The drivelines of modern Audi vehicles are integral components for propulsion. Without a way to properly transmit power from the engine to the wheels, you’re going nowhere!

Almost every modern Audi vehicle is equipped with its trademark “Quattro” all-wheel drive system. This system utilizes a drive axle at each wheel as well as a center driveshaft to send power to the rear wheels. A transfer case at the output of the transmission and a rear differential are used to evenly distribute power to each wheel.

Most newer Audi models with a longitudinal engine layout have a full-time all-wheel drive (AWD) system known as a Torsen system, or torque sensing system. The torque sensing system is used to apply drive power to the front and rear wheels, depending on traction requirements. The center differential, which is mounted at the tail of the transmission, is the workhorse of this system, constantly varying torque output between the front and rear wheels. This is a sturdy, mechanical system that rarely needs service to ensure a long life other than periodic fluid changes.

Audi Quattro vehicles use a torque sensing center differential on most larger models such as the Q7, A8, and A6 models.

In Audi vehicles with a transverse engine layout such as that found on A3 models, Audi has used a Haldex unit at the rear differential as an electronic rear differential locking mechanism. The advantage of a Haldex AWD system is the ability to quickly switch between front wheel drive bias to rear wheel bias, depending on driving conditions and traction loss. These Haldex systems generally send most of the power to the front wheels in normal driving conditions. This can actually increase fuel economy due to less parasitic power loss.

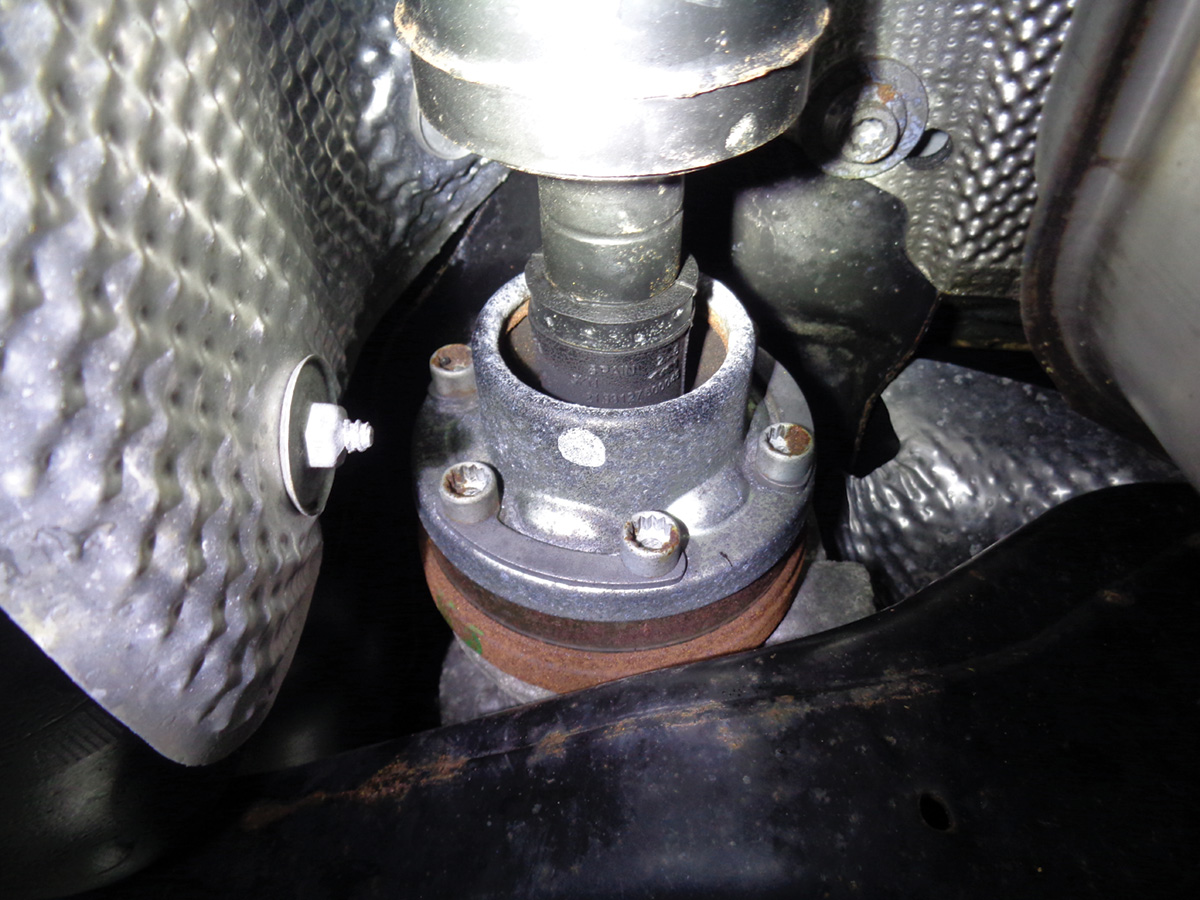

The Audi Haldex unit uses a clutch pack hydraulically activated by an electric pump at the front of the rear differential assembly. By pressurizing the hydraulic fluid, the clutch packs can be quickly locked and unlocked, controlling power sent to the rear differential. The AWD control unit activates the pump depending on amount of wheel spin detected, changing from almost 100 percent front-wheel drive to 100 percent rear bias.

The Haldex unit does require service from time to time. The clutch packs start to wear from use over time, and will begin to degrade as well as contaminate the oil supply. Audi recommends changing the Haldex fluid every 40 K miles if so equipped. Haldex- equipped vehicles also have a filter that can be accessed and replaced during service.

When servicing the Haldex unit it’s important to re-fill the unit with the proper amount of gear oil. These systems have very small passages that may take a few minutes to properly take on oil. Under-filling a Haldex unit is a sure-fire way to kill the clutch packs. Often the Haldex oil comes in a pre-measured tube per application. Use it all!

If issues are suspected with the Haldex unit, always check the electrical connections at the Haldex unit itself. It’s common for these connections to become corroded from exposure as well as damaged from oil contamination from the Haldex unit itself. If corrosion is found in the connectors, re-pinning and replacing the connector is often the only viable repair option.

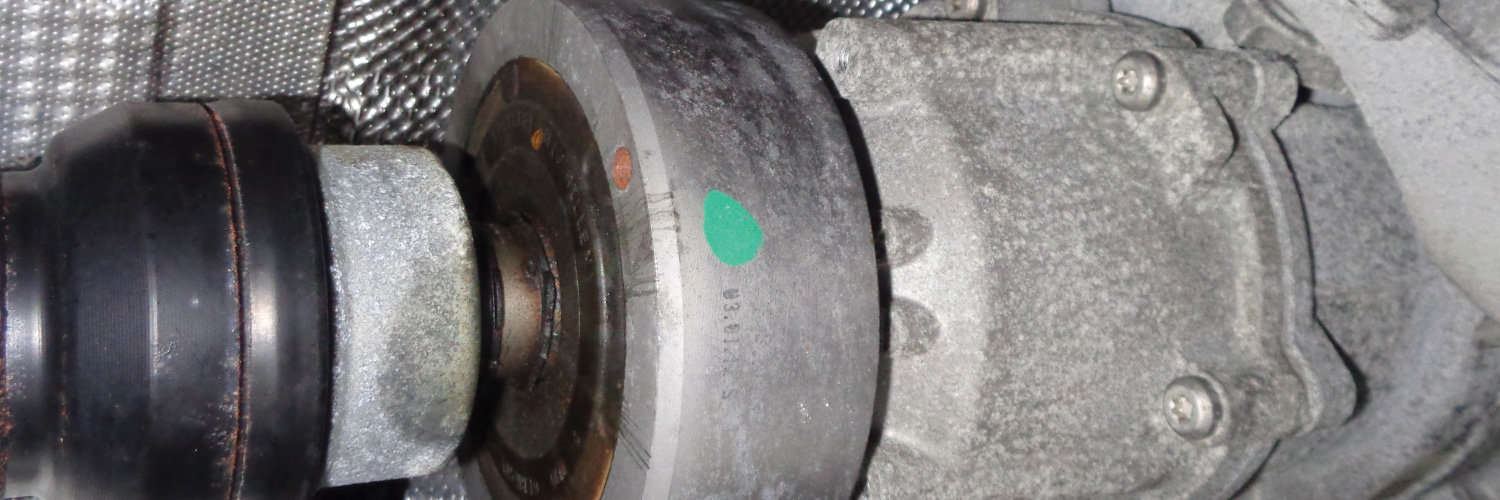

The front and rear differentials of the vehicle require service periodically as well. These are straightforward services with 40 K mile replacement intervals for most Audi vehicles. Don’t neglect these services, particularly the front transfer case, if so equipped. These lead a tough life close to the vehicle’s exhaust system. The dark burnt color compared with the new fluid’s golden hue is a good indicator of fluid that needs to be replaced.

The axle shafts and driveshaft are fairly robust on Audi vehicles but do require inspection and service periodically. Front constant velocity (C-V) boots on Audi vehicles are the most common to need repairs. The front axles are constantly in motion and also flex the outer axle joints during turning and suspension movement. This constant flexing eventually takes its toll on the rubber C-V boot as the rubber ages. Once the rubber deteriorates enough, the boot begins to fling out the axle grease. Not only does this create a nice mess, but can quickly dry out the bearings in the C-V joint causing damage to the bearings and bearing surface.

Once the axle joint dries out from lack of lubricant, noise and vibration begins to set in. This is most commonly evidenced by a rhythmic “clicking” noise while turning. This noise is generally worse when making full steering lock maneuvers such as in a parking lot. Once the axles begin making noise, the damage has usually been done to the bearing assembly in the axle. It’s possible to install new boots and grease, but be warned. The noise may not go away unless a new axle shaft assembly is fitted. This is why it is critical to spot a boot failing early before it ruins the axle.

In rare cases, a worn drive axle can cause driveline vibration. Most commonly, it feels like an out-of-balance tire. An out-of-balance or worn axle can be difficult to pinpoint due to minimal visible play in the axle, even when worn. When checking axles for play, also check for stiffness in the joint assembly, as this can cause vibration and noise. This same principle applies to the vehicle driveshaft. Occasionally, the universal joints on the driveshaft may become stiff with age, and resist movement. This can cause driveshaft vibration and noise. On higher-mileage Audi’s, the center support bearing may begin to degrade as well. Once the supporting rubber degrades enough, the driveshaft will begin to vibrate excessively. This can be felt as a vibration in the seat back or through the floor of the vehicle.

0 Comments