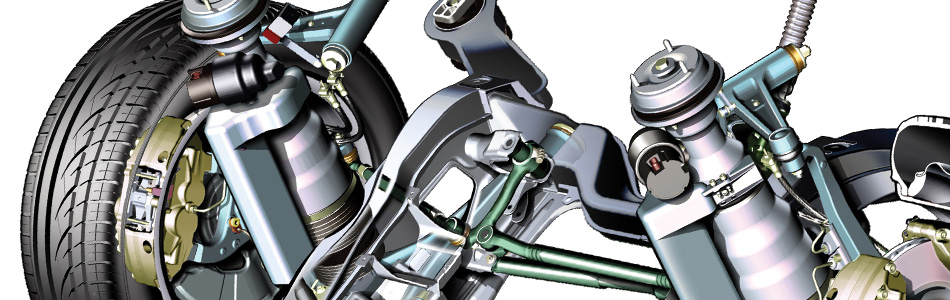

With AIRMATIC, ordinary steel springs are replaced by adjustable air springs that smooth the ride. The system includes semi-active adaptive damping (ADS) that instantly adjusts the shock absorbers to improve handling. As each air spring moves up or down, AIRMATIC adds or removes air to maintain comfort and also lessen body roll in corners. The ADS monitors the road surface and the driving style of the operator so that within 50 ms the system can firm up the shock absorbers to keep handling crisp and stable. The driver has the ability to choose Sport and Comfort modes to fine-tune the feel. With the addition of passengers or cargo, the vehicle has the ability to level itself automatically with no loss of comfort. Also, the driver can raise the vehicle based on road conditions (snow, etc.) and the ADC will lower the vehicle at higher speeds to reduce wind drag and improve performance, handling, and fuel mileage.

Some issues you may encounter are complaints of the vehicle sitting too low, or a warning on the instrument cluster to visit the workshop. Typically, when the air suspension compressor quits working, the whole car may lower to the ground and fail to raise. You press the button to raise the car, and nothing happens. If the air suspension compressor works as designed, you will hear the compressor engage and run for several seconds. A common area of failure is the relay. Also check the fuse for the compressor before condemning it. Be sure to check for voltage at the pump connector.

Sometimes there will be a failure in one of the air struts. When the seal in the strut degrades, it no longer provides the isolation required and a leak starts. If a major leak has developed, you may even hear a hissing sound from the wheel housing. The whole front or rear of the car will drop down, even when only one of the struts is malfunctioning. The lines can also be a source of an air leak, as well as the valve block. Checking for leaks consists of spraying a soap-and-water solution on the suspected areas and checking for bubbles. There are also some commercially available leak detector solutions that are reported to be more reliable in locating leaks. An area of leakage in the strut you should keep in mind is the top seal assembly. There is a strut shock repair kit available from Mercedes-Benz (PN A 220 320 25 38). Follow the installation instructions in WIS. Another great option is genuine Mercedes-Benz remanufactured AIRMATIC struts.

“Come with me on a magic carpet ride”

Looking at Mercedes-Benz advancements in suspension systems brings to mind the lyrics from that old song. Mercedes-Benz Magic Body Control can be found on late-model S-Class and S-Class coupes. This is the first ever predictive suspension system. It is unique in that stereo cameras are used to scan the road surface in real time up to 15 meters ahead of the vehicle. This function is known as a road surface scan. The stereo cameras measure obstacles with a precision of 3 mm, and at speeds of up to 80 mph. The measurement data from the exact road profile is then passed on to the suspension management system. The active suspension now knows ahead of time which bump it’s about to go over. This way the body can adapt to the road far more smoothly than a conventional vehicle suspension ever could. The suspension can actively compensate for uneven surfaces and prevents the vehicle from oscillating and vibrating. This level of comfort is unprecedented in automotive suspension systems and lets the driver feel as though he or she were gliding over the road on a magic carpet.

Lane Keeping Assist and Collision Prevention Assist

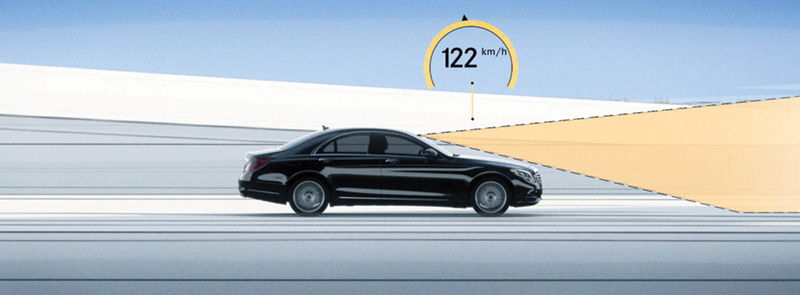

Active Lane Keeping Assist can detect if you’re straying from your lane. The system can warn you by vibrating the steering wheel, then, if necessary, it can apply the brakes to help bring you safely back into your lane. A camera mounted inside the front windshield constantly monitors the areas in front of the vehicle. If the control system recognizes that the vehicle is moving toward the line at the center or the side of the road, it can compute within milliseconds whether this is intentional. If it is determined that the action is unintentional, the system can alert the driver by vibrating the steering wheel briefly. A vibration motor in the steering wheel warns the driver with a haptic signal (3x pulsation). If there is no response or corrective action taken, the wheels opposite the lane of drift will brake to bring the vehicle back on course. Warnings are only issued if the lane is clearly recognizable. Other functional impairments can also be caused by direct sun on the camera lens, heavy rain, or other visual obstructions. Course corrective interventions are only performed by the Active Lane Keeping Assist system if the lane markings are continuous and a haptic warning has previously been issued. The system operates in a range of 37 to 124 mph. Above 124 mph (who drives that fast?), only the vibration warnings are issued. Components of the system include:

- Multifunction camera

- Vibration motor in steering wheel

- Radar sensors control unit

- Front long-range radar

- 4x short-range radar – two front and two rear

- One rear multiple-mode radar

Diagnosis can be performed in the multifunction camera (MFK), radar sensors control unit (SGR), as well as guided calibration via XENTRY diagnostics.

Collision Prevention Assist/Collision Prevention Assist Plus

The Collision Prevention Assist system from Mercedes- Benz provides a visual warning when the distance from the vehicle in front is too short. If the M-B car approaches the vehicle in front at a high rate of speed or acceleration, a dynamic distance warning is activated. When the driver brakes, the system works together with Adaptive Brake Assist to perform a collision-avoiding targeted brake application to help prevent rear-end collisions. In addition to issuing a visual and acoustic warning in the event of an imminent collision, the Collision Prevention Assist Plus system also performs autonomous partial braking with up to 60% of maximum braking power of the vehicle. Diagnosis of the system is performed in the Collision Prevention Assist control unit and the DTR – DISTRONIC® module though XENTRY diagnosis.

Who’s driving, anyway?

The systems described here as well as cutting-edge technology including DISTRONIC® Plus, DISTRONIC® Plus with Steer Assist, Night View Assist/Plus, Adaptive High Beam Assist/Plus, cruise control and Speedtronic, Downhill Speed Regulation, Speed Limit Assist/Traffic Sign Assist, Attention Assist, Parktronic with Parking Guidance, Active Park Assist, Reversing Camera, Brake Assist Plus with Intersection Assist, and Pre-Safe Brake/Plus are all indicators of the technological advancements Mercedes- Benz has made. These are great strides in providing safety and the ultimate in ride and handling.

Download PDF 〉

0 Comments