Through specific examples, we’ll discuss how to address this technology in the shop environment.

There has already been a plethora of information written on Advanced Driver Assist Systems, or ADAS. This article looks to build on the wealth of information already available on the topic through specific examples of how this technology needs to be addressed in the shop environment.

Each new model year brings changes and new technology that require a continual state of learning and searching for answers to the ADAS puzzle. Learning these systems and the components that make them work requires reading through service information and technical bulletins, as well as hands on practice.

A first step towards solving the ADAS puzzle is for technicians to be familiar with how these systems work in the real world. Many technicians may not own a vehicle equipped with ADAS and may not be used to how these systems behave on the road. This can make it difficult to know if a vehicle is operating correctly or not. Technicians should be encouraged to safely utilize these technologies on test drives or even rent vehicles with ADAS features in order to become more experienced with how each system operates.

It is also important for vehicle owners to be educated on the technology on their vehicle. There are several good resources to aid in this, including the website MyCarDoesWhat.org and the National Highway Traffic Safety Administration‘s website. Customers can be directed to both of these web pages to help them understand the technology on their respective vehicles.

P.S. Unabbreviated _ _ _ _ Script (2 Across)

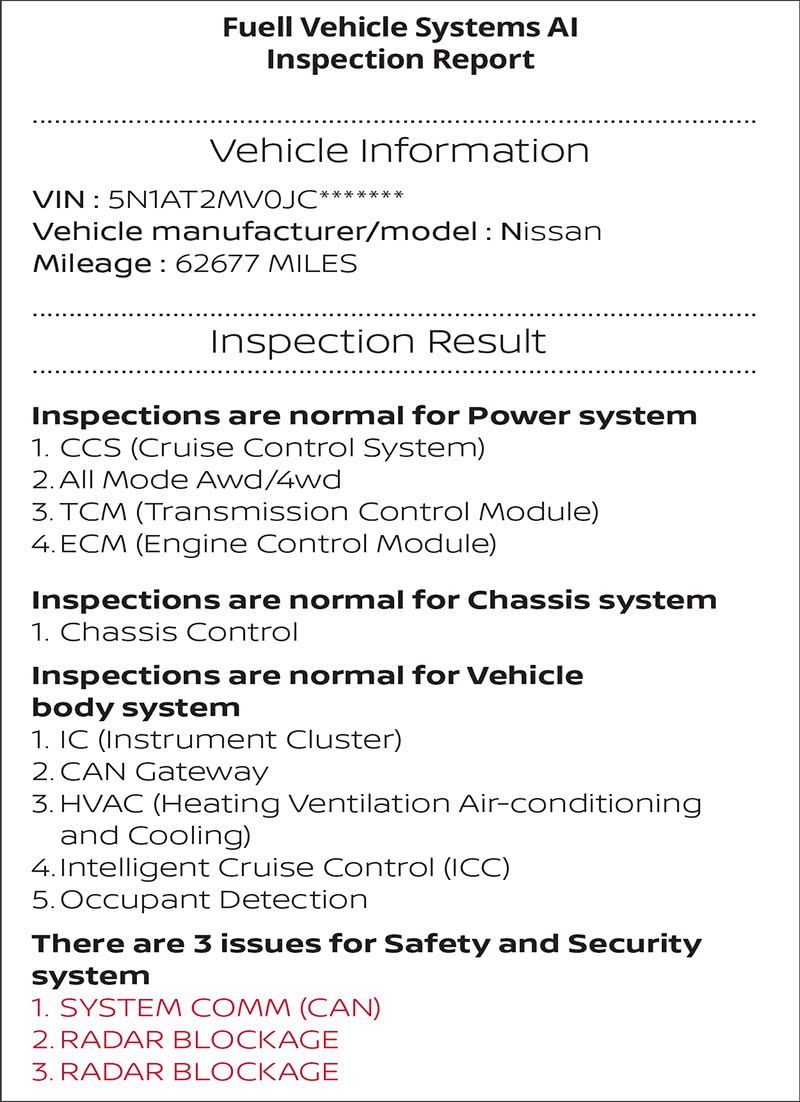

The collision industry has embraced the added steps of performing a pre-scan and post-scan on all the vehicles coming through their facility. This is not always true for the independent repair sector though. While some shops are performing a pre-scan, many shops do not, and even fewer shops perform a post scan before a vehicle is returned to its owner.

Nissan has laid out the best practices when it comes to pre- and post-scan in this position statement:

The presence of increasingly sophisticated and inter-connected technology supports and necessitates the requirement of all Nissan vehicles, having a diagnostic system scan to identify any diagnostic Trouble Codes present, even in cases where there is no identifiable Malfunction Indicator Light illuminated on the vehicle’s dashboard… A pre-repair system scan is recommended to identify items in advance that are malfunctioning on a vehicle… The post-repair diagnostic system scan is required to confirm DTCs are properly resolved and assist in system calibrations, helping to ensure our owners’ safety and satisfaction.

These additional scans require extra time spent when first checking a vehicle in for service and before releasing the vehicle to the customer. Scans may also require additional equipment and training for whoever is selected to perform the scans. This extra time and money is why many shops have not adopted the pre-scan, post-scan practice.

With the increasing amount of technology and safety systems on late-model vehicles, the extra time and money associated with these scans is minimal compared to the potential liability. There are dedicated hand held scan tools available that are specifically designed for pre-scans. They can perform a pre-scan, generate a report, and email that report all automatically once connected to the OBD port. The report can then easily be attached to a digital work order.

A repair facility needs to document any faults present for the safety and driver assistance systems present on a vehicle. Any faults, if present, need to be explained to the vehicle owner and the next course of action needs to be recommended. Should the recommended testing or repairs be declined, that needs to be clearly noted as well. The percentage of vehicles with Advanced Driver Assistance technology that are coming into independent repair shops is steadily growing, and that trend will continue as older vehicles are replaced by newer model year vehicles.

This all becomes even more important as the federal Automatic Emergency Braking mandate takes affect this year, with more regulations likely forthcoming. Even on the state level, there is legislation being introduced, like HB 5409 submitted on the floor of the Illinois State Congress at the end of January 2022.

This bill, entitled the “Advanced Driver Assistance System Repair Act,” aims to make glass installers and repair facilities legally responsible for correctly calibrating any ADAS on a vehicle they work on. It would also require the operational status of ADAS to be disclosed for any used vehicles being sold. While this bill is still in the early stages and has not yet been voted on, other states are likely to follow suit as the technology grows.

One additional benefit of pre scans is to help identify which driver assistance systems may be present on a vehicle. This is important information to know when looking up labor times for repairs and ordering parts. For example, replacing a radiator or condenser may also require a front radar calibration if the vehicle is equipped with Intelligent Cruise Control (ICC). This information needs to be known before any repairs are started in order to correctly quote a repair and to determine if the shop is equipped to handle the calibration. In the case of an ICC sensor alignment, the necessary tooling is significant and relatively expensive.

Sound Navigation and Ranging Acronym (5 Down: _ _ _ _ _)

Mentioning the word sonar usually conjures up images of submarines and battleships, or even fish finders (for the fishermen and women out there). This technology is now commonplace in the automotive world though, with most vehicles equipped with various configurations of ultrasonic sensors in the front and rear bumpers. These sonar sensors are reliable and relatively trouble free; most issues are a result of collision damage. When they do have problems, there are several methods of testing these sensors.

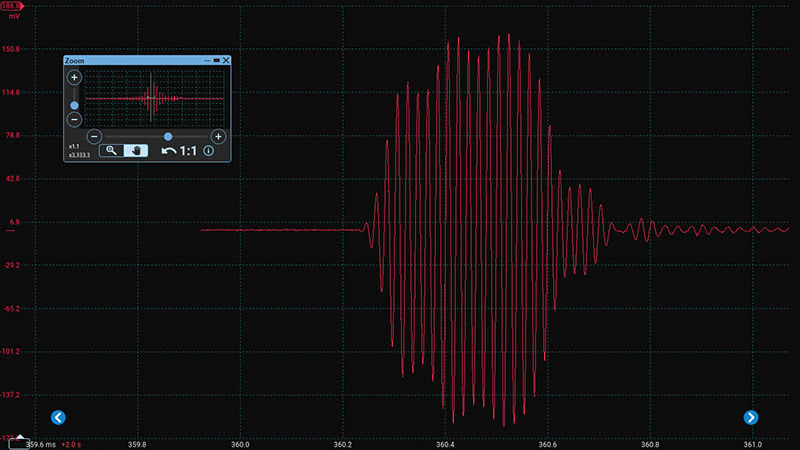

One testing option is to use the Ultrasonic Parking Sensor Detector available from PicoScope®. When the testing wand is placed in front of a sonar sensor, the frequency being emitted from the sensor is picked up and displayed on the lab scope screen. The resulting waveform can be compared to other sensors on the same vehicle or to a known good example.

There are hand-held testers available as well. This style of parking assist tester is held in front of the sensor and will light up or make a sound to confirm that a sonar sensor is, in fact, sending out a signal.

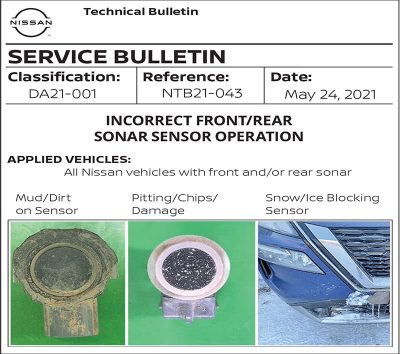

Nissan has provided additional information for sonar sensors in service bulletin NTB21-043. This TSB provides a diagnostic flow for sensor operation and gives an overview of how the sensors can be affected by environmental factors.

One final important note on testing sonar systems is to observe all safety recommendations. Testing parking assist sensors may require the transmission range selector to be in Reverse before the sensor becomes active. This may be possible with the key on and the engine off, but in some cases the engine needs to be running as well. A co-worker is required to place the vehicle in Reverse while keeping the brake pedal applied. Be sure to set the parking brake and chock the wheels for added protection.

St. Louis National Park _ _ _ _ _ _ _ Arch (6 Across)

The Central Gateway, or CGW, is a fairly new addition to Nissan’s on-board module communication networks. Gateway modules work double duty as both a firewall and router for the vehicle’s electronics. As a firewall, the CGW separates the in-vehicle networks from the Data Link Connector and outside access. As a router the Gateway bridges multiple bus networks, allowing communication between high and medium speed CAN, Ethernet Protocol, and LIN buses. The CGW is the vehicle’s Big Brother, monitoring outside contact and arbitrating internal communications.

Firewall type protection has become even more important after reports of auto manufacturers being hacked and demands made in order to remove ransomware. As more personal information is recorded and stored in on-board modules, this protection is just as important for vehicle owners as it is for manufacturers.

Gateway modules are ideally suited for future technologies like Over-The-Air (OTA) update programming, as well as Vehicle-to-Vehicle (V2V) and Vehicle-to-Infrastructure (V2I) communications. These factors confirm that secured gateways and similar technologies are the new normal for automotive networks.

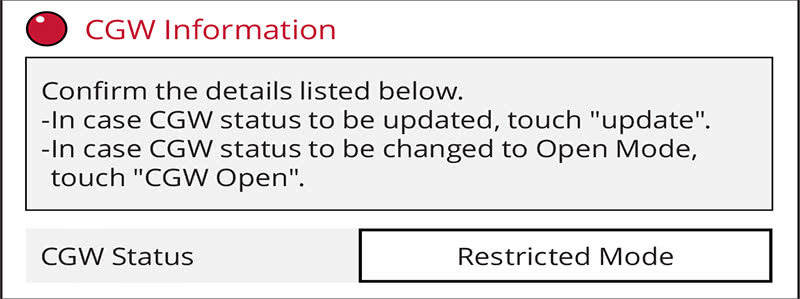

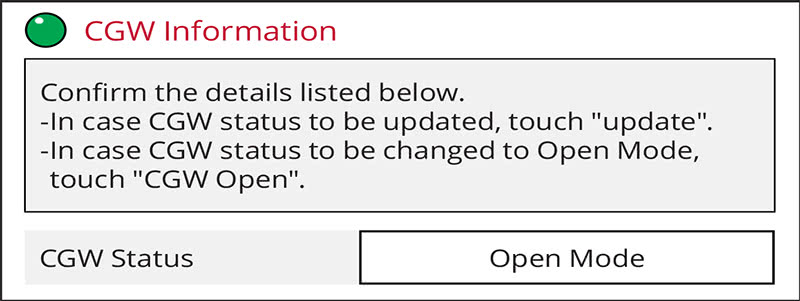

The CGW also protects software functions like programming and calibrations, so there is an additional login procedure when attempting these functions. This added layer of protection is denoted by the CGW Information tab in the CONSULT III software. Before logging in, the circle icon is red, indicating that the Gateway is in a Restricted Mode. While in Restricted Mode, the Work Support tab is not visible in the upper screen menu, and any Work Support functions are thus unavailable.

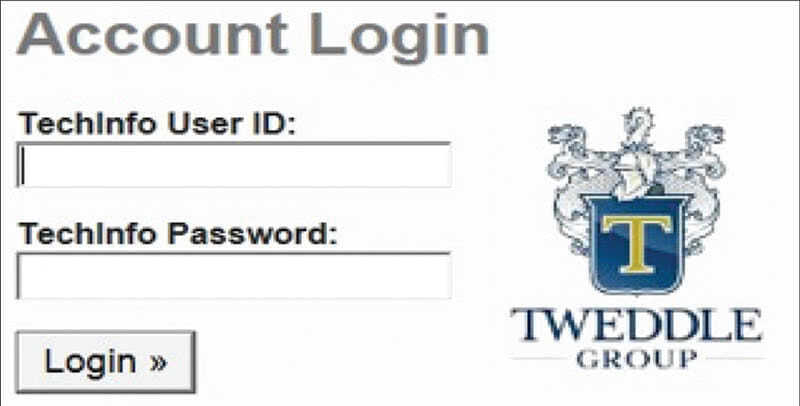

After a user’s TechInfo login credentials are re-entered and authenticated through Tweddle, the icon turns green, meaning the CGW is in Open Mode. Once the Central Gateway has been unlocked the Work Support tab is visible and can be clicked on to access the desired calibration or other function.

The CGW is an addition to the latest version of the CONSULT III Plus software. While aftermarket scan tool companies are undoubtedly working on access to the Central Gateway, the best option is to use the CONSULT III Plus software and a Nissan Vehicle Interface; either the J-47446-V12-B device or the new J-52925-V13 interface, which is available through Nissan’s TechMate website. Alternatively, the CONSULT III Plus software R2R software can also be used along with the approved J2534 pass through device.

Gary Burghoff’s Character in M*A*S*H (7 Across: _ _ _ _ _)

ADAS rely heavily on radar technology, from front distance sensors to blind spot side detection units. Nissan’s radar technology has gone through many changes. The original Intelligent Cruise Control (ICC) radar sensors were located very low in the front bumper and were prone to damage from road debris. Now the ICC sensor is mounted behind the Nissan emblem in the front grille of some vehicles.

These units require different actions when installing a new part. Some radar sensors are plug and play units, while some units need to be configured or programmed. The Blind Spot Warning sensors on the latest model years require a dynamic drive cycle be performed after entering a Work Support function in the CONSULT III.

Many vehicle owners like personalizing their vehicles, but aftermarket add-ons can wreak havoc on ADAS radar sensors. It can be hard for a customer to hear that they have to remove the red Rudolf nose blocking the front radar sensor or oversized eyelashes stuck in front of the adaptive headlights.

Not all effects from aftermarket components are quite so obvious though. For example, clear protective bumper wraps can affect parking assist sensors, and changes to a vehicle’s ride height can affect multiple systems. Even something seemingly unrelated, like aftermarket extendable side mirrors, can cause major problems.

One such case happened on a 2017 Nissan Titan. The aftermarket side mirrors caused fault codes to set and the blind spot monitors to be disabled. Why would this happen? Well, the side mirrors have LED indicator lights to alert the driver there is a vehicle in their blind spot, and the LED circuitry in the aftermarket mirrors was not correct. It would cause faults to set for both side indicator light circuits having low voltage. The only option for this truck was to install the original side mirrors. Thankfully, the owner had kept the original mirrors and the repair was relatively inexpensive.

Lights, _ _ _ _ _ _, Action! (3 Down)

The windshield mounted Lane Camera is another component that has seen a great deal of change. Camera technology and imaging software are continually being revised and improved. This evolutionary process makes it imperative to read service information carefully and search for any applicable Technical Bulletins.

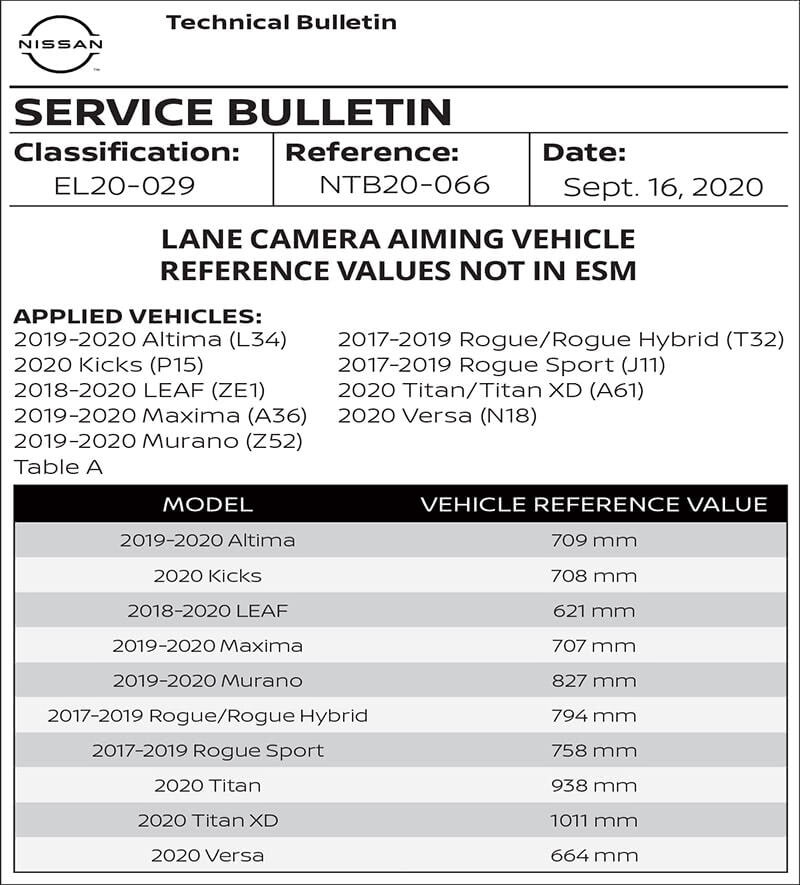

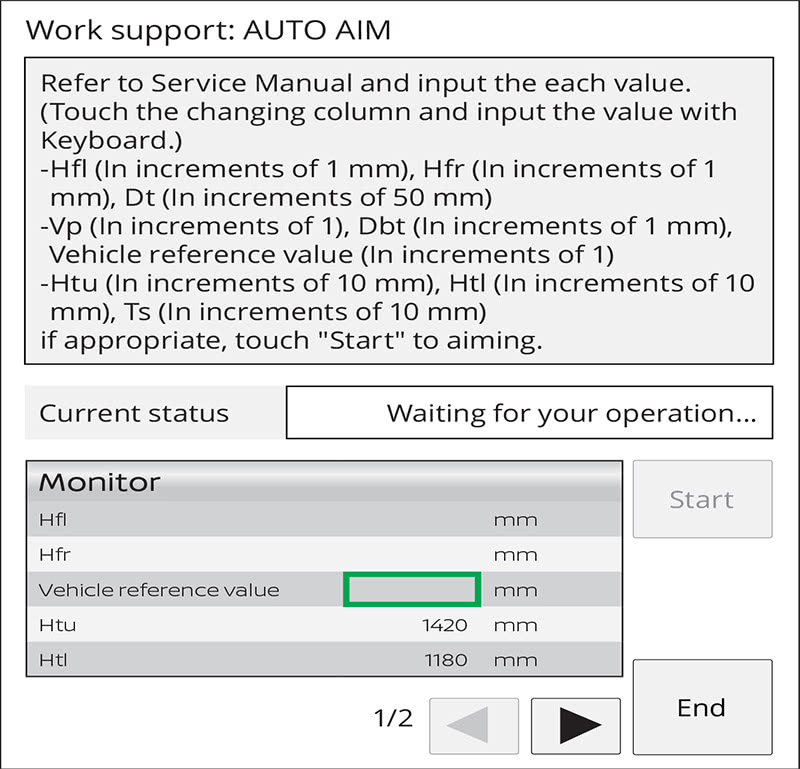

Nissan bulletin NTB20-066 is a perfect example of how important researching a calibration ahead of time is. On certain late model Nissan vehicles, a Vehicle Reference Value is required during the Lane Camera aiming procedure, but these values were not included in Electronic Service Manual. This Vehicle Reference Value needs to be entered into the CONSULT software before the Auto Aim function can be completed.

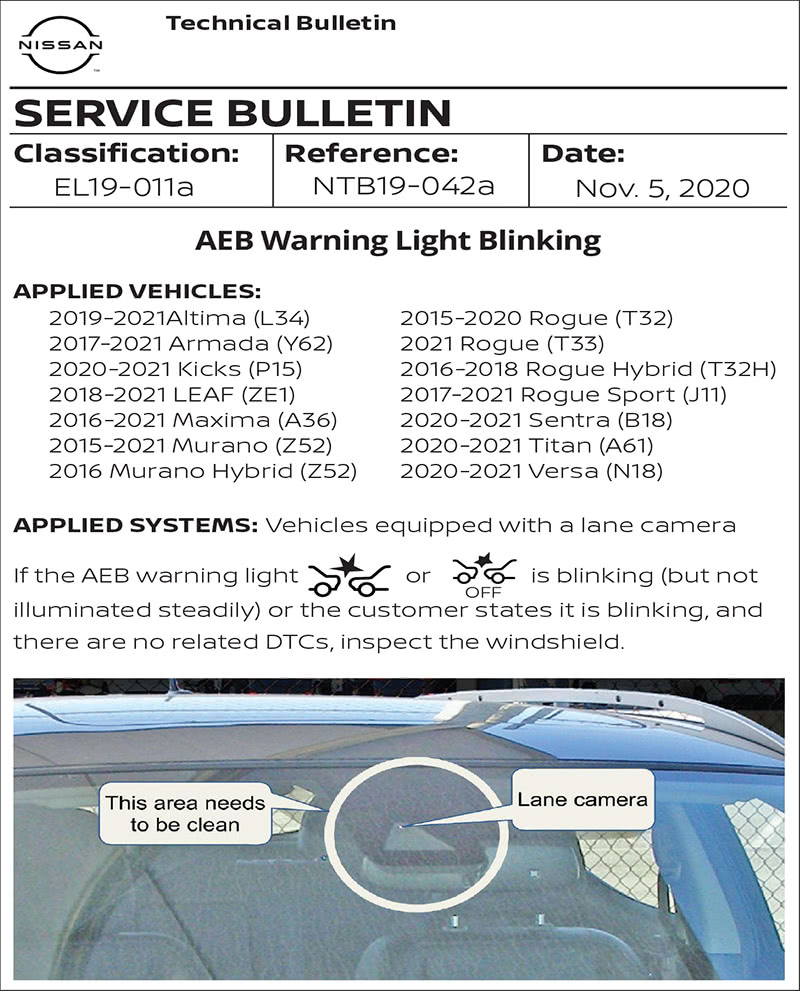

A second bulletin addresses a flashing Automatic Emergency Braking (AEB) warning light. NTB19-042a states that the most likely cause of a flashing AEB light without the presence of fault codes is a dirty windshield. It is also possible to have dust trapped between the inside of the windshield and the Lane Camera, in which case the camera would need to be removed and the glass cleaned.

Checking for the correct mounting position of the Lane Camera is also important. The camera can be snapped into place without the alignment tabs on the base of the unit being fully engaged. This is visually evident when the camera body is not flush with the mounting bracket. Many Nissan vehicles have covers that conceal the camera and mounting bracket from view, so it may be necessary to remove this cover to properly inspect the camera installation.

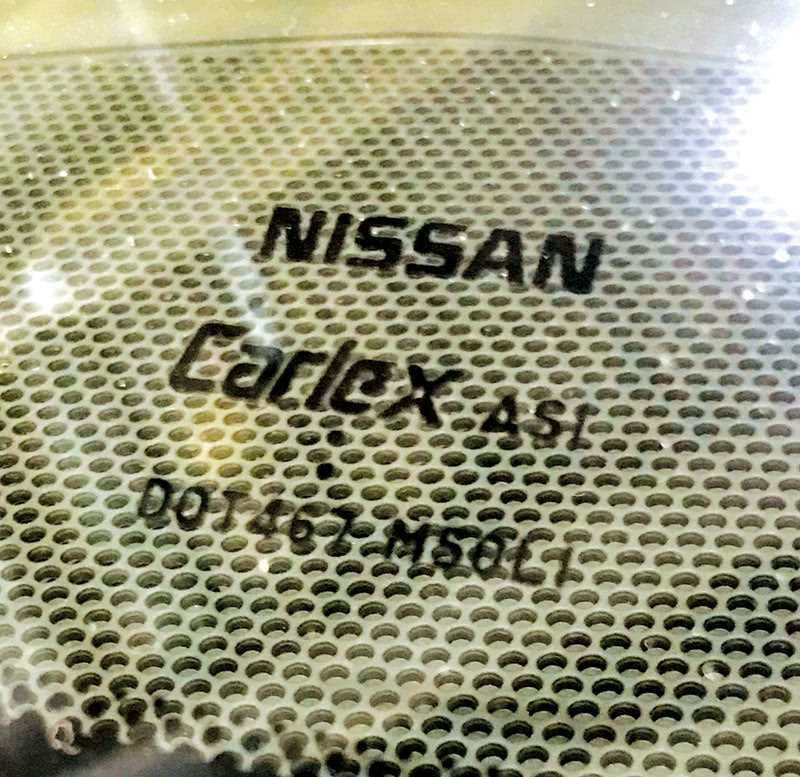

Aftermarket parts can also cause issues when dealing with the Lane Camera. Aftermarket glass may have different tolerances or refractive qualities, and if those differences are great enough they can cause a camera calibration to fail. The best option is to use OE glass and avoid any issues with failed calibrations. There is no way to know for sure if an aftermarket windshield will present problems for the Lane Camera. Nissan recommends OE glass; if that is not an option try to use the best quality aftermarket glass supplier.

The official ruling can be found in this Position Statement from Nissan:

Genuine Nissan auto glass plays an important role in the safety of the vehicle by providing structural rigidity, ocular clarity, and integration with advanced vehicle technology. In addition, glass can play a critical role in noise dampening, UV protection, and general occupant comfort and safety. For these reasons, Nissan North America DOES NOT support the use of aftermarket or recycled glass in a repair situation. If an aftermarket windshield is unavoidable in a repair situation, please be sure it meets the same specifications and similar quality to the OEM windshield being replaced.

While the continually shifting landscape of Advanced Driver Assistance Systems presents new puzzles, the answers can be found with consistent research and a willingness to learn.

0 Comments