Why recommending a preventative replacement of engine rubber makes sense, and how to prepare the estimate

Your customer is out for a nice drive in the country, or perhaps on a trip to see Aunt Edna or Cousin Eddy. Maybe just stuck in traffic on the 405 in LA. All of a sudden there’s a pop sound under the hood, or a hissing noise with some steam. The temperature gauge begins to climb or the check engine light comes on. One of the first things that will probably go through their mind is: When did we have the car into Frank’s Independent Service last? Well, if it was recent or they are a regular service customer, you don’t want that phone call. Regular inspections of the engine rubber during routine service is absolutely the right thing to do, and educating the customer of the importance of replacement intervals is imperative. Serpentine belts and coolant hoses come to mind first, but there are other rubber components to consider as well.

Chemistry of Belts and Hoses

Serpentine belts in the past were generally made of high quality reinforced rubber, specifically from neoprene rubber, a replacement for natural rubber that’s also commonly used in hoses, gaskets, seals, etc. Neoprene’s chemical stability and durability made it an ideal choice for serpentine belt manufacturers in previous years. According to most manufacturers, neoprene belt service life is anywhere from about 50,000 to 60,000 miles. But after 60,000 miles, neoprene serpentine belts tend to degrade quickly. Cracks will eventually form on the belt ribs, and sometimes large chunks of rib can also come apart. Even slight wear can make the belt slip and lose tension, resulting in potential power losses. Neoprene serpentine belts are also more likely to break completely, usually after serious neglect. Modern belts are now made from a synthetic composition called Ethylene Propylene Diene Monomer (EPDM). With the advent of EPDM neoprene has fallen out of favor with most belt makers.

The biggest advantage of EPDM serpentine belts is that they offer a longer lifespan than comparable neoprene. Mercedes-Benz engineers desired a belt that would withstand the rigors of the modern engine, high under hood temps, etc. while providing a longer service life. Although most EPDM belts are designed to last up to 100,000 miles, some techs report these belts as lasting for nearly double that mileage. Of course, we would not advocate leaving a belt on for that length of time, but EPDM is superior to neoprene. EPDM belts also retain their flexibility longer, which means the belt itself won’t lose its tension or form cracks like neoprene belts. However, this characteristic lack of cracks and other traditional signs of belt wear make it a bit tougher identify wear issues. Instead, EPDM belts wear out much like how a tire loses its tread over time.

Hoses are another matter. Their materials and construction vary based on the fluid they are carrying. Coolant, refrigerant, oil, air, hydraulic fluid and fuel are the basics that come to mind. The inner core and outer casing can be different materials altogether. Coolant hoses also use EPDM with a synthetic-fiber knit reinforcement that is heat, ozone and chemical resistant. Silicone is another material used that has excellent wear characteristics. Fuel hose is typically made of hydrogenated nitrile butadiene rubber (HNBR). It may have an aramid fiber reinforcement and a chlorinated polyethylene (CPE) cover.

We won’t belabor the make-up of all the hoses under the hood of the modern Mercedes-Benz, but suffice it to say that the chemical composition is specific to each individual hose and its intended use. Understanding how they are constructed can be a helpful input as to identifying wear issues.

Maintenance Schedules

Although Mercedes-Benz does not always have a scheduled interval for replacement of belts and hoses, most maintenance schedules recommend inspection of belts and hoses every B service, or about every 20,000 miles. What this means is, it is left to your discretion as a technician or shop owner to decide, from your inspection findings, when to recommend replacement of these components. We recommend having a clear and concise shop policy so everyone on the team has the same understanding as to when to recommend the replacement of rubber components. If you service many Mercedes-Benz vehicles, keeping a log of the models and the mileage/time intervals that you find necessary for replacement of certain components can put you ahead of the game in terms of when to make recommendations. Keep in mind, however, there is no substitute for a visual inspection. Your customer may have had service done elsewhere (heaven forbid!) and you don’t want to make a mistake of recommending a new hose or belt based on mileage alone, only to find a brand new one on the vehicle.

Manufacturer Recommendations for Belts

Looking at several OE suppliers to Mercedes-Benz, we gain an insight into when to perform replacement and also some knowledge on inspection techniques. Do be mindful that driving and environmental conditions are an important factor for wear rates on the rubber components. According to Gates Corporation, a leading manufacturer of belts and hoses and an OE supplier, multi-ribbed belts should be replaced at least every four years or 100,000 km (60,000 mi) unless differently prescribed by the

car manufacturer.

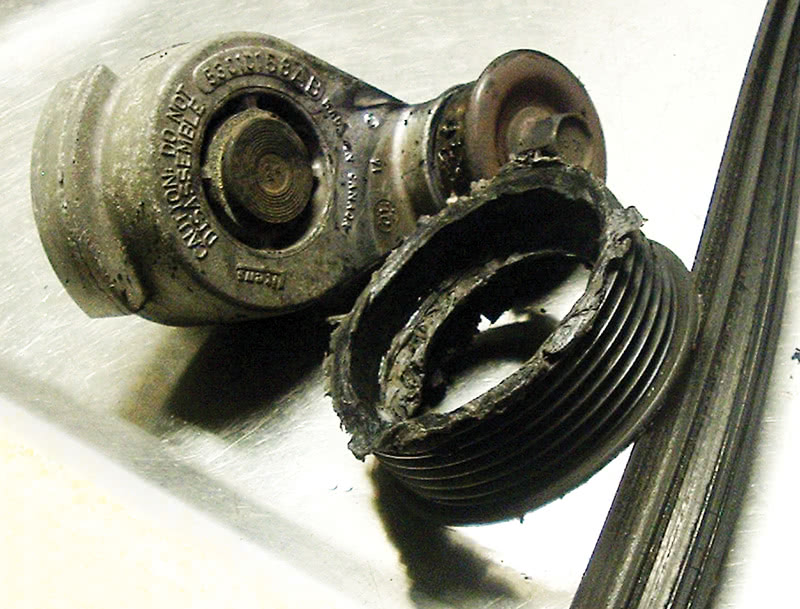

But the other belt drive components don’t last forever either. Belt tensioners, idlers, torsional vibration dampers and overrunning alternator pulleys are wear items, not hard parts as some technicians might believe. The wear of these components affects the belts and therefore, the performance of the whole system.

Putting a new belt on worn tensioners and idlers is never a good idea. The new belt’s service life could be greatly reduced in doing so. The best long-term solution is to replace all wear parts at the same time. You’ve got the belt off so you’re halfway there. Gates also advises replacement of all wear parts every 100,000 km. Although not every case of ageing is clearly evident in the form of a wear pattern, proper functioning of the engine could be greatly impaired.

While the four-year replacement interval is a basic rule of thumb, it is not exact. If you are located in a large metropolitan area with heavy traffic, idling time with stop and go, for instance, takes a toll on belt life. Normal city driving patterns can lead to extreme operating conditions, exposing belts to considerable stress and wear. Extreme ambient temperatures may be a multiplier of wear characteristics as well. For instance, those shops in Phoenix or Anchorage probably find rubber components don’t last as long they might in, say, Bakersfield.

Inspection

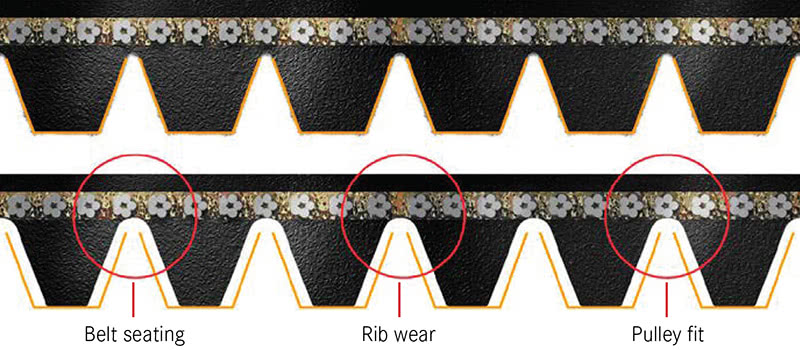

A simple visual inspection of the belt is not as simple as it used to be. As mentioned above, EPDM wears differently than traditional belts. Problem areas like cracking, chunk-out and rib separation are not so prevalent anymore and do not provide the telltale signs that replacement is needed. Those symptoms/indicators signaled that a replacement was needed. But today a simple visual inspection isn’t always enough. While the modern belts last longer, what you will find is that after certain mileage (about 60k depending on the model and routing) noise complaints will begin to show up.

Look closely at the belt ribs: Small cracks may appear along the length of the ribs. Chunks of material are missing from the ribs. The ribs are malformed. You might see any of the following:

Pilling (worn material fills the grooves), more often on diesels but not just them. Worn pulleys, misalignment, low tension or a combination of these can cause it.

Abrasion, often more apparent on the back of the belt, can be caused by road grime or worn idlers or flat pulleys.

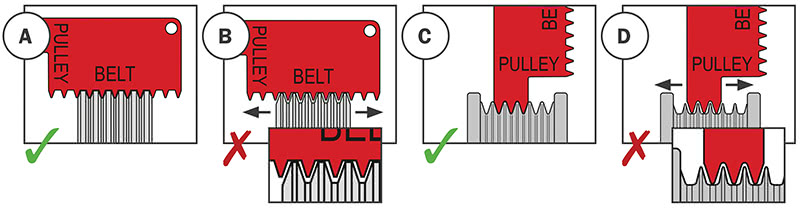

Rib separation, where a belt rib shears off or starts to separate. Most likely the belt is not correctly positioned. One of the belt ribs is placed outside the pulley groove, causing a belt rib to run without a supporting or aligning pulley groove.

Oil contamination, heavy dust accumulations or uneven rib wear.

Gravel penetration – make sure the belly pan is installed correctly.

If the belt inspection reveals any one of the symptoms above, it should be replaced along with any components that your inspection show may be a possible cause of unusual wear. But as we mentioned earlier, what about no visual wear signs? Remember the EPDM belts begin to wear much like a tire tread. There’s a handy gauge you should have in your tool box and should be part of your routine inspection. You simply place the gauge in the grooves of the belt and the pulleys. The gauge should fit tight with no side to side movement.

Hoses

As with the belts, we have an inspection-based judgement along with time and mileage considerations. Also consider what’s flowing through the hose. Normally when we think of routine hose replacement recommendations, coolant hoses come to mind. Most hose manufacturers have a recommended replacement interval of 4 years, but like the pirate’s code, it’s only a guideline. Coolant hoses have to deal with extreme temperature fluctuations, environmental concerns, as well as electrochemical degradation (ECD). ECD is caused when different kinds of metals in the cooling system generate an electrical charge, which is carried from one component to another by the coolant. This electrical charge can weaken the hose by creating tiny internal cracks in the hose. ECD is considered the number one cause of coolant hose failure and the reason to keep the cooling system in top shape with regular flushes and proper coolant. Along with ECD, an inspection may reveal:

- Leakage

- Heat damage – primarily from an overheated engine

- Ozone damage – which may appear as tiny exterior cracks in the outer shell

- Abrasion – when some other component has be rubbing on the hose

- Oil damage – the hose will be soft appear bloated

Any one of these signs would indicate the need for replacement. Most techs in the field would recommend

a change of the coolant hoses certainly no longer than 6 years or 100,000 miles. Certainly anytime you have the cooling system open for service or repair is a good time to replace all the coolant hoses.

Fuel lines are a component that not only represent a possible breakdown while driving but are also considered a safety item. Fuel leaking on a hot engine is never a good thing. These lines can be more difficult to replace, as many are routed in hard to reach areas, but you should consider making the recommendation at no longer than 100,000 miles. Your Mercedes-Benz parts dealer will have an accurate diagram of the under-hood fuel lines and can accurately get you the right parts for the VIN. The same can be said for transmission lines, power steering hoses, etc.

Other Rubber Components

There’s lots of other rubber under the hood that will eventually wear out, but much of it won’t cause a breakdown or lead to shorter engine life. Many components have small rubber isolation mounts, hold down straps, etc. It would be advisable to replace these on an as needed basis and not necessarily as routine prevention. You could spend days preparing and estimate to try and replace all of them. Say, for instance, you have the MAF off the vehicle for some reason. If the vehicle has more than 60K miles on it or over 4 years old, it may be a good time to consider replacing the rubber mounting collar.

Also consider replacing the rubber engine mounts. Although technically these aren’t simple rubber anymore, with fluid filled hydraulic systems most common, many techs agree on replacement around the 50,000 mile mark. Certainly routine inspections should be carried out, specifically looking for leaking fluid and excess movement.

Preparing the Estimate

Estimates for replacing the serpentine belt should be as simple as using a reputable flat rate guide for the model being serviced. As noted above, you should consider replacing all the drive belt components when doing so. In such a case, you would use the combination feature to accurately come up with a proper estimate.

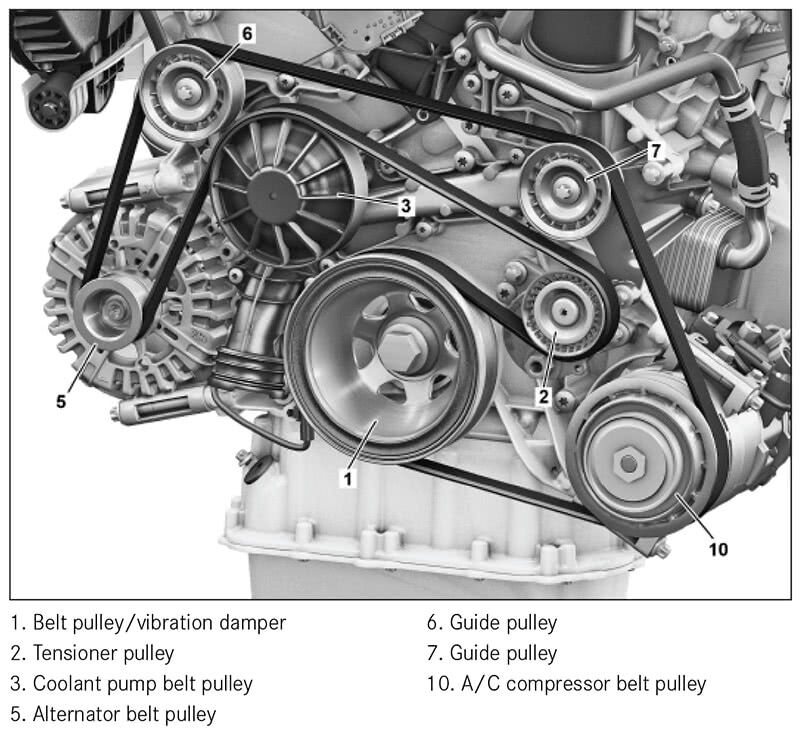

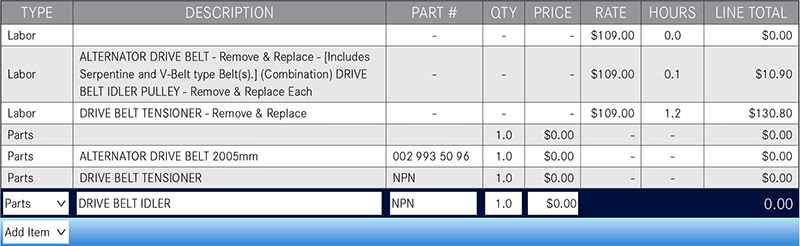

Let’s look at a 2015 GL350 (166 chassis, OM642 engine) serpentine belt change. You could look up the belt and the combinations using Mitchell Pro Demand estimator, but you will only get the belt itself and a combination of the idler pulleys, not the tensioner. So you will have to go to the tensioner as a separate line item and then use the combination of the idler(s) to complete the estimate. You don’t need to add the belt because it is understood that the belt has to come off to change the tensioner. It’s usually not a good idea to trust the parts estimator on parts, we prefer to call our local Mercedes-Benz dealer’s parts department to get accurate price and availability. Even better if you have a dealer that participates in a user interface for parts pricing. You or your service writer can prepare the estimate from the desktop without making a phone call. Many shop software programs have this capability.

Just remember to subtract for operations that overlap, say for instance a coolant pump replacement. The belt has to come off for that operation so you don’t need to add a belt labor item, but you might combo in the tensioner and idler pulley remove and replace.

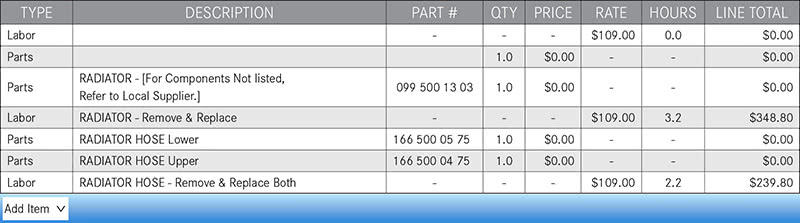

Hoses take on a very similar approach. Coolant hoses will usually have a line item you can look up and prepare, but as with the belt replacement, there may be overlapping combination items. Perhaps you have a radiator replacement on the same vehicle just mentioned. You would look up the radiator replacement labor but combo in the upper and lower hoses. Since you don’t have to take the hoses completely off, you should adjust the time to compensate for that.

Many items, fuel lines for example, may not have a line item listed in an estimator. Usually they might involve removing some component for access. You’ll need to check the Mercedes-Benz Workshop Information System (WIS) work instruction or inspect the vehicle for the necessary removal steps and then proceed from there, adding up the R & R times.

Be proactive! Perform an engine rubber inspection on your customer’s vehicles at every oil and filter service. Your customers may not have the expertise to spot a problem, so they very much depend on you, their service expert, to make reasonable recommendations for ensuring vehicle reliability. Replace belts and hoses as they show signs of distress and age to help prevent possible breakdowns, while keeping your customers’ budget in mind, and you’ll have happy customers.

0 Comments