Fire, fuel or pressure. Find what’s failed fast.

The same sorts of problems — spark, fuel, compression, timing — can keep a Mercedes-Benz engine from starting as any other. You check for many of them in similar ways to other engines, and some tests are M-B-specific.

One problem happens with a new owner, perhaps of a used car. Some carmakers calibrate their fuel gauges to read full for the first fifty miles after a fill- up, and to read empty when they still have another three or four gallons left. Not so Mercedes-Benz. When you drive away from the gas station pump, the needle starts down. When the needle reaches the bottom, the engine stops. The moral of this story: Even if a motorist tells you there’s fuel in a tank that reads very low or against the peg, pour in another gallon or so just as insurance. Two dollars’ worth of liquid diagnosis can sometimes save hours of work you’ll never recoup if it turns out the car was just out of fuel. Note: a Diesel engine often requires bleeding the air manually from the injector lines while cranking before the engine can start, if the driver has run the vehicle so low on fuel the pickup starts drawing in air.

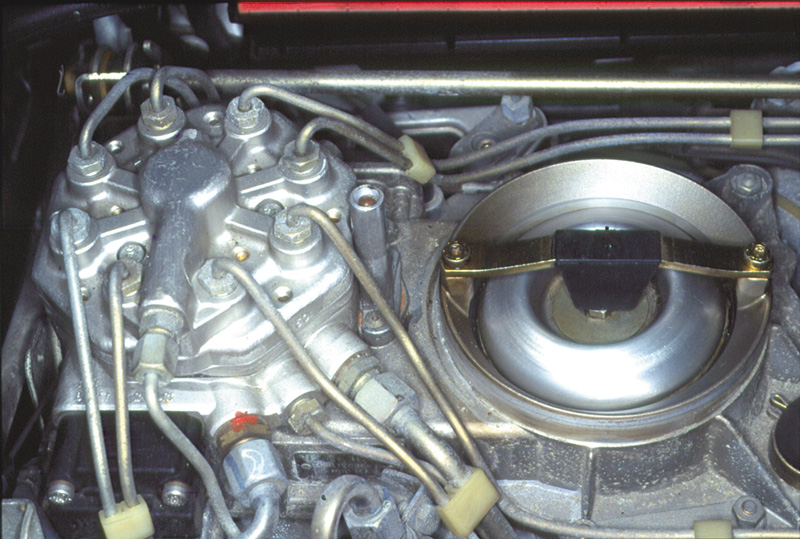

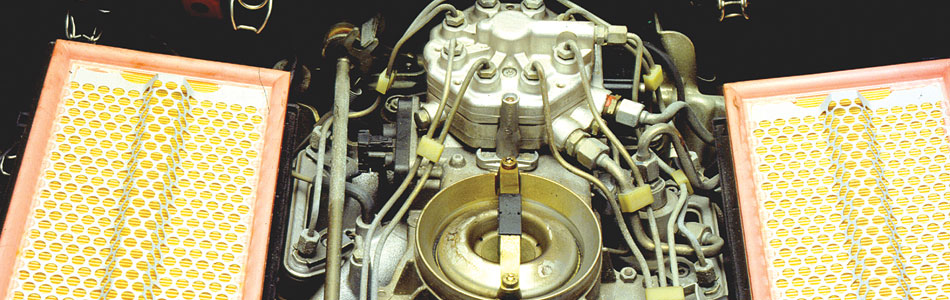

Even with a full tank, though, you can still find fuel problems. All of the cars we’re considering for this article are fuel-injected (the last Mercedes-Benz imported into the United States with a carburetor was long ago), and fuel injection systems work by pressure and volume. The CIS and CIS-E systems work when the electric fuel pump raises the pressure of the fuel in the lines enough that it forces its way past the spring-loaded mechanical valves at the tip of each of the fuel injectors. Either hydraulic problems forcing the fuel through the filter and lines or electrical problems delivering current to and from the fuel pump can reduce the fuel injected enough to hamper running or prevent the engine from starting. That being said, the originally all-mechanical CIS-E system became so increasingly electrical and electronic that one of its final versions, like the 500 SL (129) in some of our photographs, has almost as many potentiometers and electrical actuators as the fully electronic systems that followed.

Even with a full tank, though, you can still find fuel problems. All of the cars we’re considering for this article are fuel-injected (the last Mercedes-Benz imported into the United States with a carburetor was long ago), and fuel injection systems work by pressure and volume. The CIS and CIS-E systems work when the electric fuel pump raises the pressure of the fuel in the lines enough that it forces its way past the spring-loaded mechanical valves at the tip of each of the fuel injectors. Either hydraulic problems forcing the fuel through the filter and lines or electrical problems delivering current to and from the fuel pump can reduce the fuel injected enough to hamper running or prevent the engine from starting. That being said, the originally all-mechanical CIS-E system became so increasingly electrical and electronic that one of its final versions, like the 500 SL (129) in some of our photographs, has almost as many potentiometers and electrical actuators as the fully electronic systems that followed.

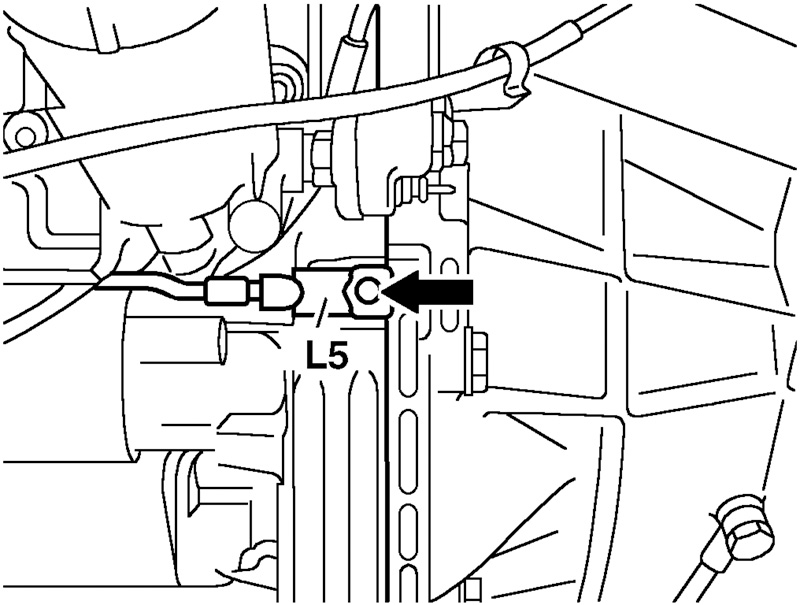

Except for fuel pump circuit failures, most no-starts will have neither spark nor fuel. The reason for this design, of course, is to minimize hydrocarbon emissions: If for any reason the fuel doesn’t or can’t ignite for lack of spark, you don’t want to inject it at all because there’s practically no exhaust dirtier than exhaust during a no-start crank. For each of the fuel and ignition systems found on these cars, the crankshaft position sensor plays a central role. With the CIS and CIS-E systems on the earlier cars, that signal must reach the control unit with a certain minimum frequency (corresponding to about 400 rpm on most engines, too low for idle, too fast for cranking) for the computer to keep the fuel pump energized. With the later versions, you need that signal and the camshaft signal to sequence the fuel injection. Because of its importance for both ignition and fuel injection, a quick check of the crankshaft signal is a reasonable first diagnostic inspection. The crankshaft position sensor is adjacent to the flywheel, on the back of the engine next to the bellhousing. Keep in mind that both the amplitude (voltage) and the frequency of the signal are critical to reaching the control unit’s recognition threshold. The computer won’t respond to an rpm signal pulse much below 1.1 volt (alternating current).

But if you find a no-start and smell gasoline, what could that mean? First, check the plugs to see whether they’re wet with fuel. If they are, of course, the engine is flooded and won’t start for that reason. However, merely drying the plugs off and re-cranking probably won’t work satisfactorily. If the system delivers fuel even when the engine won’t start, check for spark at the plugs. A defective coil, coil wire, distributor rotor, cap or plug wires could intercept the spark after the control unit has already concluded spark is on its way. Then the fuel pump will continue to pressurize the fuel, for two seconds, and the injectors can flood the plug electrodes, even within the two seconds the pump waits for a crank signal. On the electronic systems, a coolant temperature sensor that reports a very low temperature can have the same effect because it can so richen the fuel mixture that the plugs foul.

But if you find a no-start and smell gasoline, what could that mean? First, check the plugs to see whether they’re wet with fuel. If they are, of course, the engine is flooded and won’t start for that reason. However, merely drying the plugs off and re-cranking probably won’t work satisfactorily. If the system delivers fuel even when the engine won’t start, check for spark at the plugs. A defective coil, coil wire, distributor rotor, cap or plug wires could intercept the spark after the control unit has already concluded spark is on its way. Then the fuel pump will continue to pressurize the fuel, for two seconds, and the injectors can flood the plug electrodes, even within the two seconds the pump waits for a crank signal. On the electronic systems, a coolant temperature sensor that reports a very low temperature can have the same effect because it can so richen the fuel mixture that the plugs foul.

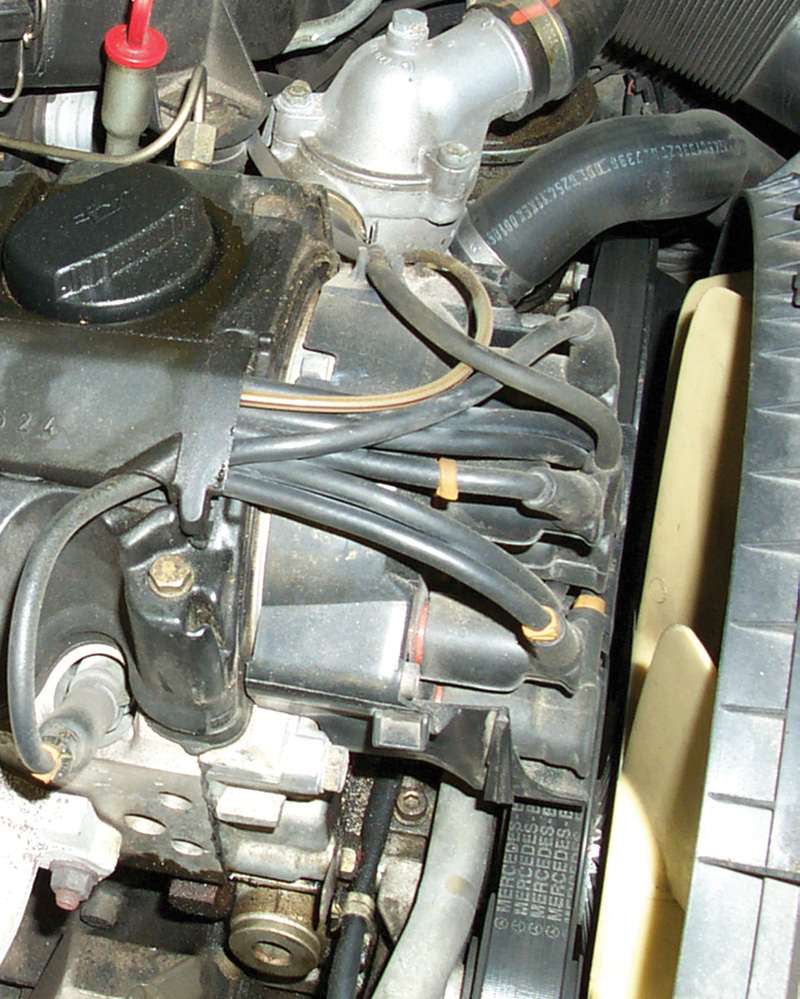

The 300 E in the photos uses a distributor on the front of the camshaft and a remote ignition coil to provide ignition to each of the six cylinders. Most of the possible no-starts result from some easily discovered open or short in the primary or secondary ignition system. If there’s no spark at a plug, see whether there’s spark at the distributor coil wire. If there is, your problem is in the cap, rotor or wires. If there’s not, check for spark at the coil tower. If there is, you’ve found an open-circuited coil wire. Check for voltage at the coil primary and for the normally cycled ground on the other side.

The 300 E in the photos uses a distributor on the front of the camshaft and a remote ignition coil to provide ignition to each of the six cylinders. Most of the possible no-starts result from some easily discovered open or short in the primary or secondary ignition system. If there’s no spark at a plug, see whether there’s spark at the distributor coil wire. If there is, your problem is in the cap, rotor or wires. If there’s not, check for spark at the coil tower. If there is, you’ve found an open-circuited coil wire. Check for voltage at the coil primary and for the normally cycled ground on the other side.

None of this should be surprising, but people sometimes forget that all gasoline engines work essentially the same way because they all depend on the chemistry of the same gasoline and oxygen.

None of this should be surprising, but people sometimes forget that all gasoline engines work essentially the same way because they all depend on the chemistry of the same gasoline and oxygen.

Some no-starts are by design: The antitheft/central locking system will prevent the engine from starting without the right key. Occasionally these systems get overenthusiastic, and their control units (on the right side in the trunk) intermittently prevent starting even with the right key. You’ll understand why we won’t provide detailed information about how to bypass the central locking or antitheft systems here. However, you may run across this scenario: On most models with antitheft/central locking systems, if you close and lock the trunk with the key while the driver’s door is open, that is ajar, the starter will not work again until you operate the driver’s door lock with the key (door closed) to reset the system. If you don’t know this, you could spend a long time chasing nonexistent problems.

Some no-starts are by design: The antitheft/central locking system will prevent the engine from starting without the right key. Occasionally these systems get overenthusiastic, and their control units (on the right side in the trunk) intermittently prevent starting even with the right key. You’ll understand why we won’t provide detailed information about how to bypass the central locking or antitheft systems here. However, you may run across this scenario: On most models with antitheft/central locking systems, if you close and lock the trunk with the key while the driver’s door is open, that is ajar, the starter will not work again until you operate the driver’s door lock with the key (door closed) to reset the system. If you don’t know this, you could spend a long time chasing nonexistent problems.

Similarly, a surge intercepted by the overvoltage protection relay (see the article on that relay in this issue, p.11) can keep an engine from starting. Rather than allow an overvoltage spike to destroy expensive control units in the car, the overvoltage protection relay disconnects the fuel pump and/or the ignition module to protect them from a runaway alternator or other such problem. Of course, merely replacing the fuse in the overvoltage protection relay or the relay itself will not permanently solve the problem until you locate and correct the source of the voltage spike.

Similarly, a surge intercepted by the overvoltage protection relay (see the article on that relay in this issue, p.11) can keep an engine from starting. Rather than allow an overvoltage spike to destroy expensive control units in the car, the overvoltage protection relay disconnects the fuel pump and/or the ignition module to protect them from a runaway alternator or other such problem. Of course, merely replacing the fuse in the overvoltage protection relay or the relay itself will not permanently solve the problem until you locate and correct the source of the voltage spike.

Some no-starts arise from the design, but not according to plan. A no-start in the early Fall on an older car with CIS-E and a cold-start injector could come from water in the cold start injector line if there has been a problem with fuel quality. Over the summer, the water has plenty of time to separate out and even to form rust. Obviously, that’s not a problem until you need the cold-start injector squirt to get the engine going.

Diesel No-Starts (and a No-Stop)

For a combination of historical and technical reasons, Mercedes-Benz has emphasized Diesel engined cars for many years. No discussion of Mercedes no-starts can leave out the Diesels, thus. Diesel engine no-starts most frequently fall into two categories: fuel delivery problems or glow-plug problems. Fuel problems can be anything from a pickup line leaking air before the pump to defective injectors or pump. Glow plugs can surprise you — on many cars, all the glow plugs must work, or the engine can’t start cold. The high compression of the Diesel engine (21 to 1) can slow the crank so much with even one missed power stroke, you won’t have the combination of crank speed and temperature required to start the engine.

The Diesel compression-ignition system also requires a functional glow plug controller, the relay/module that calculates the glow plug on-time from the temperature of the engine coolant. On the older Diesel engines, you may find just the opposite problem — the engine won’t shut off — if the vacuum pump (for the brake booster, heater doors and injection pump shutdown diaphragm) or its check valve fails. These engines included a conspicuous engine shut-off lever, visible even to the mechanically unsophisticated as soon as the hood was open.

Fuel pumps and fuel filters may be the most common long-range problem. These are finite-life components and require replacement sometime during the useful life of the vehicle. Check for power and ground to the pump before condemning it, of course. And remember a fuel pump can run without necessarily producing the pressure or volume required to power the engine. On vehicles with in-tank fuel pumps, it is usually a good idea to clean out the fuel tank at the same time you have it down. There is inevitably a certain amount of grit and dirt that finds its way in over the course of a hundred thousand miles. That grit and rust debris are frequently what cause the fuel pump check valve to lose its seal, allowing pressure bleed-down when the engine is shut off. That can result in long cranking or even in vapor lock if underhood temperatures stay high enough.

0 Comments