The concept has been around for decades, but many technicians still don’t get it. This clear explanation should help.

Three of the main parts used in fuel control: O2 sensor, fuel injector, and hot film air mass meter. The three-way catalytic converter gets the benefit.

Fuel trim is not a new concept. In fact, it’s been around in the automotive world since the late 1970s. The development of the three-way catalytic converter, which not only oxidized HC and CO, but also reduced NOx, made a means of more accurately controlling the air/fuel ratio (AFR) necessary, something beyond a carburetor, or even non-feedback K-Jetronic and EFI.

Fuel control goes by numerous names, such as fuel trim, adaptive learning, short-term fuel control, long-term fuel control, and block learn and integer. Or, as Mercedes-Benz likes to call it, Mixture Self Adaptation. Regardless of the name, they are all still the same basic fuel management strategy and just one player in the symphony of engine management. Yet many technicians still haven’t grasped the concept despite seeing the fuel trim (adaptation) numbers on an almost daily basis while viewing live scan tool data. Instead of dreading the possibility of a glowing MIL (Malfunction Indicator Lamp, a.k.a. check engine light) and fault codes in the P0170s referencing fuel trim malfunction coming through the shop bay doors, we hope we can help you view it as an opportunity by shedding some light on the matter so that you no longer need to fear this issue. Possessing a good working knowledge of fuel trim will give you a strong diagnostic edge and the confidence that you can fix it right the first time.

Balancing Act

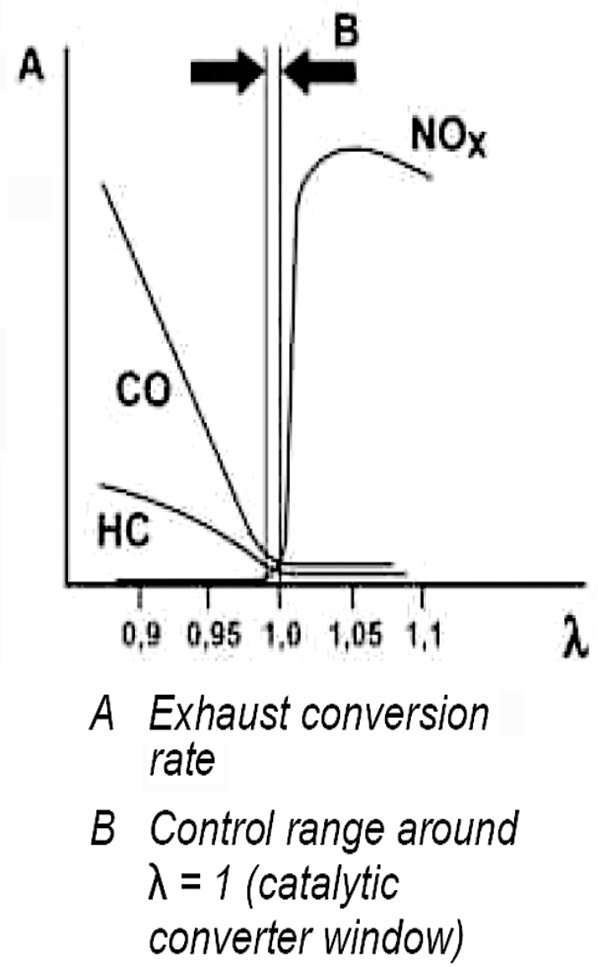

Before we get into the details of fuel trim, let’s start with a simple question: Why do we need it? The answer is emissions, emissions, and emissions (well, fuel efficiency, too). The sole purpose of fuel trim in the modern-day engine is to keep strict control over the very specific air/fuel ratio needed by the three-way cat so that the cleanest tail pipe emissions possible can be achieved. This strategy is used by the engine Electronic Control Module (ECM, or PCM for Powertrain Control Module, as SAE terms it) to maintain the air/fuel mixture at a stoichiometric ratio of 14.7 to 1 (14.7:1), also known by most Mercedes-Benz technicians as “Lambda,” which is represented by the Greek letter λ in literature.

This 1970 Mercedes SL280 engine operated with a fixed fuel curve. These ran normally at between 2 and 6% CO (carbon monoxide) emissions. We have come a long way.

What does that mean? Well, in a gasoline engine it’s the ideal ratio or optimum amount of fuel mixed with air to achieve a complete burn or consumption of the fuel during the combustion process. Stoichiometry is a measurement represented by weight (as opposed to volume, which would be something like 2,000 cubic feet of air to one cubic foot of fuel), typically grams. For example, stoichiometry for gasoline is 14.7 grams of air to every 1 gram of fuel. This ratio is different for all combustible fuels. For instance, diesel would be 14.5:1, ethanol 9.0:1, and so on. But as much as we would like a complete burn, perfection is not possible in practice due to the many variables of the internal combustion process. So the ECM does the best it can, which is very well indeed in the latest Mercedes-Benz engines. They do a pretty remarkable job of keeping tailpipe emissions very close to zero. To keep emissions at a minimum, the ECM has to perform a balancing act — not only does it need to keep the mixture stoichiometric, but it also has to have enough control to allow the mixture to swing slightly rich and lean so the catalytic converter can perform optimally, all the while contending with changes in operating conditions that could upset the mixture.

It’s all in the mix

What is Fuel Trim? We’ll break it down by definition:

- Fuel: Material that is burned to produce heat or power.

- Trim: To make neat or required size.

This WIS graph illustrates just how narrow the window is within which fuel trim works, represented by “B.”

Essentially, we are trimming (adjusting) the amount of fuel delivered to the engine cylinders to achieve a stoichiometric ratio. Fuel trim is a two-part strategy consisting of a short-term correction and long-term correction. This is the way the ECM manages and maintains this specific task. The ECM uses sensor data to calculate and adjust to the appropriate amount of fuel needed to maintain the proper AFR by changing the injection pulse width (“on” time). It’s important to note that every automobile manufacturer has its own version of fuel trim. Differences in engine volumetric efficiency, air and fuel delivery, computer management, operating parameters, and terminology make it impossible to have a one-size-fits-all program. That doesn’t mean it’s a free-for-all jungle, though. Because of the government-mandated implementation of On Board Diagnostic II (ODB II), standards almost all follow the same basic principles. Over the years Mercedes-Benz has expressed fuel trim a few different ways, but knowing the basics will allow you to decipher all from the oldest Hot Film Management (HFM) to the Motor Electronic (ME) system all the way to the latest Motronic Electronic Direct Injection (MED 17.1) system.

Fuel Trim is simple in operation. It reacts to feedback from the O2 or AFR sensor by either giving more fuel via a longer injector pulse if the sensor reports a lean condition, or taking away fuel via shorter injector pulse if a rich condition is reported. That’s basically it — the system can only react by physically controlling the on-time of the injectors. Remember, an O2 or AFR sensor is an input, so it can only report what it sees and cannot make any adjustments itself. Where it starts to get complicated is with the two-part learning management process. Usually expressed as a correction percentage number, the ECM uses learned correction to compensate for issues that drive the mixture out of 14.7:1. Typically, the set parameters for correction are a positive or negative 25% to 35% off the base fuel map. Specifications depend on and vary from manufacturer to manufacturer. Limits are set because of the very narrow window the mixture is held to for efficient catalytic converter operation. If there were no limits, the ECM might make an unchecked correction that could starve the engine for fuel to the point of stall, or supply too much fuel to the point of flooding, which could potentially damage the engine and catalytic converter.

Things that affect AFR include, but are not limited to…

- Vacuum leaks, or false air

- Restricted air flow (dirty air filter)

- Damaged air intake system (breather, MAF sensor, throttle body, manifold)

- False sensor data

- Poor quality and/or contaminated fuel

- Weak fuel pump or faulty pressure regulation

- Exhaust leaks

- Engine operation at wrong temperature

- Faulty Positive Crankcase Ventilation (PCV) system

- Faulty fuel tank evaporative system (EVAP)

- Faulty fuel injector

- Engine mechanical fault or worn components (i.e. low compression)

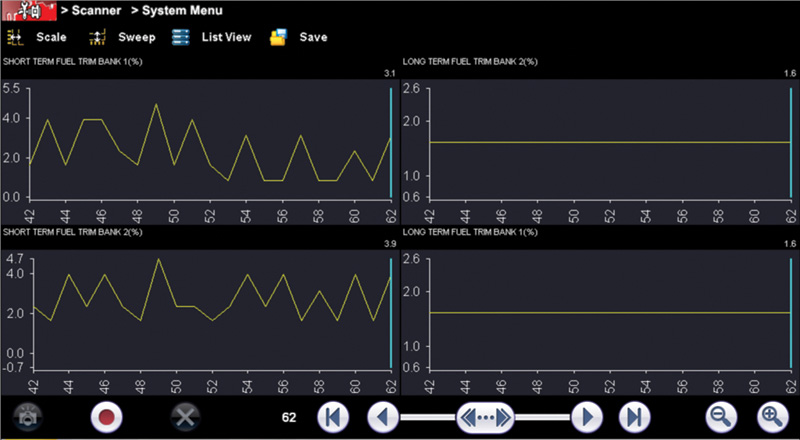

First, we have Short-Term Fuel Trim (STFT). This is a fast-acting control enacted by the ECM. STFT reacts to immediate changes in AFR by trying to bring the mixture back to 14.7:1 as quickly as possible. This control is the fine, immediate adjustment of mixture formation, and will always try to maintain an AFR of Lambda at one with self-adaptation close to zero. There is also no key-off memory with STFT because, as the name implies, this is “short term.” Once the vehicle is switched off and back on the whole process starts over again.

What if STFT cannot maintain 14.7:1? That’s where Long-Term Fuel Trim (LTFT) comes into play. If the Short Term function is unable to maintain zero, then LTFT will make corrections to the base fuel programming (fuel map). LTFT is a response to a persistent problem. This correction is saved in the ECM memory, hence the name “Long-Term.” By making a fuel map correction, the STFT is given a new starting point to operate from so that it may still perform its normal compensating duties.

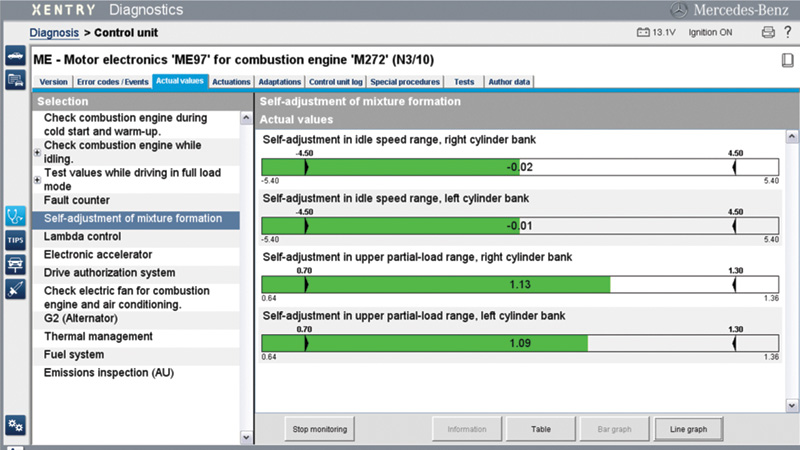

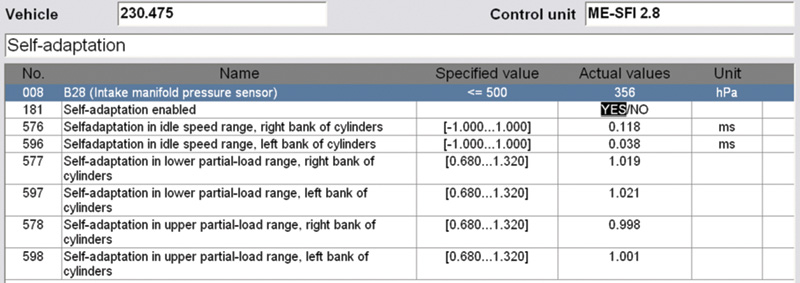

Mercedes-Benz goes a step further in controlling LTFT. It breaks LTFT on some models into three sub-sets. This method allows for even finer control over AFR. These are idle adaptation, lower part load adaptation, and upper part load adaptation.

Note: There is no full-load fuel trim as the ECM would be giving a full fuel command to a maximum air wide-open throttle condition.

This is a screen shot from Xentry on a 2012 E350. This shows how Mercedes-Benz eliminated some of the guesswork by giving technicians a colored graph that turns red if the mixture runs out of bounds.

Finding Direction

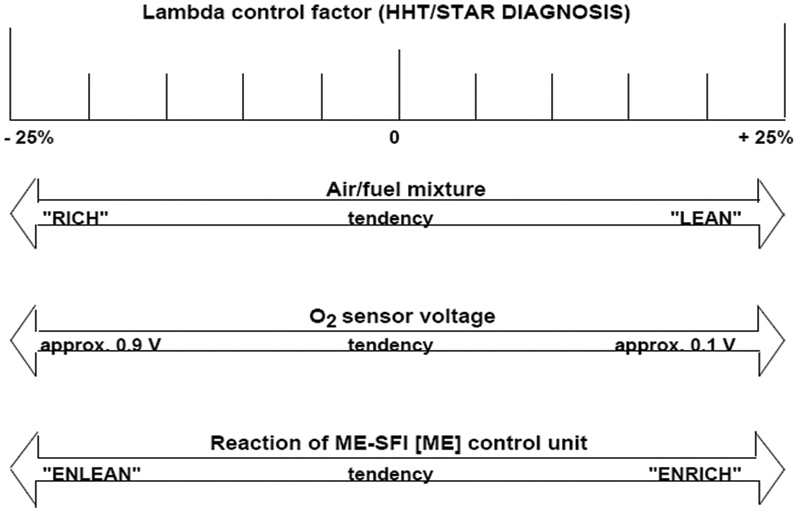

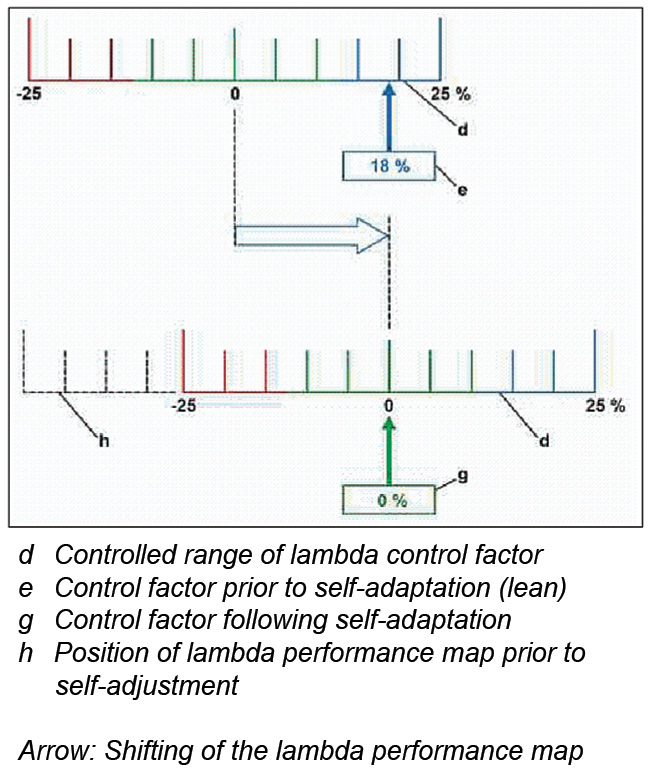

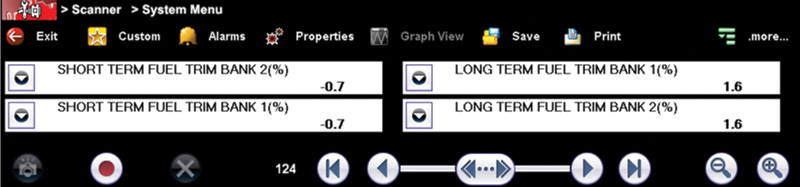

Mercedes-Benz fuel trim operates on a sliding scale principle for both STFT and LTFT. Depending on the type of scan tool being used, whether it’s a Mercedes-Benz SDS/DAS/XENTRY, or an aftermarket diagnostic tool, the scale may be represented differently, but both will have the same maximum parameters of displayed correction. All scales have a balanced starting point of 14.7:1, sometimes represented as 0 % or 1.0 = λ (Lambda). Fuel trim systems in the modern day ME (Motor Electronics) controlled Mercedes-Benz have a correction limit of + or – 32%, meaning that the system can add up to 32% of injection on time to compensate for a lean condition. This is represented as a positive correction or “high” adaptation value when viewed as live data. The opposite is also true — the system can take away up to 32% of injection time to compensate for a rich condition. This is a negative correction or “low” adaptation value.

The fuel trim system is designed and engineered to operate within these limits. For example, a spot check of live data may show adaptation numbers trending high or low. This is not necessarily a problem; the ECM is only compensating for conditions it’s seeing, but if they are trending close to the limits this may indicate a potential problem in the future. If the maximum correction limit is reached, the ECM can no longer compensate for the problem, and a fault code is thrown along with the “Check Engine Light.”

There are a number of different diagnostic strategies to deal with fuel trim faults, but we will have to save those for another day. The most important takeaway from this article is that you should know the direction of correction.

- > Positive number represents increased fuel response for an overly lean condition.

- – Neutral or zero represents a no-correction condition because Lambda is at the required 14.7:1.

- < Negative number represents decreased fuel response for an overly rich condition.

This holds true for most systems governed by the OBD II standard. Know one and you know them all! Studying the numbers of both good and bad will give you an invaluable mental diagnostic tool and a competitive edge.

0 Comments